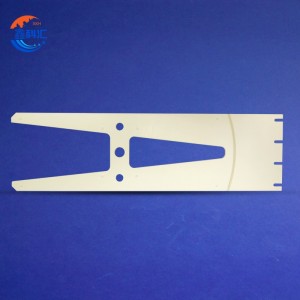

I-High-Performance Alumina Ceramic End Effector (Fork Arm) yeSemiconductor kunye neCocaroom Automation

Idayagram eneenkcukacha

Intshayelelo yeMveliso

I-Alumina Ceramic End Effector, ekwabizwa ngokuba yi-ceramic fork arm okanye isandla se-robotic ceramic, sisixhobo sokuphatha esichanekileyo esilungiselelwe iinkqubo ezizenzekelayo kwi-semiconductor, i-photovoltaic, i-panel display, kunye ne-high-purity laboratory environments. Yenzelwe ukubonelela ngozinzo olukhethekileyo lwe-thermal, ukuqina koomatshini, kunye nokuxhathisa iikhemikhali, inikezela ngokucocekileyo, okuthembekileyo, kunye nokuthutha okukhuselekileyo kwezinto eziphathekayo ezifana ne-silicon wafers, i-glass substrates, kunye ne-electronic micro-components.

Njengohlobo lwe-robotic end effector, eli candelo le-ceramic lunxibelelwano lokugqibela phakathi kwenkqubo yokuzenzekelayo kunye nomsebenzi. Idlala indima ebalulekileyo ekutshintsheni ngokuchanekileyo, ukulungelelaniswa, ukulayishwa / ukukhulula, kunye nokubeka imisebenzi kumagumbi okucoca kunye neendawo zokucoca.

Isishwankathelo seMathiriyeli – iAlumina Ceramic (Al₂O₃)

I-alumina ceramic sisixhobo sobuchwephesha esizinzile kwaye singasebenzi ngokwekhemikhali eyaziwa ngoomatshini bayo kunye neempawu zombane. I-high-purity (≥ 99.5%) i-alumina esetyenziswa kwezi ziphumo zokugqibela iqinisekisa:

-

Ukuqina okuphezulu (Mohs 9): Okwesibini kuphela kwidayimane, i-alumina ibonelela ngokuxhathisa ukunxiba.

-

Ikhono lobushushu obuphezulu: Igcina imfezeko yolwakhiwo ngaphezulu kwe-1600°C.

-

Ukungangeni kwekhemikhali: Ukumelana neeasidi, iialkali, izinyibilikisi, kunye nemekobume yeplasma etching.

-

Ukugquma kombane: Ngamandla aphezulu e-dielectric kunye nokulahlekelwa kwe-dielectric ephantsi.

-

Ukwandiswa kwe-thermal ephantsi: Iqinisekisa uzinzo lwe-dimensional kwimo yebhayisikile eshushu.

-

Ukuvelisa amasuntswana aphantsi: Kubalulekile ukuhambelana nokucoceka kwegumbi (iKlasi ye-10 ukuya kwiKlasi ye-1000).

Ezi mpawu zenza i-alumina ceramic ilungele imisebenzi ebaluleke kakhulu kubuthunywa kumashishini angachaphazelekiyo.

Usetyenziso olusebenzayo

Isiphelo sokugqibela se-alumina ceramic samkelwa ngokubanzi kwiinkqubo zobugcisa obuphezulu, ngakumbi apho izixhobo zentsimbi okanye zeplastiki zisilela ngenxa yokwanda kwe-thermal, ungcoliseko, okanye imiba yokubola. Iinkalo zesicelo eziphambili ziquka:

- Ukudluliselwa kwe-wafer ye-semiconductor

- I-Photolithography yokulayisha kunye nokukhulula iinkqubo

- Ukuphathwa kwe-Glas substrate kwi-OLED kunye nemigca ye-LCD

- Ukuhanjiswa kwe-crystalline wafer kwimveliso yeeseli zelanga

- Ukuhlolwa okuzenzekelayo kwamehlo okanye i-microelectronic

- Isampuli yothutho kwiilebhu zohlalutyo okanye zebhayomedical

- Iinkqubo ezizenzekelayo zokusingqongileyo

Ukukwazi kwayo ukwenza ngaphandle kokwazisa amasuntswana okanye intlawulo engatshintshiyo iyenza ibaluleke kakhulu kwimisebenzi yerobhothi echanekileyo kwi-automation yegumbi.

Iimpawu zoyilo kunye nokwenza ngokwezifiso

Isiphelo seceramic ngasinye sesiphumo senziwe ngobunjineli ukuze silingane ingalo ethile yerobhothi okanye isixokelelwano sokuphatha. Sixhasa ulungelelwaniso olupheleleyo olusekwe kwi:

-

Ukuhambelana kobungakanani be-wafer: 2", 4", 6", 8", 12" kunye nokunye

-

Slot geometry kunye nezithuba: Ithatha indawo yokubamba edge, inkxaso yecala elingasemva, okanye uyilo lwe-wafer olunotshi

-

Amazibuko okufunxa: Imingxuma yokucoca edityanisiweyo okanye amajelo okuphatha okungekho qhagamshelwano

-

Ukunyuswa ubumbeko: Imingxunya, imisonto, iindawo zokubeka ezilungiselelwe isixhobo sokugqibela serobhothi yakho

-

Unyango lomphezulu: Ikhazimlisiwe, igqitywe, okanye igqitywe kakuhle (Ra <0.2 µm ikhona)

-

Ukukhuselwa komda: Iikona ezijikelezileyo okanye i-chamfering ukunqanda umonakalo we-wafer

Ngokusebenzisa imizobo ye-CAD okanye imodeli ye-3D ebonelelwa ngabathengi, iinjineli zethu zinokunyusa ingalo nganye yefolokhwe ubunzima, amandla kunye nokucoceka.

Izinto eziluncedo zeCeramic End Effectors

| Uphawu | Inzuzo |

|---|---|

| High Mechanical Rigidity | Igcina ukuchaneka kwe-dimensional phantsi kwamandla okulayisha erobhothi |

| Ukusebenza kakuhle kweThermal | Yenza ngokuthembekileyo kwiindawo eziphakamileyo okanye kwi-plasma |

| Zero Metal Ungcoliseko | Akukho mngcipheko wongcoliseko lwe-ion ekusebenzeni okubalulekileyo kwe-semiconductor |

| Umphezulu weFriction ephantsi | Yehlisa umngcipheko wokukrala kwi-wafer okanye kwi-glass substrates |

| I-Anti-Static kunye ne-Non-Magnetic | Ayitsali uthuli okanye ayichaphazeli izinto ezinobuthathaka bemagnethi |

| Ubomi Obude Benkonzo | Ukumelana nokunxiba okuphezulu kwimijikelo ephindaphindwayo ye-automation yesantya esiphezulu |

| Ukuhambelana okucocekileyo kakhulu | Ifanele i-ISO 14644 amagumbi acocekileyo (iKlasi ye-100 nangaphantsi) |

Xa kuthelekiswa neengalo zeplastiki okanye ze-aluminiyam, i-alumina ceramic ibonelela ngokuphucuka ngokumangalisayo kweekhemikhali kunye nokuzinza komzimba kunye neemfuno zokugcinwa okuncinci.

| Ipropati | Metal Arm | Ingalo yePlastiki | Ingalo yeCeramic yeAlumina |

|---|---|---|---|

| Ukuqina | Phakathi | Phantsi | Phezulu kakhulu (Mohs 9) |

| Ukuzinza kweThermal | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Ukumelana nemichiza | Phakathi | Ubuhlwempu | Egqwesileyo |

| Ukufaneleka kwegumbi lokucoca | Phakathi | Phantsi | Phezulu kakhulu |

| Nxiba ukuxhathisa | Phakathi | Phantsi | Ebalaseleyo |

| Amandla eDielectric | Phantsi | Phakathi | Phezulu |

| Custom Machining Precision | Ilinganiselwe | Phakathi | Phezulu (±0.01mm kunokwenzeka) |

IiNgcaciso zobuGcisa

| Ipharamitha | Ixabiso |

|---|---|

| Izinto eziphathekayo | Ucoceko oluphezulu lweAlumina (≥ 99.5%) |

| Ubushushu bokusebenza | Ukuya kuthi ga kwi-1600°C |

| Uburhabaxa boMphezulu | Ra ≤ 0.2 µm (ukhetho) |

| Iisayizi zeWafer ezihambelanayo | 2" ukuya kwi-12" okanye ngokwesiko |

| Ukunyamezelwa kweFlatness | ±0.01 mm (ixhomekeke kwisicelo) |

| Inkxaso yokufunxa iVacuum | Ukuzikhethela, amajelo anokwenziwa ngokwezifiso |

| Iinketho zokunyusela | I-Bolt-through, i-flange, imingxuma efakwe |

Imibuzo Ebuzwa Rhoqo (FAQ)

I-Q1: Ngaba umphumo wokugqibela unokudibaniswa kwiinkqubo ezikhoyo ze-robotic?

A1:Ewe. Sixhasa uhlengahlengiso olusekwe kujongano lwakho lwerobhothi. Ungasithumelela umzobo weCAD okanye imilinganiselo yeflange ukuze ulungelelanise ngokuchanekileyo.

I-Q2: Ngaba iingalo ze-ceramic ziya kuphuka ngokulula ngexesha lokusetyenziswa?

A2:Ngelixa i-ceramic inobunkunkqele ngokwendalo, uyilo lwethu lusebenzisa ijometri ephuculweyo ukunciphisa uxinzelelo. Ngaphantsi kweemeko ezifanelekileyo zokusetyenziswa, banikezela ubomi benkonzo obude kakhulu kunesinyithi okanye iplastiki.

I-Q3: Ngaba kunokwenzeka ukusebenzisa oku kwi-vacuum ephezulu kakhulu okanye kumagumbi e-plasma etching?

A3:Ewe. I-alumina ceramic ayikhupheli ngaphandle, i-thermal stable, kunye ne-corrosion resistant-ifaneleke ngokugqibeleleyo kwi-vacuum ephezulu, igesi esebenzayo, okanye i-plasma.

I-Q4: La macandelo acocwa okanye agcinwe njani?

A4:Zinokucocwa kusetyenziswa amanzi e-DI, utywala, okanye izicoci ezihambelana negumbi elicocekileyo. Akukho kugcinwa okukhethekileyo okufunekayo ngenxa yokuzinza kweekhemikhali kunye ne-inert surface.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.