Idayimani yocingo lweSikhululo esiNye esiNdwe ngocingo oluNye umatshini wokusika weSi Wafer/Optical Glass Material Cutting

Intshayelelo yeMveliso

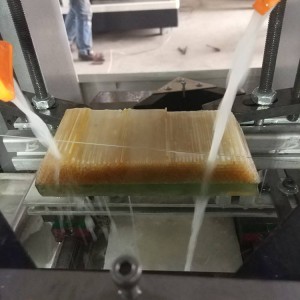

I-diamond wire ye-diamond ye-station ye-single-single cutting machine yinto ephezulu yokuchaneka kunye nezixhobo eziphezulu zokusika ezenzelwe izinto ezinzima kunye nezinqabileyo. Isebenzisa ucingo lwedayimani njengendawo yokusika kwaye ifanelekile ukusetyenzwa ngokuchanekileyo kwezixhobo ezinobunzima obuphezulu obunje ngee-silicon wafers, isafire, isilicon carbide (SiC), iiseramikhi, kunye neglasi yokukhanya. Ibandakanya uyilo lwezitishi ezintathu, lo matshini wenza ukusika ngaxeshanye kwezinto ezininzi zokusebenza kwisixhobo esinye, ukuphucula kakhulu ukusebenza kwemveliso kunye nokunciphisa iindleko zokuvelisa.

UmGaqo wokuSebenza

- I-Diamond Wire Cutting: Isebenzisa i-electroplated okanye i-resin-bounded diamond wire ukwenza ukusika okusekelwe kwi-grinding ngokusebenzisa i-high-speed reciprocating motion.

- Izitishi eziNtathu zokuSika i-Synchronous: Zixhotyiswe ngeendawo zokusebenza ezintathu ezizimeleyo, ezivumela ukusika ngaxeshanye kweziqwenga ezithathu ukunyusa umthamo.

- Ulawulo lweTension: Ibandakanya inkqubo yokulawula ukunyanzeliswa kwe-high-chane-chane ukugcina ukuqina kocingo lwedayimani oluzinzile ngexesha lokusika, ukuqinisekisa ukuchaneka.

- Ukupholisa kunye neNkqubo yokuthambisa: Iqeshe amanzi adiyiniweyo okanye isisipholisi esikhethekileyo ukunciphisa umonakalo oshushu kunye nokwandisa ubomi bocingo lwedayimani.

Iimpawu zeZixhobo

- Ukusika okuchanekileyo okuPhezulu: Ifezekisa ukuchaneka kokusika kwe-± 0.02mm, ilungele ukulungiswa kwe-wafer ye-ultra-thin (umzekelo, ii-photovoltaic silicon wafers, i-semiconductor wafers).

- Ukusebenza okuphezulu: Uyilo lwezikhululo ezithathu zonyusa imveliso ngaphezulu kwe-200% xa kuthelekiswa noomatshini besikhululo esinye.

- Ilahleko yezinto eziPhantsi: Uyilo lwe-kerf emxinwa (0.1–0.2mm) lunciphisa inkunkuma yezinto.

- I-Automation ephezulu: Ifaka ukulayishwa ngokuzenzekelayo, ukulungelelaniswa, ukusika, kunye nokukhulula iinkqubo, ukunciphisa ukungenelela kwesandla.

- Ukuguquguquka okuphezulu: Ukukwazi ukusika izinto ezahlukeneyo ezinzima kunye neziqhekezayo, kubandakanya isilicon ye-monocrystalline, isilicon yepolycrystalline, isafire, iSiC, kunye neeseramikhi.

Izinto eziluncedo kwezobuGcisa

| Inzuzo

| Inkcazo

|

| Multi-Station Synchronous Cutting

| Izikhululo ezintathu ezizimeleyo ezilawulwa ngokuzimeleyo zenza ukusika i-workpieces ezinobunzima obahlukeneyo okanye izinto, ukuphucula ukusetyenziswa kwezixhobo.

|

| Intelligent Tension Control

| Ukulawulwa kwe-loop evaliweyo kunye ne-servo motors kunye ne-sensors iqinisekisa ukunyanzeliswa kocingo rhoqo, ukuthintela ukuphuka okanye ukusika ukuphambuka.

|

| High-Rigidity Ulwakhiwo

| Izikhokelo zomgca ezichanekileyo eziphezulu kunye neenkqubo eziqhutywa yi-servo ziqinisekisa ukusika okuzinzile kunye nokunciphisa iziphumo zokungcangcazela.

|

| UkuSebenza kwamandla kunye noBungane be-Eco

| Xa kuthelekiswa nokusikwa kodaka lwendalo, ukusika ucingo lwedayimani akungcoliseki, kwaye into yokupholisa inokuphinda isetyenziswe, kucuthwe iindleko zokucocwa kwenkunkuma.

|

| Ukubeka esweni okukrelekrele

| Ixhotyiswe nge-PLC kunye neenkqubo zokulawula isikrini se-touch-screen ukujonga ixesha lokwenyani lokusika isantya, uxinzelelo, ubushushu, kunye nezinye iiparitha, ezixhasa ukulandelwa kwedatha. |

Inkcazo yobuGcisa

| Umzekelo | Isikhululo sedayimani ezintathu umatshini wokusika umgca omnye |

| Ubungakanani bobungakanani bomsebenzi omkhulu | 600*600mm |

| Isantya sokubaleka kocingo | 1000 (MIX) m/m |

| Idayimani yocingo lwedayimani | 0.25-0.48mm |

| Umthamo wokugcina umgca wevili lokubonelela | 20km |

| Ukusika uluhlu lokutyeba | 0-600mm |

| Ukusika ukuchaneka | 0.01mm |

| Ukubetha ngokuthe nkqo kwindawo yokusebenzela | 800mm |

| Indlela yokusika | Izinto eziphathekayo zimile, kwaye ucingo lwedayimane luyashukuma kwaye luhla |

| Ukusika isantya feed | 0.01-10mm/min (Ngokwemathiriyeli kunye nobukhulu) |

| Itanki yamanzi | 150L |

| Ukusika ulwelo | Anti-rust high-efficiency ukusika ulwelo |

| I-engile yokujingi | ±10° |

| Isantya sojingi | 25°/s |

| Ubuninzi bexinzelelo lokusika | 88.0N (Seta ubuncinane iyunithi0.1n) |

| Ukusika ubunzulu | 200 ~ 600mm |

| Yenza iipleyiti ezihambelanayo ngokuhambelana noluhlu lokusika lomthengi | - |

| Indawo yokusebenzela | 3 |

| Ukunikezwa Amandla | Isigaba sesithathu socingo lwe-AC380V/50Hz |

| Amandla onke esixhobo somatshini | ≤32kw |

| Injini engundoqo | 1*2kw |

| Injini yocingo | 1*2kw |

| Workbench swing motor | 0.4*6kw |

| Injini yokulawula uxinzelelo | 4.4*2kw |

| Ukukhutshwa kweengcingo kunye nemoto yokuqokelela | 5.5*2kw |

| Imilinganiselo yangaphandle (ngaphandle kwebhokisi yengalo yerocker) | 4859*2190*2184mm |

| Imilinganiselo yangaphandle (kuquka ibhokisi yengalo yerocker) | 4859*2190*2184mm |

| Ubunzima bomatshini | 3600ka |

Iinkalo zeSicelo

- Ishishini le-Photovoltaic: Ukusika i-monocrystalline kunye ne-polycrystalline ingots ye-silicon ukuphucula isivuno se-wafer.

- Ishishini leSemiconductor: Ukusikwa ngokuchanekileyo kwee-SiC kunye nee-wafers ze-GaN.

- Ishishini le-LED: Ukusika isafire substrates ukwenzela ukwenziwa kweetshiphu ze-LED.

- IiCeramics eziPhezulu: Ukwenza kunye nokusika iiseramikhi eziphezulu zokusebenza njenge-alumina kunye ne-silicon nitride.

- Iglasi yeOptical: Ukusetyenzwa ngokuchanekileyo kweglasi ecwecwe kakhulu kwiilensi zekhamera kunye neefestile ze-infrared.