Umatshini wokuMakisha weLaser we-UV wePlastiki yePlastiki yePCB yoKuphawula Umoya obandayo opholileyo 3W/5W/10W oKhetho

Idayagram eneenkcukacha

Intshayelelo kuMatshini wokuMakisha iLaser ye-UV

Umatshini wokumakisha we-laser we-UV sisixhobo soshishino esichaneke kakhulu esisebenzisa imiqadi ye-ultraviolet laser, ngokuqhelekileyo kubude be-wavelength ye-355nm, ukwenza ukunganxibelelani kunye nokumakishwa okuneenkcukacha, ukukrola, okanye ukusetyenzwa komphezulu kuluhlu olubanzi lwezinto. Olu hlobo lomatshini lusebenza ngokusekwe kubuchule bokusebenza obubandayo, obubangela impembelelo encinci ye-thermal kwizinto ezijoliswe kuzo, okwenza kube yinto efanelekileyo kwizicelo ezifuna ukuchasana okuphezulu kunye nokuguqulwa kwezinto ezincinci.

Ukumakishwa kwe-laser ye-UV kusebenza ngokukodwa kwii-substrates ezibuthathaka ezifana neeplastiki, iglasi, iiseramikhi, iisemiconductors, kunye neentsimbi ezineengubo ezikhethekileyo. I-laser ye-ultraviolet iphazamisa iibhondi ze-molecular phezu komhlaba kunokuba zinyibilike izinto eziphathekayo, okukhokelela kumanqaku agudileyo, acacileyo, kunye nesigxina ngaphandle kokonakalisa iindawo ezikufutshane.

Ngombulelo kumgangatho wayo we-ultra-fine we-beam kunye nokugqalisela okugqwesileyo, imakishi ye-laser ye-UV isetyenziswa kakhulu kumashishini afana nombane, izixhobo zonyango, i-aerospace, ukupakishwa kwezithambiso, kunye nemveliso yesekethe edibeneyo. Iyakwazi ukukrola amanani esiriyeli, iikhowudi zeQR, isicatshulwa esincinci, iilogo, kunye nezinye iziphawuli ezicace gca. Inkqubo iphinda ixabiswe ngokugcinwa kwayo okuphantsi, ukuthembeka okuphezulu, kunye nokukwazi ukudibanisa kunye nemigca yokuvelisa ngokuzenzekelayo ukuze usebenze ngokuqhubekayo.

UmGaqo wokuSebenza we-UV Laser wokuMakisha uMshini

Umatshini wokumakisha we-laser we-UV usebenza ngokusekwe kwindlela yokusabela kwefotochemical, ngokuyintloko uxhomekeke kwi-high-energy ultraviolet laser beam ukuphula iibhondi zemolekyuli kumphezulu wezinto. Ngokungafaniyo ne-laser ye-infrared yesiqhelo efaka amandla obushushu ukutshisa okanye ukunyibilikisa i-substrate, iilaser ze-UV zisebenza ngenkqubo eyaziwa ngokuba "yinkqubo ebandayo." Oku kukhokelela ekususweni kwemathiriyeli ngokuchanekileyo okanye ukulungiswa komphezulu kunye neendawo ezichatshazelwe bubushushu.

Itekhnoloji engundoqo ibandakanya i-laser-state eyomeleleyo ekhupha ukukhanya kwisiseko sobude be-wavelength (ngokuqhelekileyo i-1064nm), ethi emva koko idluliselwe kuthotho lweekristale ezingezizo ukuvelisa isizukulwana sesithathu se-harmonic (THG), okukhokelela kubude bokugqibela obuyi-355nm. Olu bude bufutshane bubonelela ngogqaliselo oluphezulu kunye nokufunxwa okuphezulu ngoluhlu olubanzi lwezixhobo, ngakumbi ezingezizo ezentsimbi.

Xa i-laser beam ye-UV egxininisiweyo inxibelelana nomsebenzi, amandla aphezulu efoton aphazamisa ngokuthe ngqo izakhiwo zeemolekyuli ngaphandle kokusasazeka kwe-thermal. Oku kuvumela ukuphawulwa kwesisombululo esiphezulu kwiisubstrates ezingeva bubushushu njenge-PET, i-polycarbonate, iglasi, iiseramikhi, kunye nezinto ze-elektroniki, apho iilaser zemveli zinokubangela ukulwa okanye ukujika kombala. Ukongezelela, inkqubo ye-laser ilawulwa nge-scanners ye-galvanometer enesantya esiphezulu kunye nesofthiwe ye-CNC, iqinisekisa ukuchaneka kwe-micron-level kunye nokuphindaphinda.

IParamete yoMshini wokuMakisha we-UV Laser

| Hayi. | Ipharamitha | Inkcazo |

|---|---|---|

| 1 | Imodeli yomatshini | UV-3WT |

| 2 | Laser Wavelength | 355nm |

| 3 | Amandla eLaser | 3W / 20KHz |

| 4 | Ireyithi yokuphindaphinda | 10-200KHz |

| 5 | Uluhlu lokumakisha | 100mm × 100mm |

| 6 | Ububanzi bomgca | ≤0.01mm |

| 7 | Ukumakisha ubunzulu | ≤0.01mm |

| 8 | Ubuncinane bonobumba | 0.06mm |

| 9 | Isantya sokumakisha | ≤7000mm/s |

| 10 | Phinda Ukuchaneka | ±0.02mm |

| 11 | Imfuneko yamandla | 220V/Isigaba esinye/50Hz/10A |

| 12 | Amandla Aphelele | 1KW |

Ukusetyenziswa koomatshini bokuMakisha iLaser ye-UV

Oomatshini bokuphawula i-laser ye-UV bamkelwa ngokubanzi kuwo wonke amashishini amaninzi ngenxa yokuchaneka okuphezulu, isiphumo esincinci se-thermal, kunye nokuhambelana noluhlu olubanzi lwezixhobo. Ngezantsi ziindawo eziphambili zesicelo:

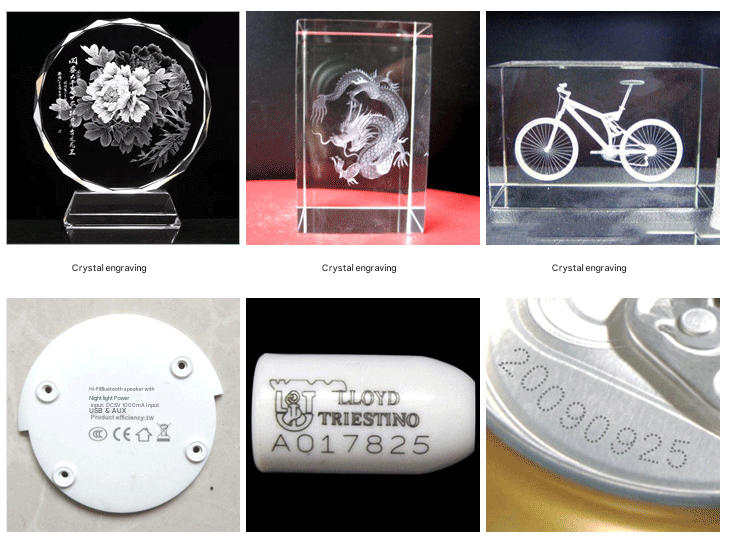

Ishishini loMbane kunye neSemiconductor: Isetyenziselwa ukuphawula iitshiphusi ze-IC ezincinci, iiPCB, izihlanganisi, abenzi boluvo, kunye namanye amacandelo e-elektroniki. I-laser ye-UV inokudala abalinganiswa abancinci kunye nabachanekileyo okanye iikhowudi ngaphandle kokonakalisa iisekethe ezibuthathaka okanye ukubangela imiba yokuqhuba.

Izixhobo zonyango kunye nokuPakisha: Ilungele ukuphawula iisirinji, iingxowa ze-IV, iityhubhu zeplastiki, kunye neepolima zodidi lwezonyango. Inkqubo yokumakisha ebandayo iqinisekisa ukuba inzala igcinwa kwaye ayihambisani nokuthembeka kwezixhobo zonyango.

Iglasi kunye neCeramics: Iilaser ze-UV zisebenza kakhulu ekukroleni iikhowudi zebhakhowudi, iinombolo zesiriyali, kunye neepateni zokuhombisa kwiibhotile zeglasi, izibuko, iithayile ze-ceramic, kunye ne-quartz substrates, zishiya imiphetho egudileyo, engenazintanda.

Amalungu ePlastiki: Ifanelekile yokumakisha iilogo, iinombolo zebhetshi, okanye iikhowudi zeQR kwi-ABS, PE, PET, PVC, kunye nezinye iiplastiki. Iilaser ze-UV zibonelela ngeziphumo ezichasene kakhulu ngaphandle kokutshisa okanye ukunyibilikisa iplastiki.

Izithambiso kunye nokuPakisha ukutya: Isetyenziswa kwizikhongozeli zeplastiki ezicace gca okanye ezinemibala, iikepusi, kunye nokupakishwa okubhetyebhetye ukuprinta imihla yokuphelelwa kwexesha, iikhowudi zebhetshi, kunye neempawu zebhrendi ezicace kakhulu.

Iimoto kunye ne-Aerospace: Ukuchonga indawo ehlala ixesha elide, enesisombululo esiphezulu, ngakumbi kwizinzwa, ukugqunywa kweengcingo, kunye nezigqubuthelo ezikhanyayo ezenziwe ngezinto ezibuthathaka.

Ngombulelo ekusebenzeni kwayo okugqwesileyo ekuphawuleni okucacileyo kunye nee substrates ezingezizo ezentsimbi, isiphawuli se-laser ye-UV ibalulekile kuyo nayiphi na inkqubo yokuvelisa efuna ukuthembeka, ucoceko, kunye nokumakishwa okuchanekileyo.

Imibuzo Ebuzwa Rhoqo (FAQ) malunga noomatshini bokuMakisha beLaser ye-UV

I-Q1: Ziziphi izinto ezihambelana noomatshini bokumakisha be-UV laser?

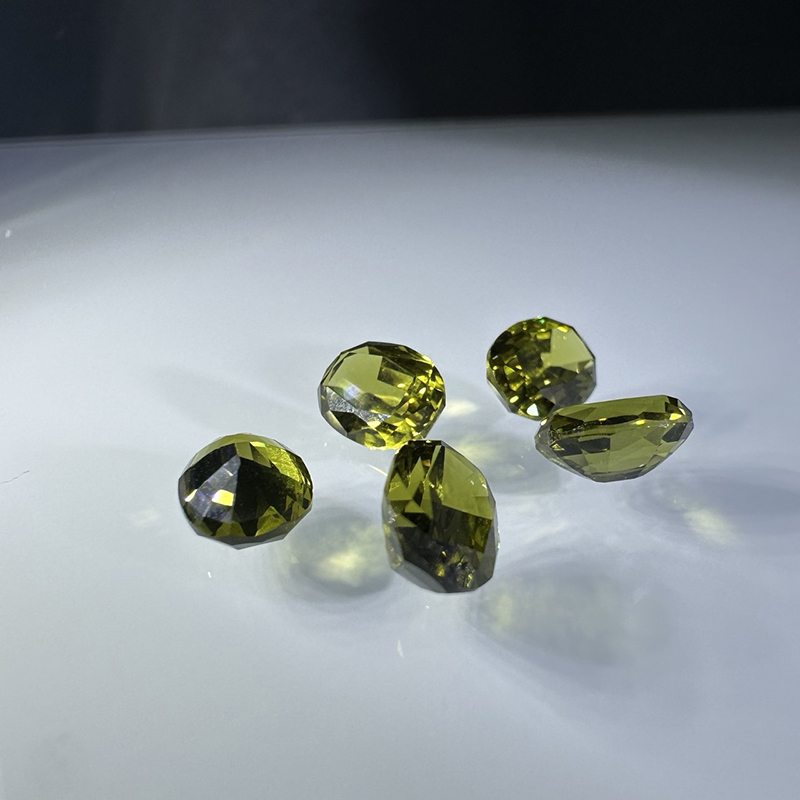

I-A1: Iimpawu ze-laser ze-UV zifanelekile kwiindidi ezininzi ezingezizo ezentsimbi kunye nezinye izixhobo zetsimbi, kubandakanywa iiplastiki (i-ABS, i-PVC, i-PET), iglasi, i-ceramics, ii-silicon wafers, isafire, kunye neentsimbi ezigqunyiweyo. Ziqhuba kakuhle kakhulu kwii-substrates ezingeva bubushushu.

I-Q2: Ukumakishwa kwe-laser ye-UV kwahluke njani kwifiber okanye kwi-CO₂ yokumakisha kwe-laser?

I-A2: Ngokungafani ne-fiber okanye i-CO₂ lasers ethembele kumandla okushisa, ii-lasers ze-UV zisebenzisa i-photochemical reaction ukuphawula umphezulu. Oku kubangela iinkcukacha ezingcono, umonakalo omncinci we-thermal, kunye namanqaku okucoca, ngakumbi kwizinto ezithambileyo okanye ezibonakalayo.

I-Q3: Ngaba i-UV laser imakishwa ngokusisigxina?

I-A3: Ewe, ukumakishwa kwe-laser ye-UV kudala ukuchasana okuphezulu, okuhlala ixesha elide, kunye nokunxiba okungaguqukiyo kokumakishwa okusisigxina phantsi kweemeko eziqhelekileyo zokusetyenziswa, kubandakanya ukuvezwa kwamanzi, ubushushu kunye neekhemikhali.

I-Q4: Luluphi ulondolozo olufunekayo kwiinkqubo zokumakisha i-UV laser?

I-A4: Iilaser ze-UV zifuna ukugcinwa okuncinci. Ukucocwa rhoqo kwamacandelo optical kunye nezihlungi zomoya, kunye nokuhlolwa kwenkqubo yokupholisa ngokufanelekileyo, kuqinisekisa ukusebenza okuzinzileyo kwexesha elide. Ubomi bemodyuli ye-laser ye-UV budla ngokudlula iiyure ezingama-20,000.

I-Q5: Ngaba inokuhlanganiswa kwimigca yokuvelisa ngokuzenzekelayo?

A5: Ngokuqinisekileyo. Uninzi lweenkqubo zokumakishwa kwelaser ye-UV zixhasa ukudityaniswa kusetyenziswa iiprothokholi zemizi-mveliso (umzekelo, i-RS232, TCP/IP, i-Modbus), ezivumela ukuba zifakwe kwiingalo zerobhothi, abahambisi, okanye kwiinkqubo zokuvelisa ezikrelekrele.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.