Iphedi ye-bionic engatyibilikiyo ethwele iphedi yokufunxa efunxayo

Iimpawu zeBionic anti-slip pad:

• Ukusetyenziswa kobunjineli obukhethekileyo be-elastomer imathiriyeli ehlanganisiweyo, ukuzuza kungabikho ntsalela, isiphumo esingenalungcoliso sicocekileyo sokuthintela ukutyibilika, sigqibelele iimfuno zokusingqongileyo zokwenziwa kwe-semiconductor.

• Ngokuchaneka kwe-micro-nano structure array design, ulawulo olukrelekrele lweempawu zokukhuhlana komphezulu, ngelixa ugcina i-coefficient ephezulu ye-friction ngelixa ufezekisa ukunamathela kwe-ultra-low.

• Uyilo olulodwa lobuxhakaxhaka lobuxhakaxhaka luvumela ukusebenza okugqwesileyo kokubini ukukhuhlana okuphezulu kwetangential (μ>2.5) kunye nokuncamathela okusezantsi okuqhelekileyo (<0.1N/cm²).

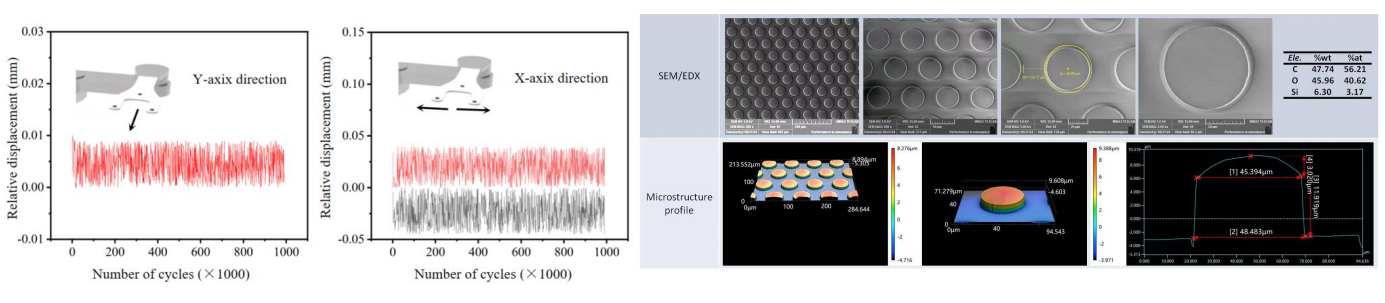

• Iimathiriyeli zePolymer eziphuhliswe ngokukodwa kwishishini le-semiconductor, elifumana ukusebenza okuzinzileyo ngaphandle kokuthomalalisa ukusetyenziswa kwakhona kwe-100,000 ngokusebenzisa iteknoloji yokuvelisa i-micro kunye ne-nano.

Ukusetyenziswa kwephedi ye-Bionic anti-slip:

(1) Ishishini le-semiconductor

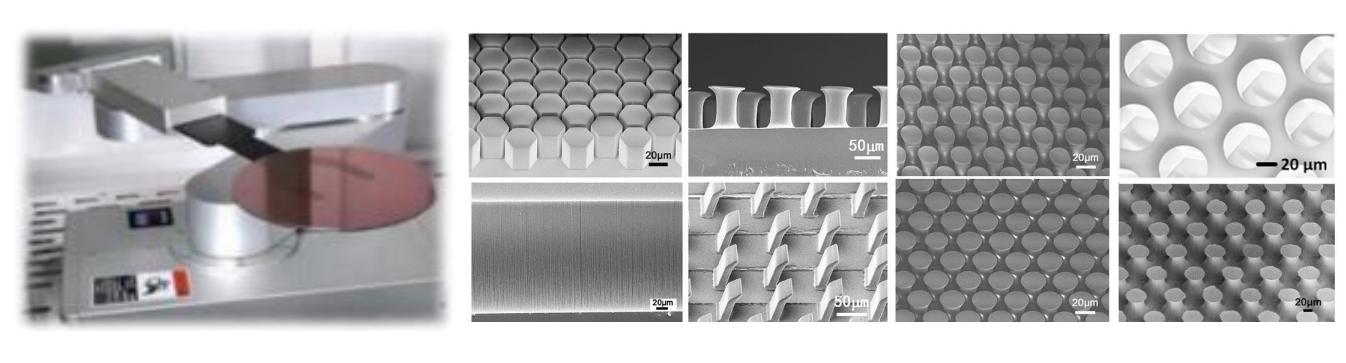

1. Ukwenziwa kwewafer:

· Ukubekwa kwindawo engatyibilikiyo ngexesha lokuhanjiswa kweewafers ezibhityileyo ukuya kuthi ga kwi-intshi ezili-12 (50-300μm)

· Ukulungiswa ngokuchanekileyo komthuthi we-wafer kumatshini we-lithography

· I-wafer non-slip liner yezixhobo zokuvavanya

2. Uvavanyo lwepakethi:

· Ukulungiswa okungonakalisi kwe-silicon carbide/gallium nitride izixhobo zamandla

· Isithinteli sokutyibilika ngexesha lokunyuswa kwetshiphu

· Vavanya ukothuka kunye nokutyibilika kwetafile yeprobe

(2) Imboni ye-Photovoltaic

1. Ukusetyenzwa kwewafer yesilicon:

· Ukulungiswa kokungatyibiliki ngexesha lokusika intonga ye-silicon ye-monocrystalline

· Ultra-obhityileyo isilicon wafer (<150μm) transmission non-slip

· Ukubekwa kweSilicon wafer kumatshini wokushicilela wesikrini

2. Indibano yecandelo:

· Inqwelomoya yeglasi elayitiweyo engatyibilikiyo

· Ukubekwa kwesakhelo sofakelo

· Ibhokisi yokubophelela ilungisiwe

(3) imboni yombane

1. Iphaneli yokubonisa:

· Inkqubo engatyibilikiyo yeOLED/LCD yeglasi engaphantsi

· Ukubekwa kwindawo echanekileyo yepolarizer fit

· Izixhobo zokuvavanya ukothuka kunye nezixhobo zokuvavanya ukutyibilika

2. Amalungu okukhanya:

· Ukudityaniswa kwemodyuli yelensi kungatyibiliki

· Ukulungiswa kweprism/isipili

· Inkqubo yokubona ukothuka kwelaser

(4) Izixhobo ezichanekileyo

1. Iqonga elichanekileyo lomatshini we-lithography li-anti-slip

2. Itheyibhile yokumejarisha yesixhobo sokubhaqa ingqina ukothuka

3. Isixhobo esizenzekelayo ingalo yomatshini engatyibiliki

Idatha yobugcisa:

| Ukwakhiwa kwezinto: | C, O, Si |

| Ukuqina konxweme (A) : | 50~55 |

| I-Elastic recovery coefficient: | 1.28 |

| Ubushushu bokunyamezela okuphezulu: | 260℃ |

| I-friction coefficient: | 1.8 |

| Ukumelana ne-PLASMA: | Ukunyamezelana |

Iinkonzo ze-XKH:

I-XKH ibonelela ngeenkonzo ze-bionic anti-slip mat epheleleyo yenkqubo yokwenza ngokwezifiso, kubandakanywa uhlalutyo lwemfuno, uyilo lwesikimu, ubungqina obukhawulezayo kunye nenkxaso yemveliso yobuninzi. Ukuxhomekeka kwi-teknoloji yokuvelisa i-micro kunye ne-nano, i-XKH inikezela ngezisombululo ezichasene ne-slip ze-semiconductor, i-photovoltaic kunye ne-photoelectric industries, kwaye uye wanceda ngempumelelo abathengi ukuba bafezekise iziphumo ezibalulekileyo ezifana nokunciphisa izinga le-debris ukuya kwi-0.005% kunye nokunyuka kwesivuno nge-15%.

Idayagram eneenkcukacha