Q: Zeziphi iitekhnoloji eziphambili ezisetyenziswa kwi-SiC wafer slicing kunye nokusetyenzwa?

A:I-silicon carbide (I-SiC) inobulukhuni besibini kuphela kwidayimani kwaye ithathwa njengento enzima kakhulu kunye ne-brittle material. Inkqubo yokusika, ebandakanya ukusika iikristale ezikhulileyo zibe ngamaqhekeza amancinci, kudla ixesha kwaye kulula ukutshiphuza. Njengenyathelo lokuqala lokungenaSiCUkusetyenzwa kwekristale enye, umgangatho wokusika uchaphazela kakhulu ukugaya okulandelayo, ukupolisha, kunye nokuncipha. Ukusika kudla ngokuzisa iintanda ezikumphezulu kunye nezingaphantsi komhlaba, okonyusa izinga lokuqhekeka kwe-wafer kunye neendleko zemveliso. Ke ngoko, ukulawula ukonakala komhlaba ngexesha lokunqunyulwa kubalulekile ekuqhubeleni phambili ukwenziwa kwesixhobo se-SiC.

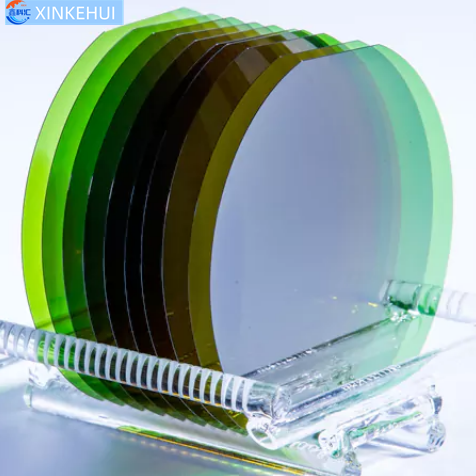

Iindlela ezichazwe ngoku ze-SiC ze-slicing ziquka i-fixed-abrasive, i-free-abrasive slicing, i-laser cut, i-layer transfer (ukwahlula okubandayo), kunye nokukhutshwa kombane. Phakathi kwezi, ukuphindaphinda ukucandwa kweengcingo ezininzi kunye ne-abrasives yedayimani esisigxina yeyona ndlela isetyenziswa kakhulu ekusetyenzweni kweekristale ze-SiC enye. Nangona kunjalo, njengoko ubungakanani be-ingot bufikelela kwi-intshi ezisi-8 nangaphezulu, ukusarha ucingo lwemveli kuye kungabi lula ukusebenza ngenxa yeemfuno eziphezulu zezixhobo, iindleko, kunye nokusebenza okuphantsi. Kukho imfuno engxamisekileyo yexabiso eliphantsi, ilahleko ephantsi, iteknoloji yokusika esebenza kakuhle kakhulu.

Umbuzo: Zeziphi iingenelo zokunqunyulwa kwelaser ngaphezulu kokusika kweentambo ezininzi zesintu?

A: Isarha yocingo yesiNtu isika iI-SiC ingotecaleni kwendlela ethile kwizilayi ezingamakhulu aliqela eemicrons. Izilayi ke ziyagutywa kusetyenziswa i-diamond slurries ukususa amanqaku asarha kunye nomonakalo ongaphantsi komhlaba, kulandelwa yi-chemical mechanical polishing (CMP) ukuphumeza iplani yehlabathi, kwaye ekugqibeleni icocwe ukufumana ii-wafers ze-SiC.

Nangona kunjalo, ngenxa yobunzima obuphezulu be-SiC kunye ne-brittleness, la manyathelo anokubangela ukuba kube lula ukulwa, ukuqhekeka, ukunyuka kwamazinga okuqhekeka, iindleko eziphezulu zokuvelisa, kunye nesiphumo sobunzima obuphezulu kunye nokungcola (uthuli, amanzi amdaka, njl.). Ukongeza, isarha yocingo iyacotha kwaye inesivuno esiphantsi. Uqikelelo lubonisa ukuba i-multi-wire slicing yendabuko ifezekisa kuphela malunga ne-50% yokusetyenziswa kwezinto, kwaye ukuya kuthi ga kwi-75% yezinto ezilahlekileyo emva kokupolisha kunye nokusila. Idatha yangaphambili yemveliso yangaphandle ibonise ukuba kungathatha malunga neentsuku ezingama-273 zokuvelisa iiyure ezingama-24 ukuvelisa ama-wafers angama-10,000-ixesha elide kakhulu.

Ngaphakathi, iinkampani ezininzi zokukhula kwekristale yeSiC zigxile ekwandiseni umthamo weziko. Nangona kunjalo, endaweni yokwandisa imveliso, kubaluleke kakhulu ukuqwalasela indlela yokunciphisa ilahleko-ingakumbi xa izivuno zokukhula kwekristale zingekabikho.

Izixhobo zokusika iLaser zinokunciphisa kakhulu ukulahleka kwezinto kwaye ziphucule isivuno. Umzekelo, usebenzisa enye 20 mmI-SiC ingotUkusarha ngocingo kungavelisa malunga nama-30 amaqhekeza angama-350 μm ubukhulu. Iintsuku ze-10-15 kunye neendlela zendabuko, ezifuna izixhobo eziphezulu kunye neendleko eziphezulu kunye nokusebenza okuphantsi. Phantsi kwezi meko, i-laser slicing's slicing's advantages iyacaca, iyenza iteknoloji yexesha elizayo ye-8-intshi yamawafa.

Ngokusikwa kwe-laser, ixesha lokusika nge-intshi nganye ye-8-intshi ingaba ngaphantsi kwemizuzu engama-20, kunye nokulahlekelwa kwezinto eziphathekayo phantsi kwe-60 μm.

Isishwankathelo, xa kuthelekiswa nokusikwa kweengcingo ezininzi, ukunqunyulwa kwelaser kunika isantya esiphezulu, isivuno esingcono, ilahleko ephantsi yezinto, kunye nokucocwa kokucoca.

Umbuzo: Yeyiphi imiceli mngeni ephambili yobugcisa kwi-SiC laser slicing?

A: Inkqubo yokunqunyulwa kwelaser ibandakanya amanyathelo amabini aphambili: ukuguqulwa kwelaser kunye nokwahlulwa kwewafer.

Undoqo wokuguqulwa kwe-laser kukubunjwa kwe-beam kunye nokwenza ngcono ipharamitha. Iiparamitha ezinje ngamandla e-laser, ububanzi bendawo, kunye nesantya sokuskena zonke zichaphazela umgangatho wokukhutshwa kwezinto kunye nempumelelo yokwahlulwa kwe-wafer okulandelayo. Ijometri yendawo elungisiweyo imisela uburhabaxa bomphezulu kunye nobunzima bokwahlula. Uburhabaxa obuphezulu bomphezulu buyenza ibe nzima ukugaya kamva kwaye kwandisa ilahleko yezinto.

Emva kokuguqulwa, ukwahlukana kwe-wafer ngokuqhelekileyo kufezekiswa ngokusebenzisa amandla okucheba, njengokuqhekeka okubandayo okanye uxinzelelo lomatshini. Ezinye iinkqubo zasekhaya zisebenzisa ii-transducers ze-ultrasonic ukukhuthaza ukungcangcazela kokwahlula, kodwa oku kunokubangela ukuqhawuka kunye neziphene zomda, ukuthoba isivuno sokugqibela.

Nangona la manyathelo mabini angekho nzima ngokwemvelo, ukungahambelani kumgangatho we-crystal-ngenxa yeenkqubo ezahlukeneyo zokukhula, amanqanaba e-doping, kunye nokusabalalisa uxinzelelo lwangaphakathi-kuchaphazela kakhulu ubunzima bokusika, isivuno, kunye nokulahlekelwa kwezinto eziphathekayo. Ukuchonga nje iindawo eziyingxaki kunye nokulungelelanisa iindawo zokuskena i-laser kusenokungaziphuculi kakhulu iziphumo.

Isitshixo sokwamkelwa okubanzi silele ekuphuhliseni iindlela ezintsha kunye nezixhobo ezinokuziqhelanisa noluhlu olubanzi lweempawu zekristale ezivela kubavelisi abahlukeneyo, ukwenza iiparamitha zenkqubo, kunye nokwakha iinkqubo zokusika i-laser ngokusebenza kwendalo yonke.

Umbuzo: Ngaba iteknoloji yokusika i-laser ingasetyenziswa kwezinye izixhobo ze-semiconductor ngaphandle kwe-SiC?

A: Itekhnoloji yokusika iLaser ngokwembali isetyenziswe kuluhlu olubanzi lwezinto. Kwi-semiconductors, ibiqale isetyenziselwa ukudaywa kwe-wafer kwaye ukusukela ngoko yandiswa ukuya kusika iikristale ezininzi.

Ngaphandle kwe-SiC, i-laser slicing ingasetyenziselwa ezinye izinto ezinzima okanye ezinqabileyo ezifana nedayimane, i-gallium nitride (GaN), kunye ne-gallium oxide (Ga₂O₃). Uphononongo lokuqala kwezi zixhobo lubonise ukuba nokwenzeka kunye neenzuzo zokunqunyulwa kwelaser kwizicelo ze-semiconductor.

Umbuzo: Ngaba ngoku kukho iimveliso zezixhobo zokusika i-laser zasekhaya ezivuthiweyo? Uphando lwakho lukweliphi inqanaba?

A:Isixhobo sokusika i-laser ye-SiC esinobubanzi obukhulu sijongwa ngokubanzi njengesixhobo esingundoqo kwikamva le-8-intshi yemveliso ye-SiC ye-wafer. Okwangoku, yiJapan kuphela enokubonelela ngeenkqubo ezinjalo, kwaye ziyabiza kwaye zixhomekeke kwizithintelo zokuthumela ngaphandle.

Imfuno yasekhaya ye-laser slicing / thinning systems iqikelelwa ukuba ibe malunga neeyunithi ze-1,000, ngokusekelwe kwizicwangciso zemveliso ye-SiC kunye nomthamo okhoyo wocingo. Iinkampani ezinkulu zasekhaya zityale imali eninzi kuphuhliso, kodwa akukho zixhobo zasekhaya ezisele zikhulile, ezifumanekayo kurhwebo ezisele zifikelele kushishino.

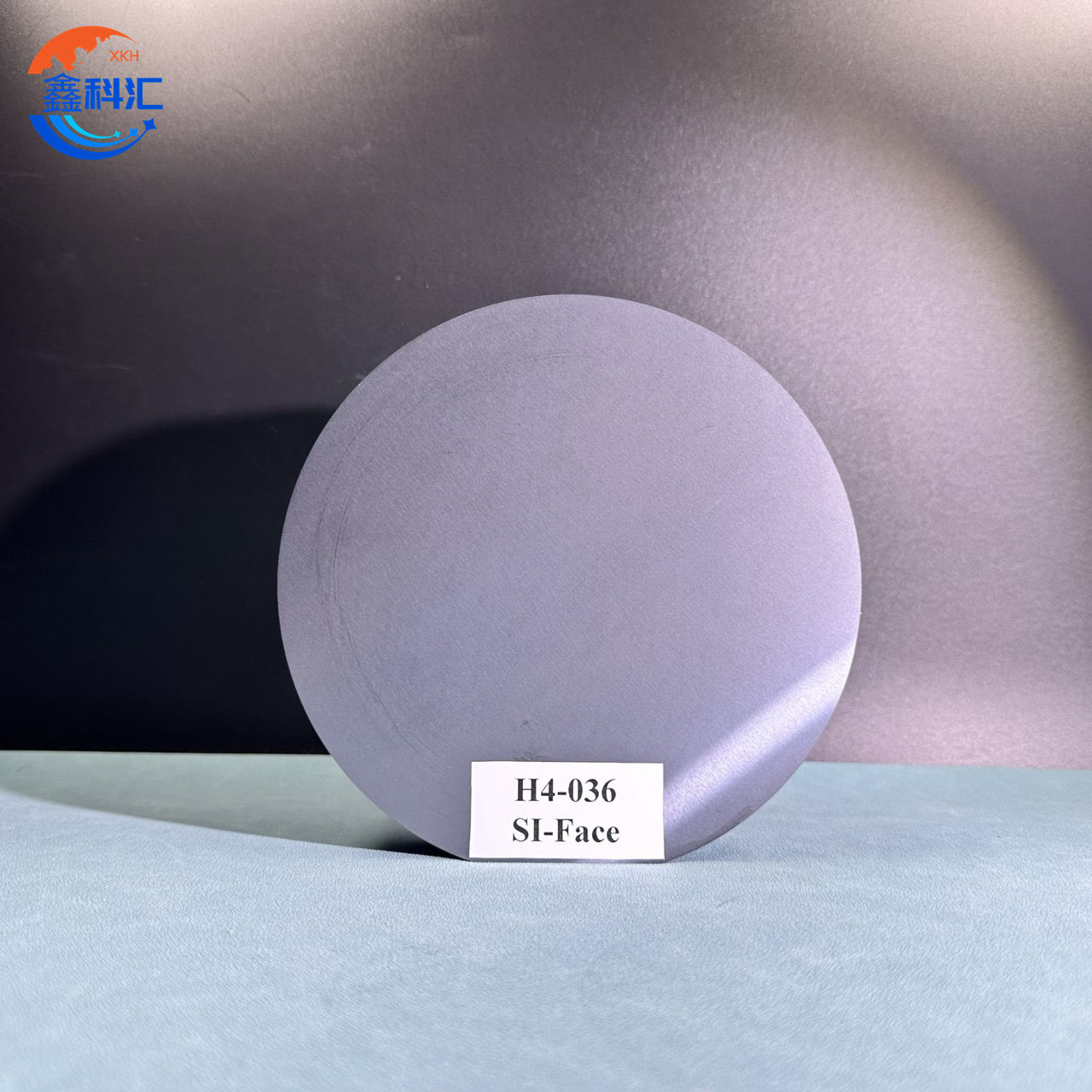

Amaqela ophando aphuhlisa itekhnoloji yokunyuswa kwelaser ukusuka ngo-2001 kwaye ngoku andise oku ukuya kutsho kwidayamitha enkulu yeSiC laser yokusika kunye nokubhitya. Baye baphuhlisa inkqubo yeprototype kunye neenkqubo zokusika ezikwaziyo: Ukusika kunye nokunciphisa i-4-6 intshi semi-insulating SiC wafersSlicing 6–8 inch conductive SiC ingotsPerformance benchmarks:6–8 inch semi-insulating SiC: slicing time 10–15 minutes/wafer; ukulahlekelwa kwezinto <30 μm6-8 intshi ye-SiC eqhubayo: ixesha lokusika i-14-20 imizuzu / i-wafer; ilahleko yezinto eziphathekayo <60 μm

Uqikelelo lwesivuno se-wafer sonyuke ngaphezulu kwe-50%

I-Post-slicing, ii-wafers zihlangabezana nemigangatho yelizwe yejometri emva kokusila kunye nokupholisha. Uphononongo lukwabonisa ukuba iziphumo ze-laser-induced thermal aziluchaphazeli kakhulu uxinzelelo okanye ijometri kwiiwafers.

Kwaesi sixhobo sinye sikwasetyenziselwe ukungqinisisa ukuba ngabanakho ukusika idayimani, iGaN, kunye neGa₂O₃ iikristale enye.

Ixesha lokuposa: May-23-2025