Intshayelelo ye-silicon carbide

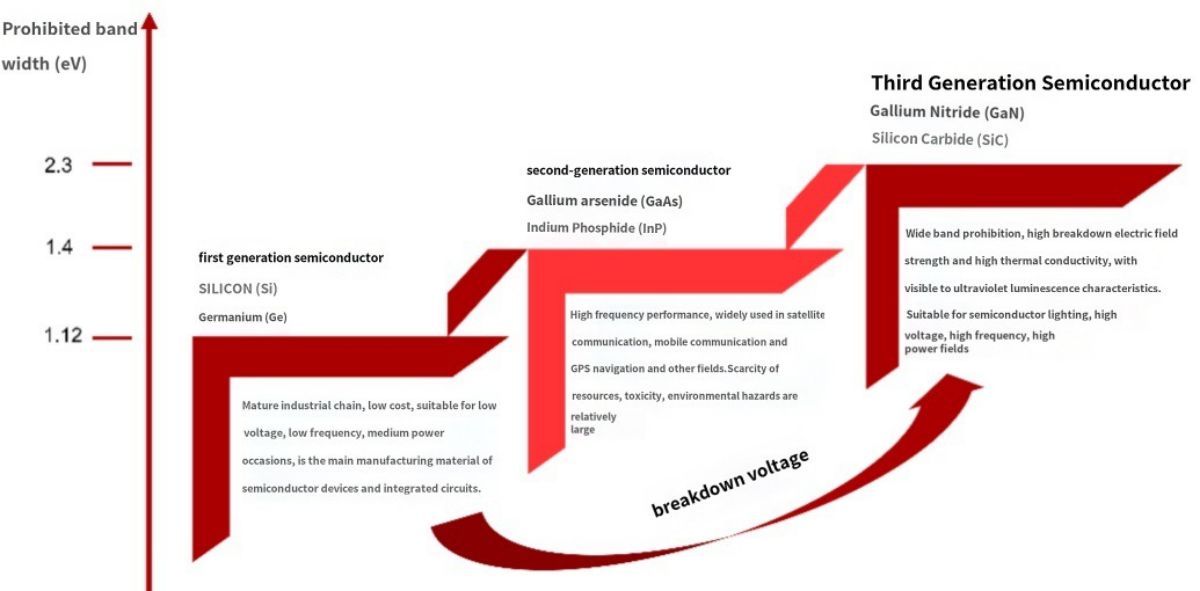

I-Silicon carbide (i-SiC) yimpahla ye-semiconductor edibeneyo eyenziwe ngekhabhoni kunye ne-silicon, enye yezinto ezifanelekileyo zokwenza ukushisa okuphezulu, ukuphindaphinda okuphezulu, amandla aphezulu kunye nezixhobo zombane ophezulu. Xa kuthelekiswa nezinto eziqhelekileyo ze-silicon (Si), i-gap yebhendi ye-silicon carbide yi-3 amaxesha e-silicon. I-conductivity ye-thermal yi-4-5 amaxesha e-silicon; I-voltage yokuqhawula i-8-10 ngamaxesha e-silicon; Umyinge we-electron saturation drift rate yi-2-3 yamaxesha e-silicon, ehlangabezana neemfuno zoshishino lwangoku lwamandla aphezulu, i-voltage ephezulu kunye ne-frequency ephezulu. Isetyenziselwa ikakhulu ukuveliswa kwezixhobo ze-elektroniki ze-high-speed, high-frequency, high-power and light-emitting electronic components. Imimandla yesicelo esezantsi ibandakanya igridi ehlakaniphile, izithuthi zamandla amatsha, amandla omoya omoya we-photovoltaic, unxibelelwano lwe-5G, njl. Ii-silicon carbide diode kunye ne-MOSFETs zisetyenziselwe urhwebo.

Ukumelana nobushushu obuphezulu. Ububanzi be-gap ye-silicon carbide yi-2-3 yamaxesha e-silicon, i-electron akulula ukuyitshintsha kumaqondo obushushu aphezulu, kwaye inokumelana namaqondo okushisa aphezulu, kunye ne-thermal conductivity ye-silicon carbide yi-4-5 yamaxesha e-silicon, okwenza isixhobo sokuchithwa kobushushu kube lula kunye nomda wokushisa ophezulu. Ukumelana nobushushu obuphezulu kunokunyusa kakhulu ubuninzi bamandla ngelixa unciphisa iimfuno kwinkqubo yokupholisa, okwenza i-terminal ibe lula kwaye incinci.

Ukumelana noxinzelelo oluphezulu. Amandla ombane ophukileyo we-silicon carbide ngamaxesha angama-10 kune-silicon, enokumelana nombane ophezulu kwaye ifaneleke ngakumbi kwizixhobo eziphezulu zombane.

Ukuxhathisa amaza aphezulu. I-Silicon carbide inezinga lokukhukuliseka kwe-electron egcweleyo kabini kune-silicon, ebangela ukungabikho komsila wangoku ngexesha lenkqubo yokuvalwa, enokuphucula ngokufanelekileyo ukutshintshwa kwamaxesha esixhobo kunye nokuqaphela i-miniaturization yesixhobo.

Ukulahleka kwamandla aphantsi. Xa kuthelekiswa nezinto zesilicon, i-silicon carbide inokumelana okuphantsi kakhulu kunye nelahleko ephantsi. Kwangelo xesha, ububanzi bebhendi-gap ephezulu yesilicon carbide kunciphisa kakhulu ukuvuza kwangoku kunye nokulahleka kwamandla. Ukongeza, isixhobo se-silicon carbide asinayo into yangoku yokulandela ngexesha lokuvala, kwaye ukulahleka kokutshintsha kuphantsi.

Itsheyini yeshishini le-silicon carbide

Ibandakanya ikakhulu i-substrate, i-epitaxy, uyilo lwesixhobo, ukuvelisa, ukutywinwa njalo njalo. I-Silicon carbide ukusuka kwisixhobo ukuya kwisixhobo samandla se-semiconductor siya kuba nakho ukukhula kwekristale enye, i-ingot slicing, ukukhula kwe-epitaxial, uyilo lwe-wafer, ukuvelisa, ukupakishwa kunye nezinye iinkqubo. Emva kokwenziwa kwe-silicon carbide powder, i-silicon carbide ingot yenziwa kuqala, kwaye emva koko i-silicon carbide substrate ifunyenwe ngokunqunyulwa, ukugaya kunye nokupolisha, kwaye i-epitaxial sheet ifunyenwe ngokukhula kwe-epitaxial. I-epitaxial wafer yenziwe nge-silicon carbide ngokusebenzisa i-lithography, i-etching, i-ion implantation, i-metal passivation kunye nezinye iinkqubo, i-wafer inqunyulwa ibe yifa, isixhobo sihlanganiswe, kwaye isixhobo sidibaniswe kwigobolondo ekhethekileyo kwaye ihlanganiswe kwimodyuli.

Umlambo ophezulu we-industry chain 1: i-substrate - ukukhula kwekristale yikhonkco yenkqubo engundoqo

I-Silicon carbide substrate i-akhawunti malunga ne-47% yeendleko ze-silicon carbide izixhobo, imiqobo ephezulu yokuvelisa i-technical , elona xabiso likhulu, iyona nto ingundoqo ye-industrialization ye-SiC ezayo.

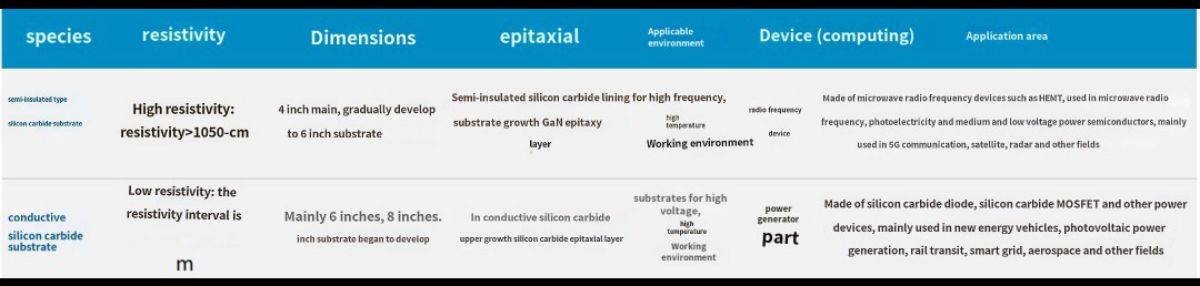

Ukususela kumbono wokungafani kwepropathi ye-electrochemical, izinto ze-silicon carbide substrate zingahlulwa zibe yi-conductive substrates (indawo yokumelana ne-15 ~ 30mΩ · cm) kunye ne-semi-insulated substrates (i-resistivity ephezulu kune-105Ω · cm). Ezi ntlobo zimbini zesubstrates zisetyenziselwa ukuvelisa izixhobo ezidityanisiweyo ezifana nezixhobo zamandla kunye nezixhobo zamaza kanomathotholo ngokulandelelana emva kokukhula kwe-epitaxial. Phakathi kwazo, i-semi-insulated silicon carbide substrate isetyenziswa ikakhulu ekwenzeni izixhobo zeRF ze-gallium nitride, izixhobo zombane kunye nokunye. Ngokukhula kwe-gan epitaxial layer kwi-semi-insulated SIC substrate, ipleyiti ye-sic epitaxial iyalungiswa, enokulungiswa ngakumbi kwi-HEMT gan iso-nitride RF izixhobo. I-conductive silicon carbide substrate isetyenziswa ikakhulu ekwenzeni izixhobo zamandla. Ngokwahlukileyo kwinkqubo yokwenziwa kwesixhobo samandla e-silicon, isixhobo samandla se-silicon carbide asinakwenziwa ngokuthe ngqo kwi-silicon carbide substrate, i-silicon carbide epitaxial layer ifuna ukukhuliswa kwi-conductive substrate ukuze ifumane i-silicon carbide epitaxial sheet, kunye ne-epitaxial layer yenziwa kwi-Schottky diode, i-IOS, kunye nezinye izixhobo ze-FET.

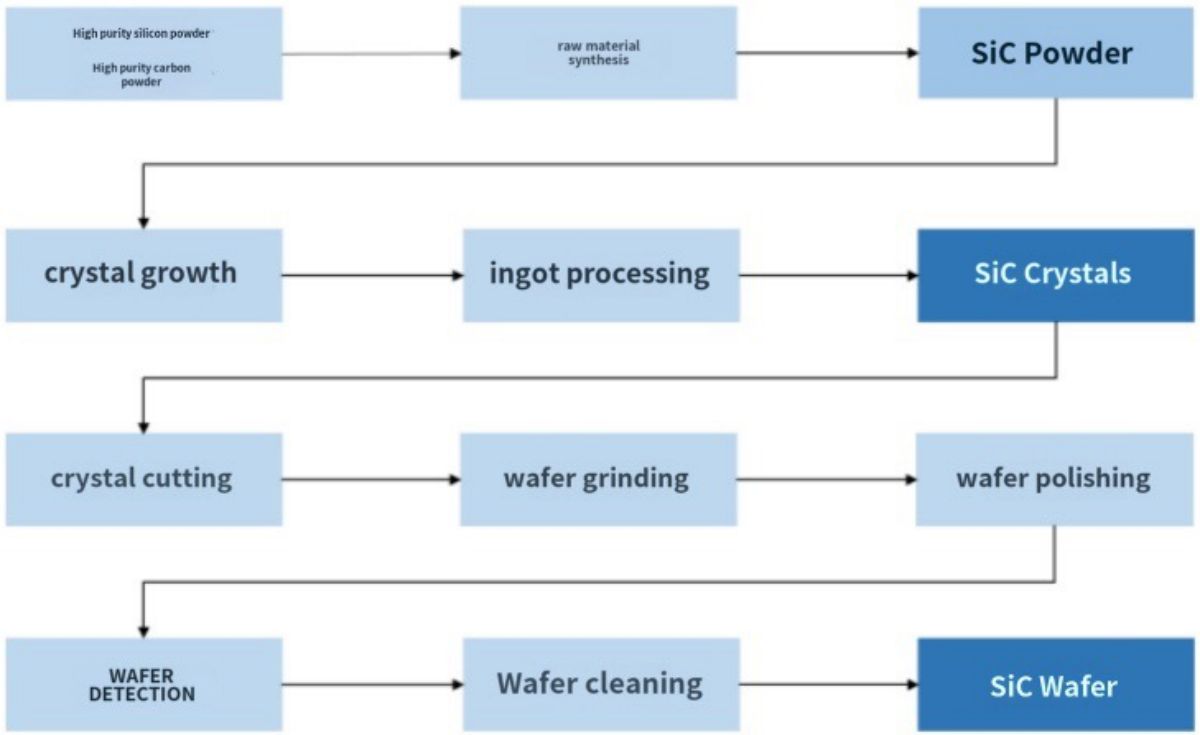

I-silicon carbide powder yadityaniswa ukusuka kwi-carbon powder ecocekileyo kunye ne-silicon powder ecocekileyo, kunye nobukhulu obahlukeneyo be-silicon carbide ingot yakhuliswa phantsi kwentsimi yobushushu obukhethekileyo, emva koko i-silicon carbide substrate yaveliswa ngeenkqubo ezininzi zokusetyenzwa. Inkqubo engundoqo ibandakanya:

I-Raw material synthesis: I-silicon powder ephezulu ecocekileyo + i-toner ixutywe ngokwefomula, kwaye ukusabela kuqhutyelwa kwigumbi lokuphendula phantsi kwemeko yokushisa ephezulu ngaphezu kwe-2000 ° C ukudibanisa amasuntswana e-silicon carbide kunye nohlobo oluthile lwekristale kunye nobukhulu bamasuntswana. Emva koko ngokutyumza, ukukhangela, ukucocwa kunye nezinye iinkqubo, ukuhlangabezana neemfuno zokucoceka okuphezulu kwe-silicon carbide powder ekrwada.

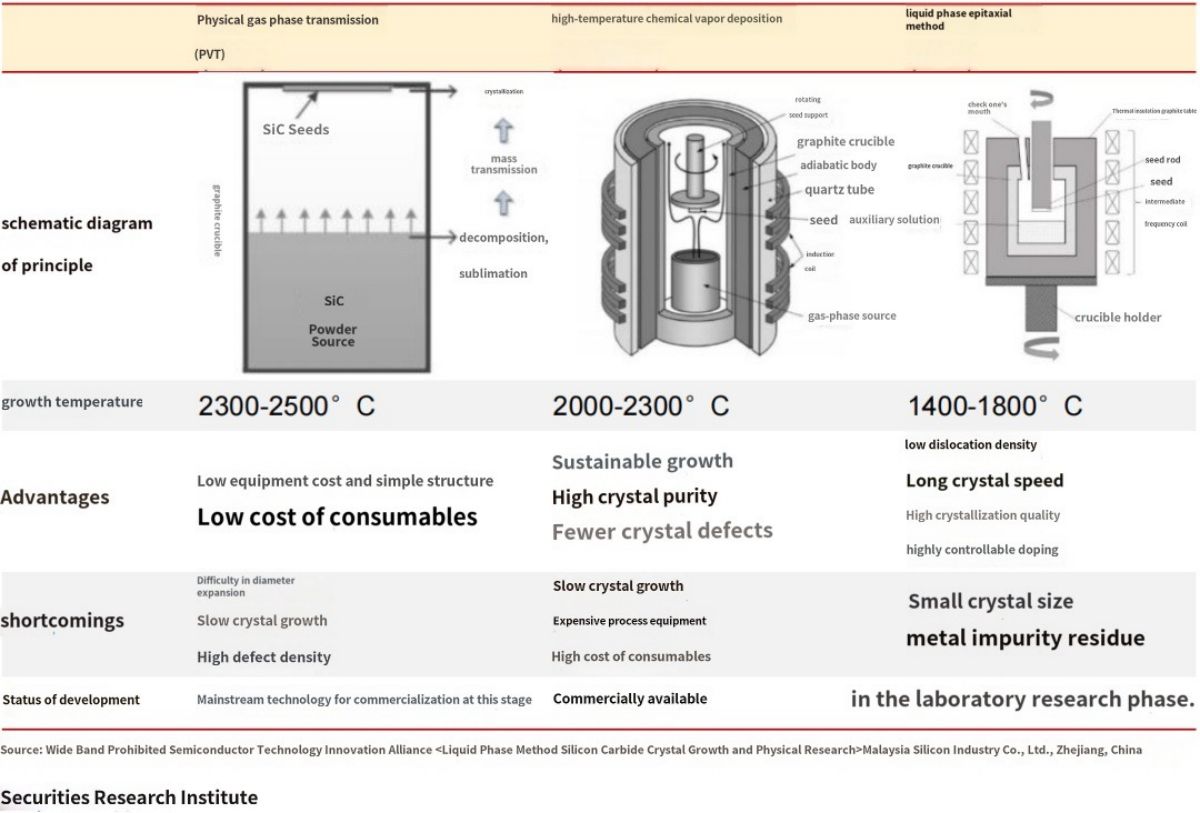

Ukukhula kweCrystal yeyona nkqubo iphambili yokwenziwa kwe-silicon carbide substrate, emisela iimpawu zombane ze-silicon carbide substrate. Okwangoku, iindlela eziphambili zokukhula kwekristale kukudluliselwa komphunga womzimba (PVT), ubushushu obuphezulu bekhemikhali yokubeka umphunga (HT-CVD) kunye ne-epitaxy yesigaba solwelo (LPE). Phakathi kwabo, indlela ye-PVT yindlela eqhelekileyo yokukhula kwezorhwebo ye-SiC substrate okwangoku, kunye nokuvuthwa okuphezulu kwezobugcisa kunye neyona nto isetyenziswa kakhulu kubunjineli.

Ukulungiswa kwe-substrate ye-SiC kunzima, okukhokelela kwixabiso eliphezulu

Ukulawula intsimi yokushisa kunzima: Ukukhula kwe-crystal intonga kufuna kuphela i-1500 ℃, ngelixa i-crystal rod ye-SiC idinga ukukhuliswa kwiqondo lokushisa eliphezulu ngaphezu kwe-2000 ℃, kwaye kukho ngaphezu kwe-250 i-isomers ye-SiC, kodwa i-4H-SiC engundoqo isakhiwo se-crystal enye yokuveliswa kwezixhobo zamandla, ukuba ayisiyiyo ulawulo oluchanekileyo, luya kufumana ezinye izakhiwo ze-crystal. Ukongeza, i-gradient yeqondo lokushisa kwi-crucible inquma izinga lokudluliselwa kwe-SiC sublimation kunye nokuhlelwa kunye nemodi yokukhula kwee-athomu zegesi kwi-crystal interface, echaphazela izinga lokukhula kwekristale kunye nomgangatho we-crystal, ngoko ke kuyimfuneko ukwenza iteknoloji yokulawula intsimi yokushisa. Xa kuthelekiswa nezinto ze-Si, umahluko kwimveliso ye-SiC ikwakwinkqubo yobushushu obuphezulu njengokufakelwa kwe-ion yobushushu obuphezulu, i-oxidation yobushushu obuphezulu, ukusebenza kobushushu obuphezulu, kunye nenkqubo yemaski enzima efunwa zezi nkqubo zobushushu obuphezulu.

Ukukhula kwe-crystal ecothayo: izinga lokukhula kwe-Si crystal rod linokufikelela kwi-30 ~ 150mm / h, kunye nokuveliswa kwe-1-3m ye-silicon crystal rod ithatha kuphela malunga nosuku lwe-1; I-SiC crystal rod kunye nendlela ye-PVT njengomzekelo, izinga lokukhula li malunga ne-0.2-0.4mm / h, iintsuku ezi-7 zikhula ngaphantsi kwe-3-6cm, izinga lokukhula lingaphantsi kwe-1% yezinto ze-silicon, amandla okuvelisa alinganiselwe kakhulu.

Iiparamitha zemveliso ephezulu kunye nesivuno esiphantsi: i-parameters engundoqo ye-SiC substrate ibandakanya ukuxinana kwe-microtubule, ukuxinana kwe-dislocation, resistivity, warpage, surface roughness, njl. Bubunjineli benkqubo entsonkothileyo ukulungiselela ii-athomu kwigumbi elivaliweyo lobushushu obuphezulu kunye nokukhula okupheleleyo kwekristale, ngelixa ulawula izalathisi zeparameter.

Izinto eziphathekayo zinobunzima obuphezulu, ubude obuphezulu, ixesha elide lokusika kunye nokugqoka okuphezulu: Ukuqina kwe-SiC Mohs ye-9.25 okwesibini kuphela kwidayimane, okukhokelela ekunyuseni okukhulu kobunzima bokusika, ukugawula kunye nokupolisha, kwaye kuthatha malunga neeyure ze-120 ukusika i-35-40 iingcezu ze-3cm ye-ingot enzima. Ukongeza, ngenxa yobunzima obuphezulu be-SiC, ukunxiba kwe-wafer processing kuya kuba ngaphezulu, kwaye umlinganiselo wokuphuma umalunga nama-60%.

Indlela yophuhliso: Ukunyuka kobungakanani + ukuhla kwexabiso

Imakethi ye-SiC yehlabathi jikelele i-6-intshi yokuvelisa umthamo iyakhula, kwaye iinkampani ezikhokelayo zingene kwimarike ye-intshi ezi-8. Iiprojekthi zophuhliso lwasekhaya zizii-intshi ezi-6 ubukhulu becala. Okwangoku, nangona uninzi lweenkampani zasekhaya zisasekelwe kwimigca yemveliso ye-intshi ezi-4, kodwa ishishini liya lisanda ukuya kutsho kwi-intshi ezi-6, kunye nokuvuthwa kwe-6-intshi exhasa iteknoloji yezixhobo ezixhasayo, iteknoloji ye-substrate ye-SiC yasekhaya iphucula ngokuthe ngcembe uqoqosho lobungakanani bemigca yemveliso yobukhulu obukhulu iya kubonakala, kwaye isithuba sangoku sasekhaya se-6-intshi sinciphise ukuya kwiminyaka eyi-7. Isayizi enkulu ye-wafer inokuzisa ukwanda kwenani leetshiphusi enye, ukuphucula izinga lesivuno, kunye nokunciphisa umlinganiselo we-chips edge, kunye neendleko zophando kunye nophuhliso kunye nelahleko yesivuno iya kugcinwa malunga ne-7%, ngaloo ndlela iphucula ukusetyenziswa kwe-wafer.

Kusekho ubunzima obuninzi kuyilo lwesixhobo

Ukuthengiswa kwe-SiC diode kuphuculwe ngokuthe ngcembe, okwangoku, inani labakhiqizi basekhaya baye baqulunqa iimveliso ze-SiC SBD, i-voltage ephakathi kunye nephezulu yeemveliso ze-SiC SBD zinozinzo oluhle, kwi-OBC yesithuthi, ukusetyenziswa kwe-SiC SBD + SI IGBT ukufezekisa ubuninzi obuzinzile. Okwangoku, akukho zithintelo kwi-patent design yeemveliso ze-SiC SBD e-China, kwaye i-gap kunye namazwe angaphandle incinci.

I-SiC MOS isenobunzima obuninzi, kusekho umsantsa phakathi kwe-SiC MOS kunye nabavelisi baphesheya kweelwandle, kwaye iqonga lokuvelisa elichaphazelekayo lisakhiwa. Okwangoku, i-ST, i-Infineon, i-Rohm kunye nezinye i-600-1700V i-SiC MOS ziye zazuza imveliso eninzi kwaye zasayinwa kwaye zathunyelwa kunye namashishini amaninzi okuvelisa, ngelixa i-design yangoku ye-SiC MOS yasekhaya sele igqityiwe ngokusisiseko, inani labavelisi boyilo basebenza ngeefabs kwinqanaba lokuhamba kwe-wafer, kwaye kamva ukuqinisekiswa kwabathengi kusafuna ixesha elithile, ngoko kusekho ixesha elide lokuthengisa.

Okwangoku, ulwakhiwo olucwangcisiweyo lukhetho oluqhelekileyo, kwaye uhlobo lomsele lusetyenziswa ngokubanzi kwintsimi yoxinzelelo oluphezulu kwixesha elizayo. Ulwakhiwo Planar SiC MOS abavelisi baninzi, isakhiwo planar akukho lula ukuvelisa iingxaki zokuwohloka zendawo xa kuthelekiswa negroove, echaphazela uzinzo umsebenzi, kwimarike ngezantsi 1200V inoluhlu olubanzi ixabiso lesicelo, kwaye isakhiwo planar ilula ngokwentelekiso kwisiphelo sokuvelisa, ukuhlangabezana manufacturability kunye nolawulo iindleko imiba emibini. Isixhobo se-groove sinezibonelelo ze-parasitic inductance ephantsi kakhulu, isantya sokutshintsha ngokukhawuleza, ilahleko ephantsi kunye nokusebenza okuphezulu.

2--SiC wafer iindaba

Ukuveliswa kweemarike ze-silicon carbide kunye nokukhula kwentengiso, nikela ingqalelo ukungalingani kwesakhiwo phakathi kokubonelela kunye nemfuno

Ngokukhula okukhawulezayo kwemfuno yentengiso ye-high-frequency kunye ne-high-power power powers, umda we-electronic limit bottleneck we-silicon-based semiconductor izixhobo ziye zavela ngokuthe ngcembe, kwaye izixhobo ze-semiconductor zesizukulwana sesithathu ezimelwe yi-silicon carbide (SiC) ngokuthe ngcembe ziye zakhula. Ngokwembono yokusebenza kwezinto, i-silicon carbide inamaxesha ama-3 ububanzi bebhendi ye-silicon, amaxesha ali-10 amandla ombane wokuqhekeka okubalulekileyo, amaxesha ama-3 ukuguquguquka kwe-thermal, ngoko ke izixhobo zamandla e-silicon carbide zifanelekile kwi-frequency ephezulu, uxinzelelo oluphezulu, ubushushu obuphezulu kunye nezinye izicelo, ukunceda ukuphucula ukusebenza kunye nokuxinana kwamandla eenkqubo zombane zamandla.

Okwangoku, ii-SiC diodes kunye ne-SiC MOSFET ziye zafudukela ngokuthe ngcembe kwimarike, kwaye kukho iimveliso ezivuthiweyo, phakathi kwazo ii-diode ze-SiC zisetyenziswa ngokubanzi endaweni ye-silicon-based diode kwezinye iindawo ngenxa yokuba abanayo inzuzo yokuhlawulela ukubuyisela umva; I-SiC MOSFET iphinda isetyenziswe ngokuthe ngcembe kwiimoto, ukugcinwa kwamandla, imfumba yokutshaja, i-photovoltaic kunye nezinye iindawo; Kwintsimi yezicelo zeemoto, indlela yokumodareyitha iya ivelele ngakumbi, ukusebenza okuphezulu kwe-SiC kufuneka kuxhomekeke kwiinkqubo zokupakisha eziphambili ukuze kuphunyezwe, ngokobuchwephesha kunye nokutywinwa kwegobolondo eliqolileyo njengento eqhelekileyo, ikamva okanye uphuhliso lokutywinwa kweplastiki, iimpawu zayo zophuhliso ezilungelelanisiweyo zifanelekile ngakumbi kwiimodyuli zeSiC.

Ixabiso le-Silicon carbide liyancipha isantya okanye ngaphaya kokucinga

Ukusetyenziswa kwezixhobo ze-silicon carbide kunqunyelwe kakhulu kwiindleko eziphezulu, ixabiso le-SiC MOSFET phantsi kwenqanaba elifanayo liphindwe ka-4 ngaphezu kwe-Si-based IGBT, oku kungenxa yokuba inkqubo ye-silicon carbide inzima, apho ukukhula kwekristale enye kunye ne-epitaxial ayinzima nje kuphela kwindalo, kodwa izinga lokukhula lihamba kade, kunye nenkqubo yokusika i-crystal ye-substrate kufuneka ihambe kwi-substrate process. Ngokusekelwe kwiimpawu zayo eziphathekayo kunye nobuchwepheshe bokucwangcisa obungavuthiweyo, isivuno se-substrate yasekhaya singaphantsi kwama-50%, kwaye izinto ezahlukeneyo zikhokelela kwi-substrate ephezulu kunye namaxabiso e-epitaxial.

Nangona kunjalo, ukubunjwa kweendleko zezixhobo ze-silicon carbide kunye nezixhobo ezisekelwe kwi-silicon zichasene kakhulu, i-substrate kunye neendleko ze-epitaxial ze-akhawunti ye-channel yangaphambili ye-47% kunye ne-23% yesixhobo sonke, ngokulandelelanayo, malunga ne-70%, ukuyila kwesixhobo, ukuvelisa kunye nokutywinwa kwamakhonkco e-akhawunti ye-channel yangasemva kuphela kwe-30%, iindleko zokuvelisa kwi-channel ye-concentrate ye-silicon-based . I-50%, kwaye iindleko ze-substrate zithatha kuphela i-7%. Isenzeko sexabiso le-silicon carbide industry chain upside down ithetha ukuba abavelisi be-epitaxy abaphezulu be-substrate banelungelo elingundoqo lokuthetha, eyona nto ingundoqo kwi-layout yamashishini asekhaya nakwamanye amazwe.

Ukusuka kwimbono eguquguqukayo kwimarike, ukunciphisa iindleko ze-silicon carbide, ukongeza ekuphuculeni i-silicon carbide crystal ende kunye nenkqubo yokusika, kukwandisa ubungakanani be-wafer, ekwayindlela evuthiweyo yophuhliso lwe-semiconductor kwixesha elidlulileyo, idatha ye-Wolfspeed ibonisa ukuba i-silicon carbide substrate iphucula ukusuka kwi-intshi ezi-6 ukuya kwi-intshi ezi-8 ukuya kwi-80% yokwandisa i-chip kunye ne-80% yokuvelisa i-chip. ukuphucula isivuno. Inokunciphisa ixabiso leyunithi edibeneyo ngama-50%.

I-2023 yaziwa ngokuba yi "8-intshi yeSiC kunyaka wokuqala", kulo nyaka, abavelisi be-silicon carbide basekhaya nabangaphandle bakhawulezisa ukubekwa kwe-8-intshi ye-silicon carbide, efana ne-Wolfspeed investment crazy ye-14.55 yeebhiliyoni zeedola zase-US zokwandiswa kwemveliso ye-silicon carbide, inxalenye ebalulekileyo yokwakhiwa kwe-8-intshi ye-intshi ye-intshi ye-SiC 20 yokuqinisekisa i-intshi ye-intshi ye-SiC. kwiinkampani ezininzi; I-Domestic Tianyue Advanced kunye ne-Tianke Heda baye basayina izivumelwano zexesha elide kunye ne-Infineon ukubonelela ngee-8-intshi ze-silicon carbide substrates kwixesha elizayo.

Ukuqala kulo nyaka, i-silicon carbide iya kukhawulezisa ukusuka kwi-intshi ezi-6 ukuya kwi-intshi ezi-8, i-Wolfspeed ilindele ukuba ngo-2024, ixabiso leyunithi ye-chip ye-8 intshi substrate xa kuthelekiswa nexabiso leyunithi ye-intshi ye-intshi engu-6 kwi-substrate ngo-2022 iya kuncitshiswa ngaphezu kwe-60%, kunye nokuncipha kweendleko zophando ziya kuvula idatha ye-Consul yesicelo ngaphandle, i-data ye-Ji Bond iya kuvula i-intshi yesicelo. Isabelo semarike yangoku yeemveliso ze-intshi ezi-8 zingaphantsi kwe-2%, kwaye isabelo semarike kulindeleke ukuba sikhule malunga ne-15% ngo-2026.

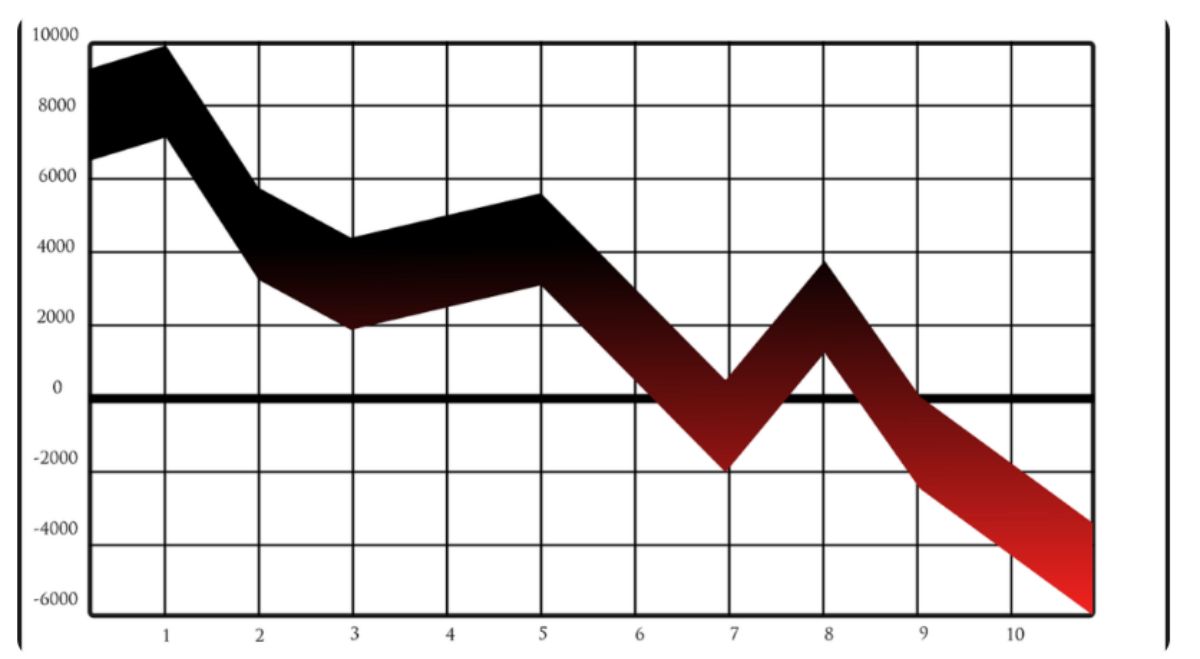

Enyanisweni, izinga lokuhla kwexabiso le-silicon carbide substrate lingadlula ingcamango yabantu abaninzi, ukunikezelwa kwemarike yangoku ye-6-intshi substrate yi-4000-5000 yuan / iqhekeza, xa kuthelekiswa nokuqala konyaka kuye kwawa kakhulu, kulindeleke ukuba kuwele ngaphantsi kwe-yuan engama-4000 kunyaka ozayo, kuyafaneleka ukuqaphela ukuba umgca wentengiso uye wanciphisa ixabiso lokuqala kubakhiqizi, ixabiso lentengiso liye lanciphisa kuqala. imodeli yemfazwe yexabiso, ikakhulu egxininiswe kubonelelo lwe-silicon carbide substrate yanele kwintsimi ye-voltage ephantsi, abavelisi basekhaya nabangaphandle bandisa ngamandla umthamo wemveliso, okanye bavumele i-silicon carbide substrate igqithise inqanaba ngaphambi kokuba kucingelwa.

Ixesha lokuposa: Jan-19-2024