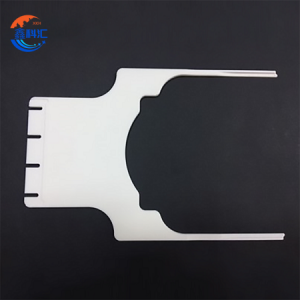

I-Alumina Ceramic End Effector / Fork Arm ye-Wafer kunye ne-Substrate Handling

Idayagram eneenkcukacha

Isishwankathelo seAlumina Ceramic End Effector

I-Alumina Ceramic End Effector, edla ngokubizwa ngokuba yi-ceramic fork arm okanye i-ceramic gripper, sisixhobo esibalulekileyo esisetyenziswa kwi-robotic automation kunye nemigca yokuvelisa igumbi lokucoca. I-Alumina Ceramic End Effector ifakwe kwingalo yerobhothi njengojongano lokugqibela kunye nemveliso, enoxanduva lokuchola, ukubamba, ukulungelelaniswa, kunye nokuhambisa iindawo ezinovakalelo kakhulu ezifana ne-silicon wafers, iipaneli zeglasi, okanye i-microelectronic components.

Yenziwe kwi-ultra-pure alumina ceramic (Al2O3), le ingalo yefolokhwe ibonelela ngesisombululo esicocekileyo nesizinzileyo seendawo apho ukungcoliseka kwesinyithi, ukuguqulwa kweplastiki, okanye ukuveliswa kwamasuntswana akunakunyamezela.

Iimpawu zezinto eziphathekayo - Kutheni i-Alumina

Malunga neAlumina Ceramic End Effector,Alumina (Al2O3) yenye yezona zisekiweyo nezithembekileyo.iiseramikhi zobunjineli eziphambili. Ibakala esilisebenzisayo (≥99.5% ubunyulu) libonelela ngendibaniselwano eyodwa yeempawu zomzimba kunye neekhemikhali ezenza ukuba ibe yimathiriyeli yokuzikhethela kwi-semiconductor kunye nezicelo zevacuum:

-

Ubunzima obugqithisileyo-Ngomlinganiselo wobulukhuni be-Mohs we-9, inika ukuqina okuhlala ixesha elide kunye nokumelana nokuqala.

-

Ukunyamezela kwe-thermal-Igcina ingqibelelo yesakhiwo ngaphaya kwe-1600 ° C, isinyithi esigqwesileyo kunye ne-polymer counterparts.

-

Ukugquma kombane-Iphelisa i-static buildup kwaye ibonelela ngokhuseleko olupheleleyo lwe-dielectric.

-

Ukunganyangeki kweekhemikhali-Akuchatshazelwa yi-acids, i-alkalis, iigesi zeplasma, kunye nezisombululo zokucoca ezinobundlobongela.

-

Umngcipheko wokungcoliseka ophantsi kakhulu-I-non-outgassing, i-low-friction surface enciphisa ukukhutshwa kwe-particle kumagumbi acocekileyo.

Ezi mpawu zivumela i-alumina ye-ceramic end effectors ukuba isebenze ngokungenasiphako kwiindawo ezibukhali, ezichanekileyo.

Izicelo ezingundoqo zeAlumina Ceramic End Effector

Ukuguquguquka kweengalo ze-alumina ceramic end effectorfork kuzenza zibaluleke kakhulu kumashishini aphezulu obuchwepheshe:

-

Iinkqubo zothutho lwe-wafer semiconductor-Ukuhambisa ngokukhuselekileyo iiwafers zesilicon ukusuka kwinkqubo ukuya kwinkqubo ngaphandle kwemikrwelo emincinci.

-

Imveliso yomboniso wephaneli ecaba-Ukuphatha ii-substrates zeglasi ezibuthathaka ze-OLED, i-LCD, okanye ukwenziwa kwe-microLED.

-

Ukuveliswa kwe-Photovoltaic (PV).-Ukuxhasa ukulayishwa kwe-wafer yelanga kunye nokukhulula phantsi komjikelo werobhothi onesantya esiphezulu.

-

Indibano yecandelo le-Optical kunye ne-elektroniki-Ukubamba iindawo ezithambileyo njengezinzwa, izichasi, kunye neechips ezincinci.

-

Vacuum kunye negumbi lokucoca oluzenzekelayo-Ukwenza imisebenzi echanekileyo kwi-ultra-clean, iimeko ezilawulwa ngamasuntswana.

Kuzo zonke iimeko, i-Alumina Ceramic End Effector ibonelela ngekhonkco elibalulekileyo phakathi kwe-robotic automation kunye nemveliso ehanjiswayo.

Uyilo kunye noKhetho loLungiso lweAlumina yeCeramic End Effector

Wonke umgca wemveliso uneemfuno ezizodwa. Ke ngoko, sibonelela ngezisombululo ezenziwe nge-Alumina Ceramic End Effector zobungakanani obahlukeneyo, iinkqubo zerobhothi, kunye neendlela zokuphatha:

Ukuhambelana kwe-wafer: Iphatha ama-wafers ukusuka ku-2 "ukuya kwi-12" kwaye inokulinganiswa kwiindawo eziqhelekileyo.

Iinketho zejometri: Ifolokhwe enye, ifolokhwe ephindwe kabini, i-slot eninzi, okanye iimilo zesiko ezineekhefu ezidibeneyo.

Ukuphatha ivacuum: Iindlela ezikhethiweyo zokufunxa i-vacuum zenkxaso ye-wafer engenaqhagamshelwano.

Ujongano lokunyuka: Imingxunya yebholiti yesiko, iiflange, okanye uyilo olusityiweyo ukulingana nayiphi na ingalo yerobhothi.

Ukugqitywa komphezulu: iindawo eziphuculweyo okanye ezigqitywe kakhulu (ezantsi ukuya kwi-Ra <0.15 μm).

Iinkangeleko zomda: Imiphetho eChamfered okanye engqukuva yokhuseleko olusicaba.

Iqela lethu lobunjineli be-Alumina Ceramic End Effector linokusebenza kwimizobo ye-CAD yabathengi okanye iinxalenye zesampulu, ukuqinisekisa ukudityaniswa komthungo kwiinkqubo ezikhoyo ezizenzekelayo.

Izibonelelo eziphambili zeAlumina zeCeramic End Effects

| Uphawu | Isizathu Sokuba Kubalulekile |

|---|---|

| Ukuchaneka komgangatho | Igcina ulungelelwaniso olugqibeleleyo nakwimijikelo enesantya esiphezulu, ephindaphindwayo. |

| Ukungangcolisi | Ukuvelisa phantse akukho masuntswana, ukuhlangabezana neemfuno ezingqongqo zokucoceka kwegumbi. |

| Ubungqina bobushushu kunye nokuhlwa | Inyamezela amanyathelo okusebenza andlongondlongo kunye nokothuka kwe-thermal. |

| Akukho ntlawulo imileyo | Ikhusela iiwafers ezibuthathaka kunye namalungu kumngcipheko we-electrostatic. |

| Ikhaphukhaphu kodwa iqinile | Inikezela ngokuqina okuphezulu ngaphandle kokubeka esichengeni umthwalo wengalo yerobhothi. |

| Ubomi benkonzo eyandisiweyo | Igqithisa iingalo zetsimbi kunye ne-polymer kubomi kunye nokuthembeka. |

Ukuthelekiswa kwezinto eziphathekayo kwe-Alumina Ceramic End Effector

| Uphawu lophawu | Ingalo yefolokhwe yeplastiki | Aluminiyam/Metal Fork Arm | IAlumina Ceramic Fork Arm |

|---|---|---|---|

| Ukuqina | Phantsi | Phakathi | Phezulu kakhulu |

| Uluhlu lweThermal | ≤ 150°C | ≤ 500°C | Ukuya kuthi ga kwi-1600°C |

| Uzinzo lweMichiza | Ubuhlwempu | Phakathi | Egqwesileyo |

| Umgangatho wokucoca | Phantsi | I-avareji | Ilungele iKlasi ye-100 okanye ngaphezulu |

| Nxiba ukuxhathisa | Ilinganiselwe | Kulungile | Ebalaseleyo |

| iNqanaba lokuLungisa | Phakathi | Ilinganiselwe | Olubanzi |

Imibuzo Ebuzwa Rhoqo (FAQ) yeAlumina Ceramic End Effector

I-Q1: Yintoni eyenza i-alumina ceramic end effector eyahlukileyo kwintsimbi?

A1:Ngokungafaniyo ne-aluminiyam okanye iingalo zentsimbi, i-alumina ceramic ayigqwali, igrumbe, okanye ingenise ii-ion zetsimbi kwiinkqubo ze-semiconductor. Ihlala izinzile phantsi kweemeko ezinzima kwaye ikhupha phantse akukho masuntswana.

I-Q2: Ngaba ezi zi-Alumina zeCeramic End Effective zinokusetyenziswa kwi-vacuum ephezulu kunye namagumbi e-plasma?

A2:Ewe. I-alumina ceramic yiyoukungakhupheli ngaphandlekwaye iyamelana neplasma, eyenza ibe yinto ekhethwayo yokusetyenzwa kwe-vacuum kunye nezixhobo zokutsala.

I-Q3: Zenziwa njani ngokwezifiso ezi ngalo zefolokhwe ze-Alumina Ceramic End Effector?

A3:Yonke iyunithi ingabayenziwe ngokwezifiso ngokupheleleyo-kubandakanya imilo, iindawo zokubeka, imingxunya yokufunxa, isitayile sokunyuka, kunye nokuphela komphetho-ukuhambelana neemfuno zenkqubo yakho yerobhothi.

I-Q4: Ngaba zibuthathaka?

A4:Ngelixa i-ceramic inobunkunkqele bendalo, injineli yethu yoyilo isasaza umthwalo ngokulinganayo kwaye inciphisa iindawo zoxinzelelo. Xa iphathwa ngokuchanekileyo, ubomi benkonzo buhlala budlula isinyithi okanye ezinye iindlela zepolymer.

Ngathi

I-XKH igxile kuphuhliso lobuchwepheshe obuphezulu, imveliso, kunye nokuthengiswa kweglasi ekhethekileyo yeglasi kunye nezinto ezintsha zekristale. Iimveliso zethu zisebenza ngombane obonakalayo, i-elektroniki yabathengi, kunye nomkhosi. Sinikezela ngezixhobo zeSapphire optical, iilensi zeselfowuni eziphathwayo, iiCeramics, LT, Silicon Carbide SIC, Quartz, kunye nesemiconductor crystal wafers. Ngobuchule bezakhono kunye nezixhobo ezibukhali, sigqwesa ekusetyenzweni kwemveliso engeyiyo eyomgangatho, sijonge ukuba lishishini eliphambili le-optoelectronic tech-tech.