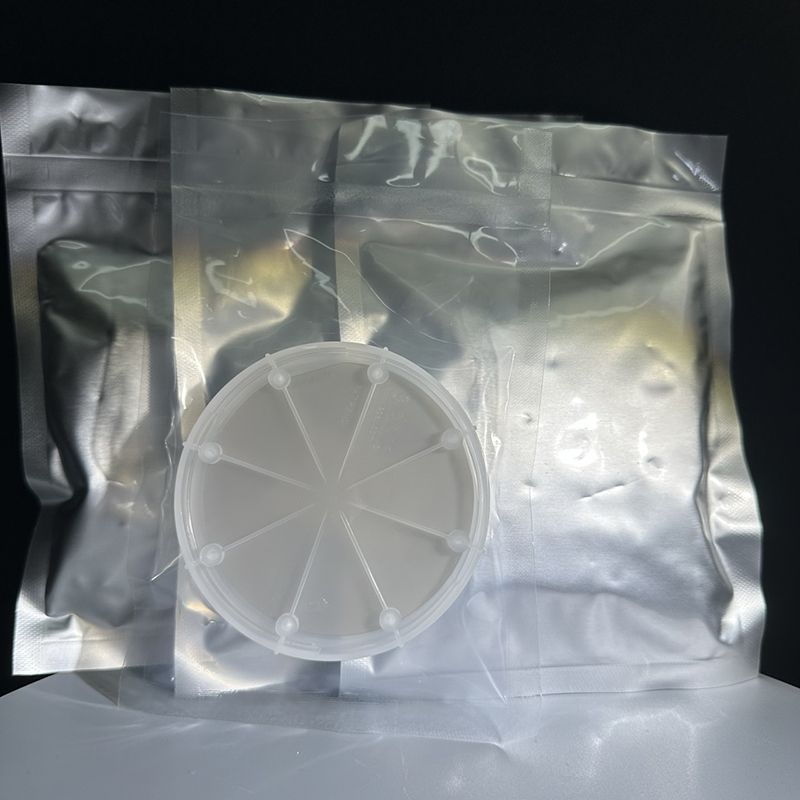

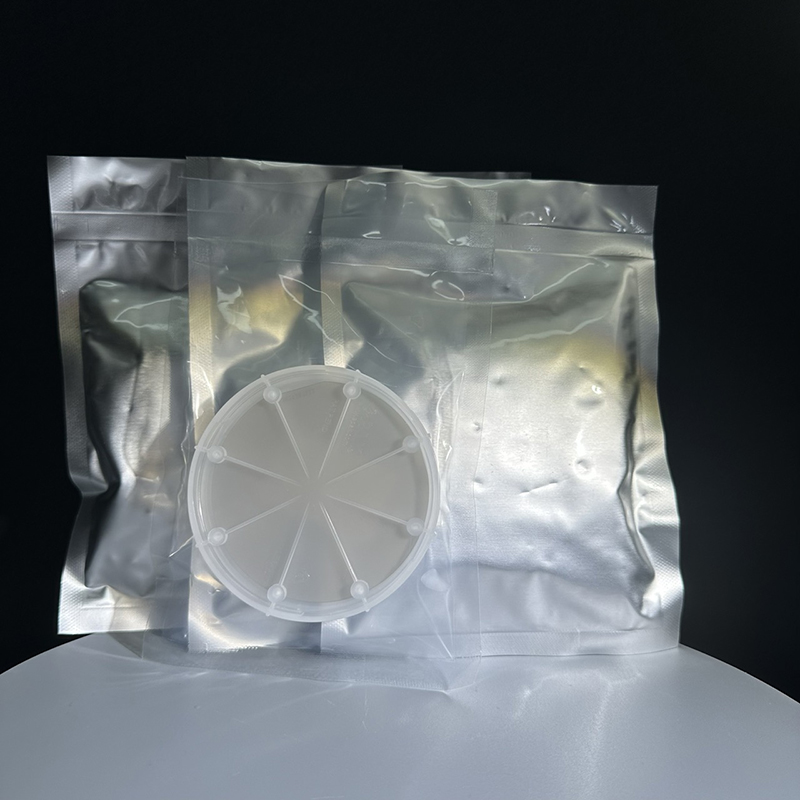

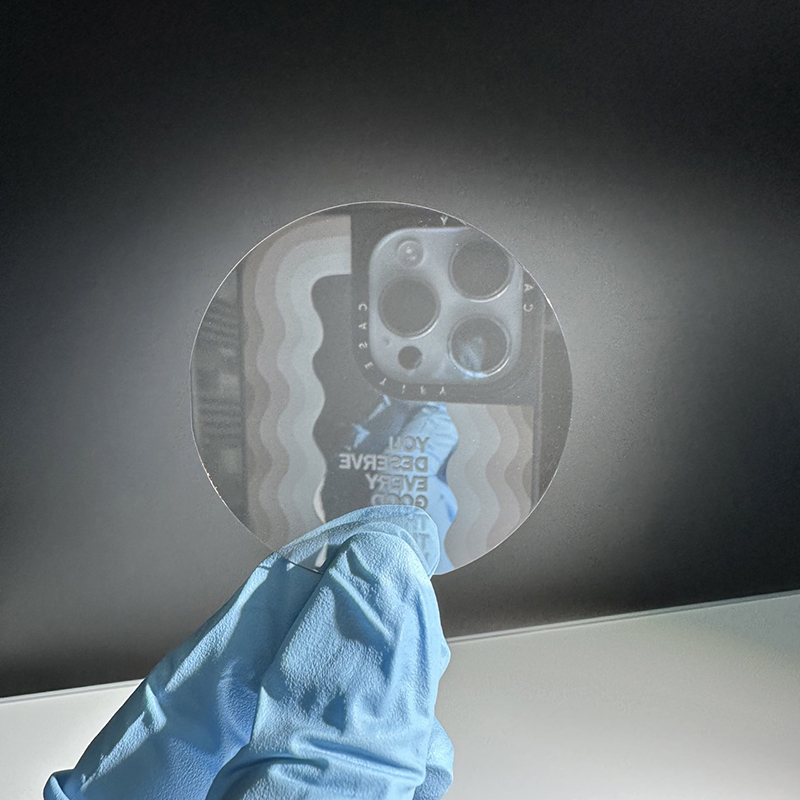

4intshi Semi-ezithukisayo SiC wafers HPSI SiC substrate Prime Production ibakala

Ukucaciswa kweMveliso

I-Silicon carbide (i-SiC) yimpahla ye-semiconductor edibeneyo eyenziwe ngamacandelo ekhabhoni kunye ne-silicon, kwaye yenye yezinto ezifanelekileyo zokwenza izixhobo eziphakamileyo zokushisa, i-high-frequency, amandla aphezulu kunye ne-voltage ephezulu. Xa kuthelekiswa nezinto eziqhelekileyo ze-silicon (Si), ububanzi obunqatshelwe ububanzi be-silicon carbide buphindwe kathathu kune-silicon; i-thermal conductivity yi-4-5 amaxesha e-silicon; i-voltage breakdown yi-8-10 amaxesha e-silicon; kunye ne-electron saturation drift rate yi-2-3 yamaxesha e-silicon, ehlangabezana neemfuno zoshishino lwangoku lwamandla aphezulu, i-high-voltage, kunye ne-high-frequency, kwaye isetyenziselwa ikakhulu ukwenza i-speed-speed, high-frequency, high-power and light-emiting electronic components, kunye neendawo zayo zokusebenza ezisezantsi ziquka i-smart grid, i-photovolta yemoto yonxibelelwano kwintsimi yomoya. yezixhobo zamandla, ii-silicon carbide diode kunye ne-MOSFETs ziqalisile ukusetyenziswa ngokurhweba.

Izinto ezilungileyo zeSiC wafers / SiC substrate

Ukumelana nobushushu obuphezulu. Ububanzi bebhendi eyalelweyo yesilicon carbide yi-2-3 yamaxesha e-silicon, ngoko ke ii-elektroni zinqabile ukuba zitsibe kumaqondo obushushu aphezulu kwaye zikwazi ukumelana nobushushu obuphezulu bokusebenza, kunye ne-thermal conductivity ye-silicon carbide yi-4-5 yamaxesha e-silicon, okwenza kube lula ukukhupha ubushushu kwisixhobo kunye nokuvumela ubushushu obuphezulu bokunciphisa ukusebenza. Iimpawu eziphezulu zokushisa zinokunyusa kakhulu ubuninzi bamandla, ngelixa zinciphisa iimfuno zenkqubo yokutshatyalaliswa kobushushu, okwenza i-terminal ibe yinto elula kwaye incinci.

Ukumelana nombane ophezulu. Amandla entsimi yeSilicon carbide yi-10 ephindwe ka-10 kune-silicon, eyenza ukuba imelane nombane ophezulu, okwenza ukuba ifaneleke ngakumbi izixhobo zombane ophezulu.

Ukuxhathisa okuphezulu-frequency. I-Silicon carbide inezinga eliphindwe kabini le-electron drift ye-silicon, ebangela ukuba izixhobo zayo kwinkqubo yokuvala ingabikho kwimeko yangoku yokudonsa, inokuphucula ngokufanelekileyo i-frequency switching frequency, ukufezekisa ukuchithwa kwesixhobo.

Ukulahleka kwamandla aphantsi. I-silicon carbide ine-low-resistance ephantsi kakhulu xa kuthelekiswa nezinto ze-silicon, ilahleko ephantsi yokuqhuba; ngelo xesha, i-bandwidth ephezulu ye-silicon carbide inciphisa kakhulu ukuvuza kwangoku, ukulahlekelwa kwamandla; Ukongeza, izixhobo ze-silicon carbide kwinkqubo yokuvala azikho kwimeko yangoku yokutsala, ilahleko ephantsi yokutshintsha.

Idayagram eneenkcukacha