Itekhnoloji ye-wafer dicing, njengenyathelo elibalulekileyo kwinkqubo yokwenziwa kwe-semiconductor, idityaniswe ngokuthe ngqo ekusebenzeni kwetshiphu, isivuno, kunye neendleko zemveliso.

#01 Imvelaphi kunye nokubaluleka kweWafer Dicing

1.1 Inkcazo yeWafer Dicing

I-wafer dicing (ekwabizwa ngokuba yi-scribing) linyathelo elibalulekileyo kwimveliso ye-semiconductor, ejolise ekwahluleni ii-wafers ezicwangcisiweyo zibe ngabantu abaninzi abafayo. Ezi zifa zihlala ziqulathe ukusebenza kwesekethe epheleleyo kwaye zizinto eziphambili ezisetyenziswa ekugqibeleni kwimveliso yezixhobo zombane. Njengoko uyilo lwetshiphu lusiya luntsonkotha ngakumbi kwaye imilinganiso iqhubeleka nokucutheka, ukuchaneka kunye neemfuno zobuchule bobuchwephesha bokwenza ii-wafer dicing ziya zisiba ngqongqo.

Kwimisebenzi eyenziwayo, ukudaywa kwe-wafer ngokuqhelekileyo kusebenzisa izixhobo ezichanekileyo ezinje ngeencakuba zedayimani ukuqinisekisa ukuba ifa ngalinye lihlala linjalo kwaye lisebenza ngokupheleleyo. Amanyathelo aphambili abandakanya ukulungiswa ngaphambi kokusika, ukulawula okuchanekileyo ngexesha lokusika, kunye nokuhlolwa komgangatho emva kokusika.

Ngaphambi kokusika, i-wafer kufuneka imakishwe kwaye ibekwe ukuze kuqinisekiswe iindlela zokusika ezichanekileyo. Ngexesha lokusika, iiparamitha ezifana noxinzelelo lwesixhobo kunye nesantya kufuneka zilawulwe ngokungqongqo ukukhusela umonakalo kwi-wafer. Emva kokusikwa, uhlolo olubanzi lwekhwalithi luyenziwa ukuze kuqinisekiswe ukuba itshiphu nganye iyahlangabezana nemigangatho yokusebenza.

Imigaqo esisiseko yetekhnoloji ye-wafer dicing ayibandakanyi kuphela ukukhethwa kwezixhobo zokusika kunye nokusetwa kweeparamitha zenkqubo kodwa kunye nefuthe leempawu zoomatshini kunye neempawu zemathiriyeli kumgangatho wokusika. Umzekelo, i-low-k dielectric silicon wafers, ngenxa yeempawu zabo ezingaphantsi komatshini, zichaphazeleka kakhulu ekugxininiseni uxinzelelo ngexesha lokusika, okukhokelela ekungaphumelelini okufana nokuqhekeka kunye nokuqhekeka. Ubunzima obuphantsi kunye nobunzima bezinto eziphantsi-k zibenza bathandeke ngakumbi kumonakalo wesakhiwo phantsi kwamandla omatshini okanye uxinzelelo lwe-thermal, ngakumbi ngexesha lokusika. Uqhagamshelwano phakathi kwesixhobo kunye nomphezulu we-wafer, kunye namaqondo obushushu aphezulu, kunokunyusa ngakumbi uxinzelelo loxinzelelo.

Ngenkqubela phambili kwisayensi yezinto eziphathekayo, itekhnoloji ye-wafer dicing iye yanda ngaphaya kwee-semiconductors ze-silicon-based ukuba zibandakanye izinto ezintsha ezifana ne-gallium nitride (GaN). Ezi zinto zintsha, ngenxa yobunzima bazo kunye nezakhiwo zesakhiwo, zibeka imingeni emitsha kwiinkqubo ze-dicing, ezifuna ukuphuculwa okungakumbi kwizixhobo zokusika kunye nobuchule.

Njengenkqubo ebaluleke kakhulu kushishino lwesemiconductor, ukudayiva kwe-wafer kuyaqhubeka ukwenziwa ngcono ekuphenduleni kwiimfuno eziguqukayo kunye nokuqhubela phambili kwetekhnoloji, ukubeka isiseko se-microelectronics yexesha elizayo kunye neetekhnoloji zesekethe ezihlanganisiweyo.

Uphuculo kwitekhnoloji ye-wafer dicing idlula ngaphaya kophuhliso lwezixhobo ezincedisayo kunye nezixhobo. Zikwabandakanya ukuphuculwa kwenkqubo, uphuculo ekusebenzeni kwesixhobo, kunye nolawulo oluchanekileyo lweeparamitha zokudayela. Ezi nkqubela phambili zijolise ekuqinisekiseni ukuchaneka okuphezulu, ukusebenza kakuhle, kunye nozinzo kwinkqubo yokudayela i-wafer, ukuhlangabezana nemfuno yoshishino lwe-semiconductor yemilinganiselo emincinci, ukuhlanganiswa okuphezulu, kunye nezakhiwo ze-chip ezintsonkothileyo.

| Indawo yokuphucula | Amanyathelo athile | Iziphumo |

| Inkqubo yokuPhucula | - Phucula ulungiselelo lokuqala, olufana nokuma kwewafer echanekileyo ngakumbi kunye nocwangciso lwendlela. | - Ukunciphisa iimpazamo zokusika kunye nokuphucula ukuzinza. |

| - Nciphisa iimpazamo zokusika kwaye uphucule uzinzo. | -Yamkela ukujongwa kwexesha lokwenyani kunye neendlela zempendulo ukulungisa uxinzelelo lwesixhobo, isantya kunye nobushushu. | |

| -Amazinga asezantsi okuqhekezwa kwe-wafer kunye nokuphucula umgangatho we-chip. | ||

| Ukwandiswa kokuSebenza kweZixhobo | -Sebenzisa iisistim zoomatshini ezichanekileyo kunye netekhnoloji yolawulo oluzenzekelayo. | - Ukuphucula ukuchaneka kokusika kunye nokunciphisa inkcitho yezinto eziphathekayo. |

| - Yazisa itekhnoloji yokusika i-laser efanelekileyo kwi-wafers yezinto ezinobunzima obuphezulu. | - Ukuphucula ukusebenza kakuhle kwemveliso kunye nokunciphisa iimpazamo ezenziwa ngesandla. | |

| - Ukwandisa izixhobo ezizenzekelayo zokubeka iliso kunye nohlengahlengiso oluzenzekelayo. | ||

| Ulawulo lweParameter echanekileyo | -Lungelela kakuhle iiparamitha njengokusika ubunzulu, isantya, uhlobo lwesixhobo kunye neendlela zokupholisa. | - Ukuqinisekisa ukunyaniseka kokufa kunye nokusebenza kombane. |

| -Yenza ngokwezifiso iiparamitha ngokusekwe kwimathiriyeli yewafer, ubukhulu, kunye nolwakhiwo. | - Ukunyusa izinga lesivuno, ukunciphisa inkcitho yezinto eziphathekayo, kunye neendleko eziphantsi zemveliso. | |

| Ukubaluleka kobuchule | -Qhubeka uphonononga iindlela ezintsha zetekhnoloji, uphucula iinkqubo, kwaye uphucule izakhono zezixhobo ukuhlangabezana neemfuno zentengiso. | - Ukuphucula isivuno sokwenziwa kwetshiphu kunye nokusebenza, ukuxhasa uphuhliso lwemathiriyeli emitsha kunye noyilo oluphambili lwetshiphu. |

1.2 Ukubaluleka kweWafer Dicing

I-Wafer dicing idlala indima ebalulekileyo kwinkqubo yokwenziwa kwe-semiconductor, ichaphazela ngokuthe ngqo amanyathelo alandelayo kunye nomgangatho kunye nokusebenza kwemveliso yokugqibela. Ukubaluleka kwayo kunokuchazwa ngolu hlobo lulandelayo:

Okokuqala, ukuchaneka kunye nokuhambelana kwe-dicing ngundoqo ekuqinisekiseni isivuno se-chip kunye nokuthembeka. Ngexesha lokwenziwa, ii-wafers zihamba ngamanyathelo okucubungula amaninzi ukwenza uninzi lwezakhiwo ezintsonkothileyo zeesekethe, ekufuneka zahlulwe ngokuchanekileyo zibe ziichips ezizimeleyo (zifa). Ukuba kukho iimpazamo eziphawulekayo ekulungelelaniseni okanye ukusika ngexesha lenkqubo yokudayela, iisekethe zingonakaliswa, ezichaphazela ukusebenza kwe-chip kunye nokuthembeka. Ngoko ke, iteknoloji ye-dicing ephezulu echanekileyo ayiqinisekisi kuphela ingqibelelo ye-chip nganye kodwa iphinde ithintele umonakalo kwiisekethe zangaphakathi, ukuphucula izinga lokuvunwa ngokubanzi.

Okwesibini, i-wafer dicing inempembelelo ebalulekileyo ekusebenzeni kakuhle kwemveliso kunye nolawulo lweendleko. Njengenyathelo elibalulekileyo kwinkqubo yokuvelisa, ukusebenza kwayo kuchaphazela ngokuthe ngqo inkqubela yamanyathelo alandelayo. Ngokulungisa inkqubo yokudayela, ukwandisa amanqanaba okuzisebenzela, kunye nokuphucula isantya sokusika, ukusebenza kakuhle kwemveliso kukongezwa kakhulu.

Ngakolunye uhlangothi, inkcitho yezinto eziphathekayo ngexesha lokudayela yinto ebalulekileyo kulawulo lweendleko. Ukusebenzisa itekhnoloji yokudayela ephucukileyo akunciphisi ilahleko yezinto ezingeyomfuneko ngexesha lenkqubo yokusika kodwa kwandisa ukusetyenziswa kwe-wafer, ngaloo ndlela kuthotywa iindleko zemveliso.

Ngenkqubela phambili yetekhnoloji ye-semiconductor, iidamitha ze-wafer ziyaqhubeka ukwanda, kwaye ukuxinana kweesekethe kunyuka ngokufanelekileyo, kubeka iimfuno eziphezulu kwitekhnoloji yokudayela. Ii-wafers ezinkulu zifuna ulawulo oluchanekileyo ngakumbi lweendlela zokusika, ngakumbi kwiindawo ezixineneyo ezixineneyo, apho nokuphambuka okuncinci kunokwenza iichips ezininzi zingasebenzi. Ukongeza, ii-wafers ezinkulu zibandakanya imigca yokusika ngakumbi kunye namanyathelo enkqubo anzima ngakumbi, efuna uphuculo olungakumbi ekuchanekeni, ukungaguquguquki, kunye nokusebenza kakuhle kwetekhnoloji yokudayela ukuhlangabezana nale mingeni.

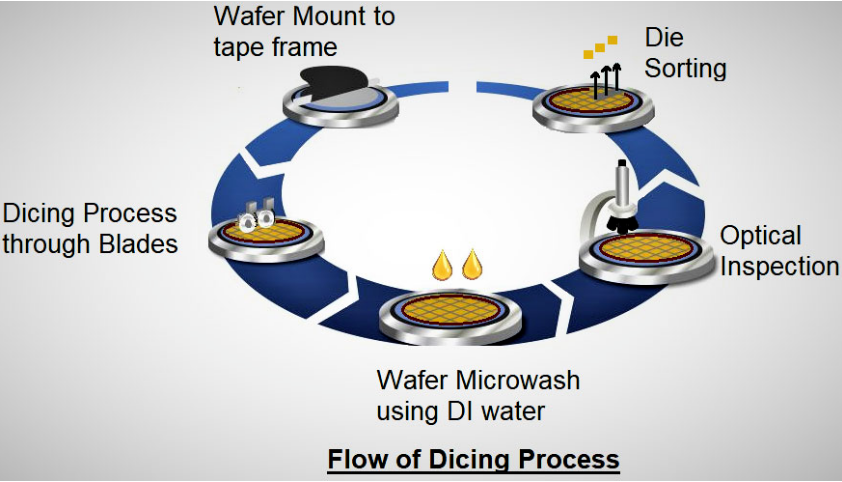

1.3 Inkqubo yeWafer Dicing

Inkqubo ye-wafer dicing ibandakanya onke amanyathelo ukusuka kwisigaba sokulungiselela ukuya kukuhlolwa komgangatho wokugqibela, kunye nesigaba ngasinye sibaluleke kakhulu ekuqinisekiseni umgangatho kunye nokusebenza kweetshiphusi ezidayiweyo. Apha ngezantsi kukho inkcazo eneenkcukacha yesigaba ngasinye.

| Isigaba | Inkcazo eneenkcukacha |

| Isigaba sokuLungiselela | -Ukucoca i-wafer: Sebenzisa amanzi acocekileyo kunye nee-agent ezikhethekileyo zokucoca, ezidibaniswe ne-ultrasonic okanye i-mechanical scrubbing, ukususa ukungcola, iinqununu, kunye nokungcola, ukuqinisekisa indawo ecocekileyo. -Isikhundla esichanekileyo: Sebenzisa izixhobo ezichanekileyo ezichanekileyo zokuqinisekisa ukuba i-wafer yahlulwe ngokuchanekileyo kwiindlela zokusika eziyilelwe. -Ukulungiswa kweWafer: Khusela i-wafer kwisakhelo se-tape ukugcina uzinzo ngexesha lokusika, ukukhusela umonakalo kwi-vibration okanye ukunyakaza. |

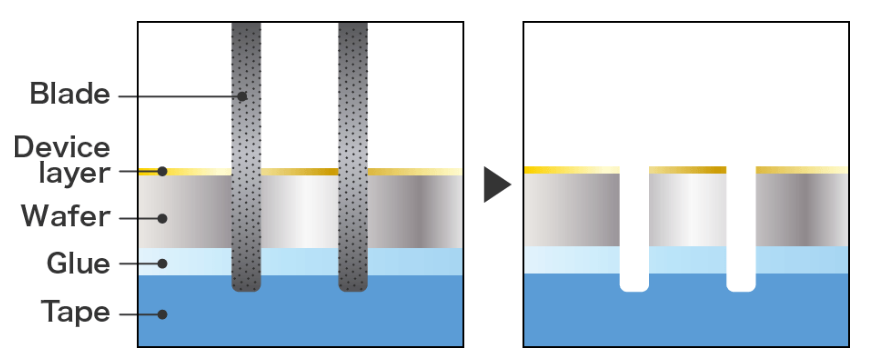

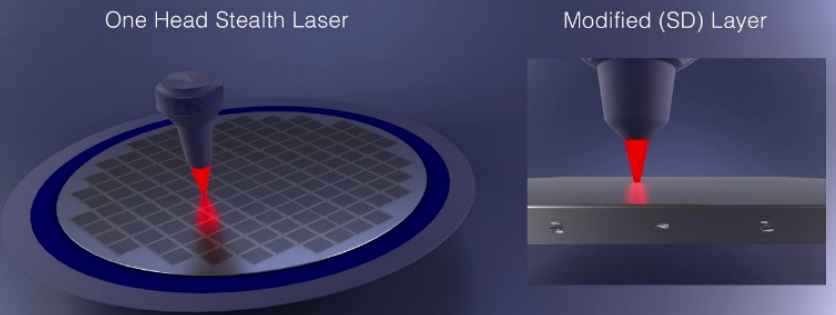

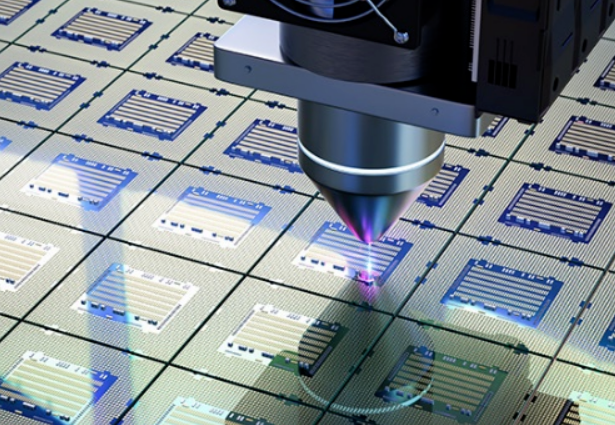

| Isigaba sokusika | -I-Blade Dicing: Sebenzisa amacwecwe ajikelezayo anesantya esiphezulu sedayimane esicatshulwe ngokwasemzimbeni, alungele izixhobo ezisekwe kwisilicon kwaye azibizi. -I-Laser Dicing: Sebenzisa imiqadi yelaser ene-eneji ephezulu ekusikeni okungadibanisiyo, ilungele izinto ezinokonakala okanye ezinobunzima obuphezulu njenge-gallium nitride, enikezela ngokuchaneka okuphezulu kunye nokulahleka kwezinto ezincinci. -Ubuchwephesha obutsha: Yazisa iteknoloji yokusika i-laser kunye ne-plasma ukuqhubela phambili ukuphucula ukusebenza kunye nokuchaneka ngelixa unciphisa iindawo ezichaphazelekayo kubushushu. |

| Inqanaba lokucoca | - Sebenzisa amanzi ahlanjululweyo (amanzi e-DI) kunye nee-agent ezikhethekileyo zokucoca, ezidityaniswe ne-ultrasonic okanye i-spray yokucoca, ukususa i-debris kunye nothuli olwenziwa ngexesha lokusika, ukukhusela i-residus ekuchaphazela iinkqubo ezilandelayo okanye ukusebenza kombane we-chip. - Amanzi acocekileyo e-DI anqanda ukuzisa izinto ezingcolisayo, eqinisekisa indawo ecocekileyo ye-wafer. |

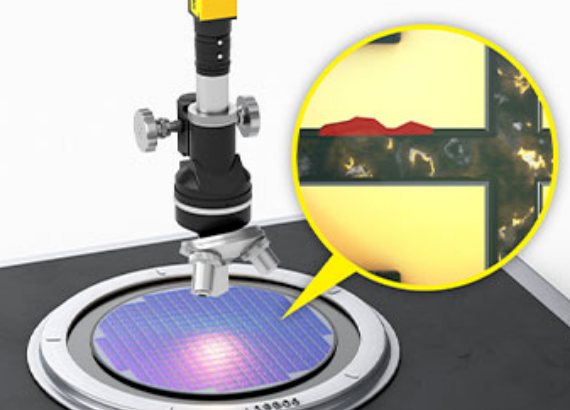

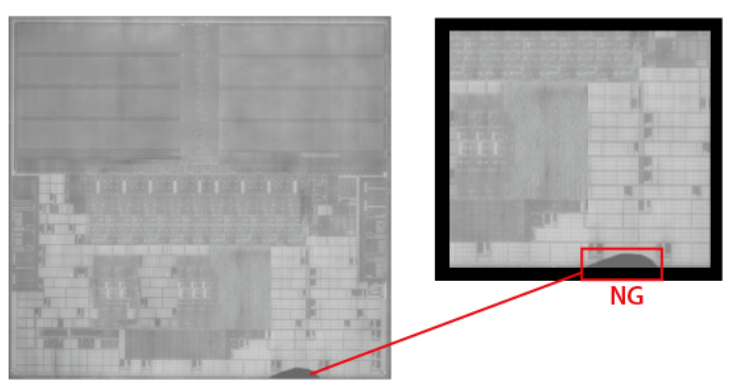

| Isigaba soHlolo | -Ukuhlolwa kwamehlo: Sebenzisa iisistim zokubona amehlo ezidityaniswe ne-AI algorithms ukuchonga ngokukhawuleza iziphene, ukuqinisekisa ukuba akukho zintlukwano okanye ukukrazula kwi-chips diced, ukuphucula ukusebenza kakuhle kokuhlolwa, kunye nokunciphisa impazamo yomntu. -Umlinganiselo woMda: Qinisekisa ukuba imilinganiselo yetshiphu iyahlangabezana neenkcukacha zoyilo. -Uvavanyo lokuSebenza koMbane: Ukuqinisekisa ukusebenza kombane kwee-chips ezibalulekileyo kuhambelana nemigangatho, ukuqinisekisa ukuthembeka kwizicelo ezilandelayo. |

| Isigaba Sokuhlela | -Sebenzisa iingalo zerobhothi okanye iikomityi zokufunxa i-vacuum ukwahlula iitshiphusi ezifanelekileyo kwisakhelo seteyiphu kwaye uzihlele ngokuzenzekelayo ngokusekelwe ekusebenzeni, ukuqinisekisa ukusebenza kakuhle kwemveliso kunye nokuguquguquka ngelixa uphucula ukuchaneka. |

Inkqubo yokusika i-wafer ibandakanya ukucocwa kwe-wafer, ukubeka, ukusika, ukucocwa, ukuhlolwa, kunye nokuhlelwa, kunye nenyathelo ngalinye libaluleke kakhulu. Ngenkqubela phambili kwi-automation, ukusika i-laser, kunye netekhnoloji yokuhlola i-AI, iinkqubo zale mihla zokusika i-wafer zinokufezekisa ukuchaneka okuphezulu, isantya, kunye nelahleko esezantsi yempahla. Kwixesha elizayo, itekhnoloji entsha yokusika efana nelaser kunye neplasma ngokuthe ngcembe iya kuthatha indawo yokusika iblade yemveli ukuhlangabezana neemfuno zoyilo oluntsonkothileyo lwetshiphu, ngakumbi ukuqhuba uphuhliso lweenkqubo zokwenziwa kwe-semiconductor.

Itekhnoloji yokusika iWafer kunye neMigaqo yayo

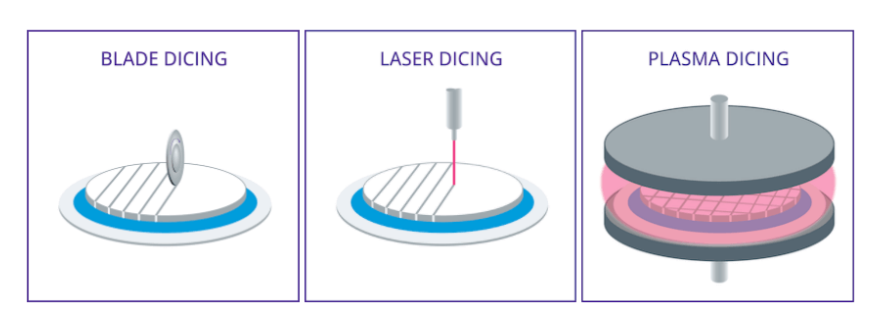

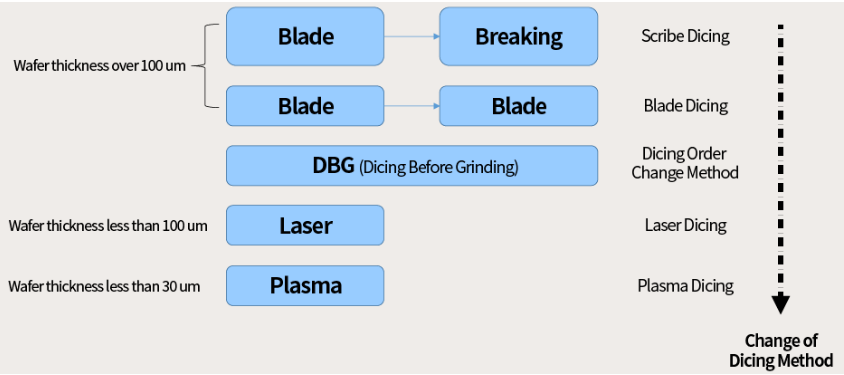

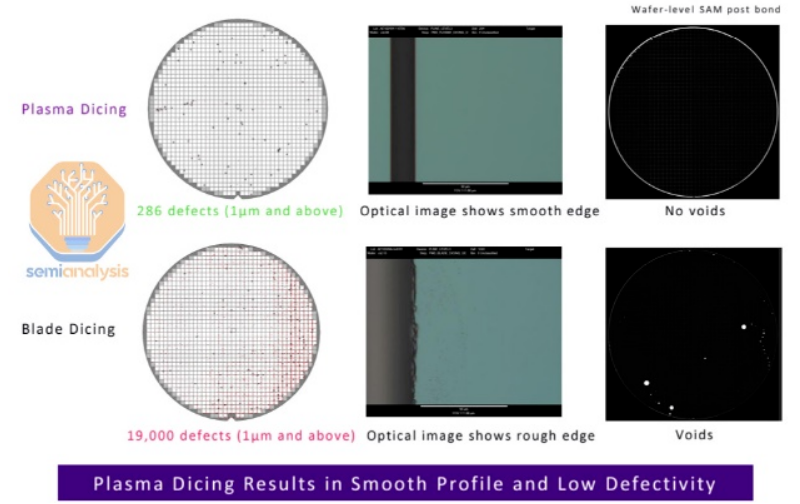

Umfanekiso ubonisa iitekhnoloji ezintathu eziqhelekileyo zokusika i-wafer:I-Blade Dicing,I-Laser Dicing, kwayeI-Plasma Dicing. Ngezantsi lucazululo oluneenkcukacha kunye nengcaciso eyongezelelweyo yezi ndlela zintathu:

Kwimveliso ye-semiconductor, ukusika i-wafer linyathelo elibalulekileyo elifuna ukukhetha indlela efanelekileyo yokusika ngokusekelwe kubukhulu be-wafer. Inyathelo lokuqala kukuqinisekisa ubukhulu be-wafer. Ukuba ubukhulu be-wafer budlula i-microns ezili-100, ukudaywa kwe-blade kunokukhethwa njengendlela yokusika. Ukuba ukucandwa kweblade akufanelekanga, indlela yokudayela ngokuqhekeka ingasetyenziswa, ebandakanya zombini ukusika ababhali kunye neendlela zokudaya iincakuba.

Xa ubukhulu be-wafer buphakathi kwe-30 kunye ne-100 ye-microns, indlela ye-DBG (Idayisi phambi kokuSila) iyacetyiswa. Kule meko, ukusika ababhali, ukusika i-blade, okanye ukulungelelanisa ulandelelwano lokusika njengoko kuyimfuneko kunokukhethwa ukufikelela iziphumo ezingcono.

Kwii-wafers ezibhityileyo ezinobunzima obungaphantsi kwe-microns ezingama-30, ukusika kwe-laser kuba yeyona ndlela ikhethwayo ngenxa yokukwazi ukusika ii-wafers ezibhityileyo ngokuchanekileyo ngaphandle kokwenza umonakalo ogqithisileyo. Ukuba ukusika kwe-laser akukwazi ukuhlangabezana neemfuno ezithile, ukusika i-plasma kunokusetyenziswa njengenye indlela. Le tshati yokuqukuqela ibonelela ngendlela ecacileyo yokwenza izigqibo ukuqinisekisa ukuba iteknoloji yokusika i-wafer ifanelekileyo ikhethwa phantsi kweemeko ezahlukeneyo zobunzima.

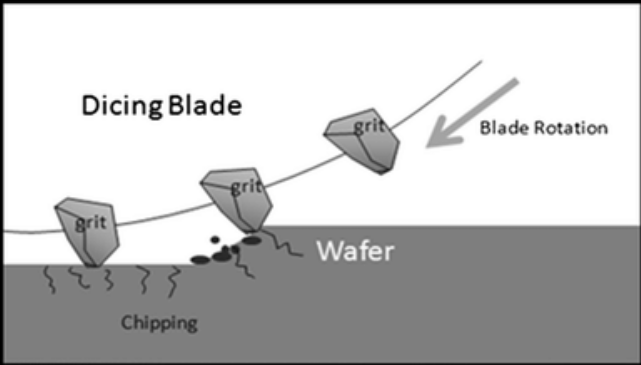

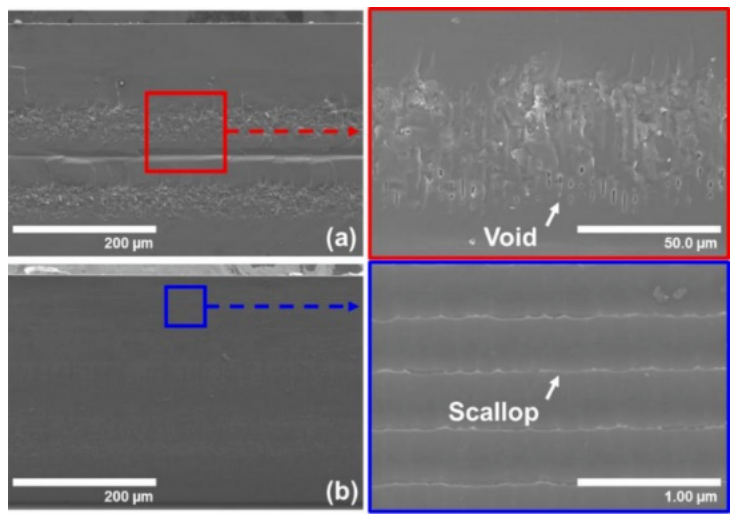

2.1 Ubugcisa bokusika oomatshini

Itekhnoloji yokusika iMechanical yindlela yemveli kwi-wafer dicing. Umgaqo ongundoqo kukusebenzisa ivili lokusila ledayimani elijikeleza ngesantya esiphezulu njengesixhobo sokusika ukusika iwafer. Izixhobo eziphambili ziquka i-spindle ephethe umoya, eqhuba isixhobo sevili lokusila idayimani ngesantya esiphezulu ukwenza ukusika ngokuchanekileyo okanye ukugoba ecaleni kwendlela yokusika echazwe kwangaphambili. Le teknoloji isetyenziswa kakhulu kwishishini ngenxa yexabiso eliphantsi, ukusebenza kakuhle, kunye nokusebenza ngokubanzi.

Iingenelo

Ubunzima obuphezulu kunye nokumelana nokunxiba kwezixhobo zevili lokusila idayimani kwenza itekhnoloji yokusika oomatshini ikwazi ukuziqhelanisa neemfuno zokusika izinto ezahlukeneyo ze-wafer, nokuba zizixhobo zemveli ezisekwe kwi-silicon okanye iisemiconductors ezintsha. Ukusebenza kwayo kulula, kunye neemfuno zobugcisa eziphantsi, ngakumbi ukukhuthaza ukuthandwa kwayo kwimveliso yobuninzi. Ukongezelela, xa kuthelekiswa nezinye iindlela zokusika ezifana nokusika kwe-laser, ukusika oomatshini kuneendleko ezilawulekayo, okwenza ukuba zilungele iimfuno zokuvelisa umthamo ophezulu.

Ukulinganiselwa

Ngaphandle kweenzuzo ezininzi, iteknoloji yokusika oomatshini nayo inemida. Okokuqala, ngenxa yokunxibelelana ngokomzimba phakathi kwesixhobo kunye ne-wafer, ukuchaneka kokusika kuncinci, okuhlala kukhokelela ekuphambukeni komda onokuthi kuchaphazele ukuchaneka kokupakishwa kwe-chip kunye novavanyo. Okwesibini, iziphene ezifana nokutshiza kunye nokuqhekeka zinokwenzeka ngokulula ngexesha lenkqubo yokusika i-mechanical, engachaphazeli kuphela izinga lesivuno kodwa inokuchaphazela kakubi ukuthembeka kunye nokuphila kwee-chips. Umonakalo obangelwa kukuxinzezeleka komatshini unobungozi ngokukodwa kwi-high-density chip production, ngakumbi xa usika izinto ezinqabileyo, apho le miba ibonakala ngakumbi.

Uphuculo lobuchwephesha

Ukoyisa le mida, abaphandi baqhubeka nokuphucula inkqubo yokusika oomatshini. Uphuculo oluphambili lubandakanya ukuphuculwa koyilo kunye nokukhethwa kwezinto eziphathekayo zamavili okugaya ukuphucula ukuchaneka kokusika kunye nokuqina. Ukongezelela, ukulungiswa koyilo lwesakhiwo kunye neenkqubo zokulawula izixhobo zokusika kuye kwaphucula ngakumbi ukuzinza kunye nokuzenzekelayo kwenkqubo yokusika. Ezi nkqubela zinciphisa iimpazamo ezibangelwa yimisebenzi yabantu kunye nokuphucula ukuhambelana kokusikeka. Ukungeniswa kovavanyo oluphezulu kunye nolawulo lwetekhnoloji yomgangatho wokubeka iliso ngexesha lokwenyani kwizinto ezingaqhelekanga ngexesha lenkqubo yokusika kuphucule kakhulu ukuthembeka kunye nesivuno.

Uphuhliso lwexesha elizayo kunye nobuchwephesha obutsha

Nangona itekhnoloji yokusika oomatshini isabambe isikhundla esibalulekileyo ekusikeni kwe-wafer, itekhnoloji entsha yokusika iqhubela phambili ngokukhawuleza njengoko iinkqubo ze-semiconductor zivela. Ngokomzekelo, ukusetyenziswa kweteknoloji yokusika i-laser ye-thermal inikeza izisombululo ezitsha kwimiba echanekileyo kunye nesiphako ekusikeni koomatshini. Le ndlela yokusika i-non-contact iyanciphisa uxinzelelo lomzimba kwi-wafer, inciphisa kakhulu iziganeko zokuqhawula kunye nokuqhekeka, ngakumbi xa usika izinto ezinqabileyo. Kwixesha elizayo, ukudityaniswa kobuchwepheshe bokusika oomatshini kunye neendlela zokusika ezikhulayo ziya kunika ukuveliswa kwe-semiconductor ngeendlela ezininzi kunye nokuguquguquka, ukuqhubela phambili ukunyusa ukusebenza kakuhle kokuveliswa kunye nomgangatho we-chip.

Ekugqibeleni, nangona iteknoloji yokusika i-mechanical inezithintelo ezithile, ukuphuculwa kobuchwepheshe obuqhubekayo kunye nokuhlanganiswa kwayo kunye neendlela ezintsha zokusika zivumela ukuba zidlale indima ebalulekileyo kwimveliso ye-semiconductor kunye nokugcina ukukhuphisana kwayo kwiinkqubo ezizayo.

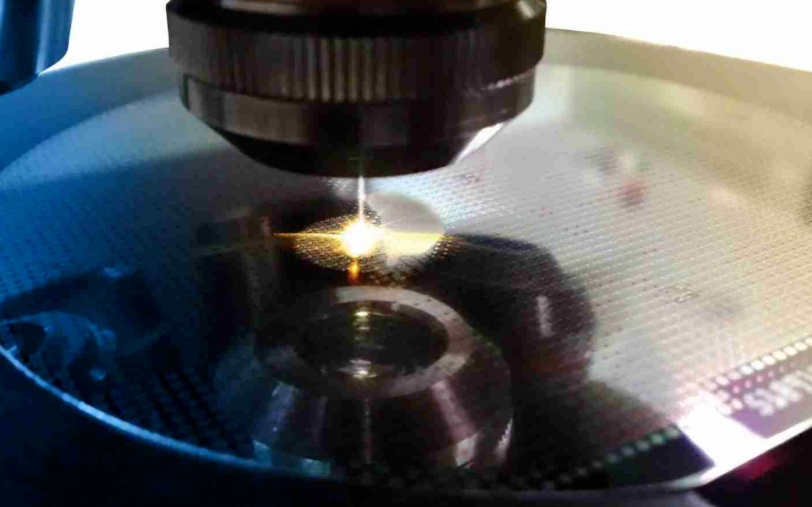

2.2 Iteknoloji yokusika iLaser

Itekhnoloji yokusika iLaser, njengendlela entsha yokusika i-wafer, ngokuthe ngcembe iye yafumana ingqwalasela ebanzi kwishishini le-semiconductor ngenxa yokuchaneka kwayo okuphezulu, ukungabikho komonakalo wonxibelelwano ngoomatshini, kunye nokukwazi ukusika ngokukhawuleza. Le teknoloji isebenzisa ukuxinana kwamandla aphezulu kunye nokukwazi ukugxila kwi-laser beam ukwenza indawo encinci echatshazelwe bubushushu kumphezulu we-wafer material. Xa i-laser beam isetyenziswe kwi-wafer, uxinzelelo lwe-thermal oluveliswayo lubangela ukuba izinto eziphathekayo ziqhekeke kwindawo echongiweyo, ukufezekisa ukusika ngokuchanekileyo.

Izinto eziluncedo Laser Cutting Technology

• Ukuchaneka okuphezulu: I-laser beam ye-laser yokubeka isithuba esichanekileyo ivumela i-micron okanye i-nanometer-level cut precision yokusika, ukuhlangabezana neemfuno zobugcisa besimanje, ubuninzi obuphezulu obuhlanganisiweyo besekethe.

• Akukho Nxibelelwano ngoomatshini: Ukusika i-Laser kunqanda ukudibanisa ngokomzimba kunye ne-wafer, ukukhusela imiba eqhelekileyo ekusikeni komatshini, njengokuqhawula kunye nokuqhekeka, ukuphucula kakhulu izinga lesivuno kunye nokuthembeka kwee-chips.

• Isantya sokusika ngokukhawuleza: Isantya esiphezulu sokusika i-laser sinegalelo ekwandiseni ukusebenza kakuhle kwemveliso, okwenza ukuba ifaneleke ngokukodwa kwimiba emikhulu, yeemeko zemveliso yesantya esiphezulu.

Imicelimngeni Ejongene Nayo

• Iindleko eziphezulu zeZixhobo: Utyalo-mali lokuqala lwezixhobo zokusika i-laser luphezulu, olubonisa uxinzelelo lwezoqoqosho, ngakumbi kumashishini amancinci ukuya kwaphakathi.

• Ulawulo lweNkqubo entsonkothileyo: Ukusika iLaser kufuna ulawulo oluchanekileyo lweeparamitha ezininzi, kubandakanywa ukuxinana kwamandla, indawo ekugxilwe kuyo, kunye nesantya sokusika, ukwenza inkqubo ibe nzima.

• Imiba yeZowuni eChatshazelwe bubushushu: Nangona indalo ye-laser ye-non-contact inciphisa umonakalo owenziwe ngumatshini, uxinzelelo lwe-thermal olubangelwa indawo echatshazelwe ngubushushu (HAZ) lunokuba nefuthe elibi kwiipropati ze-wafer material. Ukulungiswa ngakumbi kwenkqubo kuyafuneka ukunciphisa le mpembelelo.

Izalathiso zoPhuculo lweTekhnoloji

Ukujongana nale mingeni, abaphandi bagxile ekunciphiseni iindleko zezixhobo, ukuphucula ukusebenza kakuhle kokusika, kunye nokwandisa ukuhamba kwenkqubo.

• IiLaser ezisebenzayo kunye neeNkqubo zeOptical: Ngokuphuhlisa i-lasers esebenzayo kunye neenkqubo eziphambili ze-optical, kunokwenzeka ukunciphisa iindleko zezixhobo ngelixa uphucula ukuchaneka kokusika kunye nesantya.

• Ukuphucula iiParameters zeNkqubo: Uphando olunzulu malunga nokusebenzisana phakathi kwe-laser kunye nezixhobo ze-wafer ziqhutyelwa ukuphucula iinkqubo ezinciphisa indawo echaphazelekayo ukushisa, ngaloo ndlela kuphuculwe umgangatho wokusika.

• IiNkqubo zoLawulo oluBukrelekrele: Ukuphuhliswa kobuchwephesha bolawulo oluhlakaniphile lujolise ekuzenzeleni nasekulungiseleleni inkqubo yokusika i-laser, ukuphucula ukuzinza kunye nokuhambelana.

Itekhnoloji yokusika iLaser iyasebenza ngakumbi kwiiwafers ezincinci kunye neemeko zokusika ezichanekileyo. Njengoko ubungakanani be-wafer bukhula kwaye ukuxinana kweesekethe kunyuka, iindlela zokusika oomatshini bemveli ziyasokola ukuhlangabezana nokuchaneka okuphezulu kunye neemfuno eziphezulu zokwenziwa kwe-semiconductor yanamhlanje. Ngenxa yeenzuzo zayo ezizodwa, ukusika kwe-laser kuba sisisombululo esikhethiweyo kule mimandla.

Nangona itekhnoloji yokusika i-laser isajongene nemingeni efana neendleko eziphezulu zezixhobo kunye nobunzima benkqubo, iingenelo zayo ezizodwa ekuchanekeni okuphezulu kunye nomonakalo ongaqhagamshelwani nawo zenza kube ngumkhombandlela obalulekileyo wophuhliso kwimveliso ye-semiconductor. Njengoko itekhnoloji ye-laser kunye neenkqubo zokulawula ezikrelekrele ziqhubela phambili, ukusika kwe-laser kulindeleke ukuba kuphucule ngakumbi ukusebenza kakuhle kwe-wafer kunye nomgangatho, ukuqhuba uphuhliso oluqhubekayo lweshishini le-semiconductor.

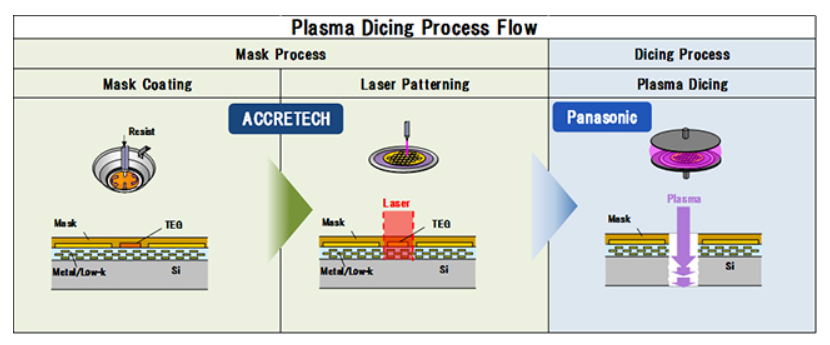

2.3 Iteknoloji yokusika iPlasma

Itekhnoloji yokusika i-Plasma, njengendlela esakhulayo yokudayela i-wafer, ifumene ingqwalasela ebalulekileyo kwiminyaka yakutshanje. Le teknoloji isebenzisa imiqadi yeplasma enamandla amakhulu ukusika ngokuchanekileyo ama-wafers ngokulawula amandla, isantya, kunye nendlela yokusika ye-plasma beam, ukufikelela kwiziphumo zokusika ezizezona zilungileyo.

Umgaqo wokuSebenza kunye nezinto eziluncedo

Inkqubo yokusika i-plasma ixhomekeke kwiqondo lokushisa eliphezulu, i-high-energy plasma beam eyenziwa zizixhobo. Lo mqadi unokufudumeza imathiriyeli ye-wafer ukuya kwindawo yayo yokunyibilika okanye yokufunxa ngexesha elifutshane kakhulu, ivumela ukusika ngokukhawuleza. Xa kuthelekiswa nomatshini wendabuko okanye ukusika kwe-laser, ukusika kweplasma kukhawuleza kwaye kuvelisa indawo encinci echaphazelekayo ukushisa, ukunciphisa ngokufanelekileyo ukuvela kweentanda kunye nomonakalo ngexesha lokusika.

Ukusetyenziswa okusebenzayo, itekhnoloji yokusika iplasma inobuchule ngakumbi ekuphatheni ii-wafers ezinemilo enzima. Amandla ayo aphezulu, umqa weplasma ohlengahlengiswayo unokusika ngokulula iiwafa ezimile ngendlela engaqhelekanga ngokuchaneka okuphezulu. Ke ngoko, kwimveliso ye-microelectronics, ngakumbi kwimveliso eyenziwe ngokwezifiso kunye nebhetshi encinci yeetshiphusi eziphezulu, le teknoloji ibonisa isithembiso esikhulu sokusetyenziswa ngokubanzi.

Imingeni kunye neMida

Ngaphandle kweenzuzo ezininzi zetekhnoloji yokusika iplasma, ikwajongene nemingeni ethile.

• Inkqubo entsonkothileyo: Inkqubo yokusika i-plasma iyinkimbinkimbi kwaye idinga izixhobo ezichanekileyo eziphezulu kunye nabaqhubi abanamava ukuqinisekisaukuchaneka kunye nokuzinza ekusikeni.

• ULawulo lweNdalo kunye noKhuseleko: Ubushushu obuphezulu, obuphezulu bendalo ye-plasma beam bufuna ulawulo olungqongqo lokusingqongileyo kunye namanyathelo okhuseleko, okwandisa ubunzima kunye neendleko zokuphunyezwa.

Izalathiso zoPhuhliso lwexesha elizayo

Ngenkqubela phambili yetekhnoloji, imiceli mngeni enxulumene nokusikwa kweplasma kulindeleke ukuba yoyiswe ngokuthe ngcembe. Ngokuphuhlisa izixhobo zokusika ezihlakaniphile kunye nezizinzileyo, ukuxhomekeka kwimisebenzi yezandla kunokuncitshiswa, ngaloo ndlela kuphuculwe ukusebenza kakuhle kwemveliso. Ngexesha elifanayo, ukulungiswa kweeparameters zenkqubo kunye nokusikwa kwendawo kuya kunceda ukunciphisa umngcipheko wokhuseleko kunye neendleko zokusebenza.

Kumzi mveliso we-semiconductor, iinguqulelo zokusikwa kwe-wafer kunye netekhnoloji yokudayiva ibalulekile ekuqhubeni uphuhliso lweshishini. Itekhnoloji yokusika iPlasma, ngokuchaneka kwayo okuphezulu, ukusebenza kakuhle, kunye nokukwazi ukuphatha iimilo ezintsonkothileyo ze-wafer, iye yavela njengomdlali omtsha obalulekileyo kule ntsimi. Nangona eminye imingeni isekhona, le miba iya kuqwalaselwa ngokuthe ngcembe ngokuqaliswa kokutsha kobuchwepheshe, oku kuzisa amathuba amaninzi kunye namathuba okwenziwa kwe-semiconductor.

Amathuba okusetyenziswa kwetekhnoloji yokusika iplasma inkulu, kwaye kulindeleke ukuba idlale indima ebaluleke ngakumbi kwimveliso ye-semiconductor kwixesha elizayo. Ngokuqhubeka kokwenziwa ngokutsha kwetekhnoloji kunye nokwenza ngcono, ukusikwa kweplasma akuzukujongana nemingeni ekhoyo kuphela kodwa kwakhona kube ngumqhubi onamandla wokukhula kweshishini le-semiconductor.

2.4 Ukunciphisa uMgangatho kunye neMiba enempembelelo

Umgangatho wokusika i-wafer ubaluleke kakhulu kwipakethe ye-chip elandelayo, uvavanyo, kunye nokusebenza ngokubanzi kunye nokuthembeka kwemveliso yokugqibela. Imiba eqhelekileyo edibana nayo ngexesha lokusika ibandakanya ukuqhekeka, ukuqhekeka, kunye nokuphambuka kokusika. Ezi ngxaki ziphenjelelwa zizinto ezininzi ezisebenzisanayo.

| Udidi | Umxholo | Impembelelo |

| Iiparamitha zeNkqubo | Ukusika isantya, izinga lokutya, kunye nobunzulu bokusika buchaphazela ngokuthe ngqo ukuzinza kunye nokuchaneka kwenkqubo yokusika. Izicwangciso ezingafanelekanga zingakhokelela ekugxininiseni uxinzelelo kunye nendawo echaphazelekayo yokushisa, okubangela ukuqhekeka kunye nokuqhekeka. Ukulungelelanisa iiparamitha ngokufanelekileyo ngokusekwe kwimathiriyeli ye-wafer, ubukhulu, kunye neemfuno zokusika ngundoqo ekufezekiseni iziphumo ezinqwenelekayo zokusika. | Iiparamitha zenkqubo efanelekileyo ziqinisekisa ukusika ngokuchanekileyo kunye nokunciphisa umngcipheko weziphene ezifana nokuqhekeka kunye nokuqhawula. |

| Izixhobo kunye nezinto eziphathekayo | -Umgangatho weBlade: Izinto eziphathekayo, ukuqina, kunye nokuxhatshazwa kokugqoka kwe-blade kuchaphazela ukugudisa kwenkqubo yokusika kunye nokukhanya kwendawo yokusika. Amagqabi akumgangatho ophantsi anyusa ukukhuhlana kunye noxinzelelo lobushushu, nto leyo enokukhokelela ekuqhekekeni okanye ekuqhekekeni. Ukukhetha i-blade impahla efanelekileyo kubalulekile. -Ukusebenza okupholileyo: Izinto zokupholisa zinceda ukunciphisa ubushushu bokusika, ukunciphisa ukukhuhlana, kunye nobutyobo obucacileyo. Ukupholisa okungasebenziyo kunokukhokelela kumaqondo obushushu aphezulu kunye nokwakhiwa kobutyobo, okuchaphazela umgangatho wokusika kunye nokusebenza kakuhle. Kubalulekile ukukhetha izinto zokupholisa ezisebenza kakuhle nezinobuhlobo nokusingqongileyo. | Umgangatho we-Blade uchaphazela ukuchaneka kunye nokugudiswa kokusikwa. Isipholisi esingasebenziyo sinokukhokelela kumgangatho osezantsi wokusika kunye nokusebenza kakuhle, kuqaqambisa imfuneko yokusetyenziswa kwesipholisi ngeyona ndlela. |

| Ukulawulwa kweNkqubo kunye noHlolo loMgangatho | -Ulawulo Lwenkqubo: Ukujongwa kwexesha langempela kunye nokulungelelaniswa kweeparitha eziphambili zokusika ukuqinisekisa ukuzinza kunye nokuhambelana kwinkqubo yokusika. -Ukuhlolwa koMgangatho: Ukuhlolwa kwembonakalo emva kokusika, imilinganiselo yokulinganisa, kunye nokuvavanya ukusebenza kombane kunceda ukuchonga nokujongana nemiba yomgangatho ngokukhawuleza, ukuphucula ukuchaneka kokusika kunye nokuhambelana. | Ukulawulwa kwenkqubo efanelekileyo kunye nokuhlolwa komgangatho kunceda ukuqinisekisa ukuhambelana, iziphumo zokusika ezikumgangatho ophezulu kunye nokufunyanwa kwangaphambili kwemiba enokubakho. |

Ukuphucula uMgangatho wokusika

Ukuphucula umgangatho wokusika kufuna indlela ebanzi ethathela ingqalelo iiparitha zenkqubo, izixhobo kunye nokukhethwa kwezinto, ulawulo lwenkqubo kunye nokuhlolwa. Ngokuqhubeka nokucokisa itekhnoloji yokusika kunye neendlela zenkqubo yokuphucula, ukuchaneka kunye nokuzinza kokusikwa kwe-wafer kunokwandiswa ngakumbi, ukubonelela ngenkxaso yobugcisa ethembekileyo kushishino lokuvelisa i-semiconductor.

#03 Emva kokuSika Ukuphatha kunye noVavanyo

3.1 Ukucoca kunye nokomisa

Amanyathelo okucoca kunye nokomisa emva kokusikwa kwe-wafer kubalulekile ekuqinisekiseni umgangatho we-chip kunye nokuqhubela phambili okugudileyo kweenkqubo ezilandelayo. Ngeli nqanaba, kubalulekile ukususa ngokupheleleyo inkunkuma ye-silicon, intsalela yokupholisa, kunye nolunye ungcoliseko olwenziwe ngexesha lokusikwa. Kubalulekile ngokulinganayo ukuqinisekisa ukuba ii-chips azonakaliswa ngexesha lokucoca, kwaye emva kokumisa, qinisekisa ukuba akukho manzi ahlala kwindawo ye-chip ukukhusela imiba efana nokugqwala okanye ukukhutshwa kwe-electrostatic.

Ukuphathwa kwePost-Cutting: Inkqubo yokuCoca kunye nokomisa

| Inkqubo Inyathelo | Umxholo | Impembelelo |

| Inkqubo yokucoca | -Indlela: Sebenzisa ii-agent ezikhethekileyo zokucoca kunye namanzi acocekileyo, adibene ne-ultrasonic okanye i-mechanical brushing techniques yokucoca. | Iqinisekisa ukususwa ngokucokisekileyo kwezinto ezingcolileyo kunye nokuthintela umonakalo kwiichips ngexesha lokucoca. |

| -UKhetho lweArhente yokucoca: Khetha ngokusekelwe kwizinto ezinqabileyo kunye nohlobo olungcolileyo ukuqinisekisa ukucoca okusebenzayo ngaphandle kokonakalisa i-chip. | Ukukhethwa kwe-ejenti ngokufanelekileyo ngundoqo ekucoceni okusebenzayo kunye nokukhusela i-chip. | |

| -Ulawulo lweParameter: Lawula ngokungqongqo ubushushu bokucoca, ixesha, kunye nokugxilwa kwesisombululo sokucoca ukukhusela imiba esemgangathweni ebangelwa ukucoca ngokungafanelekanga. | Ulawulo lunceda ukunqanda ukonakalisa i-wafer okanye ukushiya izinto ezingcolisayo ngasemva, ukuqinisekisa umgangatho ongaguqukiyo. | |

| Inkqubo yokomisa | -Iindlela zesiNtu: Ukomisa komoya wendalo kunye nokomisa komoya oshushu, okunokusebenza okuphantsi kwaye kunokukhokelela ekwakhiweni kombane omileyo. | Inokubangela ukucotha kwexesha lokomisa kunye nemiba enokubakho engatshintshiyo. |

| -Ubuchwephesha banamhlanje: Sebenzisa itekhnoloji ephezulu efana nokumisa i-vacuum kunye nokoma kwe-infrared ukuqinisekisa ukuba iitshiphusi zomile ngokukhawuleza kwaye ziphephe iziphumo ezinobungozi. | Inkqubo yokomisa ngokukhawuleza kunye nokusebenza kakuhle, ukunciphisa umngcipheko wokukhutshwa kwe-static okanye imiba enxulumene nokufuma. | |

| UKhetho lweZixhobo kunye noLondolozo | -UKhetho lweZixhobo: Ukucoca okuphezulu kunye noomatshini bomileyo baphucula ukusebenza kakuhle kunye nokulawula ngokufanelekileyo imiba enokubakho ngexesha lokuphatha. | Oomatshini abakumgangatho ophezulu baqinisekisa ukusebenza kakuhle kunye nokunciphisa amathuba okuba neempazamo ngexesha lokucoca kunye nokomisa. |

| -Ugcino lweZixhobo: Ukuhlolwa rhoqo kunye nokugcinwa kwezixhobo kuqinisekisa ukuba zihlala zikwimeko efanelekileyo yokusebenza, iqinisekisa umgangatho we-chip. | Ukugcinwa okufanelekileyo kuthintela ukusilela kwezixhobo, ukuqinisekisa ukusetyenzwa okuthembekileyo kunye nomgangatho ophezulu. |

Ukucoca emva kokusika kunye nokomisa

Amanyathelo okucoca kunye nokomisa emva kokusikwa kwe-wafer yinkqubo enzima kwaye ebuthathaka efuna ukuqwalaselwa ngononophelo kwizinto ezininzi zokuqinisekisa isiphumo sokugqibela sokusebenza. Ngokusebenzisa iindlela zenzululwazi kunye neenkqubo ezingqongqo, kunokwenzeka ukuba kuqinisekiswe ukuba i-chip nganye ingena kwisigaba esilandelayo sokupakisha kunye nokuvavanya kwimeko efanelekileyo.

Ukuhlolwa kwasemva kokusikwa kunye noVavanyo

| Inyathelo | Umxholo | Impembelelo |

| Inyathelo lokuHlola | 1.UHlolo Olubonwayo: Sebenzisa izixhobo zokuhlola ezibonwayo okanye ezizenzekelayo ukujonga iziphene ezibonakalayo njengokuqhekeka, ukuqhekeka, okanye ungcoliseko kumphezulu wetshiphu. Ukuchonga ngokukhawuleza iitshiphusi ezonakalisiweyo ukuze uphephe inkcitho. | Inceda ekuchongeni nasekupheliseni iitshiphusi ezineziphene ekuqaleni kwenkqubo, ukunciphisa ilahleko yezinto. |

| 2.Ubungakanani bomlinganiselo: Sebenzisa izixhobo ezichanekileyo zokulinganisa ukulinganisa ngokuchanekileyo imilinganiselo ye-chip, ukuqinisekisa ukuba ubungakanani bokusika budibana neenkcukacha zoyilo kunye nokuthintela imiba yokusebenza okanye ubunzima bokupakisha. | Iqinisekisa ukuba iitshiphusi zingaphakathi kwemida yobungakanani obufunekayo, ukuthintela ukuthotywa kokusebenza okanye iingxaki zendibano. | |

| 3.Uvavanyo lokuSebenza koMbane: Vavanya iiparamitha eziphambili zombane ezifana nokuchasana, amandla, kunye ne-inductance, ukuchonga ii-chips ezingahambelaniyo kunye nokuqinisekisa ukuba ii-chips ezisebenzayo kuphela ziqhubela phambili kwinqanaba elilandelayo. | Iqinisekisa kuphela iichips ezisebenzayo kunye nokusebenza-ezivavanyiweyo ziqhubela phambili kwinkqubo, zinciphisa umngcipheko wokungaphumeleli kwizigaba zamva. | |

| Inyathelo loVavanyo | 1.Uvavanyo olusebenzayo: Qinisekisa ukuba usetyenziso olusisiseko lwetshiphu lusebenza njengoko kucetyiwe, ukuchonga nokuphelisa iitshiphusi ezinezitenxo zokusebenza. | Iqinisekisa ukuba iitshiphusi ziyahlangabezana neemfuno ezisisiseko zokusebenza ngaphambi kokuba uqhubele phambili ukuya kumanqanaba amva. |

| 2.UVavanyo lokuthembeka: Vavanya uzinzo lokusebenza kwetshiphu phantsi kokusetyenziswa ixesha elide okanye imekobume erhabaxa, ebandakanya ukuguga okuphezulu, ubushushu obuphantsi, uvavanyo lokufuma ukulinganisa iimeko zehlabathi zokwenyani. | Iqinisekisa ukuba iitshiphusi zinokusebenza ngokuthembekileyo phantsi koluhlu lweemeko zokusingqongileyo, ukuphucula ixesha elide lemveliso kunye nokuzinza. | |

| 3.Uvavanyo lokuhambelana: Qinisekisa ukuba i-chip isebenza ngokufanelekileyo namanye amacandelo okanye iinkqubo, ukuqinisekisa ukuba akukho ziphene okanye ukuthotywa kwentsebenzo ngenxa yokungahambelani. | Iqinisekisa ukusebenza kakuhle kwizicelo zehlabathi lokwenyani ngokuthintela imiba ehambelanayo. |

3.3 Ukupakishwa kunye noGcino

Emva kokusikwa kwe-wafer, iitshiphusi sisiphumo esibalulekileyo senkqubo yokwenziwa kwe-semiconductor, kwaye ukupakishwa kwazo kunye nezigaba zokugcina zibaluleke ngokulinganayo. Amanyathelo okupakisha afanelekileyo kunye nokugcinwa kubalulekile kungekuphela nje ekuqinisekiseni ukhuseleko kunye nokuzinza kwee-chips ngexesha lokuthutha kunye nokugcinwa kodwa kunye nokubonelela ngenkxaso eqinile kwimveliso elandelayo, uvavanyo kunye nezigaba zokupakisha.

IsiShwankathelo soHlolo kunye naManqanaba oVavanyo:

Ukuhlolwa kunye namanyathelo okuvavanya iitshiphusi emva kokusikwa kwe-wafer kugubungela uluhlu lwemiba, kubandakanya ukuhlolwa okubonakalayo, ukulinganisa ubungakanani, uvavanyo lokusebenza kombane, uvavanyo olusebenzayo, uvavanyo lokuthembeka, kunye novavanyo lokuhambelana. La manyathelo adibeneyo kwaye ayancedisana, enza umqobo oqinileyo wokuqinisekisa umgangatho wemveliso kunye nokuthembeka. Ngokuhlola ngokungqongqo kunye neenkqubo zokuvavanya, imiba enokubakho inokuchongwa kwaye isonjululwe ngokukhawuleza, ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana neemfuno zabathengi kunye nokulindela.

| Umba | Umxholo |

| Amanyathelo okuPakisha | 1.I-Anti-static: Izinto zokupakisha kufuneka zibe neempawu ezibalaseleyo ezichasene ne-static ukukhusela umbane ongatshintshiyo ekonakaliseni izixhobo okanye ukuchaphazela ukusebenza kwazo. |

| 2.Ubungqina bokufuma: Izinto zokupakisha kufuneka zibe nokuchasana kokufuma okulungileyo ukukhusela ukubola kunye nokuwohloka kokusebenza kombane okubangelwa ngumswakama. | |

| 3.Ukothuka: Izinto zokupakisha kufuneka zinikeze ukufunxa okusebenzayo ukukhusela iitshiphusi kwi-vibration kunye nefuthe ngexesha lokuhamba. | |

| Indawo yogcino | 1.Ulawulo lokufuma: Lawula ngokungqongqo ukufuma phakathi koluhlu olufanelekileyo ukunqanda ukufunxa ukufuma kunye nokuhlwa okubangelwa kukufuma okugqithisileyo okanye imiba engashukumiyo ebangelwa kukufuma okuphantsi. |

| 2.Ucoceko: Gcina indawo yokugcina ecocekileyo ukuze ugweme ukungcoliswa kwee-chips ngothuli kunye nokungcola. | |

| 3.Ulawulo lobushushu: Misela uluhlu lweqondo lokushisa olufanelekileyo kunye nokugcina ukuzinza kweqondo lokushisa ukukhusela ukuguga okukhawulezileyo ngenxa yokushisa okugqithisileyo okanye iingxaki ze-condensation ezibangelwa ukushisa okuphantsi. | |

| Ukuhlolwa rhoqo | Hlala uhlola kwaye uvavanye ii-chips ezigciniweyo, usebenzisa ukuhlolwa okubonakalayo, imilinganiselo yobukhulu, kunye neemvavanyo zokusebenza kombane ukuchonga nokujongana nemiba enokwenzeka ngexesha elifanelekileyo. Ngokusekelwe kwixesha lokugcinwa kunye neemeko, cwangcisa ukusetyenziswa kweetshiphusi ukuqinisekisa ukuba zisetyenziswa kwimeko efanelekileyo. |

Umba we-microcracks kunye nomonakalo ngexesha lenkqubo ye-wafer dicing ngumngeni obalulekileyo kwimveliso ye-semiconductor. Uxinzelelo lokusika luyimbangela ephambili yale nto, njengoko idala iintanda ezincinci kunye nomonakalo kwi-wafer surface, ekhokelela ekunyuseni kweendleko zokuvelisa kunye nokunciphisa umgangatho wemveliso.

Ukujongana nalo mceli mngeni, kubalulekile ukunciphisa uxinzelelo kunye nokuphumeza iindlela zokusika eziphuculweyo, izixhobo kunye neemeko. Ukuqwalasela ngokucophelela izinto ezifana ne-blade material, isantya sokusika, uxinzelelo, kunye neendlela zokupholisa kunokunceda ukunciphisa ukubunjwa kwe-microcracks kunye nokuphucula isivuno esipheleleyo senkqubo. Ukongeza, uphando oluqhubekayo kwiitekhnoloji zokusika eziphucukileyo, ezinje ngelaser dicing, zijonga iindlela zokunciphisa le miba.

Njengezinto ezibuthathaka, ii-wafers zixhomekeke kutshintsho lwesakhiwo sangaphakathi xa ziphantsi koxinzelelo lwemishini, i-thermal, okanye ikhemikhali, ekhokelela ekubunjweni kwe-microcracks. Nangona ezi ntanda zisenokungabonakali ngokukhawuleza, zinokukhula kwaye zidale umonakalo omkhulu njengoko inkqubo yokuvelisa iqhubela phambili. Lo mbandela uba yingxaki ngakumbi ngexesha lokupakishwa kunye nenqanaba lovavanyo olulandelayo, apho ukuguquguquka kwamaqondo obushushu kunye noxinzelelo olongezelelweyo lomatshini kunokubangela ukuba ezi microcracks ziguquke zibe ziifractures ezibonakalayo, ezinokukhokelela ekungaphumeleli kwetshiphu.

Ukunciphisa lo mngcipheko, kubalulekile ukulawula inkqubo yokusika ngononophelo ngokulungiselela iiparamitha ezinje ngesantya sokusika, uxinzelelo kunye nobushushu. Ukusebenzisa iindlela zokusika ezinobundlongondlongo, ezifana ne-laser dicing, kunokunciphisa uxinzelelo lomatshini kwi-wafer kunye nokunciphisa ukubunjwa kwee-microcracks. Ukongeza, ukuphumeza iindlela zokuhlola ezikumgangatho ophezulu ezinje nge-infrared scanning okanye i-X-ray imaging ngexesha le-wafer dicing process inokunceda ekubhaqweni oku kuqhekeka kwenqanaba lakwangoko ngaphambi kokuba kubangele umonakalo.

Umonakalo kwi-wafer surface yinkxalabo ebalulekileyo kwinkqubo yokudayela, njengoko ingaba nefuthe elithe ngqo ekusebenzeni kwe-chip kunye nokuthembeka. Umonakalo onjalo unokubangelwa ukusetyenziswa okungafanelekanga kwezixhobo zokusika, iiparitha zokusika ezingalunganga, okanye iziphene zezinto eziphathekayo ezifumaneka kwi-wafer ngokwayo. Kungakhathaliseki ukuba yintoni isizathu, le monakalo ingakhokelela ekutshintsheni ukuxhatshazwa kombane okanye i-capacitance yesekethe, echaphazela ukusebenza ngokubanzi.

Ukuhlangabezana nale miba, kuphononongwa iindlela ezimbini eziphambili:

1.Ukuphucula izixhobo zokusika kunye neeparamitha: Ngokusebenzisa amacwecwe abukhali, ukulungelelanisa isantya sokusika, kunye nokuguqula ubunzulu bokusika, ukuxinzelela uxinzelelo ngexesha lokusika kunokunciphisa, ngaloo ndlela kuncitshiswe umonakalo.

2.Ukuphonononga itekhnoloji entsha yokusika: Iindlela eziphucukileyo ezifana nokusika i-laser kunye nokusikwa kweplasma zinika ukuchaneka okuphuculweyo ngelixa kunokunciphisa inqanaba lomonakalo owenziwe kwi-wafer. Ezi teknoloji ziyafundwa ukufumana iindlela zokufezekisa ukuchaneka kokusika okuphezulu ngelixa unciphisa uxinzelelo lwe-thermal kunye noomatshini kwi-wafer.

Indawo yeMpembelelo yeThermal kunye neziphumo zayo ekusebenzeni

Kwiinkqubo zokusika i-thermal ezifana ne-laser kunye ne-plasma yokusika, amaqondo obushushu aphezulu adala indawo yempembelelo ye-thermal kumphezulu we-wafer. Le ndawo, apho i-gradient yeqondo lokushisa ibaluleke kakhulu, inokuguqula izinto eziphathekayo, ezichaphazela ukusebenza kokugqibela kwe-chip.

Impembelelo yoMmandla oChaphazeleke nguThermal (TAZ):

Utshintsho lweSakhiwo seCrystal: Ngaphantsi kwamaqondo okushisa aphezulu, ii-athomu ezingaphakathi kwe-wafer material zinokuphinda zilungelelanise, zibangele ukuphazamiseka kwisakhiwo sekristale. Oku kugqwethwa kunciphisa izinto, ukunciphisa amandla ayo omatshini kunye nokuzinza, okwandisa umngcipheko wokungaphumeleli kwe-chip ngexesha lokusetyenziswa.

Utshintsho kwiiPropati zoMbane: Amaqondo okushisa aphezulu anokuguqula ukugxininiswa komthwali kunye nokuhamba kwizinto eziphathekayo ze-semiconductor, ezichaphazela umbane we-chip kunye nokusebenza kakuhle kokuhanjiswa. Olu tshintsho lunokukhokelela ekwehleni kokusebenza kwetshiphu, oko kunokubangela ukuba ingayilungeli injongo yayo.

Ukunciphisa ezi ziphumo, ukulawula ubushushu ngexesha lokusika, ukulungelelanisa iiparamitha zokusika, kunye nokuhlola iindlela ezifana neejethi zokupholisa okanye unyango emva kokulungiswa zizicwangciso eziyimfuneko zokunciphisa ubungakanani bempembelelo ye-thermal kunye nokugcina imfezeko yezinto eziphathekayo.

Ngokubanzi, zombini ii-microcracks kunye nemimandla yempembelelo yobushushu yimiceli mngeni ebalulekileyo kwitekhnoloji ye-wafer dicing. Uphando oluqhubekayo, kunye nokuhambela phambili kwezobuchwepheshe kunye nemilinganiselo yokulawula umgangatho, kuya kuba yimfuneko ukuphucula umgangatho weemveliso ze-semiconductor kunye nokuphucula ukhuphiswano lwabo lwemarike.

Amanyathelo okulawula uMmandla weMpembelelo yoThermal:

Ukuphucula IiParameters zeNkqubo yokuSika: Ukunciphisa isantya sokusika kunye namandla kunokunciphisa ngokufanelekileyo ubungakanani bommandla wempembelelo ye-thermal (TAZ). Oku kunceda ekulawuleni ubushushu obuveliswayo ngexesha lenkqubo yokusika, echaphazela ngokuthe ngqo izinto eziphathekayo ze-wafer.

Ubuchwephesha bokuPholisa obuPhezulu: Ukusetyenziswa kweetekhnoloji ezifana nokupholisa initrogen engamanzi kunye nokupholisa ngemicrofluidic kunokunciphisa ngokuphawulekayo uluhlu lwendawo yempembelelo yobushushu. Ezi ndlela zokupholisa zinceda ukutshabalalisa ubushushu ngokufanelekileyo, ngaloo ndlela kugcinwe izinto eziphathekayo ze-wafer kunye nokunciphisa umonakalo wokushisa.

Ukukhethwa kwezinto: Abaphandi baphonononga izixhobo ezitsha, ezifana nekhabhoni nanotubes kunye negraphene, eziphethe i-thermal conductivity egqwesileyo kunye namandla omatshini. Ezi zixhobo zinokunciphisa indawo yempembelelo ye-thermal ngelixa uphucula ukusebenza ngokubanzi kweechips.

Isishwankathelo, nangona indawo yempembelelo ye-thermal iyisiphumo esingenakuphepheka sobuchwepheshe bokusika i-thermal, inokulawulwa ngokufanelekileyo ngokusebenzisa iindlela zokulungiswa okuphuculweyo kunye nokukhethwa kwezinto eziphathekayo. Uphando lwexesha elizayo luya kujolisa ekulungiseni kakuhle nasekuzenzeleni iinkqubo zokusika i-thermal ukuze kuphunyezwe ukusebenza kakuhle nokuchaneka kwe-wafer dicing.

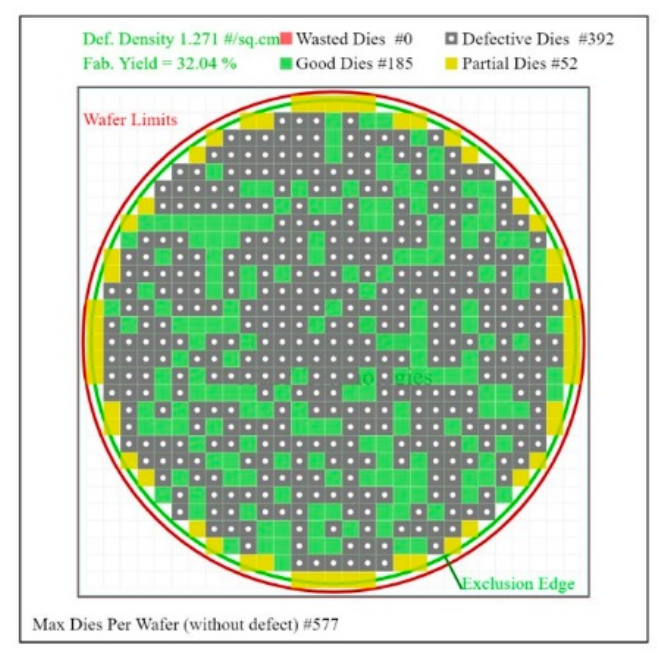

Isicwangciso soLingano:

Ukuzuza ulungelelwaniso olufanelekileyo phakathi kwesivuno se-wafer kunye nokusebenza kakuhle kwemveliso ngumngeni oqhubekayo kubuchwepheshe bokwenza i-wafer dicing. Abavelisi kufuneka baqwalasele izinto ezininzi, ezinje ngemfuno yentengiso, iindleko zemveliso, kunye nomgangatho wemveliso, ukuphuhlisa isicwangciso sokuvelisa esinengqiqo kunye neeparamitha zenkqubo. Kwangaxeshanye, ukwazisa izixhobo zokusika eziphambili, ukuphuculwa kwezakhono zabasebenzisi, kunye nokuphucula ulawulo lomgangatho wemathiriyeli ekrwada kubalulekile ekugcineni okanye nasekuphuculeni isivuno ngelixa usonyusa ukusebenza kakuhle kwemveliso.

Imingeni namathuba azayo:

Ngokuqhubela phambili kwetekhnoloji ye-semiconductor, ukusika i-wafer kujongana nemingeni emitsha kunye namathuba. Njengoko ubungakanani beetshiphu buncipha kwaye ukudibanisa kunyuka, iimfuno zokuchaneka kokusika kunye nomgangatho zikhula kakhulu. Kwangaxeshanye, itekhnoloji ekhulayo ibonelela ngemibono emitsha yophuhliso lweendlela zokusika i-wafer. Abavelisi kufuneka bahlale behambelana nokutshintsha kweemarike kunye neentsingiselo zethekhinoloji, ngokuqhubekayo uhlengahlengiso kunye nokuphucula izicwangciso zemveliso kunye nemilinganiselo yenkqubo ukuhlangabezana nokutshintsha kweemarike kunye neemfuno zobuchwepheshe.

Ukuqukumbela, ngokudibanisa iingqwalasela zemfuno yemarike, iindleko zemveliso, kunye nomgangatho wemveliso, kunye nokwazisa izixhobo eziphambili kunye netekhnoloji, ukuphucula izakhono zabaqhubi, kunye nokomeleza ulawulo lwemathiriyeli ekrwada, abavelisi banokufikelela olona lungelelwano lulungileyo phakathi kwesivuno se-wafer kunye nokusebenza kakuhle kwemveliso ngexesha le-wafer dicing, ekhokelela kwimveliso esebenzayo kunye nomgangatho ophezulu we-semiconductor yemveliso.

Ujongo lwekamva:

Ngenkqubela phambili yetekhnoloji ekhawulezayo, itekhnoloji ye-semiconductor iqhubela phambili ngesantya esingazange sabonwa ngaphambili. Njengenyathelo elibalulekileyo kwimveliso ye-semiconductor, itekhnoloji yokusika i-wafer ilungele uphuhliso olutsha olunomdla. Ukujonga phambili, itekhnoloji yokusika i-wafer kulindeleke ukuba ifezekise ukuphucuka okubalulekileyo kokuchaneka, ukusebenza kakuhle, kunye neendleko, ukufaka amandla obutsha ekukhuleni okuqhubekayo koshishino lwe-semiconductor.

Ukwandisa Ukuchaneka:

Ekufuneni ukuchaneka okuphezulu, itekhnoloji yokusika i-wafer iya kuhlala ityhala imida yeenkqubo ezikhoyo. Ngokufunda ngokunzulu iindlela zomzimba kunye neekhemikhali zenkqubo yokusika kunye nokulawula ngokuchanekileyo iiparamitha zokusika, iziphumo zokusika ezicolekileyo ziya kufezekiswa ukuze zihlangabezane neemfuno zoyilo lwesekethe. Ukongeza, ukuphononongwa kwezinto ezintsha kunye neendlela zokusika kuya kuphucula kakhulu isivuno kunye nomgangatho.

Ukuphucula ukusebenza kakuhle:

Isixhobo esitsha sokusika i-wafer siya kugxila kuyilo olukrelekrele kunye noluzenzekelayo. Ukuqaliswa kweenkqubo zokulawula eziphambili kunye ne-algorithms kuya kwenza ukuba izixhobo zilungelelanise ngokuzenzekelayo iiparitha zokusika ukuze zifake izinto ezahlukeneyo kunye neemfuno zoyilo, ngaloo ndlela ziphucula kakhulu ukusebenza kwemveliso. Izinto ezintsha ezifana netekhnoloji yokusika i-wafer ezininzi kunye neenkqubo ezikhawulezayo zokutshintsha iiblade ziya kudlala indima ebalulekileyo ekwandiseni impumelelo.

Ukunciphisa Iindleko:

Ukunciphisa iindleko lukhokelo oluphambili kuphuhliso lweteknoloji yokusika i-wafer. Njengoko izixhobo ezitsha kunye neendlela zokusika ziphuhliswa, iindleko zezixhobo kunye neendleko zokulondoloza kulindeleke ukuba zilawulwe ngokufanelekileyo. Ukongeza, ukulungiswa kweenkqubo zemveliso kunye nokunciphisa amazinga e-scrap kuya kunciphisa ngakumbi inkunkuma ngexesha lokuvelisa, okukhokelela ekunciphiseni kweendleko zokuvelisa ngokubanzi.

I-Smart Manufacturing kunye ne-IoT:

Ukudityaniswa kokwenziwa kobuchule kunye ne-Intanethi yeTekhnoloji yeZinto (IoT) kuya kuzisa utshintsho oluguqukayo kwitekhnoloji yokusika i-wafer. Ngonxibelelwano kunye nokwabelana ngedatha phakathi kwezixhobo, inyathelo ngalinye lenkqubo yokuvelisa linokubekwa iliso kwaye lilungiswe ngexesha langempela. Oku akuphuculi nje ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso kodwa ikwabonelela iinkampani ngoqikelelo oluchanekileyo lwentengiso kunye nenkxaso yokwenza izigqibo.

Kwixesha elizayo, itekhnoloji yokusika i-wafer iya kwenza inkqubela phambili ephawulekayo ekuchanekeni, ukusebenza kakuhle, kunye neendleko. Ezi nkqubela phambili ziya kuqhuba uphuhliso oluqhubekayo lweshishini le-semiconductor kwaye izise iinguqulelo ezininzi zobuchwepheshe kunye nezinto eziluncedo kuluntu.

Ixesha lokuposa: Nov-19-2024