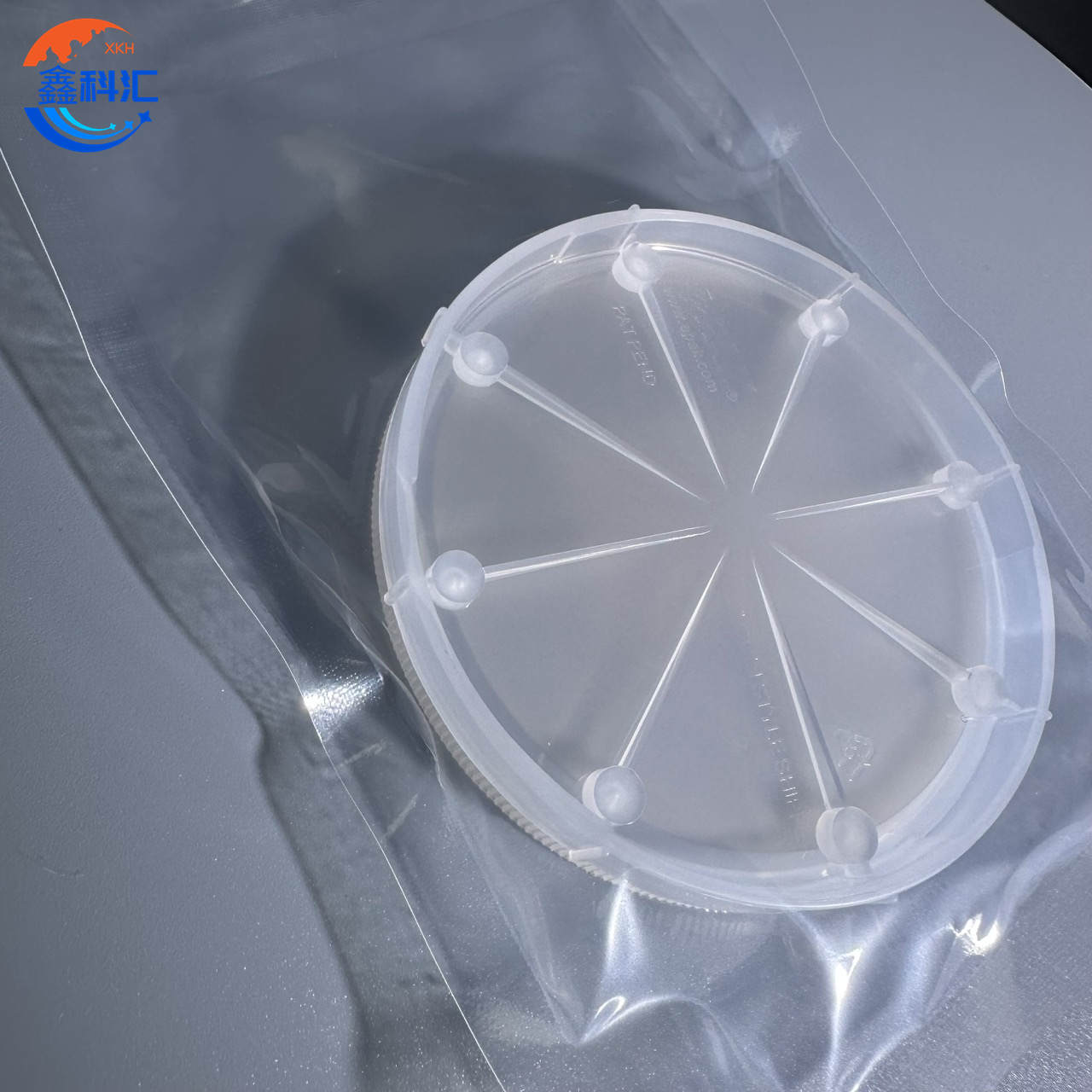

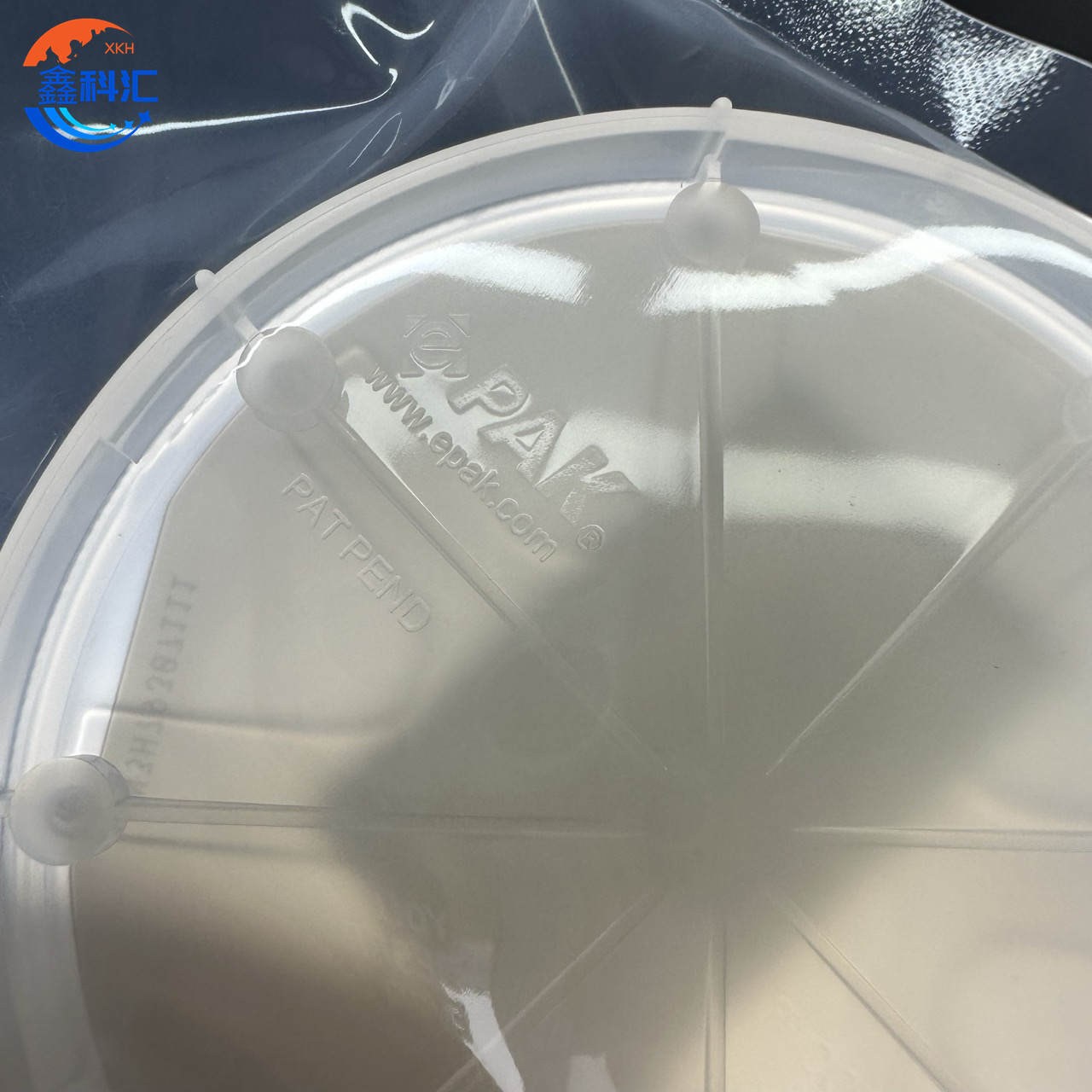

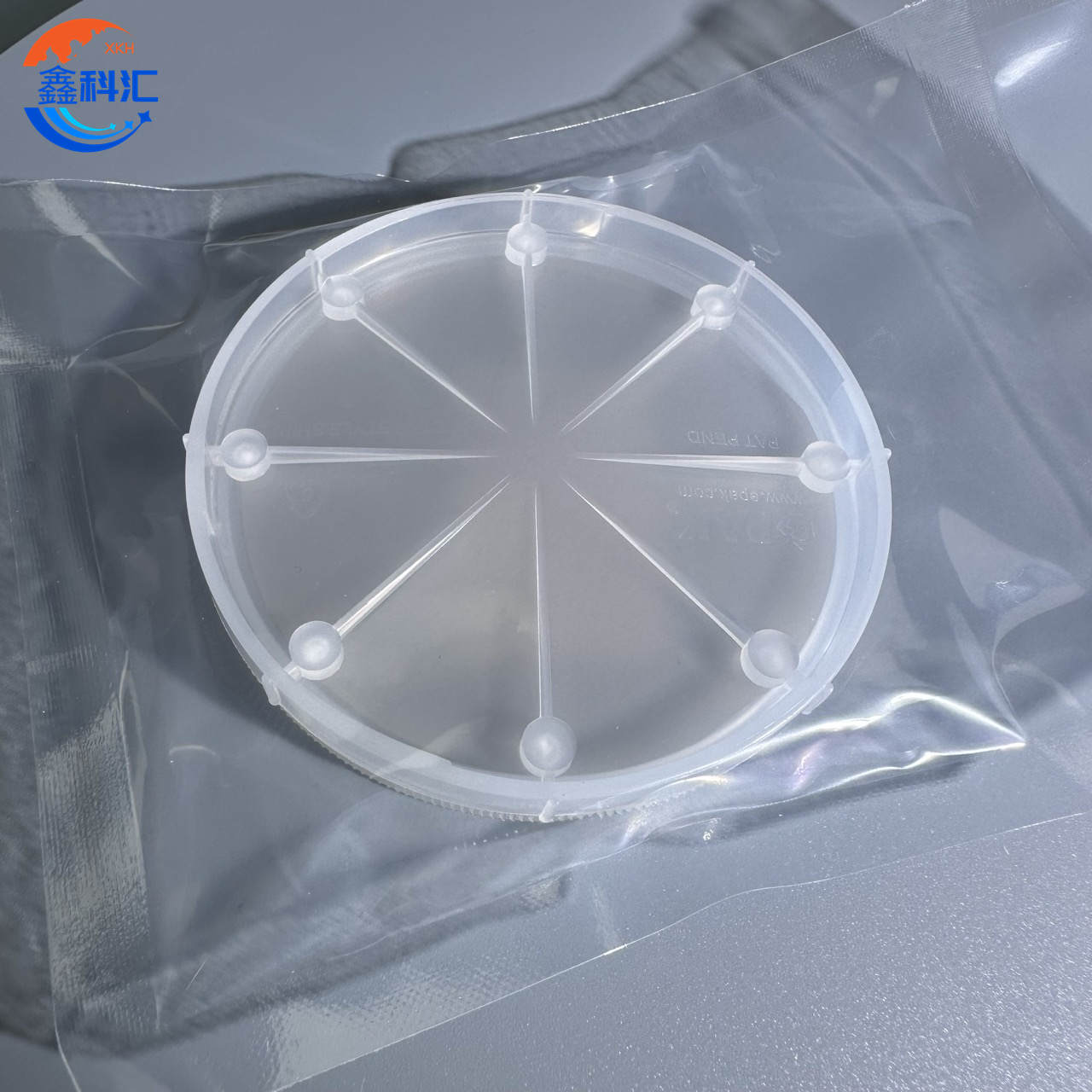

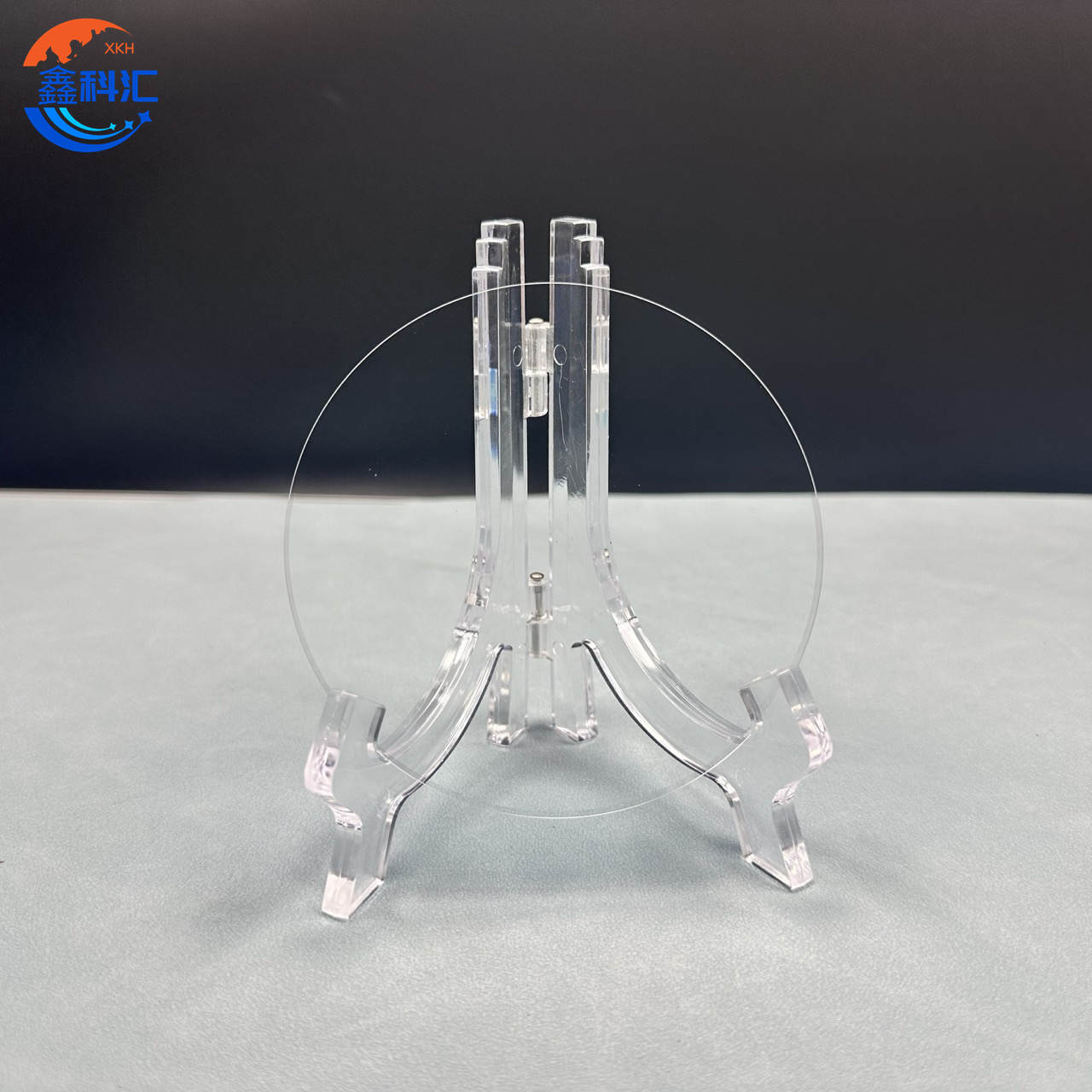

3inch Ucoceko oluphezulu lweSemi-Insulating (HPSI) SiC wafer 350um Dummy ibakala Prime

Isicelo

Ii-wafers ze-HPSI SiC zibalulekile ekwenzeni izixhobo zombane zesizukulwana esilandelayo, ezisetyenziswa kwiintlobo ngeentlobo zezicelo ezisebenza kakhulu:

IiNkqubo zokuGuqulwa koMbane: Ii-wafers ze-SiC zisebenza njengezona zinto ziphambili kwizixhobo zombane ezifana nee-MOSFETs zamandla, ii-diode, kunye nee-IGBT, ezibaluleke kakhulu kuguqulo lwamandla olusebenzayo kwiisekethe zombane. Ezi zixhobo zifumaneka kwizixhobo zombane eziphezulu, iimoto zokuqhuba, kunye nee-inverters zamashishini.

Izithuthi zoMbane (EVs):Imfuno ekhulayo yezithuthi zombane ifuna ukusetyenziswa kwamandla ombane asebenzayo, kwaye ii-wafers ze-SiC zihamba phambili kolu tshintsho. Kwi-EV powertrains, ezi ziqwenga zibonelela ngobuchule obuphezulu kunye namandla okutshintsha ngokukhawuleza, okunegalelo kumaxesha okutshaja okukhawulezayo, uluhlu olude, kunye nokuphucula ukusebenza kwesithuthi siphela.

Umoya ovuselelekayo:Kwiinkqubo zamandla ahlaziyekayo ezifana namandla elanga kunye nomoya, ii-wafers ze-SiC zisetyenziswa kwii-inverters kunye neziguquli ezenza ukuba kubanjwe amandla angaphezulu kunye nokusabalalisa. I-conductivity ephezulu ye-thermal kunye ne-voltage ephezulu yokuphuka kwe-SiC iqinisekisa ukuba ezi nkqubo zisebenza ngokuthembekileyo, naphantsi kweemeko ezinzulu zokusingqongileyo.

Ukuzenzekela kwimizi-mveliso kunye neRobhothi:Amandla ombane asebenza kakhulu kwiinkqubo ezizisebenzelayo zoshishino kunye neerobhothi zifuna izixhobo ezikwaziyo ukutshintsha ngokukhawuleza, ukuphatha imithwalo yamandla amakhulu, nokusebenza phantsi koxinzelelo oluphezulu. I-SiC-based semiconductors ihlangabezana nezi mfuno ngokubonelela ngokusebenza okuphezulu kunye nokomelela, nakwiindawo zokusebenza ezinzima.

IiNkqubo zoNxibelelwano:Kwiziseko zonxibelelwano lomnxeba, apho ukuthembeka okuphezulu kunye nokuguqulwa kwamandla okusebenzayo kubaluleke kakhulu, ii-wafers ze-SiC zisetyenziselwa umbane kunye nabaguquli be-DC-DC. Izixhobo ze-SiC zinceda ukunciphisa ukusetyenziswa kwamandla kunye nokuphucula ukusebenza kwenkqubo kumaziko edatha kunye nothungelwano lonxibelelwano.

Ngokubonelela ngesiseko esomeleleyo sezicelo zamandla aphezulu, i-HPSI SiC wafer yenza uphuhliso lwezixhobo ezisebenza ngamandla, ukunceda amashishini atshintshe kwi-greener, izisombululo ezizinzileyo.

Iipropati

| umsebenzi | IBanga leMveliso | IBanga loPhando | IBanga leDummy |

| Ububanzi | 75.0 mm ± 0.5 mm | 75.0 mm ± 0.5 mm | 75.0 mm ± 0.5 mm |

| Ukutyeba | 350 µm ± 25 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| I-Wafer Orientation | Kwi-axis: <0001> ± 0.5 ° | Kwi-axis: <0001> ± 2.0 ° | Kwi-axis: <0001> ± 2.0 ° |

| Uxinaniso lweMibhobho ye-95% yeeWafers (MPD) | ≤ 1 cm⁻² | ≤ 5 cm⁻² | ≤ 15 cm⁻² |

| Ukuxhathisa koMbane | ≥ 1E7 Ω·cm | ≥ 1E6 Ω·cm | ≥ 1E5 Ω·cm |

| I-Dopant | Ingaguqulwanga | Ingaguqulwanga | Ingaguqulwanga |

| Ukuqhelaniswa neFlethi ePhambili | {11-20} ± 5.0° | {11-20} ± 5.0° | {11-20} ± 5.0° |

| Ubude beFlethi obuPhambili | 32.5 mm ± 3.0 mm | 32.5 mm ± 3.0 mm | 32.5 mm ± 3.0 mm |

| Ubude beFlethi yesibini | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Ukuqhelaniswa neFlethi yesibini | Si jonga phezulu: 90° CW ukusuka kwiflethi yokuqala ± 5.0° | Si jonga phezulu: 90° CW ukusuka kwiflethi yokuqala ± 5.0° | Si jonga phezulu: 90° CW ukusuka kwiflethi yokuqala ± 5.0° |

| Ukungabandakanywa kuMda | 3 mm | 3 mm | 3 mm |

| LTV/TTV/Bow/Warp | 3 µm / 10 µm / ±30 µm / 40 µm | 3 µm / 10 µm / ±30 µm / 40 µm | 5 µm / 15 µm / ±40 µm / 45 µm |

| Uburhabaxa boMphezulu | Ubuso be-C: bukhazimlisiwe, ubuso beSi: CMP | Ubuso be-C: bukhazimlisiwe, ubuso beSi: CMP | Ubuso be-C: bukhazimlisiwe, ubuso beSi: CMP |

| Iintanda (zihlolwe ngokukhanya okuphezulu) | Akukho nanye | Akukho nanye | Akukho nanye |

| Iipleyiti zeHex (zihlolwe ngokukhanya okuphezulu) | Akukho nanye | Akukho nanye | Indawo eyongezelekayo 10% |

| Iindawo zePolytype (zihlolwe ngokukhanya okuphezulu) | Indawo eyongezelekayo 5% | Indawo eyongezelekayo 5% | Indawo eyongezelekayo 10% |

| Imikrwelo (ihlolwe sisibane sokukhanya okuphezulu) | ≤ Imikrwelo emi-5, ubude obuninzi ≤ 150 mm | ≤ Imikrwelo eyi-10, ubude obuninzi ≤ 200 mm | ≤ Imikrwelo eyi-10, ubude obuninzi ≤ 200 mm |

| Edge Chipping | Akukho kuvunyelweyo ≥ 0.5 mm ububanzi nobunzulu | I-2 ivunyelwe, ≤ 1 mm ububanzi kunye nobunzulu | I-5 ivunyelwe, ≤ 5 mm ububanzi kunye nobunzulu |

| Ungcoliseko loMphezulu (uhlolwe sisibane sobukhulu obuphezulu) | Akukho nanye | Akukho nanye | Akukho nanye |

Izinto Eziluncedo Ezingundoqo

Ukusebenza okuphezulu kwe-Thermal: I-SiC ephezulu ye-thermal conductivity iqinisekisa ukutshatyalaliswa kobushushu ngokufanelekileyo kwizixhobo zamandla, ezivumela ukuba zisebenze kumanqanaba aphezulu ombane kunye namaza ngaphandle kokushisa. Oku kuguqulela kwiinkqubo ezincinci, ezisebenzayo kunye nexesha elide lokusebenza.

I-Voltage ye-High Breakdown Voltage: Nge-bandgap ebanzi xa kuthelekiswa ne-silicon, ii-wafers ze-SiC zixhasa usetyenziso lwe-voltage ephezulu, ezenza zilungele izixhobo zombane ze-elektroniki ezifuna ukuxhathisa amandla ombane aphezulu, njengakwizithuthi zombane, iinkqubo zamandla egridi, kunye neenkqubo zamandla avuselelekayo.

UkuNcitshiswa koLahleko lwaMandla: Ukuchasana okuphantsi kunye nesantya sokutshintsha ngokukhawuleza kwezixhobo ze-SiC kubangela ukunciphisa ukulahlekelwa kwamandla ngexesha lokusebenza. Oku akuphuculi nje ukusebenza ngokufanelekileyo kodwa konyusa ukonga umbane ngokubanzi kwiinkqubo apho zisiwe khona.

Ukunyaniseka okuphuculweyo kwiiNdawo eziNgqongileyo: Iipropati zezinto eziphathekayo ze-SiC zivumela ukuba zenze kwiimeko ezinzima, ezifana nokushisa okuphezulu (ukuya kwi-600 ° C), i-voltage ephezulu, kunye nee-frequencies eziphezulu. Oku kwenza ukuba ii-wafers ze-SiC zilungele ukufunwa kwemizi-mveliso, iimoto, kunye nokusetyenziswa kwamandla.

UkuSebenza kwamandla: Izixhobo ze-SiC zibonelela ngoxinano lwamandla aphezulu kunezixhobo ze-silicon zemveli, ukunciphisa ubungakanani kunye nobunzima beenkqubo zombane zamandla ngelixa ziphucula ukusebenza kwazo zonke. Oku kukhokelela ekongiweni kweendleko kunye nokuncinci kokusingqongileyo kwizicelo ezifana namandla ahlaziyekayo kunye nezithuthi zombane.

I-Scalability: I-3-intshi ye-diameter kunye nokunyamezela kwemveliso echanekileyo ye-HPSI SiC wafer iqinisekisa ukuba i-scalable yemveliso yobuninzi, ihlangabezana neemfuno zophando kunye neemveliso zorhwebo.

Ukuqukumbela

I-wafer ye-HPSI SiC, ne-3-intshi yedayamitha yayo kunye ne-350 µm ± 25 µm ubukhulu, sesona sixhobo sifanelekileyo kwisizukulwana esilandelayo sezixhobo zombane ezisebenza ngamandla aphezulu. Ukudityaniswa kwayo okukhethekileyo kokusebenza kwe-thermal, i-voltage ephezulu yokuqhekeka, ukulahleka kwamandla aphantsi, kunye nokuthembeka phantsi kweemeko ezigqithisileyo kuyenza ibe yinxalenye ebalulekileyo yezicelo ezahlukeneyo zokuguqulwa kwamandla, amandla avuselelekayo, izithuthi zombane, iinkqubo zoshishino kunye nonxibelelwano.

Le wafer ye-SiC ifaneleke ngokukodwa kumashishini afuna ukufikelela kwimpumelelo ephezulu, ukonga amandla amakhulu, kunye nokuphucula ukuthembeka kwenkqubo. Njengoko iteknoloji ye-electronics yamandla iqhubeka nokuguquka, i-HPSI SiC wafer ibonelela ngesiseko sophuhliso lwesizukulwana esilandelayo, izisombululo ezisebenza ngamandla, ukuqhuba utshintsho kwikamva elizinzileyo, eliphantsi kwekhabhoni.

Idayagram eneenkcukacha