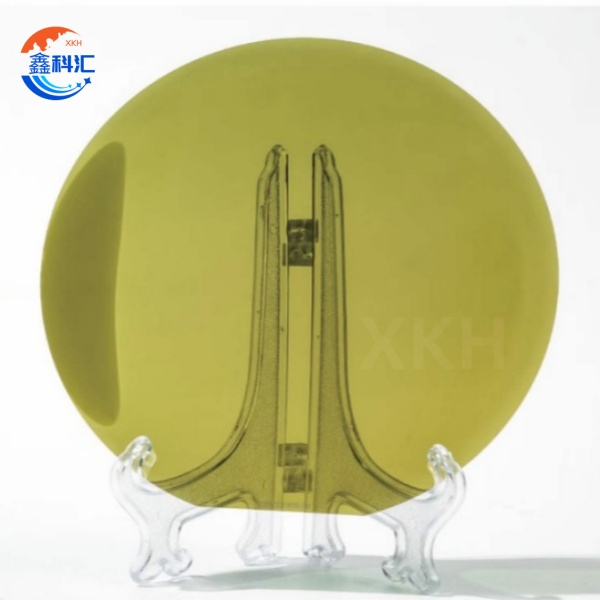

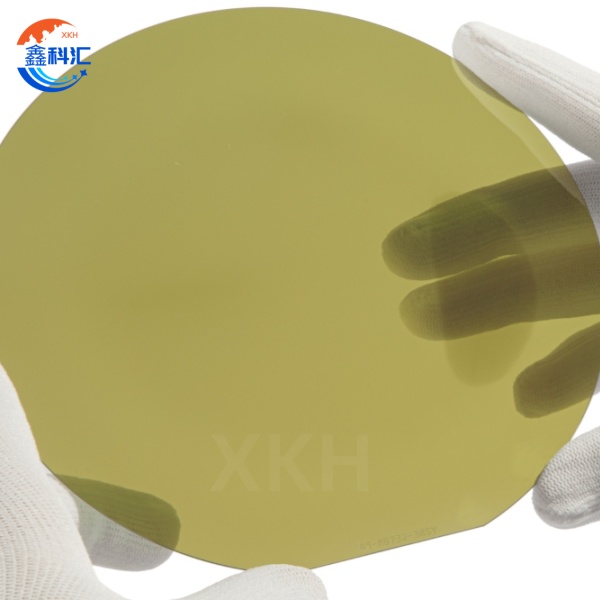

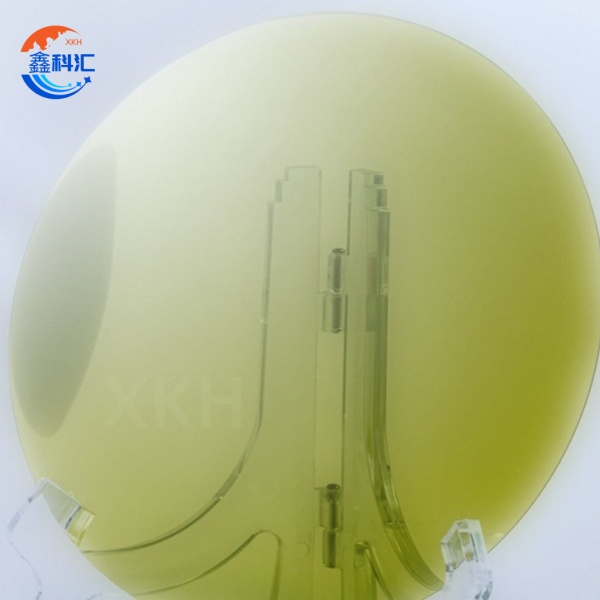

I-6 ye-intshi e-Conductive ye-SiC eDityanisiweyo Substrate 4H Ububanzi 150mm Ra≤0.2nm Warp≤35μm

Imilinganiselo yobugcisa

| Izinto | Imvelisoibakala | Dummyibakala |

| Ububanzi | 6-8 intshi | 6-8 intshi |

| Ukutyeba | 350/500±25.0 μm | 350/500±25.0 μm |

| Iipolytype | 4H | 4H |

| Ukuxhathisa | 0.015-0.025 ohm · cm | 0.015-0.025 ohm · cm |

| TTV | ≤5 μm | ≤20 μm |

| I-Wap | ≤35 μm | ≤55 μm |

| Ngaphambili (Si-face) uburhabaxa | Ra≤0.2 nm (5μm×5μm) | Ra≤0.2 nm (5μm×5μm) |

Ezona mpawu

I-1.Ixabiso leNdleko: I-6-intshi yethu ye-SiC edibeneyo ye-substrate edibeneyo isebenzisa iteknoloji "ye-graded buffer layer" eyenza ukwakheka kwezinto ezibonakalayo ukunciphisa iindleko ze-rawterial nge-38% ngelixa igcina ukusebenza kombane okugqwesileyo. Imilinganiselo eyiyo ibonisa ukuba izixhobo ze-650V ze-MOSFET ezisebenzisa le substrate zifikelela ekuthotyweni kwe-42% kwixabiso leyunithi kwindawo nganye xa kuthelekiswa nezisombululo eziqhelekileyo, ezibaluleke kakhulu ekukhuthazeni ukusetyenziswa kwesixhobo se-SiC kwi-electronics yabathengi.

I-2.IiPropati eziGqwesileyo zokuqhuba: Ngeenkqubo ezichanekileyo zokulawula i-nitrogen doping, i-substrate yethu ye-SiC edibeneyo ye-6-inch conductive ifezekisa i-resistiveivity ye-ultra-low ye-0.012-0.022Ω · cm, kunye nokuhluka okulawulwa ngaphakathi kwe-± 5%. Ngokucacileyo, sigcina ukufana kokumelana nangaphakathi kwe-5mm edge yengingqi ye-wafer, sisombulula ingxaki yesiphumo esidala kwishishini.

I-3.I-Thermal Performance: Imodyuli ye-1200V / 50A ephuhliswe ngokusebenzisa i-substrate yethu ibonisa kuphela i-45 ℃ i-junction ye-junction yeqondo lokushisa ngaphezu kwe-ambient ekusebenzeni komthwalo ogcweleyo - i-65 ℃ ngaphantsi kwe-silicon-based based devices. Oku kwenziwa sisixhobo sethu esihlanganisiweyo se-"3D thermal channel" esiphucula i-lateral thermal conductivity ukuya kwi-380W/m·K kunye nokuma kwe-thermal conductivity ukuya kwi-290W/m·K.

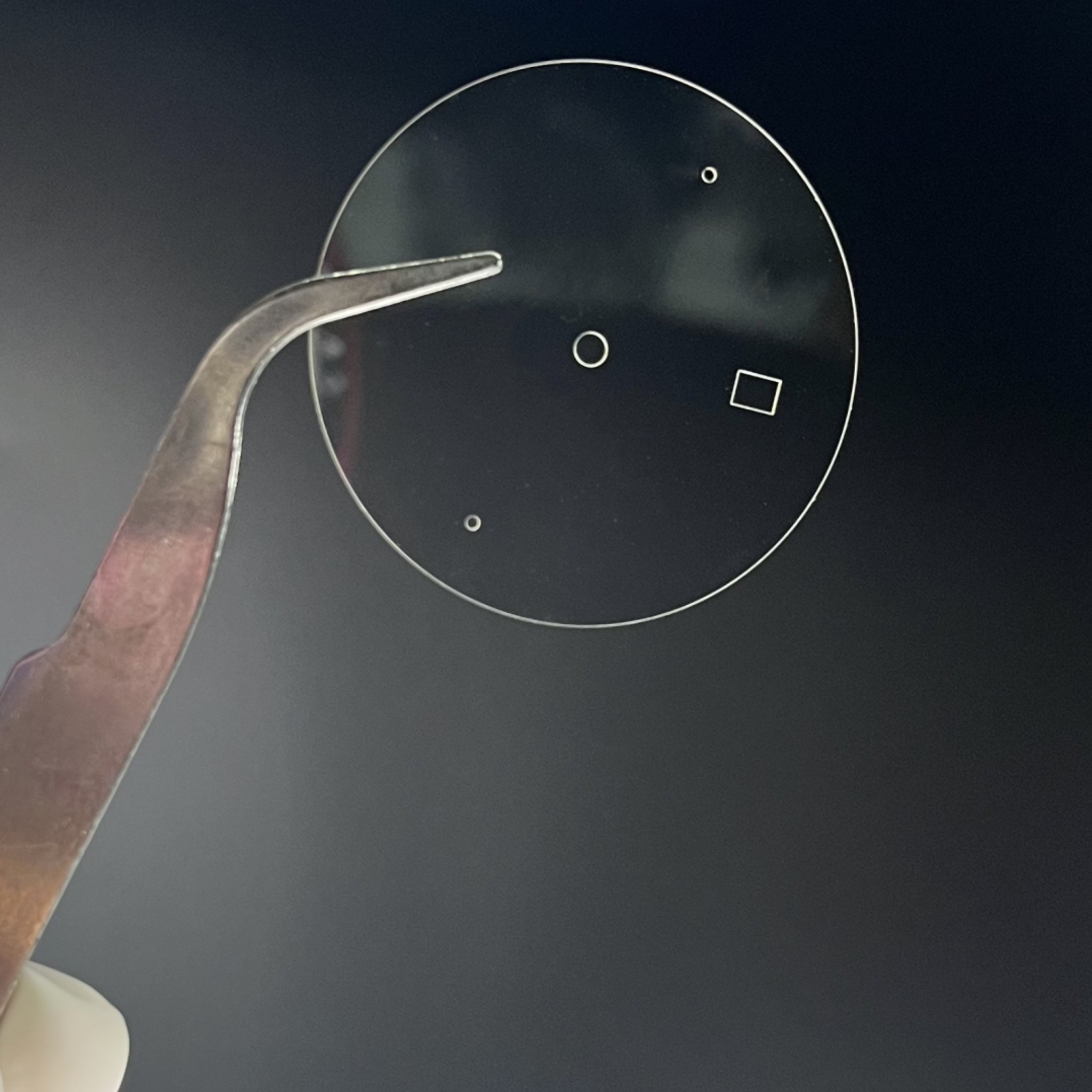

I-4.Ukuhambelana kweNkqubo: Kwisakhiwo esiyingqayizivele se-6-intshi ye-SiC edibeneyo edibeneyo ye-conductive substrates, siphuhlise inkqubo ye-laser dicing ehambelanayo yokuphumelela i-200mm / s yokusika isantya ngelixa ilawula i-edge chipping ngaphantsi kwe-0.3μm. Ukongeza, sinikezela ngeenketho ze-substrate zangaphambili ze-nickel-plated ezenza ukuba i-die bonding ethe ngqo, igcine abathengi amanyathelo amabini enkqubo.

Izicelo eziphambili

IsiXhobo esiBalulekileyo seGridi eSmart:

Kwi-ultra-high voltage direct current (UHVDC) iinkqubo zothumelo ezisebenza kwi-±800kV, izixhobo ze-IGCT ezisebenzisa i-6-intshi ye-SiC eyi-conductive substrates eyi-composite substrates ibonisa uphuculo olumangalisayo lokusebenza. Ezi zixhobo zifezekisa i-55% yokunciphisa ilahleko yokutshintsha ngexesha leenkqubo zokutshintsha, ngelixa ukwandisa ukusebenza kakuhle kwenkqubo ukudlula i-99.2%. I-substrates 'i-thermal conductivity ephezulu (380W/m·K) yenza uyilo lwe-converter ehlangeneyo enciphisa indawo yesikhululo esisezantsi nge-25% xa kuthelekiswa nezisombululo eziqhelekileyo ezisekelwe kwi-silicon.

Izithuthuthu zaMandla eZithuthi zaMandla amatsha:

Inkqubo yokuqhuba equka i-6-inch conductive SiC composite substrates ifezekisa uxinano lwamandla oguqulo olungazange lubonwe ngaphambili angama-45kW/L - uphuculo lwama-60% kuyilo lwangaphambili olusekwe kwi-silicon ye-400V. Eyona nto ichukumisayo, inkqubo igcina ukusebenza kakuhle kwe-98% kulo lonke ubushushu bokusebenza ukusuka kwi--40 ℃ ukuya ku- +175 ℃, ukusombulula imingeni yokusebenza kwemozulu ebandayo eye yaphazamisa ukwamkelwa kwe-EV kwimozulu esemantla. Uvavanyo lwehlabathi lwangempela lubonisa ukunyuka kwe-7.5% kwinqanaba lasebusika kwiimoto ezixhotywe ngobu buchwepheshe.

Iidrive zeMveliso eziguquguqukayo zoShishino:

Ukwamkelwa kwee-substrates zethu kwiimodyuli zamandla akrelekrele (ii-IPMs) kwiinkqubo ze-servo zamashishini kuguqula i-automation yokuvelisa. Kumaziko omatshini e-CNC, ezi modyuli zihambisa i-40% ngokukhawuleza kwempendulo yemoto (ukunciphisa ixesha lokukhawuleza ukusuka kwi-50ms ukuya kwi-30ms) ngelixa ukusika ingxolo ye-electromagnetic nge-15dB ukuya kwi-65dB (A).

Ii-Electronics zabathengi:

Uguqulo lwee-elektroniki lwabathengi luyaqhubeka kunye nee substrates zethu ezivumela isizukulwana esilandelayo 65W itshaja ekhawulezayo yeGaN. Ezi ziadaptha zamandla ezidityanisiweyo zifezekisa i-30% yokunciphisa umthamo (ukuhla ukuya kwi-45cm³) ngelixa zigcina umbane opheleleyo, ngenxa yeempawu eziphezulu zokutshintsha kwe-SiC-based designs. I-Thermal imaging ibonisa amaqondo obushushu aphezulu angama-68 ° C ngexesha lokusebenza rhoqo - 22 ° C epholile kunoyilo oluqhelekileyo - iphucula kakhulu ubomi bemveliso kunye nokhuseleko.

Iinkonzo zoLungiso lwe-XKH

I-XKH ibonelela ngenkxaso ebanzi yokwenza ngokwezifiso kwi-6-intshi ye-SiC edibeneyo ehlanganisiweyo substrates:

Ukutyeba Customization: Iinketho kuquka 200μm, 300μm, kunye 350μm iinkcukacha

2. Ulawulo lokuxhathisa: Uxinzelelo lwe-n-uhlobo lwe-doping olulungisekayo ukusuka ku-1×10¹⁸ ukuya ku-5×10¹⁸ cm⁻³

3. I-Crystal Orientation: Inkxaso yeendlela ezininzi ezibandakanya (0001) off-axis 4 ° okanye 8 °

4. Iinkonzo zoVavanyo: Gqibezela iingxelo zovavanyo lweparamitha ye-wafer-level

Ixesha lethu lokukhokela langoku ukusuka kwiprototyping ukuya kwimveliso yobuninzi linokuba lifutshane njengeeveki ezisi-8. Kubathengi abanobuchule, sinikezela ngeenkonzo zophuhliso lwenkqubo ezinikeleyo ukuqinisekisa ukuhambelana okugqibeleleyo neemfuno zesixhobo.