Njengesixhobo se-semiconductor substrate yesizukulwana sesithathu,i-silicon carbide (SiC)Ikristale enye inethemba elibanzi losetyenziso kwimveliso yezixhobo zombane ezisebenza ngokuphindaphindiweyo kunye nezixhobo zombane eziphezulu. Itekhnoloji yokucubungula ye-SiC idlala indima eqinisekileyo ekuvelisweni kwezinto eziphezulu ze-substrate. Eli nqaku lazisa ngemeko yangoku yophando kubuchwepheshe bokusetyenzwa kwe-SiC kokubini e-China nakwamanye amazwe, kuhlalutya kwaye kuthelekiswe iindlela zokusika, zokusila, kunye neenkqubo zokupolisha, kunye nentsingiselo ye-wafer flatness kunye noburhabaxa bomphezulu. Ikwabonisa imingeni ekhoyo kwi-SiC wafer processing kwaye ixoxa ngemikhombandlela yophuhliso yexesha elizayo.

I-silicon carbide (SiC)Ii-wafers zizixhobo ezisisiseko ezibalulekileyo zezixhobo ze-semiconductor zesizukulwana sesithathu kwaye zibambe ukubaluleka okubalulekileyo kunye nokubanakho kwentengiso kwimimandla efana ne-microelectronics, umbane wamandla, kunye nokukhanya kwe-semiconductor. Ngenxa yobunzima obuphezulu kakhulu kunye nokuzinza kweekhemikhali zeSiC iikristale enye, iindlela zokucubungula ze-semiconductor zendabuko azifanelekanga ngokupheleleyo kwi-machining yazo. Nangona iinkampani ezininzi zamazwe ngamazwe zenze uphando olubanzi malunga nokusetyenzwa okufunwayo kwe-SiC enye yeekristale, itekhnoloji efanelekileyo igcinwa iyimfihlo ngokungqongqo.

Kwiminyaka yakutshanje, i-China iye yandisa iinzame kuphuhliso lwe-SiC enye yezinto zekristale kunye nezixhobo. Nangona kunjalo, ukuqhubela phambili kwetekhnoloji yesixhobo se-SiC elizweni ngoku kuthintelwe yimida ekusetyenzweni kwetekhnoloji kunye nomgangatho we-wafer. Ke ngoko, kubalulekile ukuba iTshayina iphucule izakhono zokusetyenzwa kwe-SiC ukunyusa umgangatho we-SiC enye yee-crystal substrates kunye nokufezekisa ukusetyenziswa kwazo okusebenzayo kunye nokuveliswa kobuninzi.

Awona manyathelo okulungisa angundoqo aquka: ukusika → ukugawula ngokurhabaxa → ukugawula kakuhle → ukugudisa rhabaxa (ukupholisha ngoomatshini) → ukupolisha kakuhle (ukugulisa ngoomatshini, iCMP) → ukuhlola.

| Inyathelo | SiC Wafer Processing | ISemiconductor yesiNtu yokuLungiswa kwezinto eziNye-Crystal |

| Ukusika | Isebenzisa itekhnoloji yokusarha yeentambo ezininzi ukucanda ii-ingots ze-SiC zibe ngamaqhekeza amancinci | Ngokuqhelekileyo isebenzisa iindlela zokusika i-blade yangaphakathi okanye i-diameter yangaphandle |

| Ukusila | Yahlulahlulwe ibe rhabaxa necolekileyo yokusila ukususa amanqaku asarha kunye nomonakalo owenziwe kukusika | Iindlela zokusila zisenokwahluka, kodwa injongo iyafana |

| Ukugudisa | Iquka ukupholishwa okurhabaxa kunye nokuchaneka kakhulu kusetyenziswa umatshini kunye neekhemikhali zokupholisha ngoomatshini (CMP) | Ngokuqhelekileyo kubandakanya i-chemical mechanical polishing (CMP), nangona amanyathelo athile anokwahluka |

Ukusika iiCrystals zeSiC enye

Kwinkqubo yeSiC iikristale enye, ukusika linyathelo lokuqala nelibaluleke kakhulu. Isaphetha se-wafer, i-wafer, kunye nokwahluka kobukhulu obupheleleyo (i-TTV) ephuma kwinkqubo yokusika imisela umgangatho kunye nokusebenza kwemisebenzi yokusila kunye nokupholisha okulandelayo.

Izixhobo zokusika zinokuhlelwa ngokwemilo ngokwedayimani yesarha yangaphakathi (ID) isarha, isarha sangaphandle sedayamitha (OD), iisarha zamabhande kunye neesarha zocingo. Iisarha zocingo, nazo, zinokuhlelwa ngohlobo lwazo lokushukuma zibe ziinkqubo zocingo ezibuyelayo kunye ne-loop (ezingapheliyo). Ngokusekwe kwindlela yokusika i-abrasive, ubuchule bokusika i-wire slicing bunokwahlulwa zibe ziindidi ezimbini: i-abrasive wire sawing yasimahla kunye ne-fixed abrasive diamond wire sawing.

1.1 Iindlela zokusika ngokweSintu

Ubunzulu bokusika be-diameter yangaphandle (OD) i-saws bukhawulelwe ngububanzi be-blade. Ngethuba lenkqubo yokusika, i-blade ixhomekeke kwi-vibration kunye nokuphambuka, okubangelwa amanqanaba aphezulu engxolo kunye nokungahambi kakuhle. I-diameter yangaphakathi (ID) isarha zisebenzisa i-diamond abrasives kwi-circumference yangaphakathi ye-blade njenge-edge yokusika. Ezi blades zinokuba zincinci njenge-0.2 mm. Ngexesha lokusikwa, iblade ye-ID ijikeleza ngesantya esiphezulu ngelixa izinto eziza kunqunyulwa zishukuma ngokusondeleyo kumbindi we-blade, ukuphumeza ukunqunyulwa kwesi ntshukumo sihlobene.

I-diamond band saws ifuna ukuyeka rhoqo kunye nokuguqulwa, kwaye isantya sokusika siphantsi kakhulu-ngokuqhelekileyo asidluli kwi-2 m / s. Baphinde bahlupheke ngokunxiba okubalulekileyo koomatshini kunye neendleko eziphezulu zokugcina. Ngenxa yobubanzi be-saw blade, i-radius yokusika ayikwazi ukuba yincinci, kwaye ukusika iziqwenga ezininzi akunakwenzeka. Ezi zixhobo zesarha zemveli zikhawulelwe bubungqongqo besiseko kwaye azikwazi ukwenza amanxeba agobileyo okanye zithintele iradio ejikayo. Ziyakwazi kuphela ukusikwa ngokuthe tye, ukuvelisa i-kerfs ezibanzi, zinezinga eliphantsi lesivuno, kwaye ngenxa yoko azifanelekanga ukusika.Iikristale zeSiC.

1.2 I-Abrasive Abrasive Wire yabona i-Multi-Wire Cutting

Ubuchule bokusika i-abrasive wire khulula busebenzisa intshukumo ekhawulezayo yocingo ukuthwala uludaka kwi-kerf, ivumela ukususwa kwezinto. Ngokuyintloko isebenzisa ubume obubuyiselayo kwaye okwangoku ikhulile kwaye isetyenziswa ngokubanzi indlela yokusika i-wafer multi-wafer ye-silicon enye yekristale. Nangona kunjalo, ukusetyenziswa kwayo ekusikeni kweSiC kufundwe kancinci.

Iisarha zocingo ezirhabaxa zasimahla zinokusebenza iiwafa ezinobunzima obungaphantsi kwe-300 μm. Banikezela ngelahleko ye-kerf ephantsi, ayifane ibangele ukutshiphuzwa, kwaye ikhokelela kumgangatho olungileyo womphezulu. Nangona kunjalo, ngenxa yendlela yokususa izinto-ngokusekwe kwi-rolling kunye nokufakwa kwe-abrasives-i-wafer surface ithambekele ekuphuhliseni uxinzelelo olubalulekileyo lwentsalela, i-microcracks, kunye neengqimba zomonakalo onzulu. Oku kukhokelela kwi-wafer warping, kwenza kube nzima ukulawula ukuchaneka kweprofayile yomphezulu, kwaye kwandisa umthwalo kumanyathelo okucubungula alandelayo.

Ukusebenza kokusika kuchaphazeleka kakhulu yi-slurry; kuyimfuneko ukugcina ubukhali be-abrasives kunye nokugxilwa kwe-slurry. Unyango oluludaka kunye nokurisayikilisha kuyindleko enkulu. Xa usikwa ii-ingots ezinkulu, ii-abrasives zinobunzima bokungena kwii-kerfs ezinzulu kunye nezide. Ngaphantsi kobukhulu obufanayo obuziinkozo, ilahleko ye-kerf inkulu kuneesarha zocingo ezingagungqiyo.

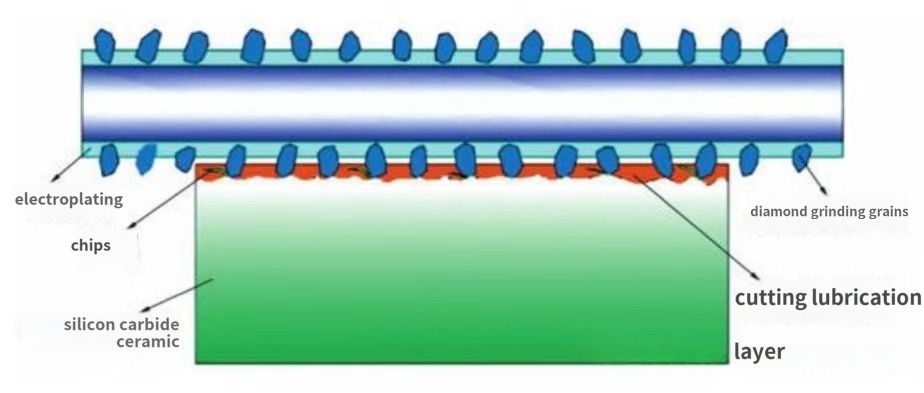

1.3 I-Fixed Abrasive Diamond Wire Saw Multi-Wire Cutting

Iisarha zocingo lwedayimani oluluqilima oluluqilima lwenziwa ngokufakela amasuntswana edayimani kwisiseko socingo lwentsimbi ngokusebenzisa i-electroplating, sintering, okanye iindlela zokubopha intlaka. Iisarha zocingo lwedayimani olwenziwa ngombane zibonelela ngezinto eziluncedo ezinje ngee-kerfs ezicutheneyo, umgangatho ongcono wesilayi, ukusebenza kakuhle okuphezulu, ukungcoliseka okuphantsi, kunye nokukwazi ukusika izinto ezinobunzima obuphezulu.

Isarha yocingo lwedayimani ebuyiselwayo ye-electroplated ngoku yeyona ndlela isetyenziswa kakhulu yokusika iSiC. Umzobo 1 (awuboniswanga apha) ubonisa umphezulu othe tyaba wee-wafers ze-SiC ezisikwe kusetyenziswa obu buchule. Njengoko ukusika kuqhubeka, i-wafer warpage iyanda. Oku kungenxa yokuba indawo yoqhagamshelwano phakathi kocingo kunye nempahla iyanda njengoko ucingo luhamba lusiya ezantsi, ukwandisa ukuxhathisa kunye nokungcangcazela kwecingo. Xa ucingo lufikelela kubukhulu bedayamitha ye-wafer, i-vibration ikwincopho yayo, ekhokelela kubuninzi be-waferpage.

Kumanqanaba okugqibela okusikwa, ngenxa yokukhawuleza kocingo, intshukumo yesantya esizinzileyo, ukuthoba isantya, ukumisa, kunye nokubuyisela umva, kunye nobunzima bokususa inkunkuma ngesipholileyo, umgangatho womphezulu we-wafer uwohloka. Ukuguqulwa kocingo kunye nokuguquguquka kwesantya, kunye namasuntswana amakhulu edayimani kucingo, zezona zizathu ziphambili zokukrweleka komhlaba.

1.4 IThekhnoloji yokwahlula okubandayo

Ukwahlula okubandayo kweekristale ze-SiC enye yinkqubo entsha kwintsimi yesizukulwana sesithathu semiconductor processing material. Kwiminyaka yakutshanje, iye yatsala ingqalelo ebalulekileyo ngenxa yeenzuzo zayo eziphawulekayo ekuphuculeni isivuno kunye nokunciphisa ilahleko yezinto eziphathekayo. Itekhnoloji inokuhlalutywa kwiinkalo ezintathu: umgaqo wokusebenza, ukuhamba kwenkqubo, kunye neenzuzo eziphambili.

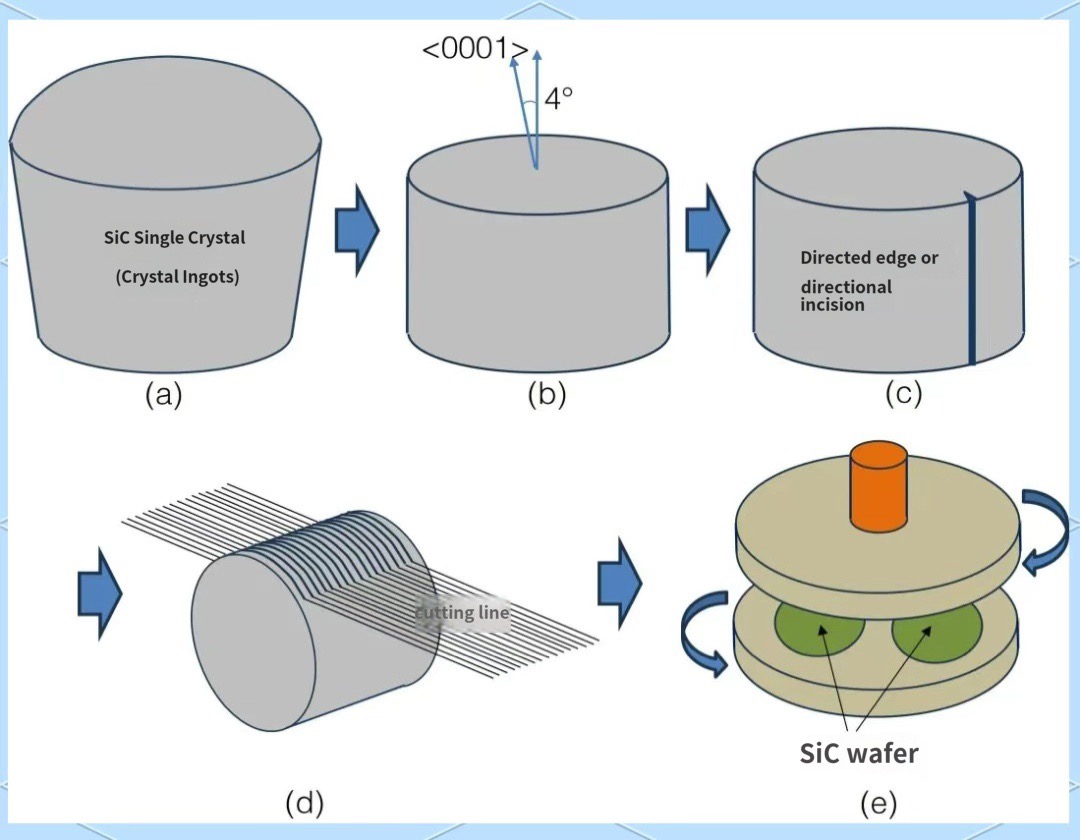

I-Crystal Orientation Determination kunye ne-Outer Diameter Grinding: Ngaphambi kokucubungula, i-crystal orientation ye-ingot ye-SiC kufuneka inqunywe. Ingot ke ibunjwe ibe yicylindrical structure (edla ngokubizwa ngokuba yiSiC puck) ngokusila ngedayamitha yangaphandle. Eli nyathelo libeka isiseko sokusika kwesikhokelo esilandelayo kunye nokusikwa.

I-Multi-Wire Cutting: Le ndlela isebenzisa amaqhekeza abrasive adibeneyo kunye neengcingo zokusika ukusika i-ingot ye-cylindrical. Nangona kunjalo, inengxaki yokulahleka kwekerf ebalulekileyo kunye nemiba yokungalingani komphezulu.

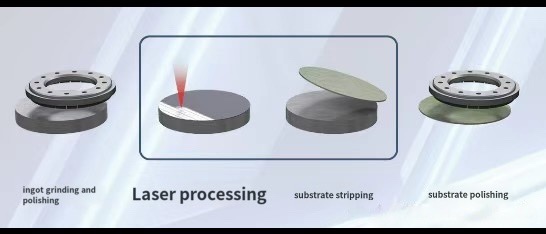

I-Laser Cutting Technology: I-laser isetyenziselwa ukwenza umaleko olungisiweyo ngaphakathi kwekristale, apho iilayiti ezincinci zinokukhutshwa. Le ndlela inciphisa ilahleko yezinto kwaye iphucula ukusebenza kakuhle, iyenza ibe linyathelo elitsha elithembisayo lokusikwa kwe-SiC wafer.

Ukusika inkqubo yokuPhucula

I-Fixed Abrasive Multi-Wire Cutting: Le okwangoku iteknoloji eqhelekileyo, ifaneleke kakuhle iimpawu eziphezulu zobunzima beSiC.

I-Electric Discharge Machining (EDM) kunye neTeknoloji yoLwahlulo olubandayo: Ezi ndlela zibonelela ngezisombululo ezahlukahlukeneyo ezilungiselelwe iimfuno ezithile.

Inkqubo yokupholisha: Kubalulekile ukulungelelanisa izinga lokususa izinto kunye nomonakalo ongaphezulu. I-Chemical Mechanical Polishing (CMP) isetyenziselwe ukuphucula ukufana komphezulu.

Ukubeka iliso ngexesha lokwenyani: Itekhnoloji yokuhlola kwi-Intanethi yaziswa ukujonga uburhabaxa bomphezulu ngexesha lokwenyani.

I-Laser Slicing: Obu buchule bunciphisa ilahleko ye-kerf kwaye bufutshane imijikelo yokusetyenzwa, nangona indawo echaphazelekayo ye-thermal ihlala ingumngeni.

I-Hybrid Processing Technologies: Ukudibanisa iindlela zoomatshini kunye neekhemikhali kwandisa ukusebenza kakuhle.

Le teknoloji sele iphumelele ukusetyenziswa kwezoshishino. U-Infineon, umzekelo, ufumene i-SILTECTRA kwaye ngoku uphethe amalungelo abenzi angundoqo axhasa imveliso yobunzima yee-intshi ezisi-8. E-China, iinkampani ezifana ne-Delong Laser ziphumelele ukusebenza kakuhle kwee-wafers ezingama-30 kwi-ingot nganye yokusetyenzwa kwe-wafer ye-intshi ezi-6, emele uphuculo lwama-40% kwiindlela zesintu.

Njengoko isantya sokwenziwa kwezixhobo zasekhaya, obu buchwephesha kulindeleke ukuba bube sisisombululo esingundoqo sokusetyenzwa kwe-SiC substrate. Ngobubanzi obukhulayo bezinto ze-semiconductor, iindlela zokusika zendabuko ziye zaphelelwa lixesha. Phakathi kweenketho zangoku, ukubuyisela iteknoloji yedayimani yocingo lwedayimani lubonisa awona mathemba athembisayo wesicelo. Ukusika iLaser, njengenkqubo evelayo, ibonelela ngeenzuzo ezibalulekileyo kwaye kulindeleke ukuba ibe yeyona ndlela iphambili yokusika kwixesha elizayo.

2,SiC Single Crystal UkuSila

Njengommeli we-semiconductors yesizukulwana sesithathu, i-silicon carbide (i-SiC) ibonelela ngeenzuzo ezibalulekileyo ngenxa ye-bandap yayo ebanzi, indawo yombane eyophukayo ephezulu, isantya esiphezulu se-electron drift velocity, kunye ne-thermal conductivity egqwesileyo. Ezi propati zenza i-SiC ibe luncedo ngakumbi kwizicelo zombane ophezulu (umzekelo, iimo ze-1200V). Itekhnoloji yokucubungula i-SiC substrates yinxalenye ebalulekileyo yokwenziwa kwesixhobo. Umgangatho ophezulu kunye nokuchaneka kwe-substrate kuchaphazela ngokuthe ngqo umgangatho we-epitaxial layer kunye nokusebenza kwesixhobo sokugqibela.

Injongo ephambili yenkqubo yokugaya kukususa iimpawu ze-surface saw kunye neengqimba zomonakalo obangelwa ngexesha lokuqhawula, kunye nokulungisa i-deformation eyenziwa yinkqubo yokusika. Ngenxa yobunzima obuphezulu kakhulu be-SiC, ukucola kufuna ukusetyenziswa kwe-abrasives eqinile njenge-boron carbide okanye idayimani. Ukusila okuqhelekileyo kwahlulwa ngokwesiqhelo kukusila ngokurhabaxa kunye nokucolwa.

2.1 UkuSila ngokurhabaxa nangokucokisekileyo

Ukusila kungahlelwa ngokusekwe kubungakanani bamasuntswana abrasive:

I-Coarse Grinding: Isebenzisa ii-abrasives ezinkulu ngokuyinhloko ukususa amanqaku e-saw kunye neengqimba zomonakalo owenziwe ngexesha lokusikwa, ukuphucula ukusebenza kakuhle.

Ukucola okucokisekileyo: Kusebenzisa iziqhoboshi ezicolekileyo ukususa umaleko womonakalo oshiywe kukusila ngokurhabaxa, ukunciphisa uburhabaxa bomphezulu, kunye nokuphucula umgangatho womphezulu.

Abenzi abaninzi basekhaya be-SiC substrate basebenzisa iinkqubo ezinkulu zokuvelisa. Indlela eqhelekileyo ibandakanya ukugaya okuphindwe kabini usebenzisa i-cast iron plate kunye ne-monocrystalline diamond slurry. Le nkqubo isusa ngempumelelo umaleko womonakalo oshiywe yisarha yocingo, ilungisa imilo ye-wafer, kwaye inciphisa i-TTV (i-Total Thickness Variation), i-Bow, kunye ne-Warp. Izinga lokususwa kwezinto eziphathekayo lizinzile, ngokuqhelekileyo lifikelela kwi-0.8-1.2 μm / min. Nangona kunjalo, umphezulu we-wafer obangelwa yi-matte kunye noburhabaxa obuphezulu-ngokuqhelekileyo malunga ne-50 nm-nto leyo ibeka iimfuno eziphezulu kumanyathelo okupolisha alandelayo.

2.2 UkuSila kwicala elinye

Iinkqubo zokusila kwicala elinye kuphela icala elinye le-wafer ngexesha. Ngethuba le nkqubo, i-wafer ifakwe kwi-wax kwipleyiti yensimbi. Ngaphantsi koxinzelelo olusetyenzisiweyo, i-substrate idlula i-deformation encinci, kwaye indawo ephezulu iyancipha. Emva kokugaya, umgangatho ophantsi ulinganiswe. Xa uxinzelelo lususiwe, umphezulu ongaphezulu udla ngokubuyela kwisimo sawo sokuqala, nto leyo echaphazela umhlaba osele ungaphantsi komhlaba-obangela ukuba amacala omabini ajike kwaye athobeke ekusicaba.

Ngaphezu koko, ipleyiti yokucola inokujika ibe ngqukuva ngexesha elifutshane, ibangele ukuba iwafa ibe yiconvex. Ukugcina i-flatness yeplate, ukugqoka rhoqo kuyadingeka. Ngenxa yokusebenza kakuhle okuphantsi kunye nokutyeba okulambatha kwe-wafer, ukucola kwicala elinye akufanelanga imveliso yobuninzi.

Ngokuqhelekileyo, # 8000 amavili okugaya asetyenziselwa ukugaya okulungileyo. EJapan, le nkqubo sele ikhulile kwaye isebenzisa #30000 yamavili okupholisha. Oku kuvumela uburhabaxa bomphezulu beewafers ezicutshungulweyo ukuba zifikelele ngaphantsi kwe-2 nm, okwenza ii-wafers zilungele i-CMP yokugqibela (i-Chemical Mechanical Polishing) ngaphandle kokucubungula okongeziweyo.

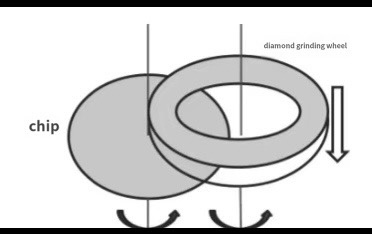

2.3 ITekhnoloji yokuThimba ecalanye

ITekhnoloji yokuThimba yeDayimani eNye-calanye yindlela inoveli yokusila kwicala elinye. Njengoko kubonisiwe kwi-Figure 5 (engaboniswanga apha), inkqubo isebenzisa ipleyiti yokugaya enedayimane. I-wafer ilungiswa nge-vacuum adsorption, ngelixa zombini i-wafer kunye nevili lokusila idayimani zijikeleza ngaxeshanye. Ivili lokusila ngokuthe ngcembe lisiya lisihla ukuze libe bhityile i-wafer ukuya kubukhulu obujoliswe kuko. Emva kokuba elinye icala ligqityiwe, i-wafer iyajikelezwa ukuze iqhube kwelinye icala.

Emva kokubhitya, i-100 mm wafer inokufikelela:

Ugobe <5 μm

TTV < 2 μm

Uburhabaxa bomphezulu < 1 nm

Le ndlela yokusetyenzwa kwe-wafer enye inika uzinzo oluphezulu, ukuhambelana okugqwesileyo, kunye nesantya esiphezulu sokususa izinto. Xa kuthelekiswa nokusila okuphindwe kabini, obu buchule buphucula ukusebenza kakuhle kokusila ngaphezulu kwe-50%.

2.4 UkuSila emacaleni amabini

Ukusila ngamacala amabini kusebenzisa ipleyiti engaphezulu nesezantsi yokusila ngaxeshanye ukucola macala omabini e-substrate, ukuqinisekisa umgangatho obalaseleyo womphezulu kumacala omabini.

Ngethuba lenkqubo, iiplate zokugaya kuqala zifake uxinzelelo kwiindawo eziphezulu ze-workpiece, ezibangela ukuguqulwa kunye nokususwa kwezinto ngokuthe ngcembe kuloo manqaku. Njengoko iindawo eziphakamileyo zilinganisiwe, uxinzelelo kwi-substrate luba lufanayo ngokuthe ngcembe, okubangela ukuguqulwa okungaguqukiyo kuwo wonke umhlaba. Oku kuvumela ukuba iindawo ezingaphezulu nezisezantsi zibe phantsi ngokulinganayo. Emva kokuba ukugaya kugqityiwe kwaye uxinzelelo lukhululiwe, inxalenye nganye ye-substrate ibuyisela ngokufanayo ngenxa yoxinzelelo olulinganayo olufunyenweyo. Oku kukhokelela kwi-warping encinci kunye ne-flatness elungileyo.

Uburhabaxa bomphezulu wewafer emva kokusila buxhomekeke kubukhulu besuntswana elirhabaxa—amasuntswana amancinane avelisa iindawo ezigudileyo. Xa usebenzisa ii-abrasives ze-5 μm zokusila ngamacala amabini, ukuqina kwe-wafer kunye nokuhluka kobunzima kunokulawulwa ngaphakathi kwe-5 μm. Imilinganiselo ye-Atomic Force Microscopy (AFM) ibonisa uburhabaxa bomphezulu (Rq) obumalunga ne-100 nm, enemingxuma yokusila ukuya kuthi ga kwi-380 nm ubunzulu kunye namanqaku abonakalayo emigca abangelwa zizenzo ezirhabaxa.

Indlela ephucuke ngakumbi ibandakanya ukucola okuphindwe kabini kusetyenziswa i-polyurethane foam pads ezidityaniswe ne-polycrystalline diamond slurry. Le nkqubo ivelisa ii-wafers ezinoburhabaxa obuphantsi kakhulu, ukuphumeza i-Ra <3 nm, eluncedo kakhulu ekuphuculeni okulandelayo kwee-substrates ze-SiC.

Nangona kunjalo, ukukrwela umphezulu kuhlala kungumba ongasonjululwanga. Ukongeza, idayimani ye-polycrystalline esetyenziswa kule nkqubo iveliswa ngokuqhushumba kwe-synthesis, engumceli mngeni wobugcisa, ivelisa amanani aphantsi, kwaye ibiza kakhulu.

Ukukhazimliswa kweeCrystals zeSiC enye

Ukufezekisa umgangatho ophakamileyo okhazimlisiweyo kwi-silicon carbide (SiC) wafers, ukupolisha kufuneka kususe ngokupheleleyo imingxuma yokusila kunye ne-nanometer-scale undulations surface. Injongo kukuvelisa indawo egudileyo, engenaziphene ngaphandle kokungcoliseka okanye ukuthotywa, akukho monakalo ongaphantsi komhlaba, kwaye akukho xinzelelo lwamatye olushiyekileyo.

3.1 Ukulungiswa komatshini kunye ne-CMP yeeWafers ze-SiC

Emva kokukhula kwe-SiC eyodwa ye-crystal ingot, iziphene zomhlaba zithintela ukuba zingasetyenziselwa ngokuthe ngqo ukukhula kwe-epitaxial. Ngoko ke, ukuqhubela phambili kuyafuneka. I-ingot iqala ukubunjwa kwifom ye-cylindrical eqhelekileyo ngokujikeleza, emva koko inqunyulwe kwii-wafers usebenzisa ukusika ucingo, ilandelwa yi-crystallographic orientation verification. Ukupholisha linyathelo elibalulekileyo ekuphuculeni umgangatho we-wafer, ukujongana nomonakalo onokuthi ube khona ngenxa yokukhubazeka kwekristale kunye namanyathelo okucubungula kwangaphambili.

Kukho iindlela ezine eziphambili zokususa umaleko womonakalo ongaphezulu kwi-SiC:

Mechanical polishing: Ilula kodwa ishiya imikrwelo; ilungele ukupeyishwa kokuqala.

I-Chemical Mechanical Polishing (CMP): Isusa imikrwelo ngokusebenzisa i-chemical etching; ilungele ukukhazimliswa okuchanekileyo.

I-Hydrogen etching: Ifuna izixhobo ezinzima, ezisetyenziswa ngokuqhelekileyo kwiinkqubo zeHTCVD.

Ipolisha encediswa yiPlasma: Intsonkothile kwaye ayifane isetyenziswe.

Ukupholisha ngoomatshini kuphela kudla ngokubangela imikrwelo, ngelixa ukupholishwa kweekhemikhali kuphela kunokukhokelela ekuhonjisweni okungalinganiyo. I-CMP idibanisa zombini izibonelelo kwaye inikezela ngesisombululo esisebenzayo, esinexabiso eliphantsi.

Umgaqo wokuSebenza we-CMP

I-CMP isebenza ngokujikeleza iwafa phantsi koxinzelelo olusetiyo ngokuchasene nephedi yokupolisha ejikelezayo. Le ntshukumo ehambelanayo, idibaniswe ne-mechanical abrasion evela kwi-nano-size abrasives kwi-slurry kunye nesenzo sekhemikhali ye-reactive agents, ifezekisa i-surface planarization.

Izinto eziphambili ezisetyenzisiweyo:

I-slurry epholishayo: Iqulethe izinto zokuthambisa kunye neekhemikhali.

Iphedi yokupholisha: Iyaphela ngexesha lokusetyenziswa, inciphisa ubungakanani bepore kunye nokusebenza kakuhle kokuhanjiswa kodaka. Ukunxiba rhoqo, ngokuqhelekileyo kusetyenziswa isinxibo sedayimani, kuyafuneka ukubuyisela uburhabaxa.

Inkqubo yeCMP eqhelekileyo

I-Abrasive: 0.5 μm idayimani eludaka

Uburhabaxa bomphezulu ekujoliswe kuwo: ~0.7 nm

Ukukhazimliswa koomatshini beMichiza:

Izixhobo zokuhombisa: AP-810 ipolishe enecala elinye

Uxinzelelo: 200 g/cm²

Isantya seplate: 50 rpm

Isantya somnini weCeramic: 38 rpm

Ukwakheka koludaka:

SiO₂ (30 wt%, pH = 10.15)

0–70 wt% H₂O₂ (30 wt%, ibakala le-reagent)

Lungisa i-pH kwi-8.5 usebenzisa i-5 wt% KOH kunye ne-1 wt% HNO₃

Isantya sokuhamba kwe-slurry: 3 L / min, ijikelezwe kwakhona

Le nkqubo iphucula ngempumelelo umgangatho we-SiC wafer kwaye ihlangabezana neemfuno zeenkqubo ezisezantsi.

Imingeni yobuGcisa kuMatshini wokuPolisha

I-SiC, njenge-bandgap semiconductor ebanzi, idlala indima ebalulekileyo kushishino lombane. Ngeempawu ezigqwesileyo zomzimba kunye neekhemikhali, iikristale ze-SiC enye zilungele iimeko ezingqongileyo ezigqithisileyo, ezinje ngobushushu obuphezulu, amaza omoya aphezulu, amandla aphezulu, kunye nokumelana nemitha. Nangona kunjalo, indalo yayo eqinile kunye ne-brittle inika imiceli mngeni emikhulu yokusila kunye nokupolisha.

Njengabavelisi behlabathi abahamba phambili betshintsha ukusuka kwi-6-intshi ukuya kwi-intshi ezisi-8-intshi, imiba efana nokuqhekeka kunye nomonakalo we-wafer ngexesha lokulungiswa iye yabonakala ngakumbi, ichaphazela kakhulu isivuno. Ukujongana nemingeni yobuchwephesha yee-intshi ezisi-8 ze-SiC substrates ngoku kuluphawu oluphambili lokuqhubela phambili kolu shishino.

Ngexesha le-8-intshi, ukusetyenzwa kwe-wafer ye-SiC ijongene nemingeni emininzi:

I-wafer scaling iyimfuneko ukunyusa imveliso ye-chip ngebhetshi nganye, ukunciphisa ilahleko emphethweni, kunye neendleko eziphantsi zemveliso-ingakumbi xa kunikwa imfuno yokunyuka kwezicelo zemoto yombane.

Ngelixa ukukhula kwe-8-intshi ye-SiC ye-crystals eyodwa ikhulile, iinkqubo zokugqibela ezifana nokusila kunye nokupholisa kusajongene neebhotile, okubangela isivuno esiphantsi (kuphela i-40-50%).

Ii-wafers ezinkulu zifumana ukuhanjiswa koxinzelelo olunzima ngakumbi, onyusa ubunzima bokulawula uxinzelelo lokupolishwa kunye nokungaguquguquki kwesivuno.

Nangona ubukhulu bee-wafers ezi-intshi ezisi-8 busondela kobo be-wafers ezi-intshi ezi-6, zivame ukonakala ngexesha lokuphatha ngenxa yoxinzelelo kunye nokulwa.

Ukunciphisa uxinzelelo olunxulumene nokusika, i-warpage, kunye nokuqhekeka, ukusika kwe-laser kusetyenziswa ngakumbi. Nangona kunjalo:

I-laser yobude obude ibangela umonakalo oshushu.

I-laser yobude obufutshane buvelisa inkunkuma enzima kwaye yenze nzulu umaleko womonakalo, inyusa ukuntsonkotha kokupolisha.

Ukuhamba kokuSebenza koomatshini be-SiC

Uqukuqelo lwenkqubo ngokubanzi lubandakanya:

Ukusika ukuqhelaniswa

Ukusila ngokurhabaxa

Ukusila kakuhle

Ukugulisa oomatshini

I-Chemical Mechanical polishing (CMP) njengenyathelo lokugqibela

Ukhetho lwendlela yeCMP, uyilo lwendlela yenkqubo, kunye nokwandisa iiparamitha kubalulekile. Kwimveliso ye-semiconductor, i-CMP linyathelo elimiselweyo lokuvelisa ii-wafers ze-SiC ezine-ultra-smooth, ezingenasiphako, kunye neendawo ezingenayo umonakalo, eziyimfuneko ekukhuleni kwe-epitaxial ephezulu.

(a) Susa i-ingot ye-SiC kwi-crucible;

(b) Yenza imilo yokuqala usebenzisa isila sangaphandle sokusila;

(c) Qinisekisa ukuqhelaniswa nekristale usebenzisa iiflethi zolungelelwaniso okanye iinotshi;

(d) Sika i-ingot ibe ziziphaluka ezicekethekileyo usebenzisa isarha yocingo oluninzi;

(e) Ukuzuza ukuguda komhlaba okufana nesipili ngokusila kunye namanyathelo okupolisha.

Emva kokugqiba uluhlu lwamanyathelo okucubungula, umda wangaphandle we-SiC wafer uhlala ubukhali, okwandisa umngcipheko wokutshiza ngexesha lokuphatha okanye ukusetyenziswa. Ukuze ugweme ubuthathaka obunjalo, ukugaya umphetho kuyadingeka.

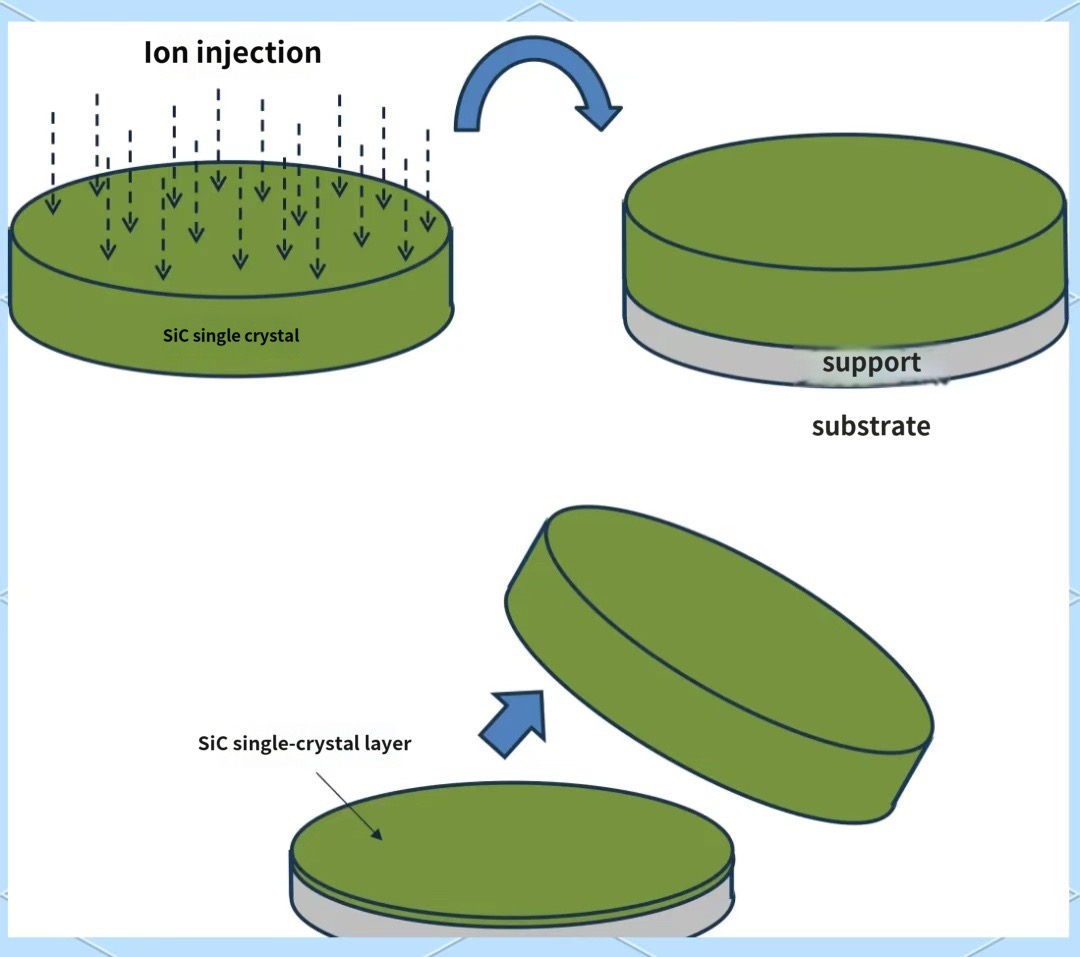

Ukongeza kwiinkqubo zemveli zokusika, indlela entsha yokulungiselela ii-wafers ze-SiC ibandakanya itekhnoloji yokudibanisa. Le ndlela ivumela ukwenziwa kwe-wafer ngokudibanisa i-SiC enye-crystal layer encinci kwi-heterogeneous substrate (i-substrate exhasayo).

Umfanekiso wesi-3 ubonisa ukuhamba kwenkqubo:

Okokuqala, i-delamination layer yenziwa kubunzulu obuchaziweyo kumphezulu we-crystal ye-SiC enye ngokufakelwa kwe-hydrogen ion okanye iindlela ezifanayo. I-crystal ye-SiC esetyenzisiweyo idityaniswe kwi-substrate exhasayo kwaye iphantsi koxinzelelo kunye nobushushu. Oku kuvumela ukudluliselwa ngempumelelo kunye nokwahlulwa kwe-SiC single-crystal layer kwi-substrate exhasayo.

Uluhlu oluhlukeneyo lwe-SiC lufumana unyango olungaphezulu ukuze lufezekise ukunyanzeliswa okufunekayo kwaye lunokusetyenziswa kwakhona kwiinkqubo zokubopha ezilandelayo. Xa kuthelekiswa nokunqunyulwa kwesiqhelo kweekristale ze-SiC, obu buchule bunciphisa imfuno yezinto ezibizayo. Nangona imiceli mngeni yobugcisa isekhona, uphando kunye nophuhliso luqhubela phambili ngenkuthalo ukwenza ukuba imveliso ye-wafer ibe nexabiso eliphantsi.

Ukunikezelwa kobunzima obuphezulu kunye nokuzinza kweekhemikhali ze-SiC-ezenza ukuba zixhathise ukuphendula kwiqondo lokushisa-i-mechanical polishing iyadingeka ukuze kususwe imigodi yokusila kakuhle, ukunciphisa umonakalo ongaphezulu, ukuphelisa imikrwelo, i-pitting, kunye neziphene zamaxolo e-orange, uburhabaxa obungaphantsi komhlaba, ukuphucula ukukhanya, kunye nokuphucula umgangatho ophezulu.

Ukufezekisa umgangatho ophuculweyo okumgangatho ophezulu, kuyimfuneko:

Lungisa iintlobo ze-abrasive,

Nciphisa ubungakanani bamasuntswana,

Lungiselela inkqubo yeeparamitha,

Khetha izixhobo zokupholisha kunye neepads ezinobulukhuni obaneleyo.

Umzobo we-7 ubonisa ukuba i-polish enamacala amabini kunye ne-1 μm abrasives inokulawula ukuguqa kunye nokuhluka kobuninzi ngaphakathi kwe-10 μm, kunye nokunciphisa uburhabaxa bomhlaba malunga ne-0.25 nm.

3.2 Ukulungiswa komatshini weMichiza (CMP)

I-Chemical Mechanical Polishing (CMP) idibanisa i-ultrafine particle abrasion kunye ne-chemical etching ukwenza umphezulu ogudileyo, ocwangcisiweyo kwizinto ezilungiswayo. Umgaqo osisiseko ngulo:

Ukusabela kweekhemikhali kwenzeka phakathi kodaka oluludaka kunye nomphezulu we-wafer, okwenza umaleko othambileyo.

I-friction phakathi kwamaqhekeza abrasive kunye ne-soft layer isusa izinto eziphathekayo.

Iinzuzo zeCMP:

Uyoyisa iingxaki zokupholisa ngoomatshini okanye iikhemikhali,

Ifezekisa isicwangciso sehlabathi kunye nesasekhaya,

Ivelisa imiphezulu enomcaba ophezulu kunye noburhabaxa obuphantsi,

Akushiyi umonakalo womphezulu okanye ongaphantsi komhlaba.

Ngeenkcukacha:

I-wafer iyahamba ngokuhambelana nephedi yokupholisha phantsi koxinzelelo.

I-Nanometer-scale abrasives (umzekelo, i-SiO₂) kwi-slurry ithatha inxaxheba ekuchebeni, ukwenza buthathaka iibhondi ezidibeneyo ze-Si-C kunye nokuphucula ukususwa kwezinto.

Iindidi zoBuchule beCMP:

I-Abrasive polishing yasimahla: Ii-Abrasives (umzekelo, i-SiO₂) zixhonywe eludaka. Ukukhutshwa kwezinto eziphathekayo kwenzeka ngokukrazuka kwemizimba emithathu (i-wafer-pad-abrasive). Ubungakanani be-abrasive (ngokuqhelekileyo i-60-200 nm), i-pH, kunye nobushushu kufuneka ilawulwe ngokuchanekileyo ukuphucula ukufana.

I-Fixed Abrasive Polishing: I-Abrasives ifakwe kwi-pad yokupholisa ukukhusela i-agglomeration-ilungele ukulungiswa okuphezulu.

Ukucocwa kwasemva kokumenyezwa:

Amaqebengwana alungisiweyo ayenzeka:

Ukucoca ngemichiza (kubandakanya amanzi e-DI kunye nokususwa kwentsalela eludaka),

DI ukuhlanjululwa kwamanzi, kunye

Ukomisa initrogen eshushu

ukunciphisa ungcoliseko olungaphezulu.

Umgangatho woMphezulu kunye nokusebenza

Uburhabaxa bomphezulu bunokuncitshiswa ukuya ku-Ra <0.3 nm, ukuhlangabezana neemfuno ze-epitaxy ze-semiconductor.

I-Global Planarization: Ukudityaniswa kokuthamba kweekhemikhali kunye nokususwa ngoomatshini kunciphisa imikrwelo kunye ne-etching engalinganiyo, igqithise iindlela ezisulungekileyo zoomatshini okanye zekhemikhali.

Ukusebenza okuphezulu: Ifanelekile kwizinto ezinzima kunye nezinqabileyo ezifana ne-SiC, kunye namazinga okususwa kwezinto eziphathekayo ngaphezu kwe-200 nm / h.

Olunye uBuchule bokuNgcwelisa obusakhulayo

Ukongeza kwi-CMP, ezinye iindlela ziye zacetywa, kubandakanya:

Electrochemical polishing, Catalyst-incediswa ukugulisa okanye etching, kunye

Ukuguliswa kweTribochemical.

Nangona kunjalo, ezi ndlela zisekwinqanaba lophando kwaye ziphuhliswe kancinci ngenxa yeempawu ze-SiC ezinomngeni.

Ekugqibeleni, ukucutshungulwa kwe-SiC yinkqubo kancinane yokunciphisa i-warpage kunye noburhabaxa ukuphucula umgangatho womphezulu, apho ukuthambeka kunye nokulawula uburhabaxa kubaluleke kakhulu kwisigaba ngasinye.

ITekhnoloji yoLungiso

Ngexesha le-wafer yokusila, i-diamond slurry enobukhulu obuhlukeneyo isetyenziselwa ukucola i-wafer ukuya kwi-flatness efunekayo kunye noburhabaxa bomphezulu. Oku kulandelwa kukupolisha, kusetyenziswa iindlela zombini zoomatshini kunye neekhemikhali zokupholisha ngoomatshini (CMP) ukuvelisa iziphako eziluqilima zesilicon carbide (SiC) ezingenakonakala.

Emva kokupholishwa, ii-wafers ze-SiC zihlolwa ngokungqongqo umgangatho zisebenzisa izixhobo ezinje nge-microscopes kunye ne-X-ray diffractometers ukuqinisekisa ukuba zonke iiparamitha zobugcisa ziyahlangabezana nemigangatho efunekayo. Okokugqibela, ii-wafers ezikhazimlisiweyo zicocwa kusetyenziswa ii-agent ezikhethekileyo zokucoca kunye namanzi e-ultrapure ukususa ungcoliseko olungaphezulu. Ziye zomiswe kusetyenziswa igesi yenitrogen yokusulungeka kwe-ultra-high kunye ne-spin dryers, igqibezela yonke inkqubo yemveliso.

Emva kweminyaka yokuzama, inkqubela phambili ebonakalayo yenziwe kwi-SiC enye yekristale processing ngaphakathi kweTshayina. Ngaphakathi, i-100 mm i-doped semi-insulating ye-4H-SiC i-crystals enye iphuhliswe ngempumelelo, kwaye i-n-uhlobo lwe-4H-SiC kunye ne-6H-SiC i-crystals enye ngoku inokuveliswa kwiibhetshi. Iinkampani ezifana neTankeBlue kunye ne-TYST sele ziphuhlise i-150 mm SiC iikristale enye.

Ngokwetekhnoloji ye-SiC wafer processing, amaziko asekhaya aye avavanya kwangaphambili iimeko zenkqubo kunye neendlela zokusikwa kwekristale, ukucola kunye nokupolisha. Bayakwazi ukuvelisa iisampulu ezihlangabezana neemfuno zokwenziwa kwesixhobo. Nangona kunjalo, xa kuthelekiswa nemigangatho yamazwe ngamazwe, umgangatho wokusetyenzwa komphezulu wee-wafers zasekhaya usasemva kakhulu. Kukho imiba emininzi:

Iithiyori zeSiC zamazwe ngamazwe kunye nobuchwepheshe bokucubungula zikhuselwe ngokuqinileyo kwaye azifumaneki lula.

Kukho ukunqongophala kophando lwethiyori kunye nenkxaso yokuphucula inkqubo kunye nokuphucula.

Iindleko zokungenisa izixhobo zangaphandle kunye namacandelo aphezulu.

Uphando lwasekhaya kuyilo lwezixhobo, ukuchaneka kokulungiswa, kunye nezixhobo zisabonisa izikhewu ezibalulekileyo xa kuthelekiswa namanqanaba amazwe ngamazwe.

Okwangoku, uninzi lwezixhobo ezichanekileyo ezisetyenziswa eTshayina zithunyelwa ngaphandle. Izixhobo zokuvavanya kunye neendlela nazo zifuna ukuphuculwa okungakumbi.

Ngophuhliso oluqhubekayo lwesizukulwana sesithathu semiconductors, ububanzi be-SiC single crystal substrates bukhula ngokuthe ngcembe, kunye neemfuno eziphezulu zomgangatho wokulungiswa komphezulu. Itekhnoloji yokulungisa iWafer iye yaba lelinye lawona manyathelo anomngeni kakhulu emva kokukhula kwekristale enye yeSiC.

Ukujongana nemiceli mngeni ekhoyo ekuqhubeni, kubalulekile ukuqhubela phambili ukufunda iindlela ezibandakanyekayo ekusikeni, ukugalela, kunye nokupholisha, kunye nokuphonononga iindlela ezifanelekileyo zenkqubo kunye neendlela zokwenziwa kwe-SiC wafer. Kwangaxeshanye, kuyafuneka ukuba kufundwe kubuchwephesha obuphambili bokusebenza bamazwe ngamazwe kunye nokwamkela iindlela zangoku ze-ultra-precision machining kunye nezixhobo zokuvelisa ii-substrates ezikumgangatho ophezulu.

Njengoko ubungakanani be-wafer bukhula, ubunzima bokukhula kwekristale kunye nokusetyenzwa nakho kuyenyuka. Nangona kunjalo, ukusebenza kakuhle kokwenziwa kwezixhobo ezisezantsi kuphucula kakhulu, kwaye ixabiso leyunithi liyancitshiswa. Okwangoku, abona bathengisi baphambili beSiC banikezela ngemveliso kwihlabathi liphela ukusuka kwi-intshi ezi-4 ukuya kwi-intshi ezi-6 ububanzi. Iinkampani ezihamba phambili ezifana neCree kunye ne-II-VI sele ziqalile ukucwangcisa ukuphuhliswa kwe-8-inch SiC imigca yokuvelisa i-wafer.

Ixesha lokuposa: May-23-2025