Kwinkqubo yophuhliso olukhulayo lweshishini le-semiconductor, ikristale ekhazimlisiweyo enyeamaqhekeza e-silicondlala indima ebalulekileyo. Zisebenza njengezona zinto zibalulekileyo kwimveliso yezixhobo ezahlukeneyo ze-microelectronic. Ukusuka kwiisekethe ezidibeneyo nezichanekileyo ezidibeneyo ukuya kwii-microprocessors ezinesantya esiphezulu kunye ne-multifunctional sensors, ikristale enye ekhazimlisiweyo.amaqhekeza e-siliconzibalulekile. Umahluko ekusebenzeni kwabo kunye neenkcukacha zichaphazela ngokuthe ngqo umgangatho kunye nokusebenza kweemveliso zokugqibela. Apha ngezantsi kukho ukucaciswa okuqhelekileyo kunye neeparamitha zeewafers ze-silicon ezikhazimlisiweyo:

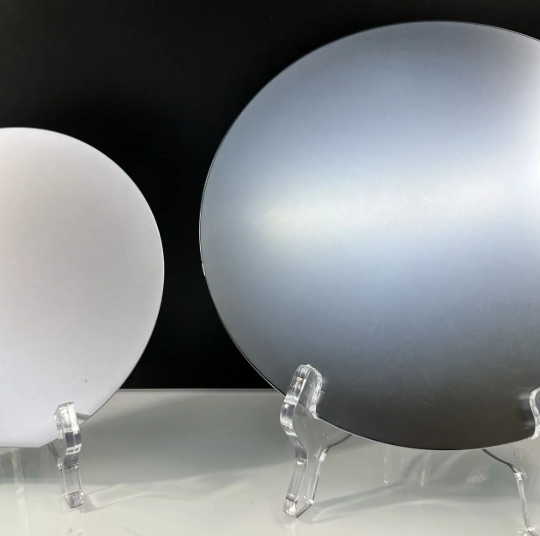

Ububanzi: Ubungakanani be-semiconductor enye yecrystal silicon wafers ilinganiswa ngobubanzi bazo, kwaye beza kwiinkcukacha ezahlukeneyo. Iidayamitha eziqhelekileyo ziquka ii-intshi ezi-2 (50.8mm), ii-intshi ezi-3 (76.2mm), ii-intshi ezi-4 (100mm), ii-intshi ezi-5 (125mm), ii-intshi ezi-6 (150mm), ii-intshi ezi-8 (200mm), ii-intshi eziyi-12 (300mm), kunye ne-18 intshi (450mm). Iidamitha ezahlukeneyo zilungele iimfuno ezahlukeneyo zemveliso kunye neemfuno zenkqubo. Umzekelo, iiwafa ezincinci zedayamitha ezincinci ziqhele ukusetyenziselwa izixhobo ezikhethekileyo, ezincinci zevolumu encinci, ngelixa iiwafa ezinkulu zedayamitha zibonisa impumelelo ephezulu yemveliso kunye neenzuzo zeendleko kwimveliso yesekethe enkulu edibeneyo. Iimfuno zomphezulu zihlelwe njengecala elinye elipolishiwe (SSP) kunye necala eliphindwe kabini elipolishiwe (DSP). Ii-wafers ezikhazimlisiweyo zecala elinye zisetyenziselwa izixhobo ezifuna umcaba ophezulu kwicala elinye, njengezinzwa ezithile. Ii-wafers ezigudisiweyo ezinamacala amabini ziqhele ukusetyenziselwa iisekethe ezidibeneyo kunye nezinye iimveliso ezifuna ukuchaneka okuphezulu kuyo yomibini imiphezulu. IMfuneko yoMphezulu (Gqiba): I-SSP yecala elinye epolishiweyo / i-DSP epholisiweyo kabini.

Uhlobo / I-Dopant: (1) I-N-type Semiconductor: Xa ii-athomu ezithile zokungcola zingeniswa kwi-intrinsic semiconductor, ziguqula ukuqhuba kwayo. Umzekelo, xa izinto ze-pentavalent ezifana ne-nitrogen (N), i-phosphorus (P), i-arsenic (As), okanye i-antimony (Sb) yongezwa, ii-electron zabo ze-valence zenza i-covalent bonds kunye nee-electron ze-valence ze-athomu ze-silicon ezingqongileyo, zishiya i-electron eyongezelelweyo ingabotshwanga yi-covalent bond. Oku kubangela ukugxininiswa kwe-electron enkulu kunogxininiso lomngxuma, okwenza i-semiconductor yohlobo lwe-N, eyaziwa ngokuba yi-electron-type semiconductor. Ii-semiconductors zohlobo lwe-N zibalulekile kwizixhobo zokuvelisa ezifuna ii-electron njengezona zithwali zentlawulo, ezifana nezixhobo ezithile zamandla. (2) I-P-uhlobo lwe-Semiconductor: Xa izinto ezingcolileyo ze-trivalent ezifana ne-boron (B), i-gallium (i-Ga), okanye i-indium (In) zingeniswa kwi-silicon semiconductor, ii-electron ze-valence ze-athomu zokungcola zenza iibhondi ze-covalent kunye nee-athom ze-silicon ezijikelezayo, kodwa ziswele ubuncinane i-electron ye-valence enye kwaye ayikwazi ukwenza i-covalent epheleleyo. Oku kukhokelela ekugxininiseni komngxuma omkhulu kunogxininiso lwe-electron, okwenza i-semiconductor yohlobo lwe-P, eyaziwa ngokuba yi-semiconductor yohlobo lomngxuma. I-P-type semiconductors idlala indima ephambili kwizixhobo zokuvelisa apho imingxuma isebenza njengabathwali bentlawulo, njenge-diode kunye nee-transistors ezithile.

Ukuxhathisa: Ukuxhathisa sisixa esiphambili somzimba esilinganisa ukuqhutywa kombane kweewafers ze-silicon ezikhazimlisiweyo. Ixabiso layo libonisa ukusebenza kokuqhutywa kwezinto. Okuya kusezantsi ukuxhathisa, kokukhona i-conductivity ye-silicon wafer; ngokuchaseneyo, okukhona i-resistivity iphezulu, ihlwempuzekile ukuqhuba. I-resistantivity ye-silicon wafers imiselwa ziipropathi zazo zendalo, kwaye ubushushu bunempembelelo enkulu ngokunjalo. Ngokubanzi, ukuxhathisa kwee-wafers ze-silicon konyuka ngobushushu. Kwizicelo ezisebenzayo, izixhobo ezahlukeneyo ze-microelectronic zineemfuno ezahlukeneyo zokuxhathisa kwii-silicon wafers. Ngokomzekelo, ii-wafers ezisetyenziselwa ukuveliswa kweesekethe ezidibeneyo zifuna ulawulo oluchanekileyo lokumelana nokuqinisekisa ukusebenza kwesixhobo esizinzile nesithembekileyo.

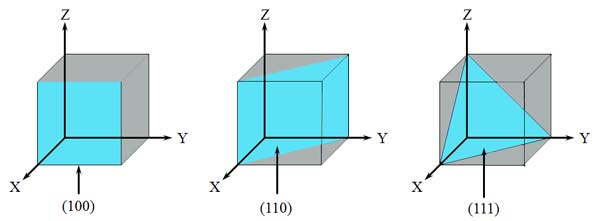

Ukuqhelaniswa: I-crystal orientation ye-wafer imele i-crystallographic direction ye-silicon lattice, ngokuqhelekileyo ichazwe yi-Miller indices ezifana (100), (110), (111), njl. Ukuqhelaniswa kwe-crystal ehlukeneyo kuneempawu ezibonakalayo ezibonakalayo, ezifana nokuxinana komgca, okuhluka ngokusekelwe kwi-orientation. Lo mahluko unokuchaphazela ukusebenza kwe-wafer kumanyathelo okucubungula alandelayo kunye nokusebenza kokugqibela kwezixhobo ze-microelectronic. Kwinkqubo yokuvelisa, ukukhetha isiqwenga se-silicon esilungelelaniswe ngokufanelekileyo kwiimfuno ezahlukeneyo zesixhobo kunokwandisa ukusebenza kwesixhobo, ukuphucula ukusebenza kakuhle kwemveliso, kunye nokuphucula umgangatho wemveliso.

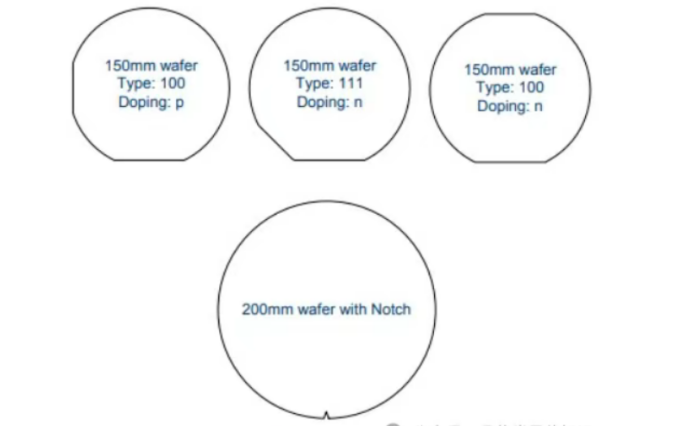

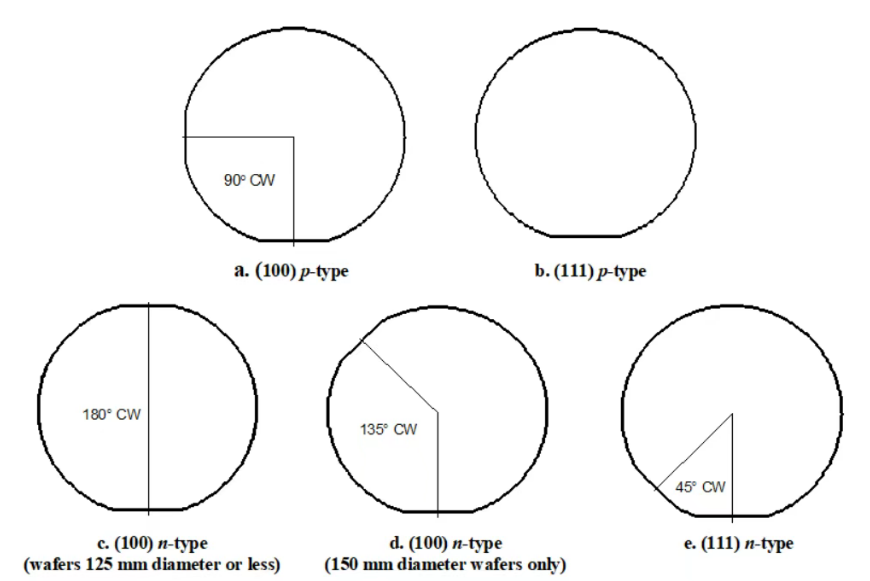

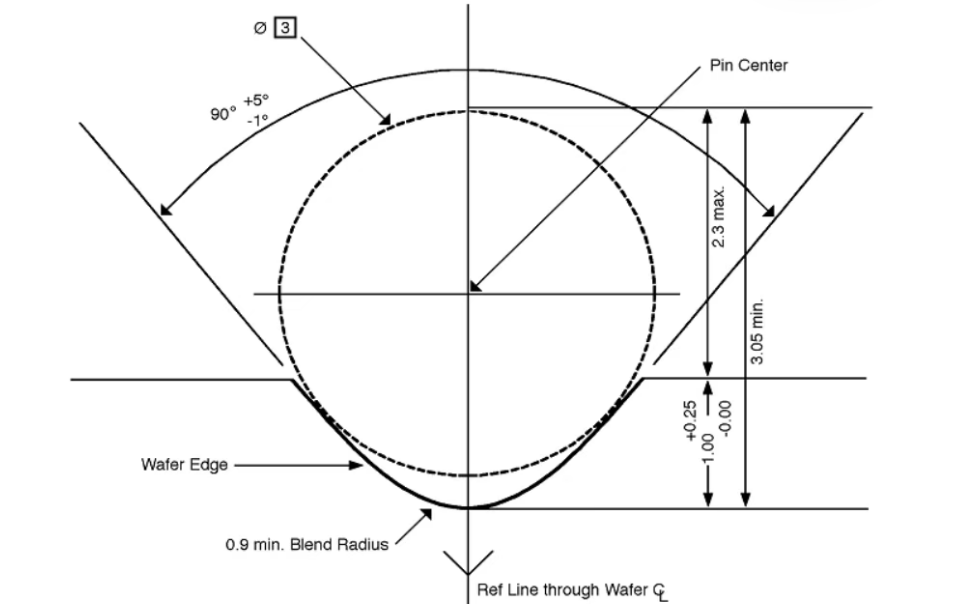

I-Flat/Notch: Umphetho osicaba (I-Flat) okanye i-V-notch (Inotshi) kumjikelo we-silicon wafer idlala indima ebalulekileyo kulungelelwaniso lwecrystal orientation kwaye sisichongi esibalulekileyo ekwenziweni nasekusetyenzweni kwewafer. IiWafers ezinobubanzi obuhlukeneyo zihambelana nemigangatho eyahlukeneyo yobude beFlethi okanye iNotshi. Imiphetho yolungelelwaniso ihlelwe ngokweflethi yokuqala kunye neyesibini. Iflethi ephambili isetyenziselwa ukumisela isiseko sekristale yokuqhelaniswa kunye nereferensi yokusetyenzwa kwe-wafer, ngelixa iflethi yesibini incedisa ngakumbi kukulungelelaniswa okuchanekileyo kunye nokusetyenzwa, iqinisekisa ukusebenza okuchanekileyo kunye nokungaguquguquki kwe-wafer kuwo wonke umgca wemveliso.

Ukutyeba: Ubukhulu be-wafer buchazwa ngokwesiqhelo kwiimicrometers (μm), ezinobubanzi obuqhelekileyo phakathi kwe-100μm kunye ne-1000μm. Ii-wafers ezinobunzima obahlukeneyo zifanelekile kwiindidi ezahlukeneyo zezixhobo ze-microelectronic. Ii-wafers ezibhityileyo (umzekelo, i-100μm – 300μm) zisoloko zisetyenziselwa ukwenziwa kwetshiphu ezifuna ulawulo olungqongqo lokutyeba, ukunciphisa ubungakanani kunye nobunzima betshiphu nokwandisa ukuxinana kohlanganiso. Ii-wafers ezityebileyo (umzekelo, i-500μm - 1000μm) zisetyenziswa ngokubanzi kwizixhobo ezifuna amandla aphezulu omatshini, njengezixhobo ze-semiconductor yamandla, ukuqinisekisa uzinzo ngexesha lokusebenza.

Uburhabaxa boMphezulu: Uburhabaxa bomphezulu yenye yeeparameters eziphambili zokuvavanya umgangatho we-wafer, njengoko ichaphazela ngokuthe ngqo ukunamathela phakathi kwe-wafer kunye nezixhobo zefilimu ezicekethekileyo ezifakwe emva koko, kunye nokusebenza kombane kwesixhobo. Idla ngokubonakaliswa njengengcambu yentsingiselo yesikwere (RMS) uburhabaxa (nge-nm). Uburhabaxa bomphezulu osezantsi buthetha ukuba umphezulu we-wafer ugudileyo, onceda ukunciphisa izinto ezinje ngokusasazwa kwe-electron kunye nokuphucula ukusebenza kwesixhobo kunye nokuthembeka. Kwiinkqubo zokwenziwa kwe-semiconductor ephucukileyo, iimfuno zoburhabaxa bomphezulu ziya zisiba ngqongqo ngakumbi, ngakumbi kwimveliso yesekethe ehlanganisiweyo yodidi oluphezulu, apho uburhabaxa bomphezulu kufuneka bulawuleke bube zii-nanometers ezimbalwa okanye nangaphantsi.

Ukutyeba Kukonke (i-TTV): Umahluko wobungqingqwa bubonke ubhekisa kumahluko phakathi kobukhulu kunye nobuncinane bobungqingqwa obulinganiswa kwiindawo ezininzi kumphezulu we-wafer, obonakaliswa ngokuqhelekileyo nge-μm. I-TTV ephezulu inokukhokelela ekuphambukeni kwiinkqubo ezifana ne-photolithography kunye ne-etching, ibe nefuthe ekusebenzeni kwesixhobo kunye nesivuno. Ke ngoko, ukulawula i-TTV ngexesha lokwenziwa kwe-wafer linyathelo eliphambili ekuqinisekiseni umgangatho wemveliso. Ukwenziwa kwesixhobo se-microelectronic esichaneke kakhulu, i-TTV idla ngokufuneka ukuba ibe phakathi kwee-micrometer ezimbalwa.

Isaphetha: I-Bow ibhekisa ekutenxeni phakathi komphezulu we-wafer kunye nenqwelomoya ethe tyaba efanelekileyo, eqhele ukulinganiswa nge-μm. IiWafers ezigobileyo ezigqithileyo zinokophuka okanye zibe noxinzelelo olungalinganiyo ngexesha lokusetyenzwa okulandelayo, okuchaphazela ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Ngokukodwa kwiinkqubo ezifuna i-flatness ephezulu, njenge-photolithography, ukugoba kufuneka kulawulwe ngaphakathi koluhlu oluthile ukuze kuqinisekiswe ukuchaneka kunye nokuhambelana kwephethini ye-photolithographic.

I-Warp ibonisa ukutenxa phakathi komphezulu we-wafer kunye nemilo engqukuva efanelekileyo, nayo ilinganiswa nge-μm. Ngokufana nesaphetha, i-warp sisilathisi esibalulekileyo se-wafer flatness. I-warp egqithisileyo ayichaphazeli kuphela ukuchaneka kokubekwa kwe-wafer kwisixhobo sokucubungula kodwa inokubangela imiba ngexesha lenkqubo yokupakisha i-chip, efana nokungahambi kakuhle phakathi kwe-chip kunye nezinto zokupakisha, ezithi zichaphazele ukuthembeka kwesixhobo. Kwimveliso ye-semiconductor yomgangatho ophezulu, iimfuno ze-warp ziya ziba ngqongqo ngakumbi ukuhlangabezana neemfuno zokwenziwa kwetshiphu eziphambili kunye neenkqubo zokupakisha.

Iprofayili yomda: Iprofayili yomda we-wafer ibaluleke kakhulu ekusebenzeni kwayo kunye nokuphathwa kwayo. Ngokuqhelekileyo ichazwe yi-Edge Exclusion Zone (EEZ), echaza umgama ukusuka kwi-wafer edge apho kungavunyelwanga ukuqhubekeka. Iprofayili eyilwe ngokufanelekileyo kunye nolawulo oluchanekileyo lwe-EEZ lunceda ukunqanda iziphene, ukugxininiswa koxinzelelo, kunye neminye imiba ngexesha lokucubungula, ukuphucula umgangatho we-wafer kunye nesivuno. Kwezinye iinkqubo zokwenziwa ezihambele phambili, ukuchaneka kweprofayili yomphetho kuyafuneka ukuba ibe kwinqanaba le-sub-micron.

I-Particle Count: Inani kunye nobukhulu bokuhanjiswa kwamasuntswana kumphezulu we-wafer kuchaphazela kakhulu ukusebenza kwezixhobo ze-microelectronic. Amasuntswana agqithisileyo okanye amakhulu angakhokelela ekungasebenzini kwesixhobo, esifana neesekethe ezimfutshane okanye ukuvuza, ukunciphisa isivuno semveliso. Ngoko ke, ukubalwa kwamasuntswana ngokuqhelekileyo kulinganiswa ngokubala iinqununu kwindawo nganye yeyunithi, njengenani leengqungquthela ezinkulu kune-0.3μm. Ulawulo olungqongqo lokubalwa kwamasuntswana ngexesha lokwenziwa kwe-wafer ngumlinganiselo obalulekileyo wokuqinisekisa umgangatho wemveliso. Ubuchwephesha obuphezulu bokucoca kunye nendawo yokuvelisa ecocekileyo isetyenziselwa ukunciphisa ukungcoliseka kwamasuntswana kumphezulu we-wafer.

![]()

![]()

![]()

![]()

![]()

Imveliso ehambelanayo

Ikristale enye yeSilicon wafer Si Substrate Uhlobo N/P Optional Silicon Carbide Wafer

FZ CZ Si wafer kwisitokhwe 12inch Silicon wafer Prime okanye Test

Ixesha lokuposa: Apr-18-2025