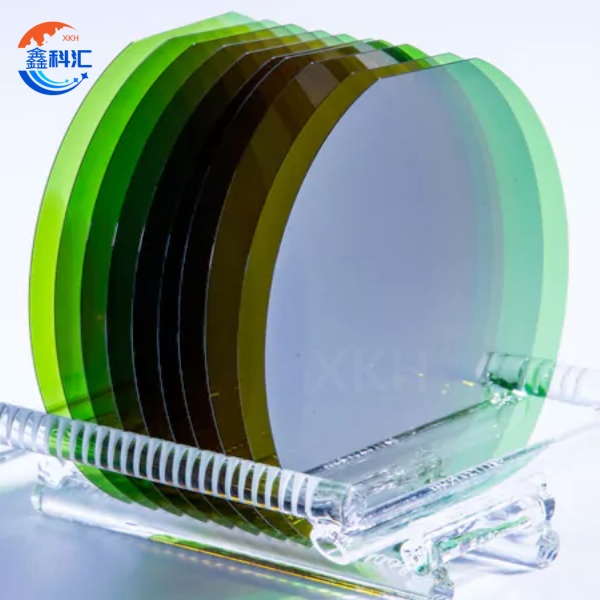

I-intshi ye-12 ye-SiC Substrate N yoHlobo olukhulu Ubungakanani obuKhulu obuPhezulu bokusebenza kwe-RF yezicelo

Imilinganiselo yobugcisa

| I-12 intshi yeSilicon Carbide (SiC) Inkcazo yeSubstrate | |||||

| IBanga | Imveliso yeZeroMPD IBanga (Z Grade) | Imveliso esemgangathweni IBanga (P Grade) | IBanga leDummy (D Grade) | ||

| Ububanzi | 3 0 0 mm~1305mm | ||||

| Ukutyeba | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| I-Wafer Orientation | I-off axis : 4.0 ° ukuya ku- <1120 > ±0.5 ° ye-4H-N, Kwi-axis : <0001>±0.5 ° ye-4H-SI | ||||

| Ukuxinana kweMibhobho | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ukuxhathisa | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Ukuqhelaniswa neFlethi okuPhambili | {10-10} ±5.0° | ||||

| Ubude beFlethi obuPhambili | 4H-N | N / A | |||

| 4H-SI | Inotshi | ||||

| Ukungabandakanywa kuMda | 3 mm | ||||

| LTV/TTV/Saphetha/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Uburhabaxa | IsiPolish Ra≤1 nm | ||||

| I-CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| I-Edge Cracks ngokuKhanya okuPhakamileyo Iipleyiti zeHex ngokuKhanya okuPhakamileyo Iindawo zePolytype NgokuKhanya okuPhakamileyo Ukubandakanywa kweCarbon ebonakalayo I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Akukho nanye Indawo eyongezelekayo ≤0.05% Akukho nanye Indawo eyongezelekayo ≤0.05% Akukho nanye | Ubude obongezelekayo ≤ 20 mm, ubude obunye≤2 mm Indawo eyongezelekayo ≤0.1% Indawo eyongezelekayo≤3% Indawo eyongezelekayo ≤3% Ubude obongezelekayo≤1×i-wafer idayamitha | |||

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥0.2mm ububanzi nobunzulu | I-7 ivunyelwe, ≤1 mm nganye | |||

| (TSD) Ukushenxiswa kwesikrufu somsonto | ≤500 cm-2 | N / A | |||

| (BPD) Isiseko sokuchithwa kwenqwelomoya | ≤1000 cm-2 | N / A | |||

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | Akukho nanye | ||||

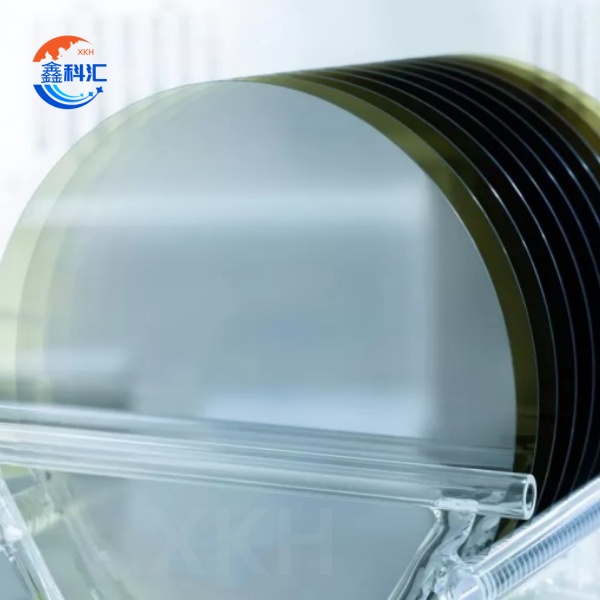

| Ukupakishwa | Multi-wafer Cassette Okanye Single Wafer Container | ||||

| Amanqaku: | |||||

| 1 Imida yeziphene isebenza kuwo wonke umphezulu we-wafer ngaphandle kwendawo yokukhutshwa komphetho. 2Imikrwelo kufuneka ijongwe kuSi face kuphela. 3 Idatha yokususa isuka kwi-KOH etshisiweyo kuphela. | |||||

Ezona mpawu

1. I-Advantage yobungakanani obukhulu: I-12-intshi ye-SiC substrate (i-12-intshi ye-silicon carbide substrate) inika indawo enkulu ye-wafer enye, eyenza ukuba ii-chips ezininzi ziveliswe nge-wafer nganye, ngaloo ndlela ukunciphisa iindleko zokuvelisa kunye nokunyusa isivuno.

2. Izinto eziSebenzayo eziphezulu: I-silicon carbide ye-high-temperature resistance and high breakdown field field yenza i-substrate ye-12-intshi ilungele ukusetyenziswa kwe-voltage ephezulu kunye ne-high-frequency applications, njenge-EV inverters kunye neenkqubo zokutshaja ngokukhawuleza.

3. UkuPhathwa kokuPhathwa: Nangona ubunzima obuphezulu kunye nemingeni yokucubungula ye-SiC, i-substrate ye-SiC ye-intshi eyi-12 ifezekisa iziphene eziphantsi komhlaba ngokusebenzisa ubuchule bokusika kunye nokupolisha, ukuphucula isivuno sesixhobo.

4. Ulawulo oluPhezulu lwe-Thermal: Nge-conductivity engcono ye-thermal kunezinto ezisekelwe kwi-silicon, i-substrate ye-intshi eyi-12 ijongene ngokufanelekileyo nokutshatyalaliswa kobushushu kwizixhobo eziphezulu zamandla, ukwandisa ixesha lokuphila kwezixhobo.

Izicelo eziphambili

1. Izithuthi zoMbane: I-12-intshi ye-SiC substrate (i-12-intshi ye-silicon carbide substrate) yinxalenye ephambili yeenkqubo zokuqhuba umbane zesizukulwana esilandelayo, ezenza ukuba i-inverters ephezulu ephucula uluhlu kunye nokunciphisa ixesha lokutshaja.

2. Izitishi zeSiseko ze-5G: Ii-substrates ze-SiC ezinkulu zixhasa izixhobo ze-RF ze-high-frequency, ukuhlangabezana neemfuno zezikhululo ze-5G zamandla aphezulu kunye nokulahlekelwa okuphantsi.

I-3.Iimveliso zamandla amashishini: Kwii-inverters zelanga kunye ne-smart grids, i-substrate ye-intshi eyi-12 inokumelana ne-voltages ephezulu ngelixa inciphisa ukulahlekelwa kwamandla.

I-4.I-Electronics yoMthengi: Iitshaja ezikhawulezayo zexesha elizayo kunye nezixhobo zamandla eziko ledatha zinokuthatha i-12-intshi ye-SiC substrates ukuphumeza ubungakanani obudibeneyo kunye nokusebenza okuphezulu.

Iinkonzo ze-XKH

Sisebenza ngokukhethekileyo kwiinkonzo zokulungisa ezilungiselelwe i-12-intshi ye-SiC substrates (i-12-intshi ye-silicon carbide substrates), kuquka:

1. I-Dicing & Polishing: Umonakalo ophantsi, ukulungiswa kwe-substrate ephezulu ehambelana neemfuno zabathengi, ukuqinisekisa ukusebenza kwesixhobo esizinzileyo.

2. Inkxaso yokuKhula kwe-Epitaxial: Iinkonzo ze-epitaxial wafer ezikumgangatho ophezulu ukukhawulezisa ukuveliswa kwe-chip.

3. I-Small-Batch Prototyping: Ixhasa ukuqinisekiswa kwe-R&D kumaziko ophando kunye namashishini, kucuthwe imijikelo yophuhliso.

4. I-Technical Consulting: Izisombululo zokugqibela zokugqibela ukusuka ekukhethweni kwezinto eziphathekayo ukuya kwinkqubo yokuphucula, ukunceda abathengi ukuba banqobe imingeni yokucubungula i-SiC.

Nokuba yeyemveliso yobuninzi okanye uhlengahlengiso olukhethekileyo, iinkonzo zethu ze-SiC ze-12-intshi zihambelana neemfuno zeprojekthi yakho, zixhobisa ukuqhubela phambili kobuchwepheshe.