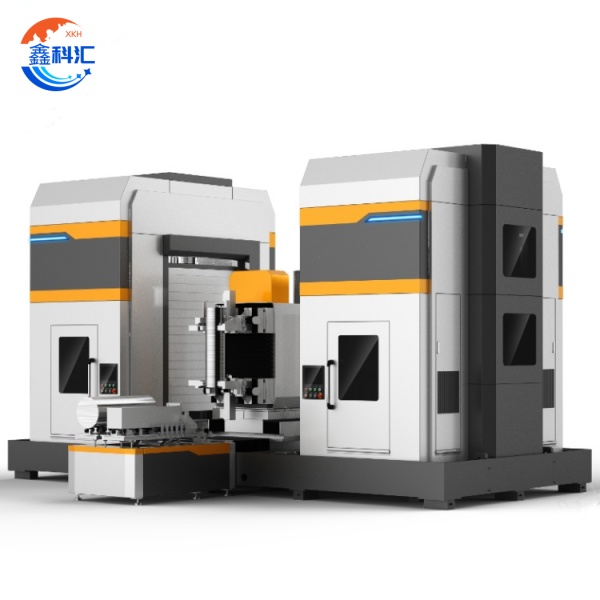

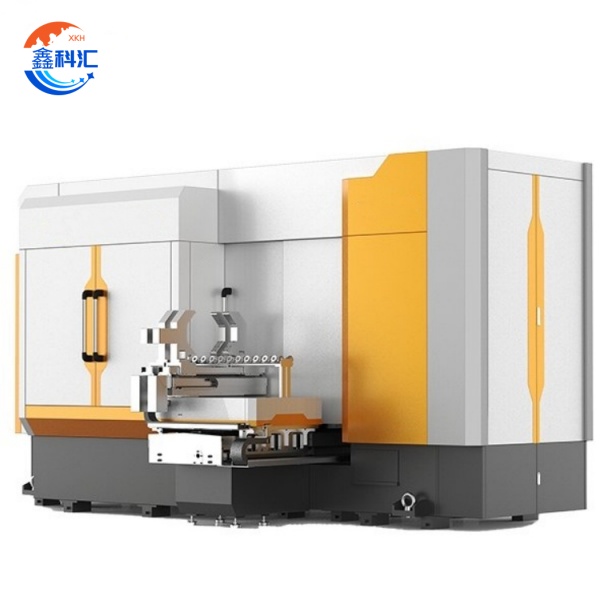

Isikhululo esiphindwe kabini somatshini wesikwere se-monocrystalline yesilicon yentonga yokusetyenzwa kwe-6/8/12 intshi yomphezulu womphezulu Ra≤0.5μm

Iimpawu zesiXhobo:

(1) Isitishi esiphindwe kabini ukusetyenzwa kwe-synchronous

· Ukusebenza ngokuphindwe kabini: Ukucutshungulwa kwangaxeshanye kweentonga ezimbini ze-silicon (Ø6"-12") kwandisa imveliso nge-40% -60% vs. izixhobo ze-Simplex.

· Ulawulo oluzimeleyo: Isikhululo ngasinye sinokulungelelanisa ngokuzimeleyo iiparitha zokusika (uxinzelelo, isantya sokutya) ukulungelelanisa neenkcukacha zentonga ye-silicon.

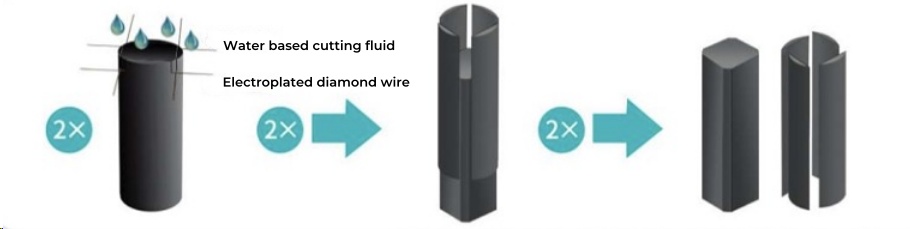

(2) Ukusika okuphezulu

· Ukuchaneka komgangatho: ukunyamezela komgama webar yesikwele ± 0.15mm, uluhlu ≤0.20mm.

· Umgangatho womphezulu: ukuqhawula i-edge <0.5mm, ukunciphisa inani lokugaya okulandelayo.

(3) Ukulawula ngobulumko

· Ukusika okuguquguqukayo: ukujongwa kwexesha lokwenyani le-silicon rod morphology, ukulungiswa okuguquguqukayo kwendlela yokusika (njengokulungisa intonga ye-silicon egobileyo).

· Ukulandeleka kwedatha: rekhoda iiparamitha zokusetyenzwa kwentonga nganye yesilicon ukuxhasa inkqubo ye-MES docking.

(4) Iindleko eziphantsi ezinokusetyenziswa

· Ukusetyenziswa kwedayimane yocingo: ≤0.06m/mm (ubude bentonga ye-silicon), ububanzi bocingo ≤0.30mm.

Ujikelezo olupholileyo: Inkqubo yokucoca yandisa ubomi benkonzo kwaye inciphisa ukulahlwa kolwelo oluyinkunkuma.

Itekhnoloji kunye neenzuzo zophuhliso:

(1) Ukusika ukusetyenziswa kweteknoloji

- I-Multi-line cutting: i-100-200 imigca yedayimane isetyenziswe ngokufanayo, kwaye isantya sokusika si-≥40mm / min.

- Ulawulo loxinzelelo: Inkqubo yokulungelelanisa i-loop evaliweyo (± 1N) ukunciphisa umngcipheko wokuqhawula ucingo.

(2) Ukwandiswa kokuhambelana

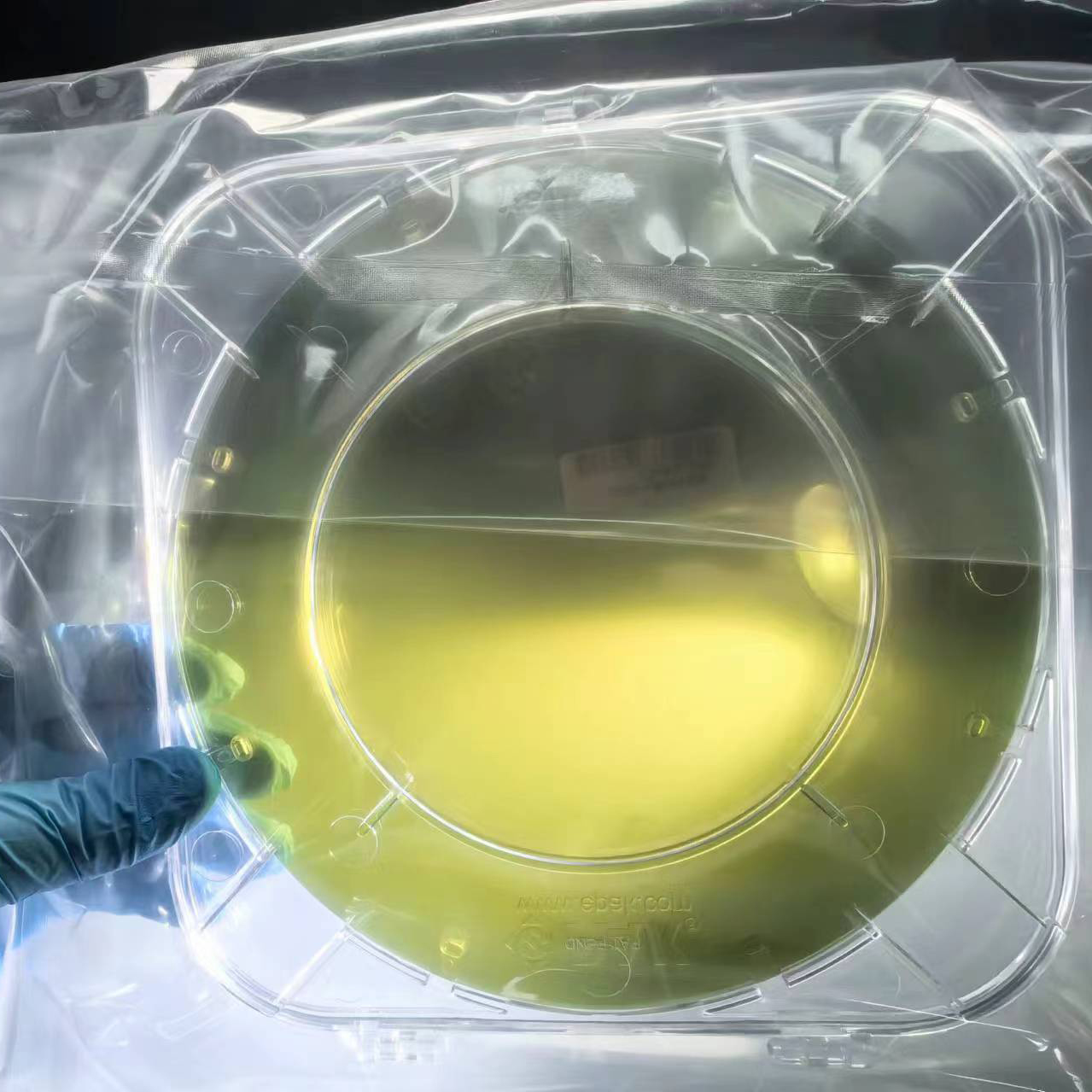

- Ukulungelelaniswa kwezinto: Inkxaso ye-P-uhlobo / i-N-uhlobo lwe-silicon ye-monocrystalline, ehambelana ne-TOPCon, i-HJT kunye nezinye iintsimbi ze-silicon eziphezulu zebhetri.

- Ubungakanani obuguquguqukayo: ubude bentonga ye-silicon 100-950mm, umgama wentonga yesikwele 166-233mm eguquguqukayo.

(3) Ukuphuculwa okuzenzekelayo

- Ukulayishwa kwerobhothi kunye nokukhulula: ukulayishwa ngokuzenzekelayo / ukukhulula iintonga ze-silicon, betha ≤3 imizuzu.

- Ukuxilonga okuhlakaniphile: Ukugcinwa kwangaphambili ukunciphisa ixesha lokuphumla elingacwangciswanga.

(4) Ubunkokeli boshishino

- Inkxaso ye-wafer: iyakwazi ukucubungula i-≥100μm i-silicon e-ultra-thin eneentonga zesikwere, izinga lokuqhekeka <0.5%.

- Ukusetyenziswa kakuhle kwamandla: Ukusetyenziswa kwamandla kwiyunithi nganye ye-silicon rod kuncitshiswe nge-30% (vs. izixhobo zemveli).

Imilinganiselo yobugcisa:

| Igama lepharamitha | Ixabiso lesalathisi |

| Inani leebha ezisetyenzisiweyo | 2 iziqwenga / iseti |

| Uluhlu lobude bebha | 100 ~ 950mm |

| Uluhlu lomda womatshini | 166 ~ 233mm |

| Ukusika isantya | ≥40mm/min |

| Isantya socingo lwedayimani | 0~35m/s |

| Idayimani yedayimani | 0.30 mm okanye ngaphantsi |

| Ukusetyenziswa komgca | 0.06 m/mm okanye ngaphantsi |

| Idayamitha yentonga ehambelanayo engqukuva | Ugqitywe intonga yesikweri ububanzi +2mm, Qinisekisa izinga lokupasa lokupholisha |

| Ulawulo lokuqhawula umda | Umphetho okrwada ≤0.5mm, Akukho ukutshiphuza, umgangatho ophezulu womphezulu |

| Ubude be-arc ukufana | Uluhlu loqikelelo <1.5mm, Ngaphandle kokuphazamiseka kwentonga ye-silicon |

| Imilinganiselo yomatshini (umatshini omnye) | 4800×3020×3660mm |

| Amandla alinganisiweyo ewonke | 56kW |

| Ubunzima obufileyo bezixhobo | 12t |

Umatshini wokuchaneka kwetafile:

| Into echanekileyo | Uluhlu lokunyamezela |

| Unyamezelo lomda webar yesikwere | ±0.15mm |

| Umda webar yesikwere | ≤0.20mm |

| I-engile kumacala onke entonga yesikwere | 90°±0.05° |

| I-Flatness yentonga yesikwere | ≤0.15mm |

| Irobhothi iphindaphinda ukuchaneka kokubeka | ±0.05mm |

Iinkonzo ze-XKH:

I-XKH inikezela ngeenkonzo ezipheleleyo zomjikelo we-silicon ye-mono-crystalline oomatshini be-silicon dual-station, kubandakanywa ukulungelelanisa izixhobo (ezihambelanayo kunye neentonga ze-silicon ezinkulu), ukuthunyelwa kwenkqubo (ukusika i-parameter optimization), uqeqesho lokusebenza kunye nenkxaso yokuthengisa emva kokuthengisa (unikezelo lwamacandelo abalulekileyo, ukuxilongwa okude), ukuqinisekisa ukuba abathengi bafezekise isivuno esiphezulu (> 99%) kunye nemveliso yexabiso eliphantsi, kunye nokubonelela ngokuphuculwa kwe-technical upgrades (ukusika i-AI). Ixesha lokuhanjiswa ziinyanga ezi-2-4.

Idayagram eneenkcukacha