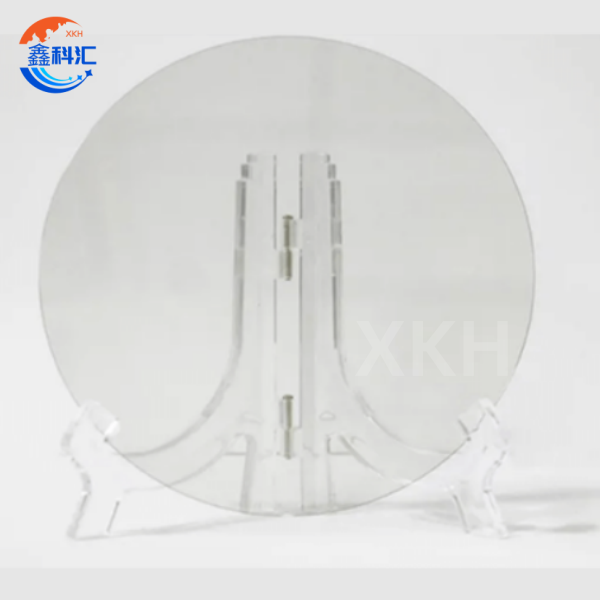

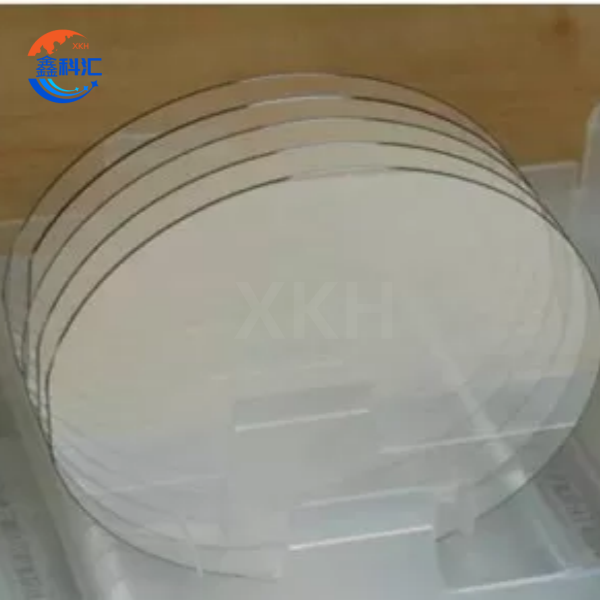

I-6 Intshi ye-4H SEMI Uhlobo lwe-SiC edibeneyo ye-substrate Ukutyeba 500μm TTV≤5μm ibakala le-MOS

Imilinganiselo yobugcisa

| Izinto | Inkcazo | Izinto | Inkcazo |

| Ububanzi | 150±0.2 mm | Ngaphambili (Si-face) uburhabaxa | Ra≤0.2 nm (5μm×5μm) |

| Iipolytype | 4H | I-Edge Chip, Scratch, Crack (uhlolo olubonwayo) | Akukho nanye |

| Ukuxhathisa | ≥1E8 Ω·cm | TTV | ≤5 μm |

| Ukugqithisela umaleko Ukutyeba | ≥0.4 μm | I-Wap | ≤35 μm |

| Ilize (2mm>D>0.5mm) | ≤5 i-ea/Wafer | Ukutyeba | 500±25 μm |

Ezona mpawu

1. Ukusebenza okubalaseleyo okuPhakamileyo

I-6-inch semi-insulating ye-SiC composite substrate isebenzisa idizayini ye-dielectric ehleliweyo, iqinisekisa ukuhluka kwe-dielectric rhoqo <2% kwi-Ka-band (26.5-40 GHz) kunye nokuphucula ukuhambelana kwesigaba ngama-40%. I-15% yokwandisa ukusebenza kakuhle kunye ne-20% yokusetyenziswa kwamandla aphantsi kwiimodyuli ze-T / R usebenzisa le substrate.

2. UkuPhumelela koLawulo lweThermal

Isakhiwo esidityanisiweyo "sebhulorho ye-thermal" sivumela ukuhanjiswa kwe-thermal esecaleni kwe-400 W/m·K. Kwi-28 GHz 5G isiseko se-PA modules, ukushisa kwe-junction kuphakama kuphela nge-28 ° C emva kweeyure ze-24 zokusebenza okuqhubekayo-50 ° C ngaphantsi kunezisombululo eziqhelekileyo.

3. Umgangatho weWafer oPhezulu

Ngokusebenzisa indlela yoThutho loMphunga woMzimba (PVT), sifezekisa uxinano lwe-dislocation <500/cm² kunye noKwahluka koButyenene buBonke (TTV) <3 μm.

4. UkuLungiswa koMveliso-oLuhlobo

Inkqubo yethu ye-laser annealing ephuhliswe ngokukodwa i-6-intshi ye-semi-insulating ye-SiC ehlanganisiweyo substrate inciphisa ukuxinwa kobume bomgangatho ngemiyalelo emibini yobukhulu phambi kwe-epitaxy.

Izicelo eziphambili

1. ISikhululo seSikhululo se-5G Amacandelo angundoqo

Kwii-antenna ezinkulu ze-MIMO, izixhobo ze-GaN HEMT kwi-6-inch semi-insulating SiC composite substrates zifikelela kwi-200W yokukhupha amandla kunye> 65% ukusebenza kakuhle. Iimvavanyo zentsimi kwi-3.5 GHz zibonise ukunyuka kwe-30% kwi-radius yokhuseleko.

2. IiNkqubo zoNxibelelwano ngeSatellite

I-Low-Earth orbit (LEO) i-satellite transceivers esebenzisa le substrate ibonisa i-8 dB ephezulu ye-EIRP kwi-Q-band (40 GHz) ngelixa inciphisa ubunzima nge-40%. Iitheminali ze-SpaceX Starlink ziyamkele ukuveliswa ngobuninzi.

3. IiNkqubo zeRadar zoMkhosi

Iimodyuli ze-radar ye-radar yezigaba ze-T / R kule substrate ifikelela kwi-6-18 GHz i-bandwidth kunye nenani lengxolo eliphantsi njenge-1.2 dB, ukwandisa uluhlu lokufumanisa nge-50 km kwiinkqubo ze-radar zokulumkisa kwangaphambili.

4. I-Automotive Millimeter-Wave Radar

I-79 GHz iitshiphusi ze-radar zeemoto ezisebenzisa le substrate ziphucula isisombululo se-angular ukuya kwi-0.5 °, ukuhlangabezana neemfuno zokuqhuba ezizimeleyo ze-L4.

Sinikezela ngesisombululo senkonzo esibanzi se-6-intshi ye-semi-insulating ye-SiC ehlanganisiweyo. Ngokuphathelele ukwenza izinto ngokweziko iiparamitha, sixhasa ulawulo oluchanekileyo lokumelana phakathi koluhlu lwe-10⁶-10¹⁰ Ω·cm. Ngokukodwa kwizicelo zomkhosi, sinokunikezela ngokhetho lokuxhathisa okuphezulu kwe>10⁹ Ω·cm. Inika iinkcukacha ezintathu zobukhulu be-200μm, 350μm kunye ne-500μm ngaxeshanye, kunye nokunyamezela okulawulwa ngokungqongqo ngaphakathi kwe-± 10μm, ukuhlangabezana neemfuno ezahlukeneyo ukusuka kwizixhobo eziphezulu zokujikeleza ukuya kwizicelo zamandla aphezulu.

Ngokumalunga neenkqubo zokunyanga komhlaba, sinika izisombululo ezimbini zeengcali: I-Chemical Mechanical Polishing (CMP) inokufezekisa i-atomic-level surface flatness kunye ne-Ra<0.15nm, ukuhlangabezana nezona mfuno zokukhula kwe-epitaxial; I-epitaxial ilungele itekhnoloji yonyango lomphezulu olungele iimfuno zemveliso ekhawulezileyo inokubonelela ngemiphezulu egudileyo kunye ne-Sq<0.3nm kunye nobukhulu obushiyekileyo be-oxide <1nm, ngokulula ukwenza lula inkqubo yonyango lwangaphambili ekupheleni komxhasi.

I-XKH ibonelela ngezisombululo ezibanzi ezilungiselelweyo ze-6-intshi ye-semi-insulating ye-SiC composite substrates

1. ULungiso lweParameter yeMathiriyeli

Sinikezela ngolungelelwaniso oluchanekileyo lokumelana phakathi koluhlu lwe-10⁶-10¹⁰ Ω·cm, kunye neendlela ezikhethekileyo zokumelana ne-ultra-high> 10⁹ Ω·cm ekhoyo kwizicelo zomkhosi/ze-aerospace.

2. Ukutyeba Iinkcukacha

Iinketho ezintathu zobukhulu obusemgangathweni:

· 200μm (ilungiselelwe izixhobo ezisebenza ngamaza aphezulu)

· 350μm (ubalulo olusemgangathweni)

· 500μm (yenzelwe usetyenziso lwamandla aphezulu)

· Zonke iindidi zigcina ukunyamezelwa kobunzima obuyi-±10μm.

3. IiTekhnoloji zoNyango oluphezulu

I-Chemical Mechanical Polishing (CMP): Iphumeza ukutyeba komphezulu kwinqanaba le-atomic nge-Ra<0.15nm, ukuhlangabezana neemfuno ezingqongqo zokukhula kwe-epitaxial ye-RF kunye nezixhobo zombane.

4. I-Epi-Ready Surface Processing

· Ihambisa imiphezulu egudileyo ngokweSq<0.3nm uburhabaxa

· Ilawula ubukhulu beoksidi yendalo ukuya <1nm

· Ukuphelisa ukuya kutsho kumanyathelo ama-3 okwenziwa kwangaphambili kuncedo lwabathengi