I-SOI (i-Silicon-On-Insulator) ii-wafersImele imathiriyeli ekhethekileyo yesemiconductor enomaleko wesilicon obhityileyo kakhulu owenziwe phezu komaleko weoksidi ekhuselayo. Esi sakhiwo sesandwich sahlukileyo sinikezela ngophuculo olubalulekileyo lokusebenza kwizixhobo ze-semiconductor.

Ukuqulunqwa koLwakhiwo:

Umaleko weSixhobo (iSilikoni ePhezulu):

Ukutyeba ukusuka kwii-nanometers ukuya kwii-micrometers, kusebenza njengomaleko osebenzayo wokwenziwa kwe-transistor.

Umaleko we-Oxide oNcinciweyo (IBHOKISI):

Isilicon dioxide insulating layer (0.05-15μm ubukhulu) ethi ngombane ihlukanise umaleko wesixhobo kwi-substrate.

Isiseko seSubstrate:

Isilicon enkulu (100-500μm ubukhulu) ibonelela ngenkxaso yomatshini.

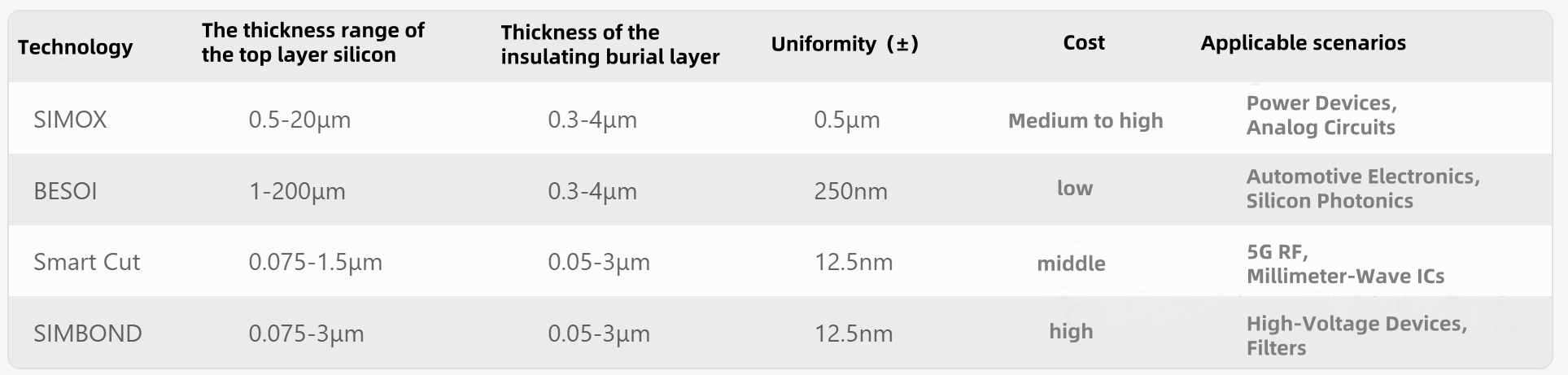

Ngokwetekhnoloji yenkqubo yokulungiselela, iindlela eziphambili zenkqubo ye-SOI silicon wafers zingahlelwa njenge: SIMOX (iteknoloji yokuhlukanisa inaliti ye-oksijini), i-BESOI (i-teknoloji yokunciphisa i-bonding), kunye ne-Smart Cut (iteknoloji yokuhlutha ngobukrelekrele).

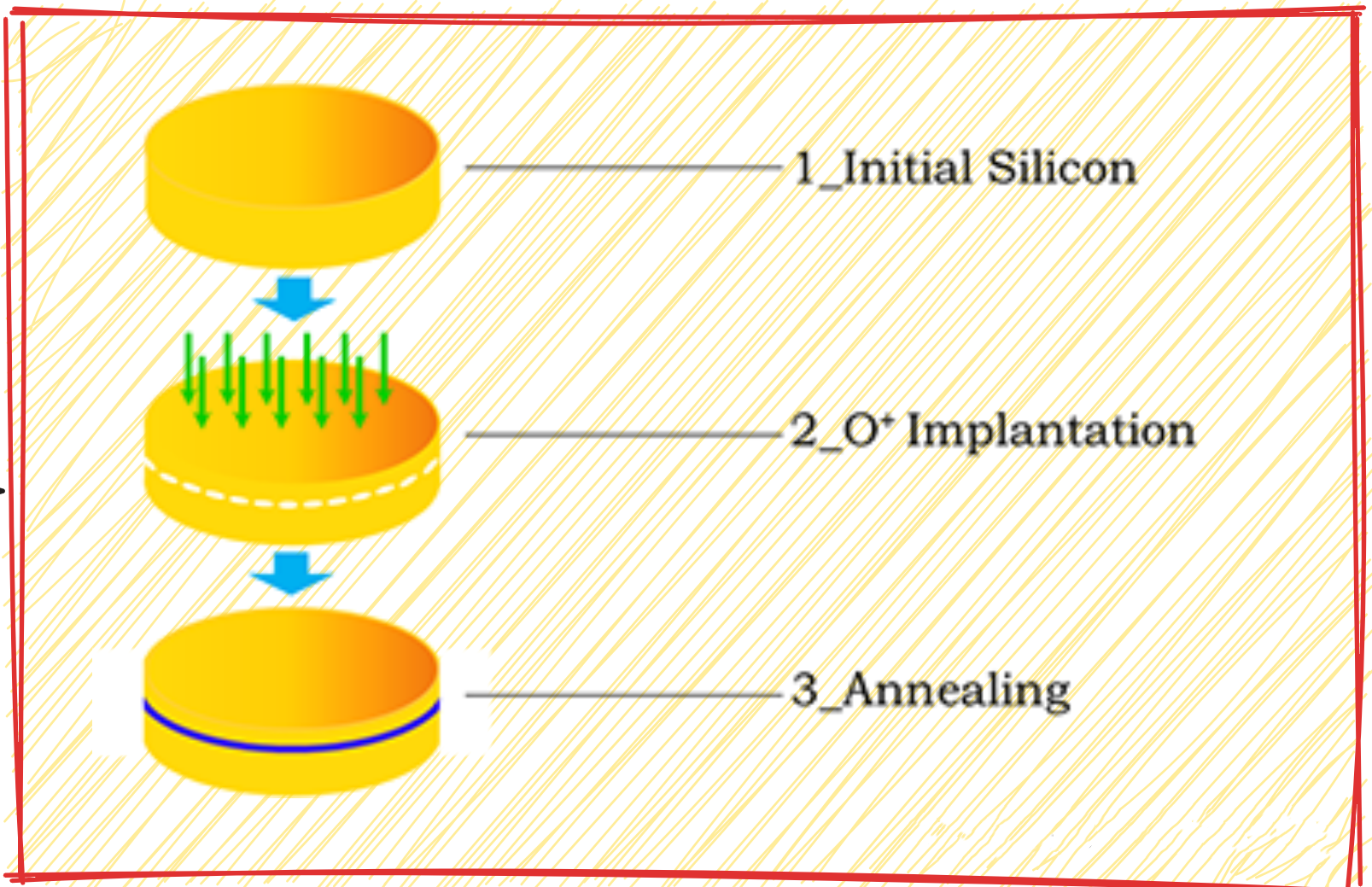

I-SIMOX (itekhnoloji yokuhlukanisa inaliti ye-oksijini) bubuchule obubandakanya ukutofa ii-ion ze-oksijini ezinamandla aphezulu kwii-silicon wafers ukwenza umaleko ofakwe kwi-silicon dioxide, othi emva koko ube phantsi kwe-annealing yobushushu obuphezulu ukulungisa iziphene zelathisi. Undoqo sisitofu seoksijini ye-ion ngqo ukwenza umaleko weoksijini engcwatyiweyo.

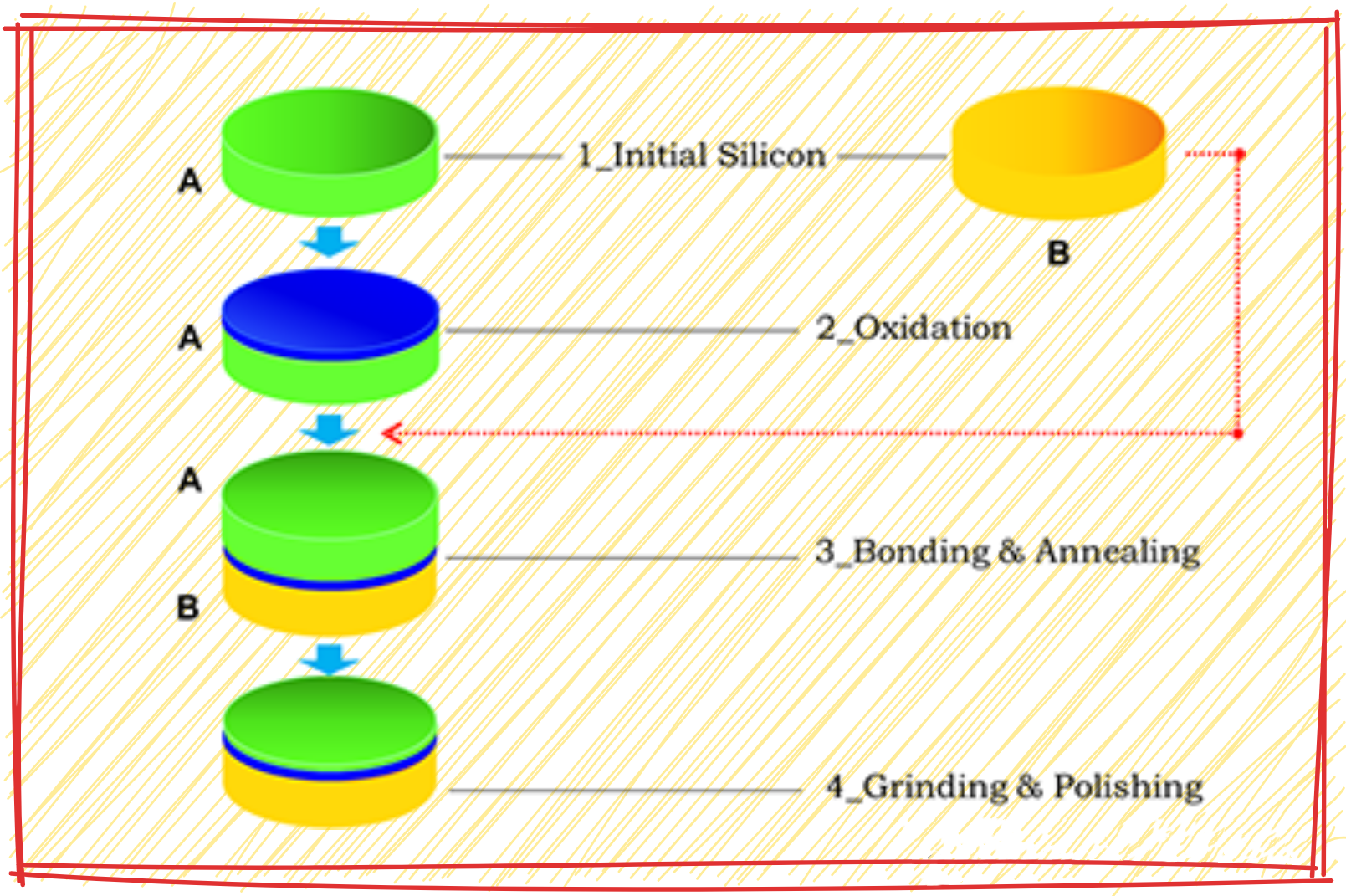

I-BESOI (itekhnoloji ye-Bonding Thinning) ibandakanya ukudibanisa ii-silicone zafers ezimbini kwaye emva koko unciphise enye yazo ngokusila ngoomatshini kunye ne-chemical etching ukwenza ubume be-SOI. Undoqo ulele ekudibaneni nasekunciphiseni.

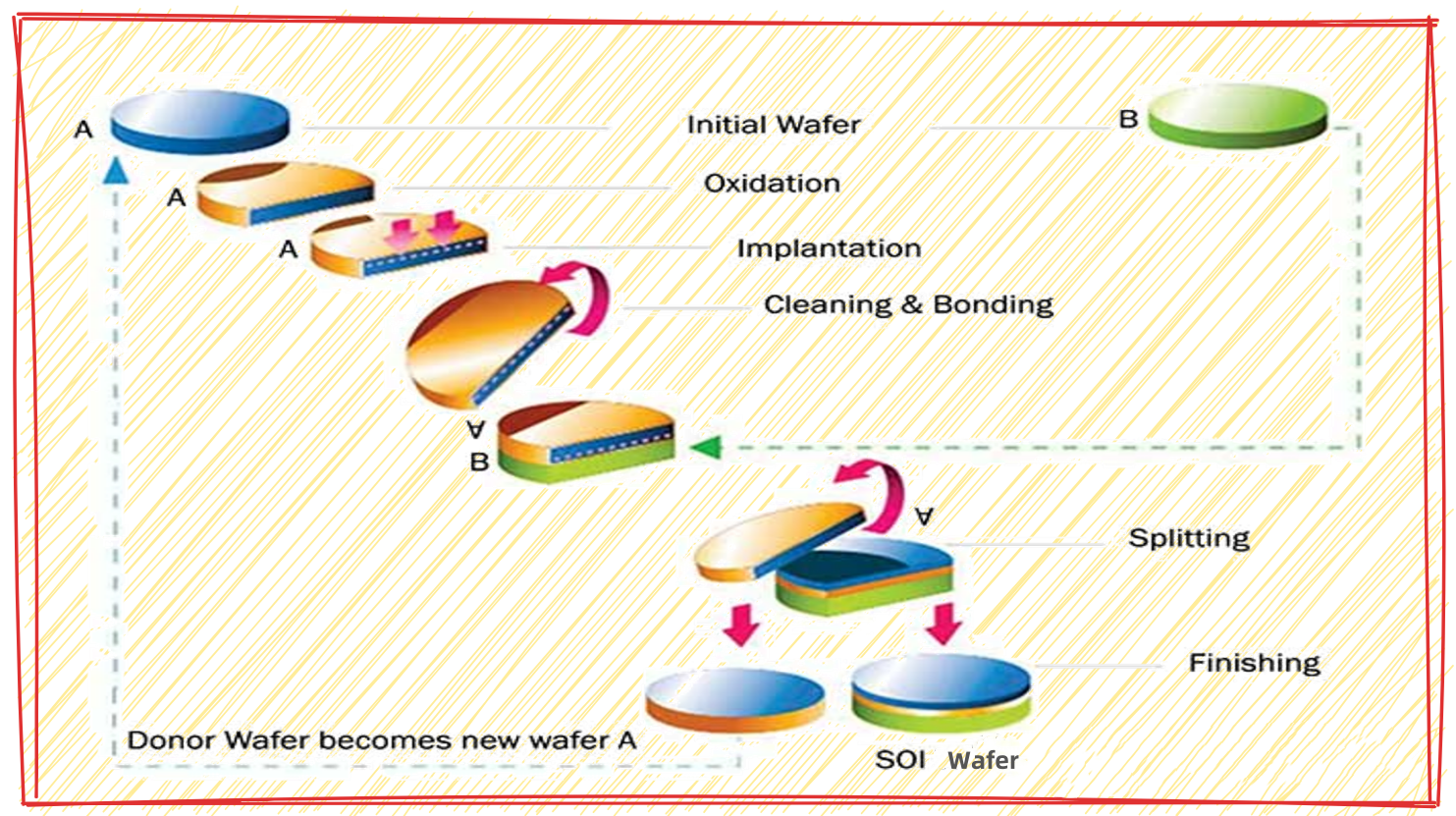

I-Smart Cut (iteknoloji ye-Intelligent Exfoliation) yenza i-exfoliation layer ngokusebenzisa inaliti ye-hydrogen ion. Emva kokudibanisa, unyango lobushushu lwenziwa ukukhupha i-silicon wafer ecaleni kwe-hydrogen ion layer, yenze umaleko wesilicon obhityileyo kakhulu. Undoqo kukuhlutywa naliti ye-hydrogen.

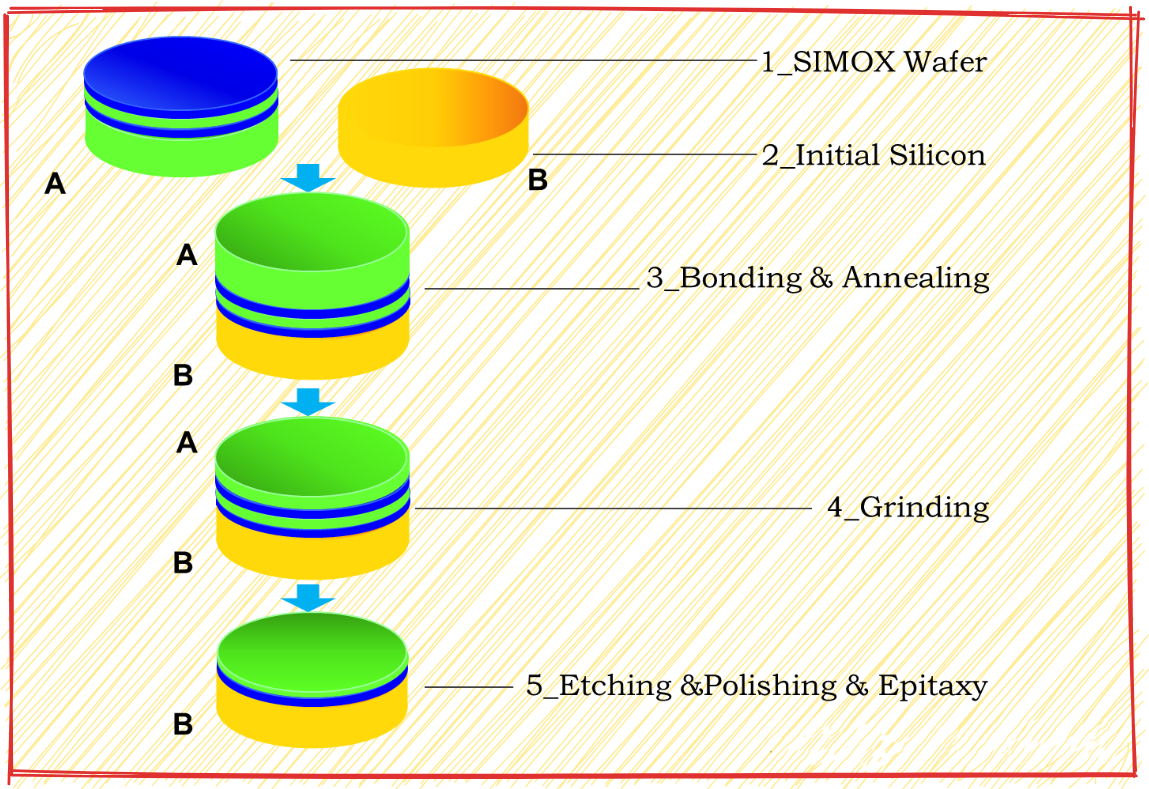

Okwangoku, kukho enye itekhnoloji eyaziwa ngokuba yi-SIMBOND (itekhnoloji ye-oxygen bonding bonding), eyaphuhliswa nguXinao. Ngapha koko, yindlela edibanisa ukubekelwa bucala inaliti ye-oxygen kunye nobuchwepheshe bokudibanisa. Kule ndlela yobugcisa, i-oksijini efakiweyo isetyenziswa njengoluhlu lwesithintelo esincinci, kwaye i-oksijini engcwatyelwe ngokwenene ngumaleko we-oxidation ye-thermal. Ngoko ke, kwangaxeshanye iphucula iiparitha ezifana nokufana kwe-silicon ephezulu kunye nomgangatho we-oksijeni engcwatyelwe.

I-SOI silicon wafers eyenziwe ngeendlela ezahlukeneyo zobugcisa zineeparamitha ezahlukeneyo zokusebenza kwaye zifanelekile iimeko ezahlukeneyo zokusetyenziswa.

Oku kulandelayo yitheyibhile yesishwankathelo sezinto ezilungileyo zokusebenza ezingundoqo ze-SOI silicon wafers, ezidityaniswe neempawu zabo zobugcisa kunye neemeko zesicelo zangempela. Xa kuthelekiswa ne-silicon yesininzi, i-SOI ineenzuzo ezibalulekileyo kwibhalansi yesantya kunye nokusetyenziswa kwamandla. (PS: Ukusebenza kwe-22nm FD-SOI kusondele kuleyo ye-FinFET, kwaye iindleko zincitshiswe nge-30%.)

| Inzuzo yokusebenza | Umgaqo wobugcisa | Ukubonakaliswa okuthe ngqo | Iimeko zosetyenziso oluqhelekileyo |

| Ubuncinci beParasitic Capacitance | I-Insulating layer (BOX) ithintela ukudityaniswa kwentlawulo phakathi kwesixhobo kunye ne-substrate | Isantya sokutshintsha sinyuke nge-15% -30%, ukusetyenziswa kwamandla kuncitshiswe ngama-20% -50% | I-5G RF, iitshiphusi zonxibelelwano ezikwi-frequency ephezulu |

| Ukuvuza okuNcitshisiweyo kwangoku | I-Insulating layer icinezela iindlela zangoku ezivuzayo | Ukuvuza kwangoku kuncitshiswe nge>90%, ubomi bebhetri obandisiweyo | Izixhobo ze-IoT, Izixhobo zombane eziNyekayo |

| Ukuqina kweRadiation ephuculweyo | Insulating layer blocks ukuqokelelwa kwentlawulo eyenziwe ngemitha | Ukunyamezela kwemitha kuphuculwe i-3-5x, ukunciphisa ukuphazamiseka kwesiganeko esisodwa | Iziphekepheke, izixhobo zoshishino lweNyukliya |

| Ulawulo lweMpembelelo yesijelo esifutshane | Umaleko obhityileyo wesilicon unciphisa uphazamiseko lwentsimi yombane phakathi kombhobho kunye nomthombo | Ukuphuculwa kozinzo lombane wethreshold, i-subthreshold slope ephuculweyo | Iitshiphusi ze-node eziphucukileyo (<14nm) |

| Ukuphuculwa koLawulo lweThermal | Umaleko wokugquma unciphisa ukudityaniswa kwe-thermal conduction | I-30% encinci yokuqokelela ubushushu, i-15-25 ° C iqondo lokushisa eliphantsi lokusebenza | 3D ICs, Automotive electronics |

| UkuSebenzisa okuPhakamileyo | Ukunciphisa amandla e-parasitic kunye nokuphucula ukuhamba kwe-carrier | I-20% ukulibaziseka okuphantsi, isekela> 30GHz ukusetyenzwa komqondiso | Unxibelelwano lwe-mmWave, iitships zeSatellite comm |

| Ukwandiswa koYilo oluguquguqukayo | Akukho doping kakuhle efunekayo, ixhasa umva biasing | I-13% -20% amanyathelo enkqubo ambalwa, i-40% yoxinaniso oluphezulu lokudibanisa | Ii-ICs ezixubeneyo, iiSensors |

| I-Latch-up Immunity | Umaleko ogqumayo wahlula udibaniso lwePN yeparasitic | I-Latch-up threshold yangoku inyuke ukuya kwi->100mA | Izixhobo zamandla ombane aphezulu |

Ukushwankathela, iingenelo eziphambili ze-SOI zezi: ibaleka ngokukhawuleza kwaye inamandla ngakumbi.

Ngenxa yezi mpawu zokusebenza ze-SOI, inezicelo ezibanzi kwiinkalo ezifuna ukusebenza okugqwesileyo kunye nokusebenza kokusetyenziswa kwamandla.

Njengoko kubonisiwe ngezantsi, ngokusekwe kumyinge wemimandla yesicelo ehambelana ne-SOI, kunokubonwa ukuba iRF kunye nezixhobo zombane ziphendula uninzi lwentengiso ye-SOI.

| Indawo yosetyenziso | Ukwabelana kwimakethi |

| I-RF-SOI (iRadio Frequency) | 45% |

| Amandla e-SOI | 30% |

| I-FD-SOI (Iphele ngokupheleleyo) | 15% |

| I-Optical SOI | 8% |

| Uluvo lwe-SOI | 2% |

Ngokukhula kweemarike ezinjengonxibelelwano oluphathwayo kunye nokuqhuba ngokuzimeleyo, ii-SOI silicon wafers zikwalindeleke ukuba zigcine izinga elithile lokukhula.

I-XKH, njengomqambi ohamba phambili kwi-teknoloji ye-Silicon-On-Insulator (i-SOI) ye-wafer, ihambisa izisombululo ezibanzi ze-SOI ukusuka kwi-R & D ukuya kwimveliso yomthamo usebenzisa iinkqubo zokuvelisa ezikhokelayo kwishishini. Ipotfoliyo yethu epheleleyo iquka ama-200mm/300mm iiwafer ze-SOI ezithatha i-RF-SOI, i-Power-SOI kunye nokwahluka kwe-FD-SOI, ezinolawulo olungqongqo lomgangatho oqinisekisa ukungaguquguquki okukhethekileyo kokusebenza (ukutyeba okufanayo phakathi kwe ±1.5%). Sinikezela ngezisombululo ezilungiselelweyo kunye ne-oxide engcwatyiweyo (BOX) ubukhulu bomaleko ukusuka kwi-50nm ukuya kwi-1.5μm kunye neenkcukacha ezahlukeneyo zokuxhathisa ukuhlangabezana neemfuno ezithile. Ukusebenzisa iminyaka eli-15 yobuchwephesha bobugcisa kunye nekhonkco lonikezelo lwehlabathi elomeleleyo, sibonelela ngokuthembekileyo ngemathiriyeli ye-SOI ekumgangatho ophezulu kubavelisi be-semiconductor abakumgangatho ophezulu kwihlabathi liphela, ivumela ukwenziwa kwezinto ezintsha ze-chip kunxibelelwano lwe-5G, ii-elektroniki zemoto, kunye nokusetyenziswa kobukrelekrele bokwenziwa.

Ixesha lokuposa: Apr-24-2025