Iikristale zodwa zinqabile kwindalo, kwaye nangona zisenzeka, zihlala zincinci kakhulu-ngokuqhelekileyo kwi-millimeter (mm) isikali-kwaye kunzima ukuzifumana. Iidayimani ezixeliweyo, ii-emeralds, ii-agates, njl. uninzi luboniswa kwiimyuziyam ukuze luboniswe. Nangona kunjalo, ezinye iikristale enye zibamba ixabiso elibalulekileyo kwimizi-mveliso, njenge-silicon yekristale enye kumzi-mveliso wesekethe edibeneyo, isafire edla ngokusetyenziswa kwiilensi zamehlo, kunye nesilicon carbide, efumana amandla kwi-semiconductors yesizukulwana sesithathu. Ukukwazi ukuvelisa ngobuninzi ezi kristale enye kwimizi-mveliso ayibonisi kuphela amandla kumashishini kunye nobuchwepheshe besayensi kodwa ikwaluphawu lobutyebi. Imfuneko ephambili yokuveliswa kwekristale enye kwishishini ubukhulu obukhulu, njengoko oku kungundoqo ekunciphiseni iindleko ngokufanelekileyo. Apha ngezantsi kukho iikristale eziqhele ukudibana nazo kwimarike:

1. Ikristale enye yeSapphire

I-crystal eyodwa yeSapphire ibhekisela kwi-α-Al₂O₃, ene-hexagonal crystal system, ubunzima be-Mohs be-9, kunye neepropati ezizinzileyo zeekhemikhali. Ayinyibiliki kulwelo oluneasidi okanye ialkaline edlekayo, imelana nobushushu obuphezulu, kwaye ibonisa ukuhanjiswa kokukhanya okugqwesileyo, ukuhanjiswa kwe-thermal, kunye nokugqunywa kombane.

Ukuba ii-Al ions kwikristale zitshintshwa yi-Ti kunye ne-Fe ion, i-crystal ibonakala iluhlaza okwesibhakabhaka kwaye ibizwa ngokuba yisafire. Ukuba ithathelwe indawo yiCr ions, ibonakala ibomvu kwaye ibizwa ngokuba yiruby. Nangona kunjalo, isafire yeshishini icocekile i-α-Al₂O₃, ayinambala kwaye iyabonakala, ngaphandle kokungcola.

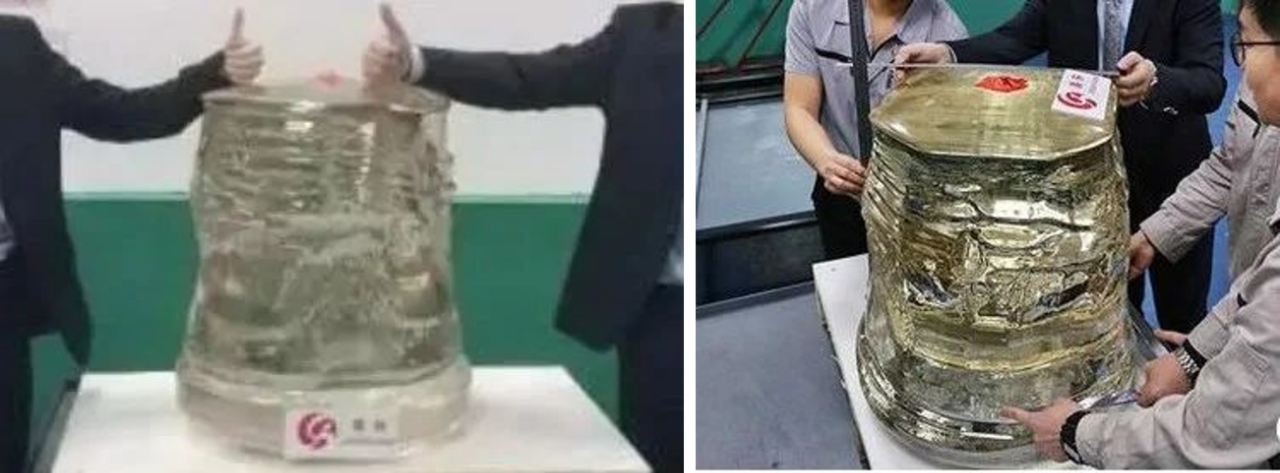

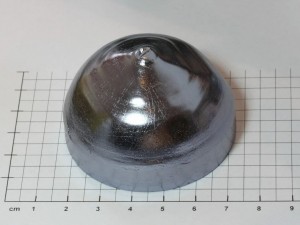

Isafire yeshishini ngokuqhelekileyo ithatha imo yeewafers, 400-700 μm ubukhulu kunye ne-4-8 intshi ubukhulu. Ezi zaziwa njengee-wafers kwaye zisikwa kwii-crystal ingots. Kuboniswe ngezantsi i-ingot esandula ukutsalwa kwiziko elinye lekristale, elingekagudiswa okanye lisikwe.

Ngo-2018, iNkampani ye-elektroniki ye-Jinghui e-Inner Mongolia ikhulise ngempumelelo eyona kristale yesafire ye-450 kg yehlabathi. Eyona crystal inkulu yangaphambili yesafire kwihlabathi jikelele yayiyi-350 kg yekristale eveliswe eRussia. Njengoko kubonwe emfanekisweni, le kristale inesimo esiqhelekileyo, ibonakala ngokucacileyo, ayinamaqhekeza kunye nemida yengqolowa, kwaye inamaqamza ambalwa.

2. ISilicon yeCrystal enye

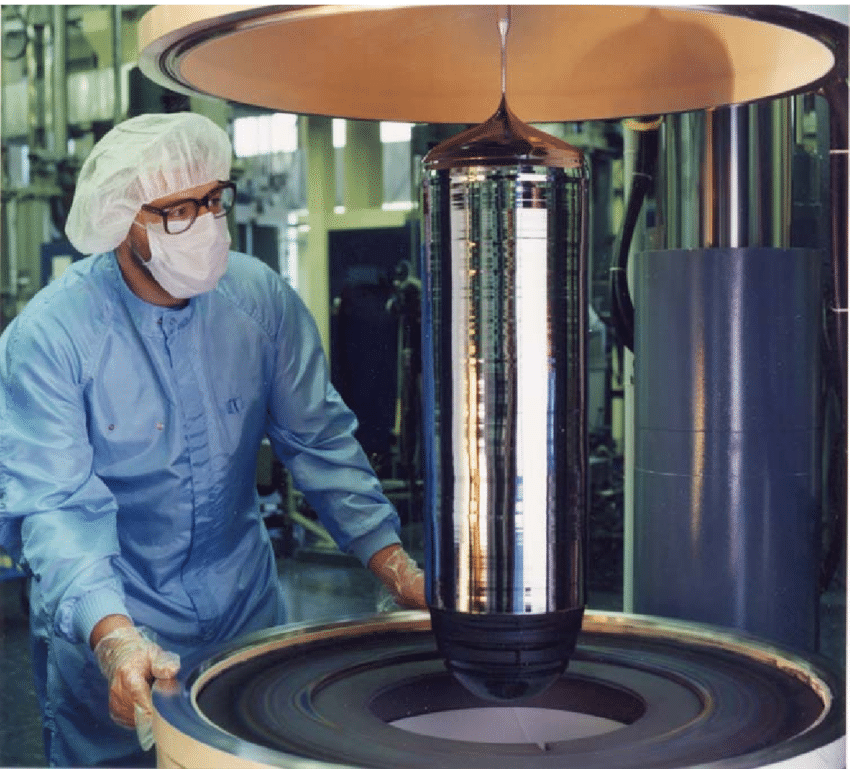

Okwangoku, i-silicon enye ye-crystal esetyenziselwa i-chips yesekethe edibeneyo inobunyulu be-99.9999999% ukuya kwi-99.999999999% (9-11 nines), kunye ne-420 kg ye-silicon ingot kufuneka igcine isakhiwo esifanelekileyo njengedayimane. Ngokwendalo, nedayimane enye (200 mg) yedayimani inqabile.

Imveliso yehlabathi ye-single-crystal ingots ye-silicon ilawulwa ziinkampani ezinkulu ezintlanu: iShin-Etsu yaseJapan (28.0%), i-SUMCO yaseJapan (21.9%), i-GlobalWafers yaseTaiwan (15.1%), i-SK Siltron yaseMzantsi Korea (11.6%), kunye ne-Siltronic yaseJamani (11.3%). Noyena mvelisi mkhulu we-semiconductor wafer kwi-China, i-NSIG, ibambe kuphela malunga ne-2.3% yesabelo semarike. Nangona kunjalo, njengomntu omtsha, amandla ayo akufanele ajongelwe phantsi. Ngo-2024, i-NSIG iceba ukutyala imali kwiprojekthi yokuphucula i-300 mm yemveliso ye-silicon ye-wafer yeesekethe ezidibeneyo, kunye nokutya okuqikelelweyo kwe-¥ 13.2 yezigidigidi.

Njengemathiriyeli ekrwada yeetshiphusi, ii-ingots ze-silicon ezicwengileyo eziphakamileyo zisuka kwi-intshi ezi-6 ukuya kwi-intshi ezili-12. Iziseko eziphambili ze-chip zamazwe aphesheya, ezinje nge-TSMC kunye ne-GlobalFoundries, zenza iichips ukusuka kwi-12-intshi ye-silicon wafers eyona ndawo yentengiso, ngelixa ii-wafers ezi-8-intshi zikhutshwa ngokuthe ngcembe. Inkokeli yasekhaya i-SMIC isasebenzisa ikakhulu ii-intshi ezi-6. Okwangoku, yi-SUMCO yaseJapan kuphela enokuvelisa ii-wafer substrates ezi-12-intshi eziphezulu.

3. Gallium Arsenide

I-Gallium arsenide (i-GaAs) i-wafers iyinto ebalulekileyo ye-semiconductor, kwaye ubukhulu bayo buyiparameter ebalulekileyo kwinkqubo yokulungiselela.

Okwangoku, ii-wafers ze-GaAs ziveliswa ngokwesayizi yee-intshi ezi-2, ii-intshi ezi-3, ii-intshi ezi-4, ii-intshi ezi-6, ii-intshi ezisi-8, kunye ne-12 intshi. Phakathi kwezi, ii-wafers ze-intshi ezi-6 yenye yezona zinto zisetyenziswa kakhulu.

Ubuninzi be-crystals obuphezulu obukhuliswe yi-Horizontal Bridgman (HB) indlela ngokuqhelekileyo i-3 intshi, ngelixa indlela ye-Liquid-Encapsulated Czochralski (LEC) inokuvelisa i-crystals enye ukuya kwi-intshi ye-12 ububanzi. Nangona kunjalo, ukukhula kwe-LEC kufuna iindleko eziphezulu zezixhobo kwaye zivelise iikristale ezingafaniyo kunye nokuxinana okuphezulu kokuchithwa. Iindlela ze-Vertical Gradient Freeze (VGF) kunye ne-Vertical Bridgman (VB) okwangoku zikwazi ukuvelisa i-crystals enye ukuya kwii-intshi ezi-8 ububanzi, kunye nesakhiwo esifanayo kunye noxinano oluphantsi lokuchithwa.

Itekhnoloji yemveliso yee-intshi ezi-4 kunye ne-intshi ezi-6 ze-semi-insulating ze-GaAs ezikhazimlisiweyo zilawulwa ngokuyintloko ziinkampani ezintathu: iSumitomo Electric Industries yaseJapan, iFreiberger Compound Materials yaseJamani, kunye ne-AXT yase-US. Ngo-2015, ii-intshi ezi-6 zee-substrates sele zibalelwe ngaphezulu kwe-90% yesabelo semarike.

Ngo-2019, imakethi ye-GaAs yehlabathi jikelele yayilawulwa yiFreiberger, iSumitomo, kunye neBeijing Tongmei, kunye nezabelo zentengiso ze-28%, 21%, kunye ne-13% ngokulandelelana. Ngokoqikelelo ngokubonisana nefemu iYole, intengiso yehlabathi jikelele yee-GaAs substrates (eziguqulelwe kwii-intshi ezi-2) zifikelele malunga neziqwenga ezimalunga ne-20 yezigidi ngo-2019 kwaye kuqikelelwa ukuba ziya kudlula iziqwenga ezingama-35 ezigidi ngo-2025. (CAGR) ye-9.67% ukusuka ngo-2019 ukuya ku-2025.

4. I-Silicon Carbide Ikristale enye

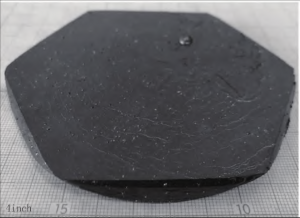

Okwangoku, imarike inokuxhasa ngokupheleleyo ukukhula kwe-intshi ezi-2 kunye ne-3-intshi ububanzi besilicon carbide (SiC) iikristale enye. Iinkampani ezininzi ziye zaxela ukukhula ngempumelelo kwe-4-intshi ye-4H-uhlobo lwe-SiC iikristale enye, ephawula impumelelo yaseTshayina yamanqanaba odidi lwehlabathi kwi-teknoloji yokukhula kwekristale ye-SiC. Nangona kunjalo, kusekho umsantsa obalulekileyo phambi korhwebo.

Ngokuqhelekileyo, ii-ingots ze-SiC ezikhuliswe ngeendlela zesigaba se-liquid zincinci, kunye nobukhulu kwinqanaba leesentimitha. Esi sisizathu sexabiso eliphezulu lee-wafers ze-SiC.

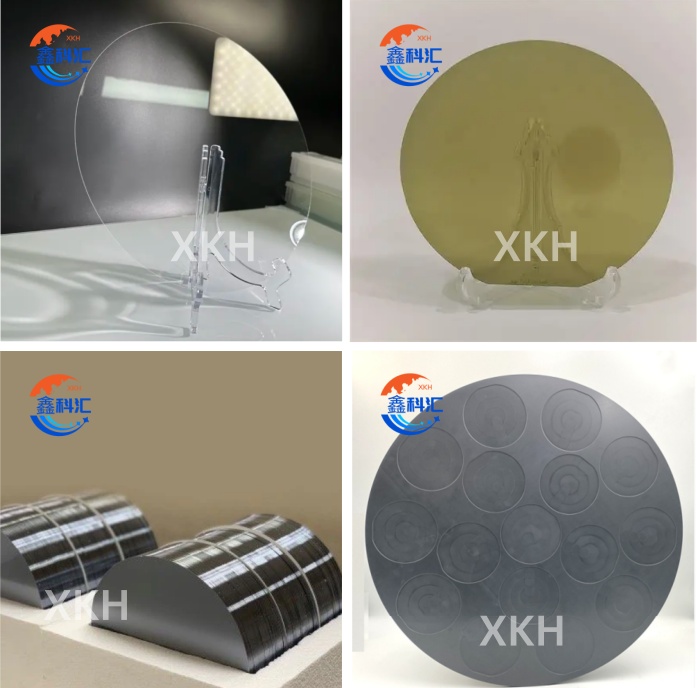

I-XKH igxile kakhulu kwi-R&D kunye nokusetyenzwa ngokwezifiso kwezinto eziphambili ze-semiconductor, kubandakanya isafire, isilicon carbide (SiC), ii-silicon wafers, kunye neekeramics, ezigquma ikhonkco lexabiso elipheleleyo ukusuka ekukhuleni kwekristale ukuya kumatshini ochanekileyo. Ukusebenzisa amandla oshishino oludityanisiweyo, sibonelela ngeewafers zesafire ezisebenza kakhulu, ii-silicon carbide substrates, kunye ne-ultra-high-purity wafers ye-silicon, exhaswa zizisombululo ezilungiselelwe ezifana nokusika isiko, ukugquma komphezulu, kunye nokwenziwa kwejiyometri entsonkothileyo, ukuhlangabezana neemfuno ezigqithisileyo zokusingqongileyo kwiinkqubo ze-laser, ukwenziwa kwe-semiconductor, kunye nokusetyenziswa kwamandla ahlaziyiweyo.

Ukuthobela imigangatho yomgangatho, iimveliso zethu zibonisa ukuchaneka kwenqanaba le-micron,>1500 °C ukuzinza kwe-thermal, kunye nokumelana okuphezulu kwe-corrosion, ukuqinisekisa ukuthembeka kwiimeko zokusebenza ezinzima. Ukongeza, sibonelela ngee-quartz substrates, izinto zetsimbi / ezingezizo ezentsimbi, kunye nezinye izinto ze-semiconductor-grade, evumela utshintsho olungenamthungo ukusuka kwiprototyping ukuya kwimveliso yobuninzi kubathengi kuwo wonke amashishini.

Ixesha lokuposa: Aug-29-2025