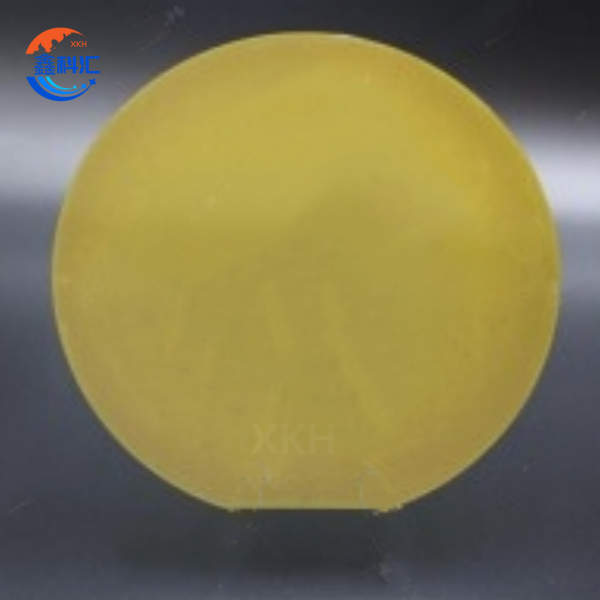

I-6 intshi eqhuba ikristale enye yeSiC kwi-polycrystalline SiC composite substrate Ububanzi be-150mm P uhlobo lwe-N

Imilinganiselo yobugcisa

| Ubungakanani: | 6 intshi |

| Ububanzi: | 150 mm |

| Ukutyeba: | 400-500 μm |

| IiParameters zefilimu ye-Monocrystalline SiC | |

| I-Polytype: | I-4H-SiC okanye i-6H-SiC |

| Ukugxila kwiDoping: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Ukutyeba: | 5-20 μm |

| Ukuchasa iPhepha: | 10-1000 Ω/sq |

| Ukuhamba kwe-Elektroni: | 800-1200 cm²/Vs |

| Ukushukuma komngxuma: | 100-300 cm²/Vs |

| I-Polycrystalline SiC Buffer Layer Parameters | |

| Ukutyeba: | 50-300 μm |

| I-Thermal Conductivity: | 150-300 W/m·K |

| Iiparamitha zeMonocrystalline SiC Substrate | |

| I-Polytype: | I-4H-SiC okanye i-6H-SiC |

| Ukugxila kwiDoping: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Ukutyeba: | 300-500 μm |

| Ubungakanani benkozo: | > 1 mm |

| Uburhabaxa boMphezulu: | < 0.3 mm RMS |

| IiPropati zoomatshini kunye nezoMbane | |

| Ukuqina: | 9-10 Mohs |

| Amandla acinezelayo: | 3-4 GPA |

| Tensile strength: | 0.3-0.5 GPA |

| Ukomelela kweNdawo yoKwahlulwa: | > 2 MV/cm |

| Ukunyamezelwa kwethamo iyonke: | > 10 uMnu |

| Ukunyangwa kweMpembelelo yesiganeko esinye: | > 100 MeV·cm²/mg |

| I-Thermal Conductivity: | 150-380 W/m·K |

| Uluhlu lobushushu obusebenzayo: | -55 ukuya kuma-600°C |

Iimpawu eziphambili

I-6-inch conductive monocrystalline SiC kwi-polycrystalline SiC composite substrate inika ibhalansi ekhethekileyo yesakhiwo sezinto eziphathekayo kunye nokusebenza, okwenza ukuba ilungele iimeko ezibango zoshishino:

I-1.Indleko-Esebenzayo: Isiseko se-polycrystalline SiC sinciphisa kakhulu iindleko xa kuthelekiswa ne-SiC epheleleyo ye-monocrystalline, ngelixa i-monocrystalline SiC layer esebenzayo iqinisekisa ukusebenza kwe-device-grade, ilungele ukusetyenziswa kweendleko.

2.IiPropati zoMbane eziKhethekileyo: Umaleko we-SiC we-monocrystalline ubonisa ukuhamba kwe-carrier ephezulu (>500 cm²/V·s) kunye noxinano oluphantsi, oluxhasa i-frequency ephezulu kunye nokusebenza kwesixhobo samandla aphezulu.

I-3.I-High-Temperature Stability: I-SiC yendalo yokumelana nobushushu obuphezulu (> 600 ° C) iqinisekisa ukuba i-substrate edibeneyo ihlala izinzile phantsi kweemeko ezinzima, okwenza ukuba zilungele izithuthi zombane kunye nezicelo zeemoto zoshishino.

I-4.6-intshi yoMgangatho we-Wafer Ubungakanani: Xa kuthelekiswa ne-4-intshi ye-SiC substrates yendabuko, ifomathi ye-intshi ye-6 inyusa isivuno se-chip ngaphezu kwe-30%, ukunciphisa iindleko zesixhobo seyunithi nganye.

I-5.Uyilo oluKhombisayo: I-N-type yangaphambili okanye i-P-type layers inciphisa amanyathelo okufakelwa kwe-ion kwimveliso yesixhobo, ukuphucula ukusebenza kakuhle kwemveliso kunye nesivuno.

I-6.Ulawulo oluPhezulu lwe-Thermal: Isiseko se-polycrystalline SiC ye-thermal conductivity (~ 120 W / m·K) isondela kwi-monocrystalline SiC, ijongene ngokuphumelelayo nemingeni yokutshatyalaliswa kobushushu kwizixhobo eziphezulu zamandla.

Ezi mpawu zibeka i-6-inch conductive monocrystalline SiC kwi-polycrystalline SiC composite substrate njengesisombululo sokukhuphisana kumashishini afana namandla ahlaziyekayo, ukuthutha ngololiwe, kunye ne-aerospace.

Izicelo eziphambili

I-6-inch conductive monocrystalline SiC kwi-polycrystalline SiC composite substrate ifakwe ngempumelelo kwiinkalo ezininzi ezifunwa kakhulu:

I-1.Electric Vehicle Powertrains: Isetyenziswa kwi-high-voltage ye-SiC MOSFETs kunye neediode zokuphucula ukusebenza kakuhle kwe-inverter kunye nokwandisa uluhlu lwebhetri (umz., i-Tesla, imizekelo ye-BYD).

I-2.Ii-Industrial Motor Drives: Ivumela imodyuli yamandla aphezulu, i-high-switching-frequency power, ukunciphisa ukusetyenziswa kwamandla kumatshini onzima kunye nee-injini zomoya.

I-3.I-Photovoltaic Inverters: Izixhobo ze-SiC ziphucula ukusebenza kakuhle kokuguqulwa kwelanga (> 99%), ngelixa i-substrate edibeneyo inciphisa ngakumbi iindleko zenkqubo.

I-4.Izothutho zikaLoliwe: Isetyenziswe kwiziguquli ze-traction kwi-high-speed-speed rail kunye ne-subway systems, enikezela ukuxhathisa i-high-voltage (> 1700V) kunye ne-compact form factor.

I-5.I-Aerospace: Ilungele iinkqubo zamandla zesathelayithi kunye neesekethe zokulawula injini yenqwelomoya, ekwaziyo ukumelana nobushushu obugqithisileyo kunye nemitha.

Kwimveliso ebonakalayo, i-6-inch conductive monocrystalline SiC kwi-polycrystalline SiC composite substrate ihambelana ngokupheleleyo neenkqubo eziqhelekileyo zesixhobo se-SiC (umzekelo, i-lithography, i-etching), engadingi utyalo-mali olongezelelweyo.

Iinkonzo ze-XKH

I-XKH ibonelela ngenkxaso ebanzi ye-6-intshi ye-monocrystalline SiC eqhubayo kwi-polycrystalline SiC ehlanganisiweyo substrate, egubungela i-R&D kwimveliso yobuninzi:

1.Ukwenziwa ngokwezifiso: Ubukhulu be-monocrystalline umaleko ohlengahlengiswayo (5–100 μm), ugxininiso lwe-doping (1e15–1e19 cm⁻³), kunye nokuqhelaniswa nekristale (4H/6H-SiC) ukuhlangabezana neemfuno ezahlukeneyo zesixhobo.

I-2.I-Wafer Processing: Ukunikezelwa ngobuninzi bee-substrates ze-6-intshi kunye ne-backside thinning kunye neenkonzo ze-metallization zokudibanisa i-plug-and-play.

I-3.Ukuqinisekiswa koBuchule: Kubandakanya uhlalutyo lwe-XRD crystallinity, uvavanyo lwempembelelo yeHolo, kunye nokulinganisa ukuchasana kwe-thermal ukukhawulezisa isiqinisekiso sezinto eziphathekayo.

4.I-Rapid Prototyping: Iisampuli ze-2 ukuya kwi-4-intshi (inkqubo efanayo) kumaziko ophando ukukhawulezisa imijikelo yophuhliso.

I-5.Uhlalutyo lokungaphumeleli kunye noPhuculo: Izisombululo zenqanaba lezinto eziphathekayo zokujongana nemingeni (umzekelo, i-epitaxial layer defects).

Injongo yethu kukuseka i-6-inch conductive monocrystalline SiC kwi-polycrystalline SiC composite substrate njengesisombululo esikhethiweyo seendleko ze-electronics ze-SiC, enikezela ngenkxaso yokuphela-ukuphela ukusuka kwiprototyping ukuya kwimveliso yevolumu.

Ukuqukumbela

I-6-inch conductive monocrystalline SiC kwi-polycrystalline SiC composite substrate ifezekisa ibhalansi yokuphumelela phakathi kokusebenza kunye neendleko ngokusebenzisa i-mono / polycrystalline hybrid structure yayo. Njengoko izithuthi zombane zisanda kunye ne-Industry 4.0 inkqubela phambili, le substrate ibonelela ngesiseko esithembekileyo sezinto zombane zesizukulwana esilandelayo. I-XKH yamkele intsebenziswano ukuphonononga ngakumbi amandla obuchwepheshe be-SiC.