Isiqulatho

1. IiNjongo eziPhambili kunye nokubaluleka kokucocwa kweWafer

2. UVavanyo lokuNgcoliseka kunye neeNdlela zoHlahlo oluPhezulu

3.IiNdlela zokuCoca eziphambili kunye neMithetho-siseko yobuGcisa

4. UkuPhunyezwa koBuchule kunye noLawulo lweNkqubo ebalulekileyo

5. Iindlela zexesha elizayo kunye nezalathiso ezitsha

6.XKH Izisombululo zokuphela-ukuya-ekuphelweni kunye nenkqubo ye-Ecosystem yeNkonzo

Ukucoca i-wafer yinkqubo ebalulekileyo kwimveliso ye-semiconductor, njengoko ungcoliseko lwezinga le-athomu lunokuthoba ukusebenza kwesixhobo okanye isivuno. Inkqubo yokucoca ngokuqhelekileyo ibandakanya amanyathelo amaninzi okususa ukungcola okwahlukeneyo, okufana neentsalela ze-organic, ukungcola kwesinyithi, amasuntswana, kunye ne-oxides yendalo.

1. Iinjongo zokuCoca iWafer

- Susa izingcolisi eziphilayo (umzekelo, iintsalela zefotoresist, iminwe yeminwe).

- Ukuphelisa ubumdaka besinyithi (umzekelo, Fe, Cu, Ni).

- Susa ungcoliseko lwentonga (umzekelo, uthuli, amaqhekeza esilicon).

- Susa iioksidi zendalo (umzekelo, iileya zeSiO₂ ezenziwe ngexesha lokuba sesichengeni somoya).

2. Ukubaluleka kokucocwa okuQoncekileyo kweWafer

- Iqinisekisa isivuno senkqubo ephezulu kunye nokusebenza kwesixhobo.

- Yehlisa iziphene kunye namazinga e-wafer scrap.

- Ukuphucula umgangatho womphezulu kunye nokungaguquguquki.

Ngaphambi kokucoca ngokungqongqo, kubalulekile ukuvavanya ungcoliseko olukhoyo lomphezulu. Ukuqonda uhlobo, ukuhanjiswa kobungakanani, kunye nokucwangciswa kwendawo yezingcoliso kumphezulu we-wafer kwandisa ikhemistri yokucoca kunye negalelo lamandla omatshini.

3. Ubuchwephesha boHlahlo obuNqobileyo boVavanyo loNgcoliseko

3.1 Uhlalutyo lweNcam yoMphezulu

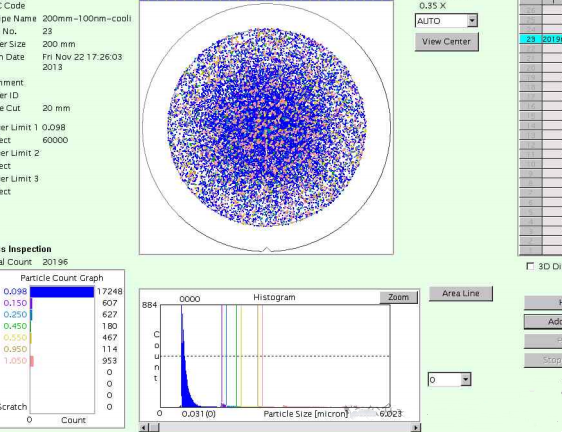

- Izixhobo zokubala ezikhethekileyo zisebenzisa ukusasazwa kwelaser, okanye umbono wekhompyuter ukubala, ubungakanani, kunye nobutyobo bemephu.

- Amandla okusasaza ukukhanya ahambelana nobungakanani bamasuntswana amancinci angamashumi e-nanometers kunye noxinaniso olusezantsi njenge-0.1 amasuntswana/cm².

- Ukulinganisa ngemigangatho kuqinisekisa ukuthembeka kwe-hardware. Izikena zangaphambili kunye nasemva kokucoca ziqinisekisa ukusebenza kakuhle kokususa, ukuphuculwa kwenkqubo yokuqhuba.

3.2 Uhlalutyo lwe-Elemental Surface

- Iindlela zobuchule ezijongana nomphezulu zichonga ukuqamba okusisiseko.

- I-X-reyi I-Photoelectron Spectroscopy (XPS/ESCA): Ihlalutya ubume bemichiza engaphezulu ngokufaka i-wafer nge-X-reyi kunye nokulinganisa ii-electron ezikhutshwayo.

- I-Glow Discharge Optical Emission Emission Spectroscopy (GD-OES): I-Sputters i-ultra-thin surface layers ngokulandelelana ngelixa ihlalutya i-spectra ekhutshwayo ukumisela ubunzulu obuxhomekeke kubunzulu be-elemental.

- Imida yokuchongwa ifikelela kumacandelo esigidi (ppm), ekhokelela ekukhetheni ikhemistri yokucoca.

3.3 Uhlalutyo lwe-Morphological Contamination

- Ukuskena i-Electron Microscopy (SEM)okwisigqibo esiphezulu ukuveza iimilo zongcoliseko kunye nomlinganiselo wenkalo, ebonisa iindlela zokubambelela (ikhemikhali ngokuchasene noomatshini).

- I-Atomic Force Microscopy (AFM): Imephu ye-nanoscale topography ukulinganisa ubude bamasuntswana kunye neempawu zoomatshini.

- I-Ion Beam (FIB) egxininisiweyo yokuSila + iMikroskopu yoThutho lwe-Electron (TEM): Ibonelela ngezimvo zangaphakathi zezingcolisi ezingcwatyiweyo.

4. Iindlela zokucoca ezikwinqanaba eliphezulu

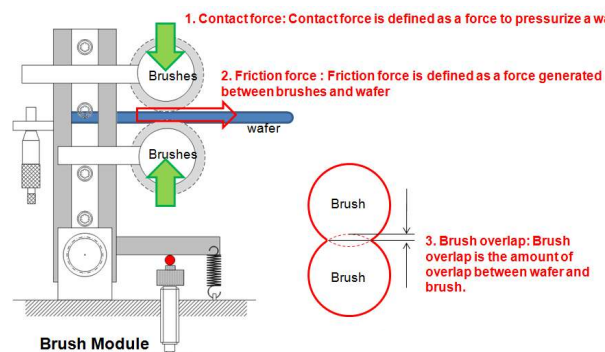

Ngelixa ukucocwa kwe-solvent kususa ngokufanelekileyo i-organic contaminants, ubuchule obongezelelweyo obuphambili bufunekayo kwiincinci ze-inorganic, iintsalela zetsimbi, kunye nee-ionic contaminants:

.

4.1 Ukucoca iRCA

- Ephuhliswe yi-RCA Laboratories, le ndlela isebenzisa inkqubo yokuhlamba kabini ukususa ukungcola kwe-polar.

- SC-1 (Standard Clean-1)] Isusa ungcoliseko lwendalo kunye namasuntswana kusetyenziswa umxube we-NH₄OH, H₂O₂, kunye ne-H₂O (umz., 1:1:5 umlinganiselo we-~20°C). Yenza umaleko obhityileyo wesilicon dioxide.

- SC-2 (Standard Clean-2): Isusa ubumdaka besinyithi usebenzisa iHCl, H₂O₂, neH₂O (umz., umlinganiselo we-1:1:6 ku-~80°C). Ishiya umphezulu ongenakwenziwa.

- Ukulinganisa ukucoceka kunye nokukhuselwa komphezulu.

.

4.2 Ukucocwa kwe-Ozone

- Intywilisela ii-wafers kumanzi e-ozone-saturated deionized (O₃/H₂O).

- Ngokufanelekileyo i-oxidizes kwaye isuse i-organics ngaphandle kokonakalisa i-wafer, ishiya umphezulu wekhemikhali.

.

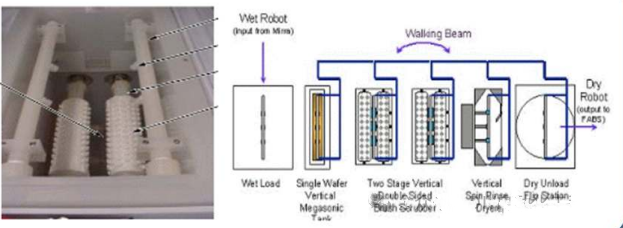

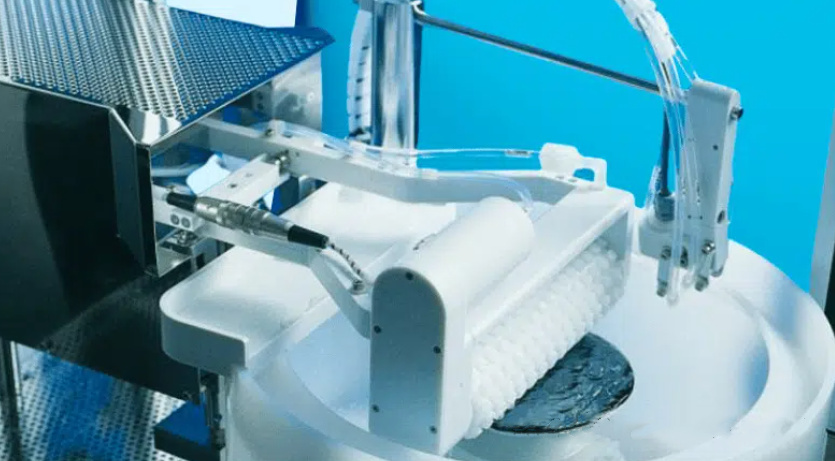

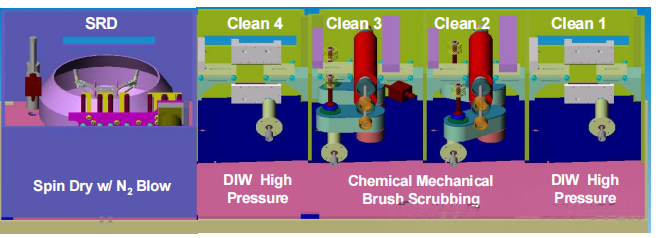

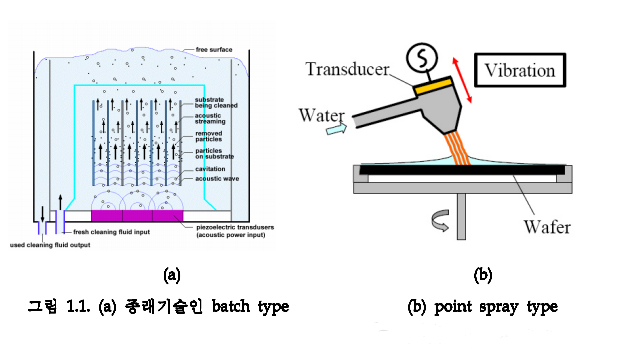

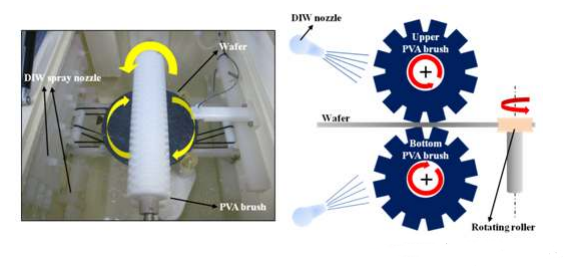

4.3 Ukucoca iMegasonic.

- Isebenzisa amandla e-high-frequency ultrasonic (ngokuqhelekileyo yi-750–900 kHz) edityaniswa nezisombululo zokucoca.

- Ivelisa amaqamza e-cavitation akhupha izinto ezingcolisayo. Ingena kwiijometri ezintsonkothileyo ngelixa unciphisa umonakalo kwizakhiwo ezibuthathaka.

4.4 Ukucoca iCryogenic

- Ipholisa ngokukhawuleza ii-wafers kumaqondo obushushu e-cryogenic, izingcoliso ezimdaka.

- Ukuhlanjwa okulandelayo okanye ukuxukuxa ngobunono kususa amasuntswana akhululweyo. Ikhusela ukungcoliseka kwakhona kunye nokusasazwa kumphezulu.

- Ukukhawuleza, inkqubo eyomileyo kunye nokusetyenziswa kweekhemikhali ezincinci.

Ukuqukumbela:

Njengomboneleli okhokelayo wezisombululo ze-semiconductor ezigcweleyo, i-XKH iqhutywa kubuchule obutsha betekhnoloji kwaye iimfuno zabathengi ukuhambisa inkqubo yokuphela kwenkonzo yendalo, ebandakanya ukubonelela ngezixhobo eziphezulu, ukwenziwa kwe-wafer, kunye nokucoca ngokuchanekileyo. Asiboneleli kuphela ngezixhobo zesemiconductor ezamkelwa kumazwe ngamazwe (umzekelo, oomatshini be-lithography, ii-etching systems) ezinezisombululo ezilungiselelweyo kodwa sikwangoovulindlela bobuchwephesha—kuquka ukucocwa kweRCA, ukucocwa kwe-ozone, nokucoca i-megasonic—ukuqinisekisa ucoceko olukwinqanaba leathom—ukwenza iwafer, ukuphucula ngokubonakalayo isivuno sabathengi. Ukusetyenziswa kwamaqela asabela ngokukhawuleza asekuhlaleni, kunye nothungelwano lwenkonzo yobukrelekrele, sibonelela ngenkxaso ebanzi ukusuka kufakelo lwezixhobo kunye nokuphuculwa kwenkqubo ukuya kugcino oluqikelelweyo, sixhobisa abathengi ukuba boyise imiceli mngeni yobugcisa kwaye baqhubele phambili ekuchanekeni okuphezulu kunye nophuhliso oluzinzileyo lwe-semiconductor. Sikhethele i-synergy ephindwe kabini yobuchule bobugcisa kunye nexabiso lentengiso.

Ixesha lokuposa: Sep-02-2025