Ii-wafers ze-SiC zi-semiconductors ezenziwe kwi-silicon carbide. Esi sixhobo saphuhliswa kwi-1893 kwaye ifanelekile kwiintlobo ezahlukeneyo zezicelo. Ngokukodwa ezifanelekileyo kwi-Schottky diodes, i-junction barrier Schottky diodes, iiswitshi kunye ne-metal-oxide-semiconductor field-effect transistors. Ngenxa yokuqina kwayo okuphezulu, lolona khetho lubalaseleyo kumacandelo ombane ombane.

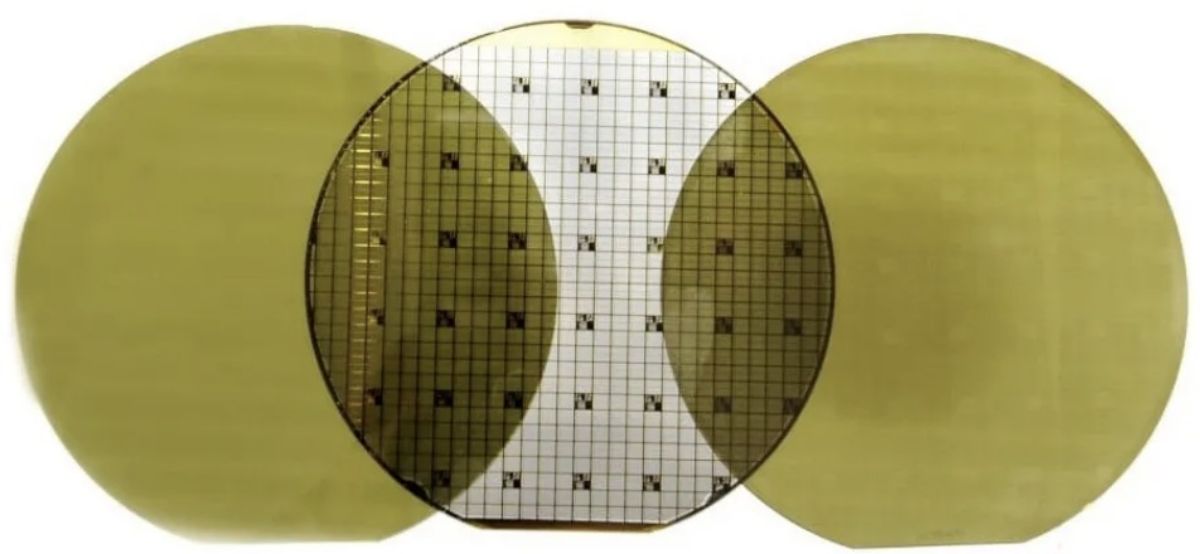

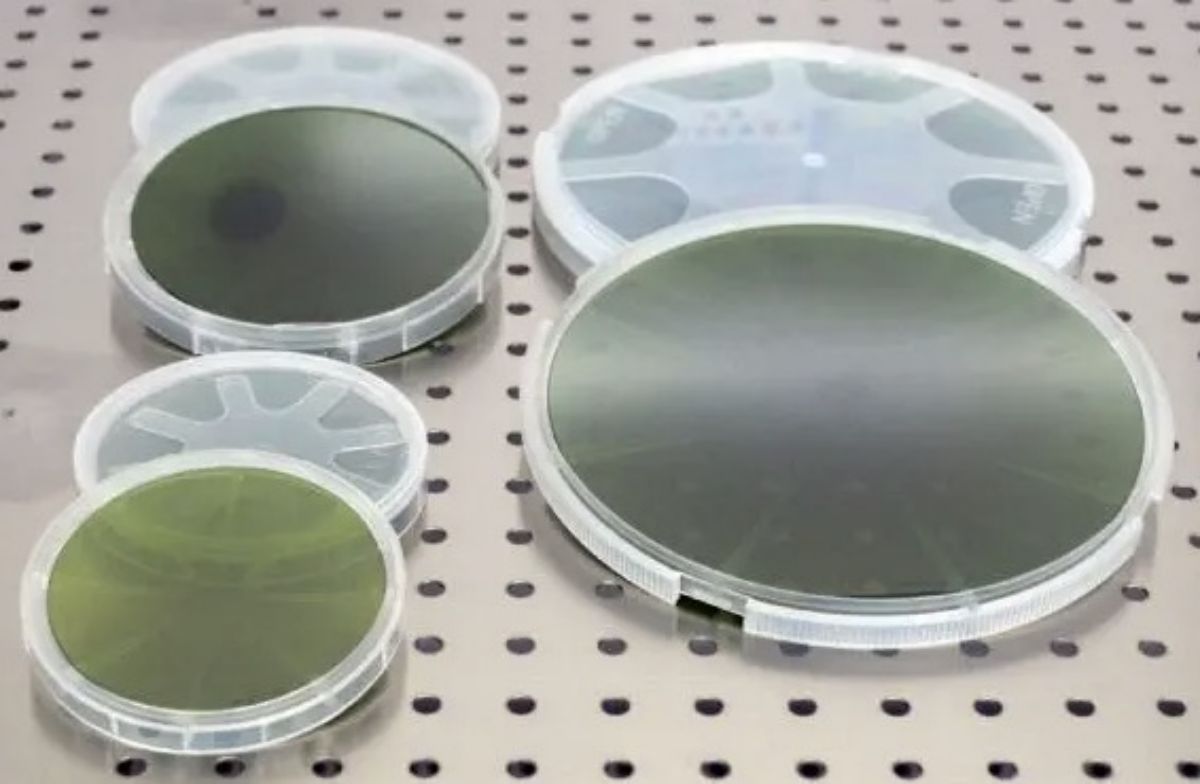

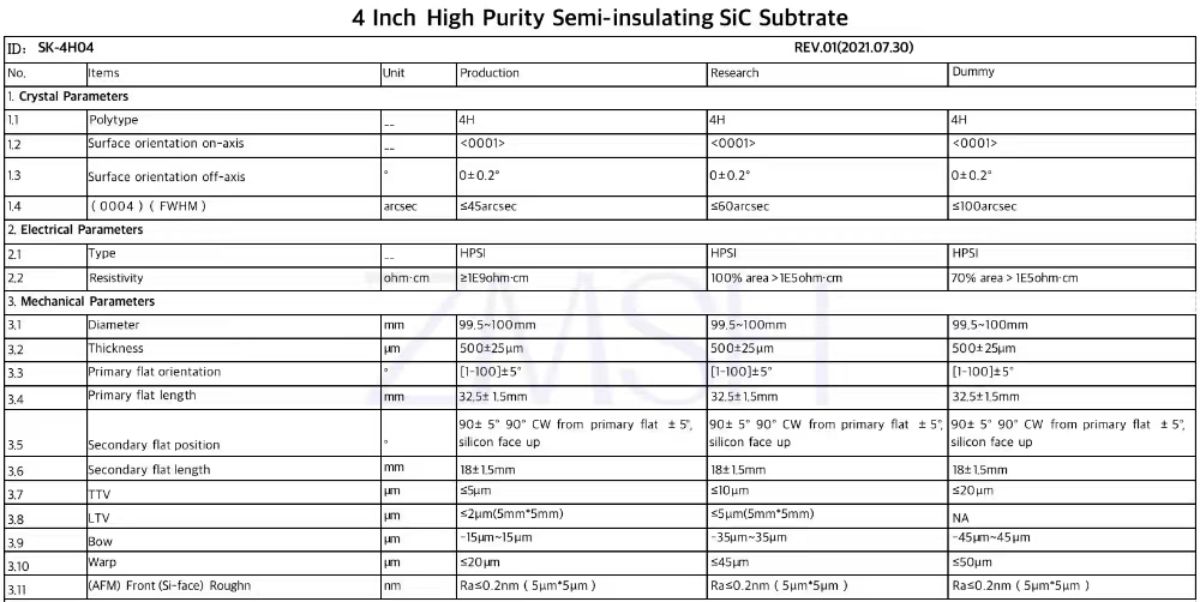

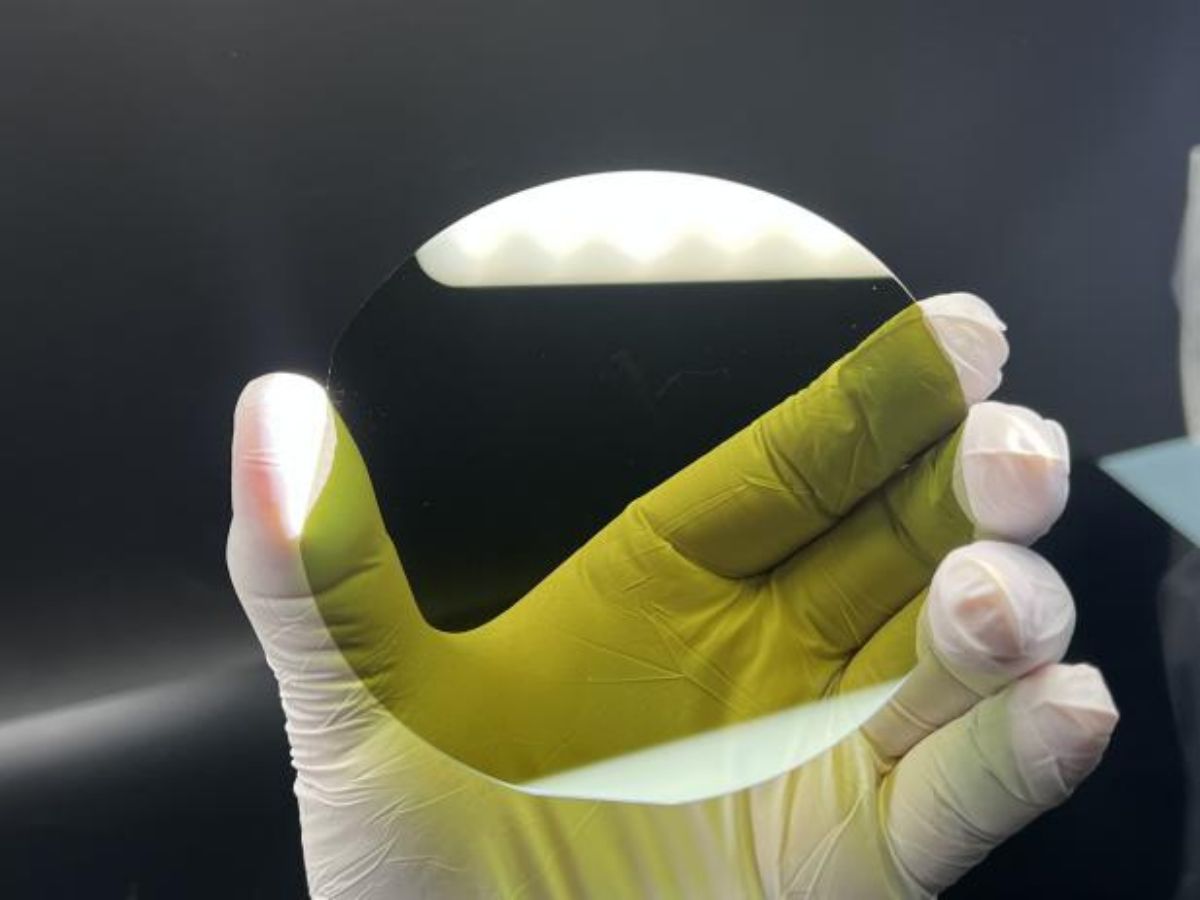

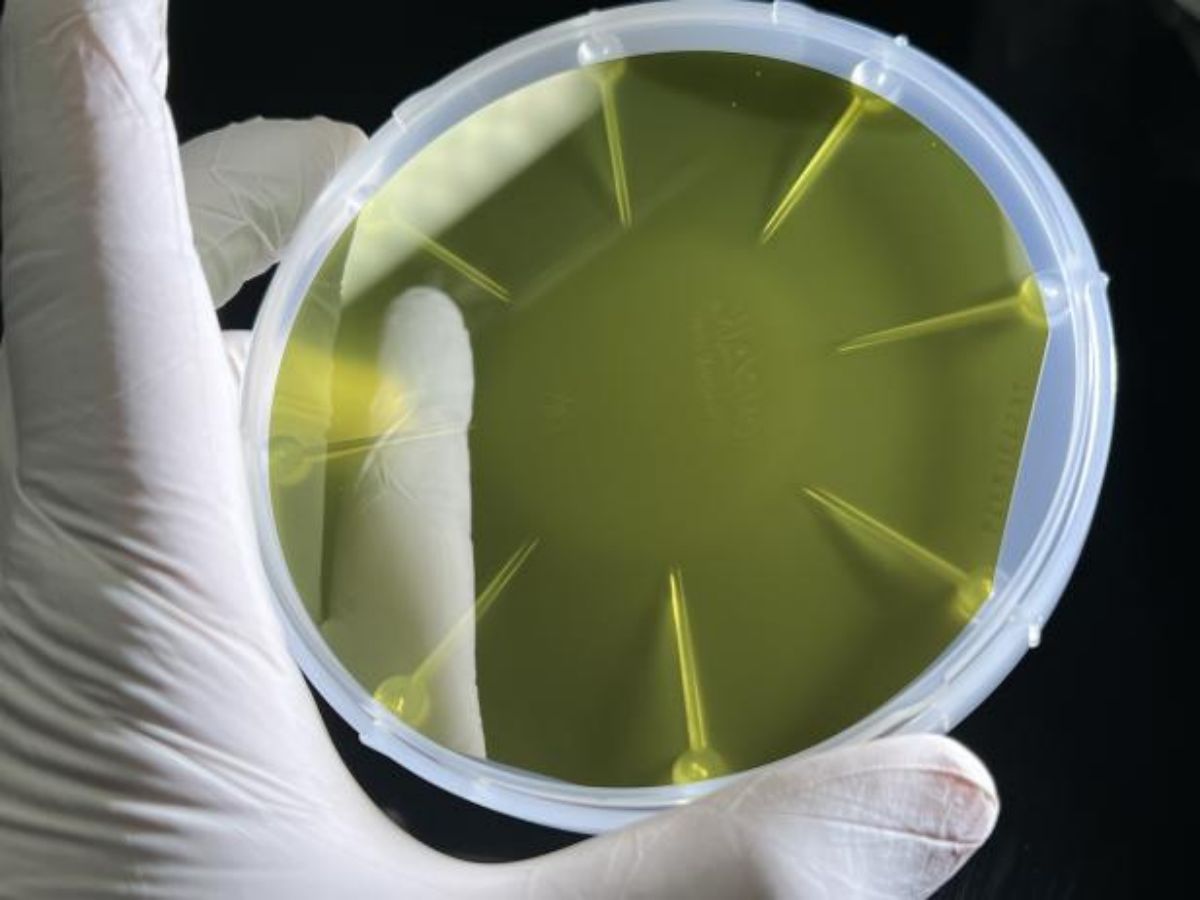

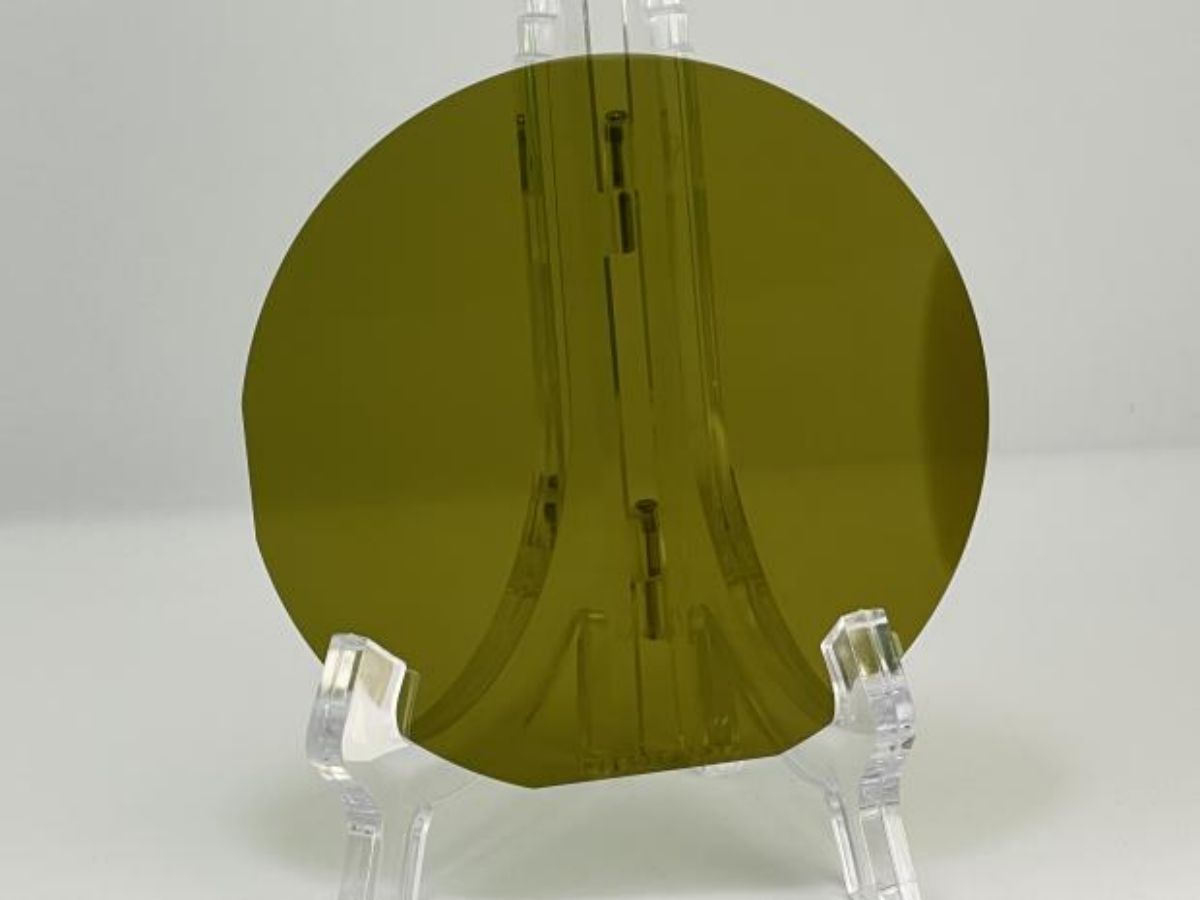

Okwangoku, zimbini iindidi eziphambili zeewafers zeSiC. Eyokuqala sisilutyana esikhazimlisiweyo, esisiqhekeza esinye se-silicon carbide. Yenziwe ngokucoceka okuphezulu kweekristale zeSiC kwaye ingaba yi-100mm okanye i-150mm ububanzi. Isetyenziswa kwizixhobo zombane ezinamandla aphezulu. Uhlobo lwesibini yi-epitaxial crystal silicon carbide wafer. Olu hlobo lwe-wafer lwenziwa ngokongeza umaleko omnye we-silicon carbide crystals kumphezulu. Le ndlela idinga ulawulo oluchanekileyo lobunzima bezinto eziphathekayo kwaye yaziwa ngokuba yi-N-type epitaxy.

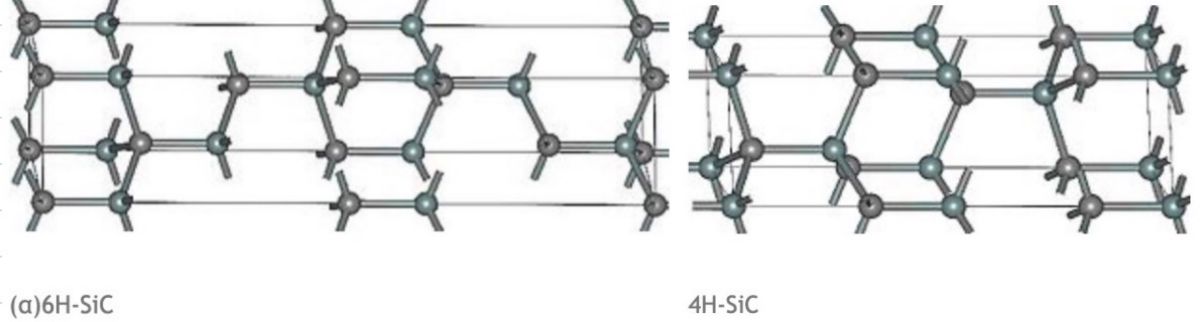

Uhlobo olulandelayo yi-beta silicon carbide. I-Beta SiC iveliswa kumaqondo obushushu angaphezu kwe-1700 degrees Celsius. I-Alpha carbides zezona zixhaphakileyo kwaye zine-hexagonal crystal structure efana ne-wurtzite. Ifomu ye-beta iyafana nedayimane kwaye isetyenziswa kwezinye izicelo. Ibisoloko ilukhetho lokuqala lwamandla esithuthi sombane seemveliso ezigqityiweyo. Abathengisi abaninzi beqela lesithathu le-silicon carbide wafer basebenza ngoku kwesi sixhobo sitsha.

Ii-wafers ze-ZMSH ze-SiC zizinto ezithandwa kakhulu ze-semiconductor. Yimathiriyeli ye-semiconductor ekumgangatho ophezulu ekufanelekele usetyenziso oluninzi. I-ZMSH ii-silicon carbide wafers zizixhobo eziluncedo kakhulu kwiintlobo ngeentlobo zezixhobo zombane. I-ZMSH ibonelela ngoluhlu olubanzi lwee-wafers ze-SiC ezikumgangatho ophezulu kunye nee-substrates. Zifumaneka ngohlobo lwe-N kunye neefom ze-semi-insulated.

I-2---Silicon Carbide: Ukuya kwixesha elitsha lee-wafers

Iimpawu ezibonakalayo kunye neempawu ze-silicon carbide

I-Silicon carbide inesakhiwo esikhethekileyo sekristale, isebenzisa isakhiwo esivaliweyo esinehexagonal esifana nedayimane. Esi sakhiwo senza ukuba i-silicon carbide ibe ne-conductivity egqwesileyo ye-thermal kunye nokumelana nokushisa okuphezulu. Xa kuthelekiswa nezinto ze-silicon zemveli, i-silicon carbide inobubanzi bebhendi enkulu, ebonelela ngesithuba sebhendi ye-electron ephezulu, ekhokelela ekuhambeni okuphezulu kwe-electron kunye nokuvuza okuphantsi kwangoku. Ukongeza, i-silicon carbide ikwanesantya esiphezulu se-electron saturation drift kunye ne-resistivity esezantsi yemathiriyeli ngokwayo, ibonelela ukusebenza okungcono kwezicelo zamandla aphezulu.

Iimeko zesicelo kunye nethemba le-silicon carbide wafers

Ukusetyenziswa kombane wombane

I-silicon ye-carbide wafer inethemba elibanzi lokusetyenziswa kwintsimi yombane we-elektroniki. Ngenxa yokuhamba kwazo okuphezulu kwe-electron kunye nokuhamba kakuhle kwe-thermal, ii-wafers ze-SIC zingasetyenziselwa ukuvelisa izixhobo zokutshintsha koxinzelelo lwamandla aphezulu, njengeemodyuli zamandla kwizithuthi zombane kunye ne-solar inverters. Uzinzo oluphezulu lobushushu be-silicon carbide wafers lwenza ukuba ezi zixhobo zisebenze kwiindawo eziphezulu zokushisa, zibonelela ngokusebenza kakuhle kunye nokuthembeka.

Usetyenziso lwe-Optoelectronic

Kwintsimi yezixhobo ze-optoelectronic, ii-silicon carbide wafers zibonisa izibonelelo zabo ezizodwa. Izinto zeSilicon carbide zineempawu zebhendi ebanzi, eyenza ukuba ifikelele amandla aphezulu e-photonon kunye nokulahleka kokukhanya okuphantsi kwizixhobo ze-optoelectronic. I-silicon carbide wafers ingasetyenziselwa ukulungiselela izixhobo zokunxibelelana ngesantya esiphezulu, i-photodetectors kunye ne-lasers. I-conductivity yayo egqwesileyo ye-thermal kunye ne-crystal defect density ephantsi yenza ukuba ilungele ukulungiswa kwezixhobo eziphezulu ze-optoelectronic.

Outlook

Ngokukhula kwemfuno yezixhobo zombane ezisebenza ngokuphezulu, ii-silicon carbide wafers zinekamva elithembisayo njengemathiriyeli eneempawu ezigqwesileyo kunye namandla osetyenziso olubanzi. Ngokuphuculwa okuqhubekayo kweteknoloji yokulungiselela kunye nokunciphisa iindleko, ukusetyenziswa kwezorhwebo kwe-silicon carbide wafers kuya kukhuthazwa. Kulindeleke ukuba kule minyaka imbalwa izayo, ii-silicon carbide wafers ziya kungena ngokuthe ngcembe kwimarike kwaye zibe lukhetho oluphambili lwamandla aphezulu, ukuphindaphindwa okuphezulu kunye nobushushu obuphezulu bezicelo.

3---Uhlalutyo olunzulu lwentengiso ye-SiC wafer kunye neendlela zobuchwepheshe

Uhlalutyo olunzulu lwe-silicon carbide (SiC) abaqhubi beemarike ze-wafer

Ukukhula kwe-silicon carbide (SiC) imakethi ye-wafer kuphenjelelwa zizinto ezininzi eziphambili, kwaye uhlalutyo olunzulu lwempembelelo yezi zinto kwimarike lubalulekile. Nanga amanye abaqhubi bemarike abaphambili:

Ukugcinwa kwamandla kunye nokukhuselwa kwendalo: Ukusebenza okuphezulu kunye neempawu zokusetyenziswa kwamandla aphantsi kwezixhobo ze-silicon carbide zenza ukuba zidume kwintsimi yokugcina amandla kunye nokukhuselwa kwendalo. Imfuno yezithuthi zombane, ii-inverters zelanga kunye nezinye izixhobo zokuguqula amandla ziqhuba ukukhula kwemarike yee-silicon carbide wafers njengoko inceda ukunciphisa inkcitho yamandla.

Izicelo ze-Electronics zamandla: I-silicon carbide igqwesa kwizicelo ze-electronics zamandla kwaye ingasetyenziselwa amandla ombane phantsi koxinzelelo oluphezulu kunye neendawo zokushisa eziphezulu. Ngokuthandwa kwamandla avuselelekayo kunye nokukhuthaza inguqu yamandla ombane, imfuno ye-silicon carbide wafers kwimarike yombane we-elektroniki iyaqhubeka nokukhula.

I-SiC yafeza ikamva lophuhliso lobuchwephesha bokwenza uhlalutyo oluneenkcukacha

Ukuveliswa ngobuninzi kunye nokunciphisa iindleko: Ukuveliswa kwe-SiC ye-future SiC kuya kugxila ngakumbi kwimveliso yobuninzi kunye nokunciphisa iindleko. Oku kuquka iindlela zokukhula eziphuculweyo ezifana nekhemikhali yokubeka umphunga (CVD) kunye ne-physical vapor deposition (PVD) ukwandisa imveliso nokunciphisa iindleko zemveliso. Ukongeza, ukwamkelwa kweenkqubo zokuvelisa ezikrelekrele kunye nezizenzekelayo kulindeleke ukuba kuphuculwe ngakumbi ukusebenza kakuhle.

Ubungakanani obutsha be-wafer kunye nesakhiwo: Ubungakanani kunye nokwakheka kwee-wafers ze-SiC kunokutshintsha kwixesha elizayo ukuhlangabezana neemfuno zezicelo ezahlukeneyo. Oku kunokubandakanya iiwafa ezinkulu zedayamitha, izakhiwo ezingafaniyo, okanye iiwafa ezininzi ukunika ubunwele boyilo kunye neendlela zokusebenza.

UkuSebenza koMbane kunye nokuVeliswa kokuHlaza: Ukwenziwa kwee-wafers ze-SiC kwixesha elizayo kuya kugxininisa kakhulu ekusebenzeni kwamandla kunye nokuveliswa kohlaza. Iifektri ezinikwa amandla ahlaziyekayo, izinto eziluhlaza, ukusetyenzwa ngokutsha kwenkunkuma kunye neenkqubo zokuvelisa ikhabhoni ephantsi ziya kuba yimikhwa kwimveliso.

Ixesha lokuposa: Jan-19-2024