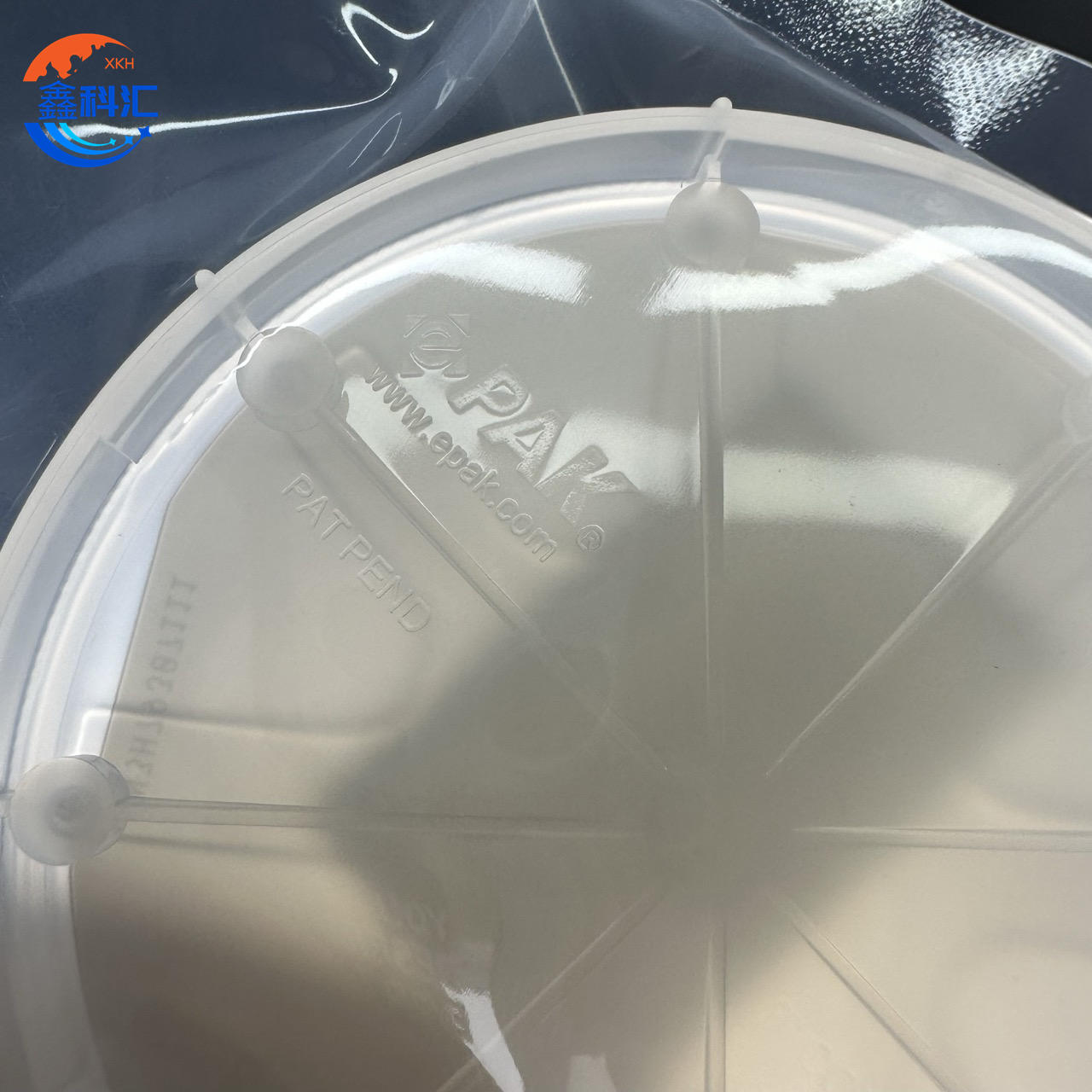

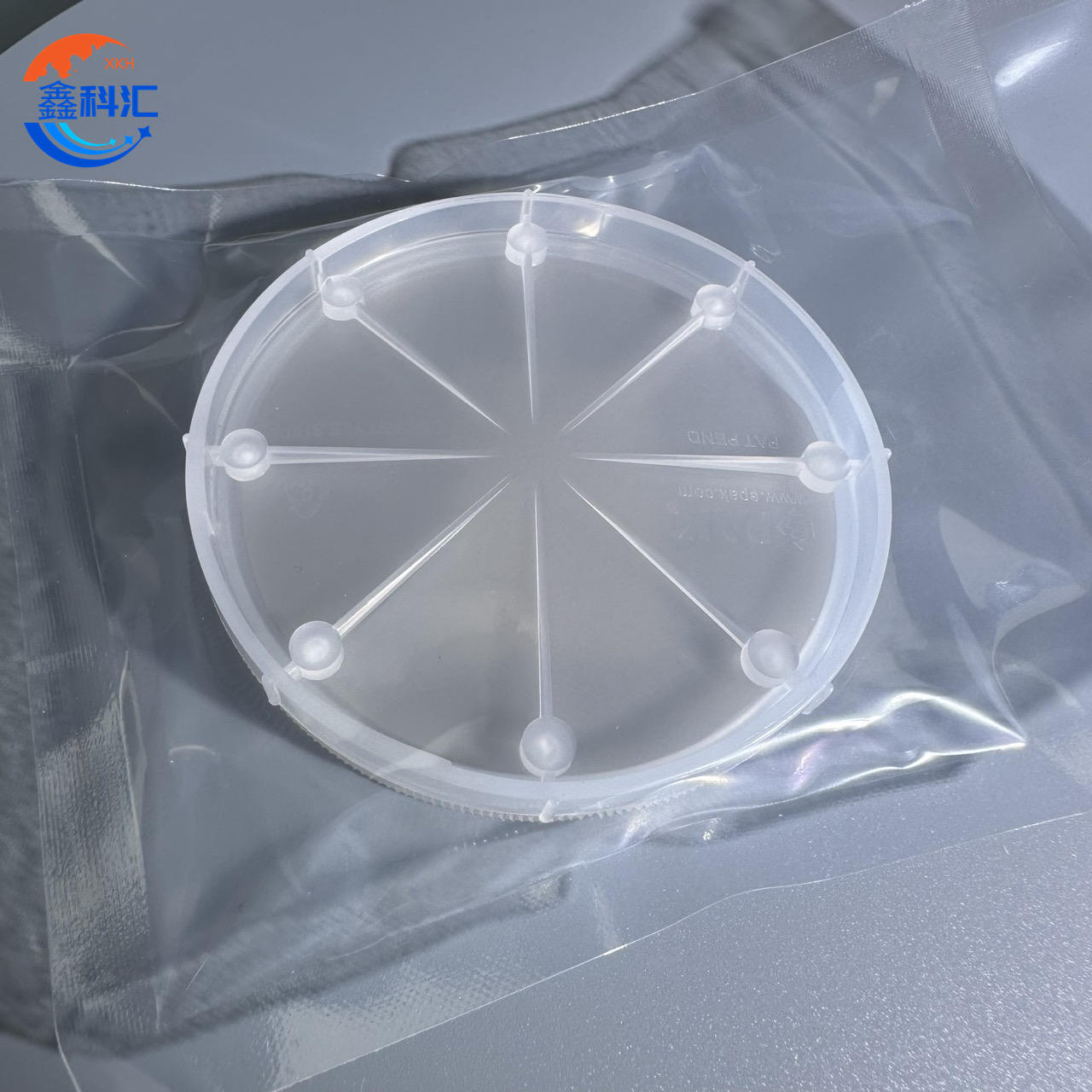

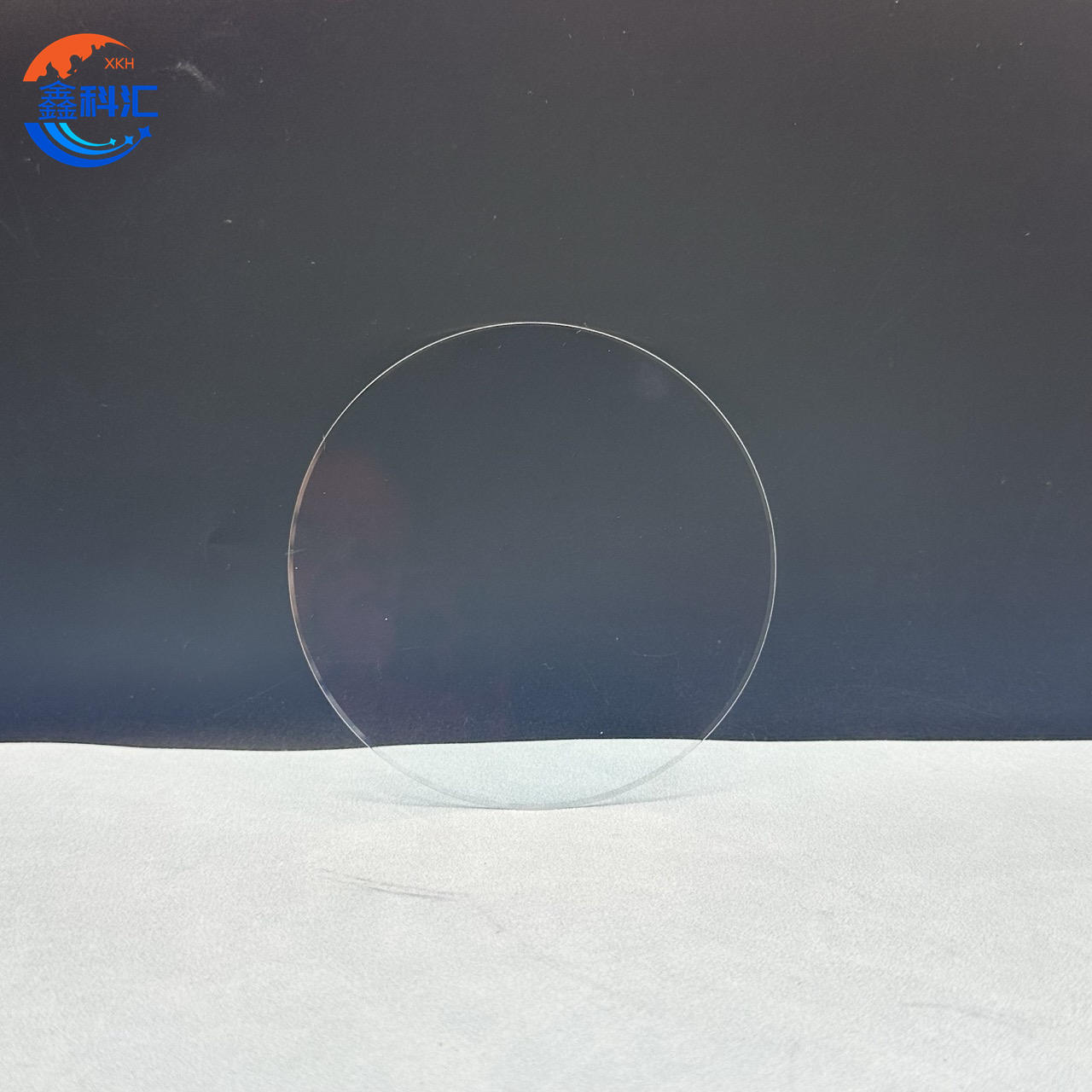

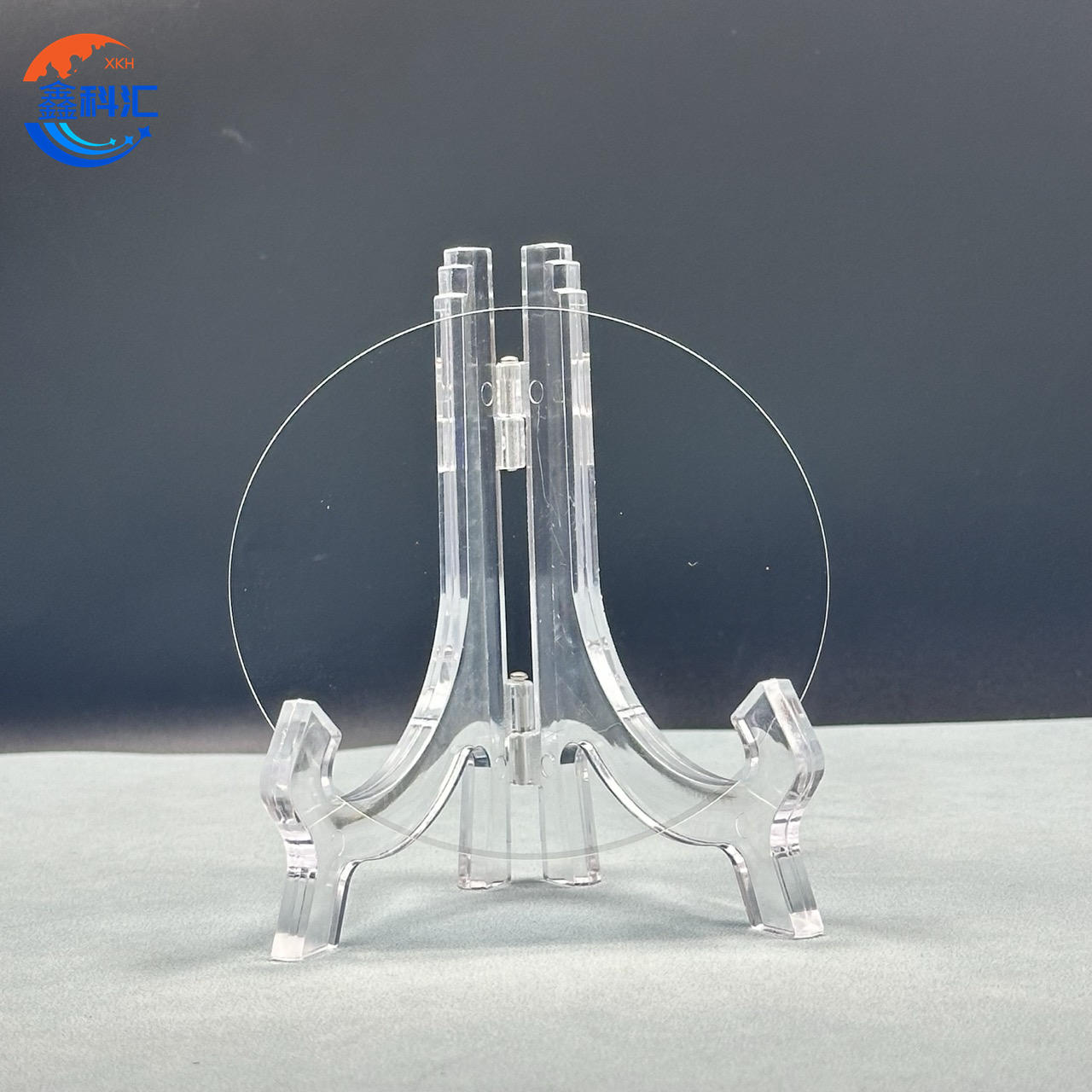

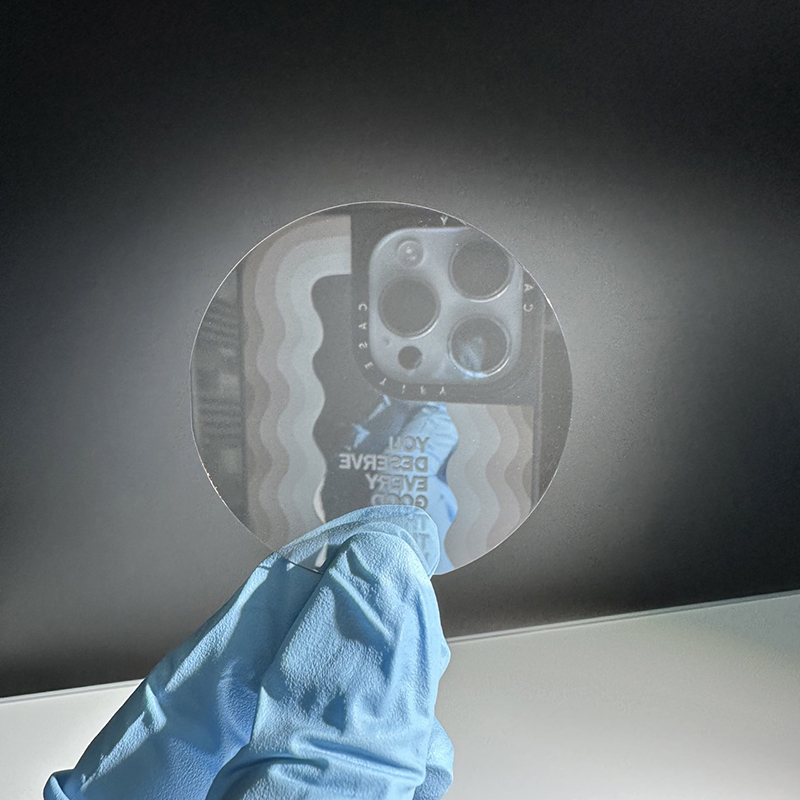

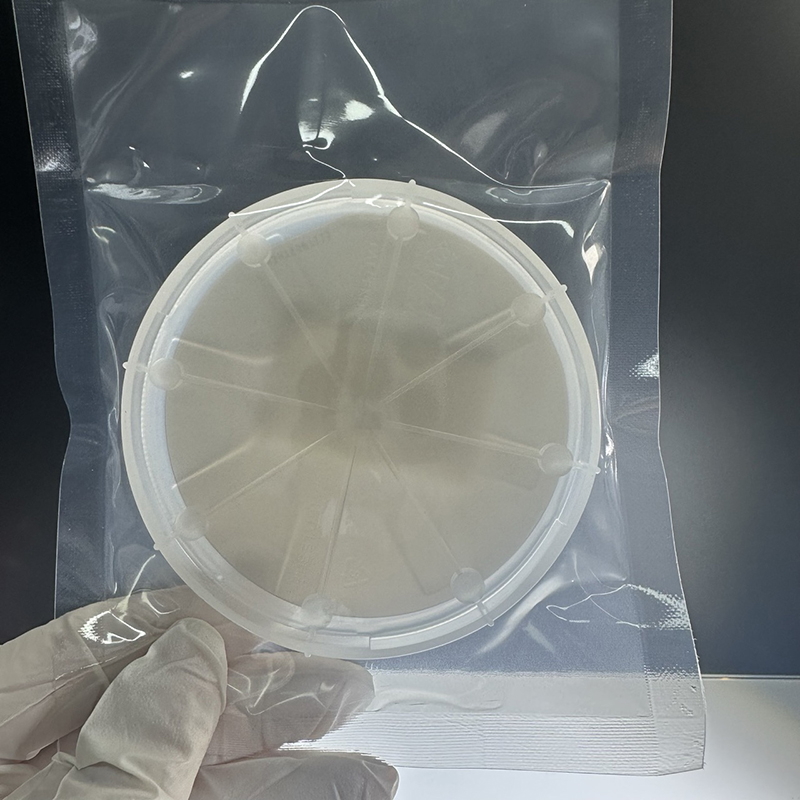

I-intshi ezi-3 zoKucoceka okuPhezulu (Akungatshitshiswanga) iSilicon Carbide Wafers semi-Insulating Sic Substrates (HPSl)

Iipropati

1. IiPropati zoMzimba kunye noLwakhiwo

● Uhlobo lwezinto eziphathekayo: Ukucoceka okuphezulu (Akunqunywanga) iSilicon Carbide (SiC)

● Ububanzi: 3 intshi (76.2 mm)

● Ubukhulu: 0.33-0.5 mm, ngokwezifiso ngokusekelwe kwiimfuno zesicelo.

● I-Crystal Structure: I-4H-SiC i-polytype ene-hexagonal lattice, eyaziwayo ngokuhamba okuphezulu kwe-electron kunye nokuzinza kwe-thermal.

● Uqhelaniso:

oStandard: [0001] (C-plane), ilungele uluhlu olubanzi lwezicelo.

oNgokuzikhethela: I-off-axis (4° okanye 8° tilt) ukwenzela ukukhula okuphuculweyo kwe-epitaxial yeeleya zesixhobo.

●Ukuthe tyaba: Ubunzima bubonke umahluko (TTV) ●Umgangatho woMphezulu:

oLikhazimlisiwe ukuya oLow-defect density (<10/cm² uxinano lwemicropipe). 2. IiPropati zoMbane ● Ukuxhathisa: >109^99 Ω·cm, kugcinwa ngokupheliswa kweedopanti zangabom.

● Amandla e-Dielectric: Ukunyamezela kwamandla aphezulu kunye nokulahlekelwa kwe-dielectric encinci, ilungele ukusetyenziswa kwamandla aphezulu.

● I-Thermal Conductivity: 3.5-4.9 W / cm·K, eyenza ukutshatyalaliswa kokushisa okusebenzayo kwizixhobo zokusebenza eziphezulu.

3. IiPropati zeThermal kunye neMechanical

● I-Bandgap ebanzi: 3.26 eV, ukuxhasa ukusebenza phantsi kombane ophezulu, ukushisa okuphezulu, kunye neemeko eziphezulu zemitha.

● Ukuqina: Isikali se-Mohs 9, ukuqinisekisa ukomelela ngokuchasene nokunxitywa komatshini ngexesha lokulungiswa.

● I-Coefficient yoKwandiswa kweThermal: 4.2×10−6/K4.2 \ amaxesha 10^{-6}/\text{K}4.2×10−6/K, iqinisekisa uzinzo lwe-dimensional phantsi kweenguqu zobushushu.

| Ipharamitha | IBanga leMveliso | IBanga loPhando | IBanga leDummy | Iyunithi |

| IBanga | IBanga leMveliso | IBanga loPhando | IBanga leDummy | |

| Ububanzi | 76.2 ± 0.5 | 76.2 ± 0.5 | 76.2 ± 0.5 | mm |

| Ukutyeba | 500 ± 25 | 500 ± 25 | 500 ± 25 | µm |

| I-Wafer Orientation | Kwi-axis: <0001> ± 0.5 ° | Kwi-axis: <0001> ± 2.0 ° | Kwi-axis: <0001> ± 2.0 ° | isidanga |

| Uxinaniso lweMibhobho (MPD) | ≤ 1 | ≤ 5 | ≤ 10 | cm−2^-2−2 |

| Ukuxhathisa koMbane | ≥ 1E10 | ≥ 1E5 | ≥ 1E5 | Ω·cm |

| I-Dopant | Ingaguqulwanga | Ingaguqulwanga | Ingaguqulwanga | |

| Ukuqhelaniswa neFlethi okuPhambili | {1-100} ± 5.0° | {1-100} ± 5.0° | {1-100} ± 5.0° | isidanga |

| Ubude beFlethi obuPhambili | 32.5 ± 3.0 | 32.5 ± 3.0 | 32.5 ± 3.0 | mm |

| Ubude beFlethi yesibini | 18.0 ± 2.0 | 18.0 ± 2.0 | 18.0 ± 2.0 | mm |

| Ukuqhelaniswa neFlethi yesibini | I-90 ° CW ukusuka kwiflethi yokuqala ± 5.0 ° | I-90 ° CW ukusuka kwiflethi yokuqala ± 5.0 ° | I-90 ° CW ukusuka kwiflethi yokuqala ± 5.0 ° | isidanga |

| Ukungabandakanywa kuMda | 3 | 3 | 3 | mm |

| LTV/TTV/Bow/Warp | 3/10 / ±30/40 | 3/10 / ±30/40 | 5/15 / ±40/45 | µm |

| Uburhabaxa boMphezulu | Ubuso beSi: CMP, C-ubuso: bukhazimlisiwe | Ubuso beSi: CMP, C-ubuso: bukhazimlisiwe | Ubuso beSi: CMP, C-ubuso: bukhazimlisiwe | |

| Iintanda (Ukukhanya okuPhezulu) | Akukho nanye | Akukho nanye | Akukho nanye | |

| Iipleyiti zeHex (Ukukhanya okuPhezulu) | Akukho nanye | Akukho nanye | Indawo eyongezelekayo 10% | % |

| Iindawo zePolytype (Ukukhanya okuPhezulu) | Indawo eyongezelekayo 5% | Indawo eyongezelekayo 20% | Indawo eyongezelekayo 30% | % |

| Imikrwelo (UkuKhanya okuPhezulu) | ≤ Imikrwelo emi-5, ubude obuqokelelweyo ≤ 150 | ≤ Imikrwelo eyi-10, ubude obuqokelelweyo ≤ 200 | ≤ Imikrwelo eyi-10, ubude obuqokelelweyo ≤ 200 | mm |

| Edge Chipping | Akukho nanye ≥ 0.5 mm ububanzi/ubunzulu | I-2 ivunyelwe ≤ 1 mm ububanzi / ubunzulu | I-5 ivunyelwe ≤ 5 mm ububanzi / ubunzulu | mm |

| Ungcoliseko loMphezulu | Akukho nanye | Akukho nanye | Akukho nanye |

Usetyenziso

1. I-Electronics yamandla

I-bandgap ebanzi kunye ne-thermal conductivity ephezulu ye-HPSI SiC substrates ibenza balungele izixhobo zamandla ezisebenza kwiimeko ezigqithisileyo, ezifana:

● I-High-Voltage Devices: Kubandakanya i-MOSFET, ii-IGBTs, kunye ne-Schottky Barrier Diodes (SBDs) yokuguqulwa kwamandla ngokufanelekileyo.

● IiNkqubo zaMandla aVuselelwayo: Ezinje ngee-inverters zelanga kunye nabalawuli be-injini yomoya.

● IZithuthi zoMbane (EVs): Zisetyenziswa kwii-inverters, iitshaja, kunye neenkqubo zokuqeqesha amandla ukuphucula ukusebenza kakuhle nokunciphisa ubukhulu.

2. Izicelo zeRF kunye neMicrowave

Ukumelana okuphezulu kunye nelahleko ephantsi yedielectric yeewafers zeHPSI zibalulekile kwirediyo-frequency (RF) kunye neenkqubo zemicrowave, kubandakanya:

● Iziseko zoNxibelelwano zoNxibelelwano: Izitishi ezisisiseko ze-5G uthungelwano kunye nonxibelelwano lwesathelayithi.

● I-Aerospace kunye noKhuseleko: Iinkqubo ze-radar, ii-antenna ze-phased-array, kunye nezixhobo ze-avionics.

3. Optoelectronics

Ukungafihli kunye nebhendi ebanzi ye-4H-SiC yenza ukuba isetyenziswe kwizixhobo ze-optoelectronic, ezifana:

● Iifoto ze-UV: Ukujongwa kokusingqongileyo kunye nokuxilongwa kwezonyango.

● Ii-LED zaMandla aphezulu: Ukuxhasa iinkqubo zokukhanyisa eziqinileyo.

● I-Laser Diodes: Izicelo zamashishini kunye nezonyango.

4. Uphando kunye noPhuhliso

Iisubstrates ze-HPSI SiC zisetyenziswa ngokubanzi kwiilebhu ze-R&D zemfundo kunye nezoshishino zokuphonononga iipropathi zemathiriyeli eziphambili kunye nokwenziwa kwesixhobo, kubandakanywa:

● I-Epitaxial Layer Growth: Izifundo ngokunciphisa isiphene kunye nokuphucula umaleko.

● Izifundo zokuHamba kweCarrier: Uphando lwe-electron kunye nokuthuthwa komngxuma kwizinto ezicocekileyo.

● Iprototyping: Uphuhliso lokuqala lwezixhobo ezintsha kunye neesekethe.

Iingenelo

Umgangatho ophezulu:

Ubunyulu obuphezulu kunye noxinzelelo oluphantsi lwesiphako lubonelela ngeqonga elithembekileyo lezicelo eziphambili.

Uzinzo lweThermal:

Iimpawu ezigqwesileyo zokutshatyalaliswa kobushushu zivumela izixhobo ukuba zisebenze ngokufanelekileyo phantsi kwamandla aphezulu kunye neemeko zokushisa.

Ukuhambelana okubanzi:

Ulungelelwaniso olukhoyo kunye nokhetho lobungakanani besiko luqinisekisa ukuguquguquka kwiimfuno ezahlukeneyo zesixhobo.

Ukuqina:

Ubulukhuni obukhethekileyo kunye nokuzinza kwesakhiwo kunciphisa ukunxiba kunye nokuguqulwa ngexesha lokucubungula nokusebenza.

Ukuguquguquka:

Ifanelekile kuluhlu olubanzi lwamashishini, ukusuka kumandla ahlaziyekayo ukuya kwi-aerospace kunye nonxibelelwano.

Ukuqukumbela

I-3-inch High Purity Semi-Insulating Silicon Carbide wafer imele incopho yetekhnoloji ye-substrate yamandla aphezulu, i-high-frequency, kunye nezixhobo ze-optoelectronic. Ukudityaniswa kwayo kweempawu ezibalaseleyo zobushushu, zombane, kunye nezomatshini ziqinisekisa ukusebenza okuthembekileyo kwiindawo ezinomngeni. Ukusuka kumbane we-elektroniki kunye neenkqubo zeRF ukuya kwi-optoelectronics kunye ne-R&D ephucukileyo, ezi substrates zeHPSI zibonelela ngesiseko sezinto ezintsha zangomso.

Ngolwazi oluthe vetshe okanye ukwenza iodolo, nceda uqhagamshelane nathi. Iqela lethu lobugcisa liyafumaneka ukubonelela ngesikhokelo kunye neenketho zokwenza ngokwezifiso ezilungiselelwe iimfuno zakho.

Idayagram eneenkcukacha