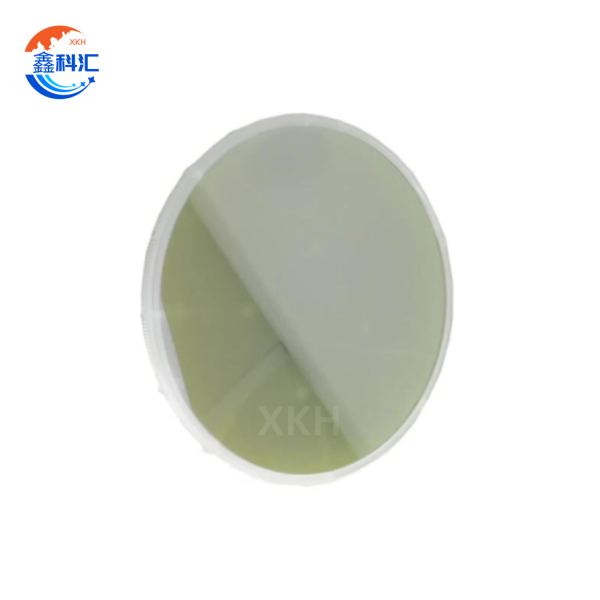

Isiko N Uhlobo lweSiC yeMbewu Substrate Dia153/155mm yoMbane woMbane

Yazisa

I-Silicon Carbide (i-SiC) i-substrates yembewu isebenza njengesiseko se-semiconductors yesizukulwana sesithathu, esahlulwe ngokugqithiswa kwe-thermal conductivity ephezulu, ukuchithwa okuphezulu kwamandla ombane, kunye nokuhamba kwe-electron ephezulu. Ezi zakhiwo zibenza zibe yimfuneko kumbane wombane, izixhobo zeRF, izithuthi zombane (EVs), kunye nokusetyenziswa kwamandla ahlaziyekayo. I-XKH igxile kwi-R&D kunye nokuveliswa kwee-substrates zembewu ye-SiC ekumgangatho ophezulu, isebenzisa iindlela eziphambili zokukhula kwekristale ezifana ne-Physical Vapor Transport (PVT) kunye ne-High-Temperature Chemical Vapor Deposition (HTCVD) ukuqinisekisa umgangatho wecrystalline ohamba phambili kwishishini.

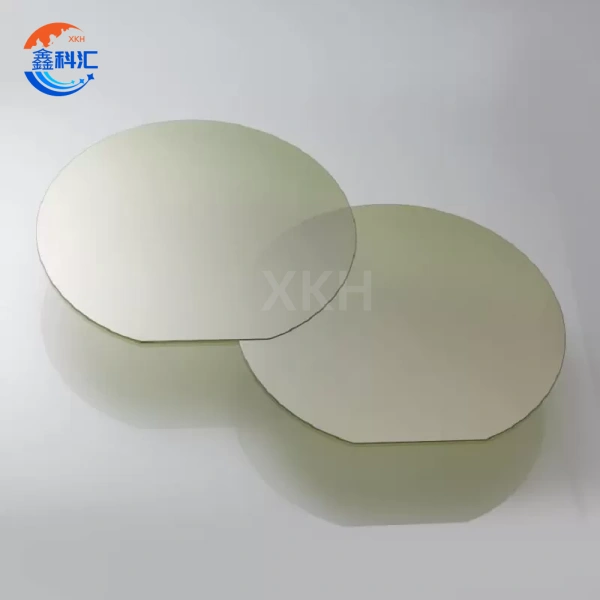

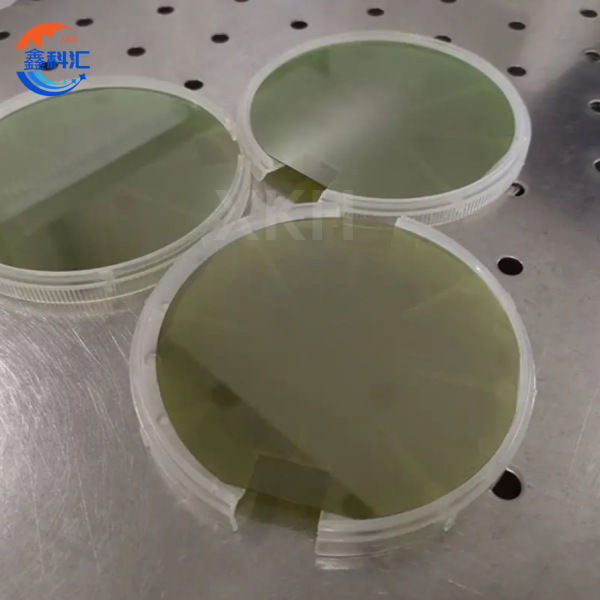

I-XKH inikezela nge-4-intshi, i-6-intshi, kunye ne-8-intshi ye-SiC yembewu substrates ene-customizable N-type/P-type doping, ukuphumeza amanqanaba okumelana ne-0.01-0.1 Ω·cm kunye noxinzelelo lwe-dislocation ngaphantsi kwe-500 cm⁻², ezenza zibe zilungele ukuvelisa i-MOSFETs, i-Schottky Barriers Districts Inkqubo yethu yemveliso edityanisiweyo ngokuthe nkqo igubungela ukukhula kwekristale, ukunqunyulwa kwewafer, ukupolisha, kunye nokuhlolwa, kunye nomthamo wenyanga wemveliso odlula ama-5,000 eewafa ukuze kuhlangatyezwane neemfuno ezahlukeneyo zamaziko ophando, abavelisi be-semiconductor, kunye neenkampani zamandla avuselelekayo.

Ukongeza, sibonelela ngezisombululo eziqhelekileyo, ezibandakanya:

Ukuqhelaniswa neCrystal ngokwezifiso (4H-SiC, 6H-SiC)

I-doping ekhethekileyo (iAluminiyam, iNitrogen, iBoron, njl.

Ukugudisa okugudileyo (Ra <0.5 nm)

I-XKH ixhasa ukusetyenzwa kwesampulu esekwe kwisampulu, ukubonisana nobugcisa, kunye neprototyping yebhetshi encinci ukuhambisa izisombululo ze-SiC substrate eziphuculweyo.

Imilinganiselo yobugcisa

| Silicon carbide seed imbewu | |

| Iipolytype | 4H |

| Imposiso yokujonga umphezulu | 4° ukuya <11-20>±0.5º |

| Ukuxhathisa | ukwenza ngokwezifiso |

| Ububanzi | 205±0.5mm |

| Ukutyeba | 600±50μm |

| Uburhabaxa | I-CMP, iRa≤0.2nm |

| Ukuxinana kweMibhobho | ≤1 i/cm2 |

| Imikrwelo | ≤5,UBude buBonke≤2*Ububanzi |

| Iitshiphusi ze-Edge / i-indenti | Akukho nanye |

| Ukumakishwa kwelaser yangaphambili | Akukho nanye |

| Imikrwelo | ≤2,UBude obuBubonke≤Ububanzi |

| Iitshiphusi ze-Edge / i-indenti | Akukho nanye |

| Iindawo zePolytype | Akukho nanye |

| Ukumakishwa kwelaser yangasemva | 1mm (ukusuka kumphetho ophezulu) |

| Edge | Chamfer |

| Ukupakishwa | Multi-wafer cassette |

I-SiC Seed Substrates - Iimpawu eziphambili

1. IiPropati zoMzi oKhethekileyo

· I-thermal conductivity ephezulu (~ 490 W / m · K), idlula ngokuphawulekayo i-silicon (Si) kunye ne-gallium arsenide (i-GaAs), iyenza ilungele ukupholisa isixhobo soxinaniso lwamandla aphezulu.

· Amandla omhlaba wokuqhawula (~ 3 MV / cm), okwenza umsebenzi ozinzileyo phantsi kweemeko eziphezulu ze-voltage, ezibaluleke kakhulu kwii-inverters ze-EV kunye neemodyuli zamandla oshishino.

· I-Bandgap ebanzi (3.2 eV), ukunciphisa imisinga yokuvuza kumaqondo obushushu aphezulu kunye nokuphucula ukuthembeka kwesixhobo.

2. Umgangatho oPhezulu weCrystalline

· I-PVT + HTCVD iteknoloji yokukhula komxube inciphisa iziphene zemicropipe, igcine ingxinano yokususa kwindawo engaphantsi kwama-500 cm⁻².

· Umnsalo we-wafer / i-warp <10 μm kunye nobunzima bomhlaba u-Ra <0.5 nm, ukuqinisekisa ukuhambelana ne-lithography ephezulu echanekileyo kunye neenkqubo zokubeka ifilimu encinci.

3. Iinketho ezahlukeneyo zokuDoping

·N-uhlobo (Nitrogen-doped): Ukuxhathisa okuphantsi (0.01-0.02 Ω·cm), elungiselelwe izixhobo zeRF eziphezulu.

· Uhlobo lwe-P (i-Aluminium-doped): Ilungele amandla e-MOSFETs kunye nee-IGBTs, ukuphucula ukuhamba kwe-carrier.

· I-Semi-insulating SiC (Vanadium-doped): Ukumelana > 10⁵ Ω·cm, ilungiselelwe iimodyuli ze-5G RF zangaphambili.

4. Uzinzo lweNdawo

· Ukumelana nobushushu obuphezulu (>1600°C) kunye nobulukhuni bemitha, ilungele i-aerospace, izixhobo zenyukliya, kunye nezinye iimeko ezingqongileyo ezigqithisileyo.

I-SiC Seed Substrates - Izicelo eziphambili

1. I-Electronics yamandla

· Izithuthi zoMbane (EVs): Zisetyenziswa kwiitshaja ezisebhodini (OBC) kunye nee-inverters ukuphucula ukusebenza kakuhle kunye nokunciphisa iimfuno zolawulo lwe-thermal.

· Iinkqubo zamandla oShishino: Ukuphucula i-photovoltaic inverters kunye neegridi ezihlakaniphile, ukufezekisa> 99% ukusebenza kakuhle kokuguqulwa kwamandla.

2. Izixhobo zeRF

· Izitishi zeSiseko ze-5G: I-Semi-insulating SiC substrates yenza i-GaN-on-SiC RF iamplifiers yamandla, exhasa i-high-frequency, ukuhanjiswa kwesignali yamandla aphezulu.

UNxibelelwano lweSathelayithi: Iimpawu zelahleko ephantsi ziyenza ilungele izixhobo zamaza emilimitha.

3. Amandla aVuselelwayo kunye noGcino lwaMandla

· Amandla eSolar: I-SiC MOSFETs ikhulisa ukusebenza kakuhle kokuguqulwa kwe-DC-AC ngelixa inciphisa iindleko zenkqubo.

· IiNkqubo zokuGcinwa kwamandla (ESS): Iphucula abaguquli bamacala amabini kwaye yandisa ubomi bebhetri.

4. Ukhuselo & ne-Aerospace

· IiNkqubo zeRadar: Izixhobo ze-SiC ezinamandla aphezulu zisetyenziswa kwi-AESA (i-Active Electronically Scanned Array) iirada.

· Ulawulo lwaMandla kwiziphekepheke: Imitha ye-SiC ekwaziyo ukumelana nemitha ibalulekile kwimishini enzulu.

5. UPhando kunye neeTekhnoloji ezikhulayo

· I-Quantum Computing: High-purity SiC yenza ukuba uphando lwe-spin qubit.

· IiSensors zoBubushushu obuPhezulu: zibekwe kuphononongo lwe-oyile kunye nokubeka iliso kwi-reactor yenyukliya.

I-SiC Seed Substrates - Iinkonzo ze-XKH

1. Izinto eziluncedo kwikhonkco lonikezelo

· Imveliso edibeneyo edibeneyo: Ulawulo olupheleleyo ukusuka kwi-high-purity SiC powder ukuya kwii-wafers ezigqityiweyo, ukuqinisekisa amaxesha okukhokela kwiiveki ezi-4-6 kwiimveliso eziqhelekileyo.

· Ukhuphiswano lweendleko: Uqoqosho lwesikali luvumela i-15-20% yamaxabiso aphantsi kunabo bakhuphisana nabo, ngenkxaso yeeMvumelwano zeXesha elide (LTAs).

2. Iinkonzo zokuLungisa

· I-Crystal orientation: 4H-SiC (eqhelekileyo) okanye i-6H-SiC (izicelo ezikhethekileyo).

· Ukulungiswa kwe-doping: Ukulungelelaniswa kohlobo lwe-N/P-uhlobo/i-semi-insulating properties.

· Ukupholishwa okuphucukileyo: ukupolisha kwe-CMP kunye ne-epi-ready surface treatment (Ra <0.3 nm).

3. Inkxaso yobuGcisa

· Uvavanyo lwesampulu yasimahla: Ibandakanya i-XRD, i-AFM, kunye neengxelo zokulinganisa iziphumo zeHolo.

· Uncedo lokulinganisa isixhobo: Ixhasa ukukhula kwe-epitaxial kunye nokulungiswa koyilo lwesixhobo.

4. Ukuphendula ngokukhawuleza

· Iprototyping yomthamo ophantsi: Ubuncinci beodolo yee-wafers ezili-10, ezihanjiswa kwiiveki ezi-3.

· Ulungelelwaniso lwehlabathi jikelele: Intsebenziswano neDHL kunye neFedEx yokuhanjiswa kwindlu ngendlu.

5. Uqinisekiso loMgangatho

· Ukuhlolwa kwenkqubo epheleleyo: Igubungela i-X-reyi ye-Topography (XRT) kunye nohlalutyo loxinaniso.

· Iziqinisekiso zamazwe ngamazwe: Ihambelana ne-IATF 16949 (i-automotive-grade) kunye nemigangatho ye-AEC-Q101.

Ukuqukumbela

Ii-substrates zembewu ye-XKH's SiC zigqwesa kumgangatho wekristale, uzinzo lwekhonkco lokubonelela, kunye nokuguquguquka ngokwezifiso, ukukhonza amandla ombane, unxibelelwano lwe-5G, amandla avuselelekayo, kunye nobuchwepheshe bokukhusela. Siyaqhubeka nokuqhubela phambili i-8-intshi ye-SiC yobuchwephesha bokuvelisa ubukhulu bokuqhubela phambili ishishini le-semiconductor lesizukulwana sesithathu.