I-Diamond-Copper i-Composite ye-Thermal Management Materials

Idayagram eneenkcukacha

Intshayelelo yeMveliso

II-Diamond-Copper Composite (Cu-Diamond)yiIsixhobo solawulo sobushushu obuphezulu kakhuluedibanisa eyona conductor yobushushu yehlabathi —idayimani- kunye neempawu eziphezulu zombane kunye nezomatshini zeubhedu.

Yenzelwe ukusika i-electronics kunye nezixhobo zamandla, le ngqungquthela ifezekisa ibhalansi ekhethekileyoukugqithiswa kwe-thermal conductivity, ukwandiswa kwe-thermal okulawulwayo, kwayeuzinzo lomatshini, eyenza ukusebenza okuthembekileyo naphantsi kwezona ndawo zifuna kakhulu ukushisa.

Ngokungafaniyo nobhedu oluqhelekileyo, i-tungsten, okanye i-molybdenum-based substrates, i-Diamond-Copper composite ihambisaukuya kuthi ga kabini i-thermal conductivityngelixa unciphisa kakhulu ubunzima, ubenze ukhetho olukhethiweyoukupakishwa kwe-semiconductor, iinkqubo ze-laser, i-electronics ye-aerospace, kunye neemodyuli ze-LED ezinamandla aphezulu.

Umgaqo wezinto eziphathekayo

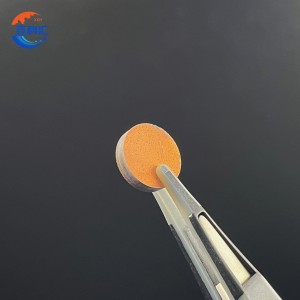

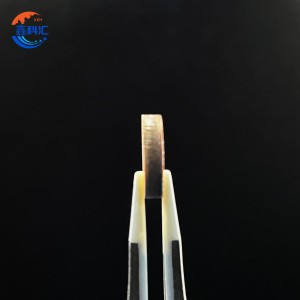

Embindini wobuxoki obuhlanganisiweyoamasuntswana edayimaniifakwe ngokufanayo ngaphakathi ai-matrix yobhedu.

Iqhekeza ngalinye ledayimane lisebenza njenge-micro heat sink, lisasaza ubushushu ngokukhawuleza, ngelixa i-matrix yobhedu iqinisekisa ukuqhutyelwa kombane kunye nokunyaniseka kwesakhiwo.

Ngokusebenzisa iindlela zokuvelisa eziphambili - kubandakanywaukungeniswa kwevacuum, ukutyabeka kweekhemikhali, kwayeI-spark plasma sintering (SPS)- ibhondi ye-interface eyomeleleyo kwaye ezinzileyo yenziwe, iqinisekisa ukuthembeka kwexesha elide phantsi kwebhayisikili eqhubekayo ye-thermal.

Iimbalasane zobuGcisa

| | |

|---|---|

| | |

| | |

| | |

| | |

| | |

Usetyenziso

-

Iimodyuli zeSemiconductor zaMandla aphezulu(IGBT, MOSFET, RF & microwave packages)

-

IiDiode zeLaser kunye nezixhobo ze-Optoelectronic

-

I-Aerospace kunye neeNkqubo zokuPholisa zoKhuselo

-

I-High-Performance LED Heat Spreaders

-

I-IC kunye ne-CPU Ukushisa kweeSinki zeKhompyutha ePhezulu

-

I-Amplifiers yamandla kunye neZixhobo zoNxibelelwano lwe-Optical

Kutheni ukhetha i-Diamond-Copper Composite?

Ngokubaimiba yobushushu.

Ngexesha le-miniaturization kunye nokuxinana kwamandla aphezulu, ukulawula ubushushu buchaza ngokufanelekileyo ubomi kunye nokusebenza kwesixhobo ngasinye.

Umdibaniso weCu-Diamond uqinisekisa:

-

Ubomi besixhobo eside

-

Uzinzo oluphuculweyo lokusebenza

-

Ukuphucula ukusebenza kakuhle kwamandla

-

Ukunciphisa ukudinwa kwe-thermal

FAQ yeeglasi zeQuartz

I-Q1: Ngaba ii-Cu-Diamond composites zingenziwa ngokwezifiso kwizinto ezithile ze-chip?

Ewe. Iqhekeza ledayimani yedayimani kunye ne-CTE inokulungiswa ngokuchanekileyo ukuhambelana ne-Si, i-GaN, okanye izixhobo ezisekelwe kwi-SiC.

I-Q2: Ngaba i-metallization iyadingeka ngaphambi kokuthengiswa?

Ewe. I-Surface metallization (i-Ni / Au, i-Ti / Ni / Au) iyacetyiswa ukuba kuqinisekiswe ukuxhamla okugqwesileyo kunye nokuxhatshazwa okuncinci kwe-thermal.

I-Q3: Isebenza njani phantsi kweemeko eziphakamileyo okanye ezishushu ze-pulsed?

Ukusasazwa kobushushu obuphezulu beDayimani kuqinisekisa ukulingana kobushushu obukhawulezayo, kuyenza ilungele i-high-frequency kunye ne-pulse-loaded components.

I-Q4: Yintoni ubushushu bokusebenza okuphezulu?

Umdibaniso uhlala uzinzile600°Ckwindawo engasebenziyo okanye efunxayo, kuxhomekeke kwi-coating kunye ne-bonding interface.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.