I-SiC wafer's abstract

I-silicon carbide (i-SiC) yafersibe yindawo ekhethwayo kumandla aphezulu, amaza aphezulu, kunye nobushushu obuphezulu be-elektroniki kuwo wonke amacandelo eemoto, ahlaziyekayo, kunye ne-aerospace. Iipotifoliyo zethu zibandakanya iipolytypes eziphambili kunye nezicwangciso ze-doping-nitrogen-doped 4H (4H-N), i-high-purity semi-insulating (HPSI), i-nitrogen-doped 3C (3C-N), kunye ne-p-type 4H / 6H (4H / 6H-P) - inikezelwa ngamabakala amathathu omgangatho: I-PRIME (iphuculwe ngokupheleleyo, i-device-graded, inkqubo ye-DUMMY) UPHANDO (umaleko we-epi wesiko kunye neeprofayili ze-doping ze-R&D). I-Wafer diameters span 2″, 4″, 6″, 8″, kunye ne-12″ ukuze zilungele zombini izixhobo zelifa kunye neefabs eziphambili. Sikwabonelela ngee-boules ze-monocrystalline kunye neekristale zembewu ezijoliswe ngokuchanekileyo ukuxhasa ukukhula kwekristale yangaphakathi.

Ii-wafers zethu ze-4H-N zibonakalisa ukuxinana komthuthi ukusuka kwi-1×10¹⁶ ukuya kwi-1×10¹⁹ cm⁻³ kunye nokuxhathisa kwe-0.01–10 Ω·cm, ukuhambisa ukuhamba kwe-electron okugqwesileyo kunye neendawo zokwaphuka ngaphezulu kwe-2 MV/cm-zilungele iidiode ze-Schottky, kunye ne-JSSFETY. I-HPSI substrates idlula i-1×10¹² Ω·cm ukuxhathisa ngoxinaniso lwemicropipe ngaphantsi kwe-0.1 cm⁻², iqinisekisa ukuvuza okuncinci kwi-RF kunye nezixhobo ze-microwave. I-Cubic 3C-N, ekhoyo kwiifomathi ze-2 "kunye ne-4", yenza i-heteroepitaxy kwi-silicon kwaye ixhasa i-novel photonic kunye nezicelo ze-MEMS. I-P-uhlobo lwe-4H/6H-P yama-wafers, afakwe nge-aluminiyam ukuya kwi-1×10¹⁶–5×10¹⁸ cm⁻³, iququzelela ulwakhiwo lwezixhobo ezihambelanayo.

I-SiC wafer, ii-PRIME wafers zenziwa ukupolishwa kwekhemikhali ukuya ku-<0.2 nm RMS yoburhabaxa bomphezulu, ukuguquguquka okupheleleyo phantsi kwe-3 µm, kunye ne-bow <10 µm. Isubstrates zeDUMMY zikhawulezisa ukudibanisa kunye novavanyo lokupakisha, ngelixa iiwafers UPHANDO zibonakalisa ubukhulu be-epi-layer ye-2–30 µm kunye ne-bespoke doping. Zonke iimveliso ziqinisekiswa nge-X-ray diffraction (i-rocking curve <30 arcsec) kunye ne-Raman spectroscopy, kunye neemvavanyo zombane-imilinganiselo yeHolo, iphrofayili ye-C-V, kunye ne-micropipe scanning-ukuqinisekisa ukuthotyelwa kwe-JEDEC kunye ne-SEMI.

Iibhowule ukuya kuthi ga kwi-150 mm ubukhulu zikhuliswa nge-PVT kunye ne-CVD kunye nokuxinana kwe-dislocation ngaphantsi kwe-1×10³ cm⁻² kunye nezibalo ze-micropipe eziphantsi. Iikristale zembewu zisikwa ngaphakathi kwe-0.1 ° ye-axis ye-c ukuqinisekisa ukukhula okuphindayo kunye nezivuno eziphezulu zokusika.

Ngokudibanisa iipolytypes ezininzi, ukwahluka kwe-doping, amabakala asemgangathweni, ubungakanani be-SiC wafer, kunye ne-boule yangaphakathi kunye nemveliso yekristale yembewu, iqonga lethu le-SiC substrate lilungelelanisa amatyathanga okubonelela kwaye likhawulezise uphuhliso lwesixhobo kwizithuthi zombane, iigridi ezihlakaniphile, kunye nezicelo ezirhabaxa zokusingqongileyo.

I-SiC wafer's abstract

I-silicon carbide (i-SiC) yafersbaye baba yi-substrate ye-SiC yokuzikhethela kumandla aphezulu, i-high-frequency, kunye nobushushu obuphezulu be-elektroniki kuwo wonke amacandelo emoto, ahlaziyekayo, kunye ne-aerospace. Iipotifoliyo zethu zibandakanya i-polytypes eziphambili kunye ne-doping schemes-i-nitrogen-doped 4H (4H-N), i-high-purity semi-insulating (HPSI), i-nitrogen-doped 3C (3C-N), kunye ne-p-type 4H / 6H (4H / 6H-P) -enikezelwa ngamabakala amathathu omgangatho: SiC waferI-PRIME (egudiswe ngokupheleleyo, iisubstrates zodidi lwesixhobo), i-DUMMY (egqitywe okanye ayipolishwanga kulingo lwenkqubo), kunye noPHANDO (umaleko we-epi oqhelekileyo kunye neeprofayili ze-doping ze-R&D). I-SiC Wafer diameters span 2″, 4″, 6″, 8″, kunye ne-12″ ukuze zilungele zombini izixhobo zelifa kunye neefabs eziphambili. Sikwabonelela ngee-boules ze-monocrystalline kunye neekristale zembewu ezijoliswe ngokuchanekileyo ukuxhasa ukukhula kwekristale yangaphakathi.

Iziqwenga zethu ze-4H-N SiC zibonakalisa uxinaniso lokuthwala ukusuka kwi-1×10¹⁶ ukuya kwi-1×10¹⁹ cm⁻³ kunye nokuxhathisa kwe-0.01–10 Ω·cm, ukuhambisa ukuhamba kwe-electron okugqwesileyo kunye nemimandla yokwaphuka ngaphezulu kwe-2 MV/cm—ilungele ii-Schottky diodes, ii-MOSFET diodes, kunye ne-JFETS. I-HPSI substrates idlula i-1×10¹² Ω·cm ukuxhathisa ngoxinaniso lwemicropipe ngaphantsi kwe-0.1 cm⁻², iqinisekisa ukuvuza okuncinci kwi-RF kunye nezixhobo ze-microwave. I-Cubic 3C-N, ekhoyo kwiifomathi ze-2 "kunye ne-4", yenza i-heteroepitaxy kwi-silicon kwaye ixhasa i-novel photonic kunye nezicelo ze-MEMS. I-SiC wafer P-uhlobo lwe-4H/6H-P ii-wafers, ezifakwe nge-aluminiyam ukuya kwi-1×10¹⁶–5×10¹⁸ cm⁻³, ziququzelela ulwakhiwo lwezixhobo ezihambelanayo.

I-SiC wafer PRIME wafers zenziwa ukupolishwa kwekhemikhali ukuya ku-<0.2 nm RMS yoburhabaxa bomphezulu, ukuguquguquka kobunzima bubonke phantsi kwe-3 µm, kunye ne-bow <10 µm. Isubstrates zeDUMMY zikhawulezisa ukudibanisa kunye novavanyo lokupakisha, ngelixa iiwafers UPHANDO zibonakalisa ubukhulu be-epi-layer ye-2–30 µm kunye ne-bespoke doping. Zonke iimveliso ziqinisekiswa nge-X-ray diffraction (i-rocking curve <30 arcsec) kunye ne-Raman spectroscopy, kunye neemvavanyo zombane-imilinganiselo yeHolo, iphrofayili ye-C-V, kunye ne-micropipe scanning-ukuqinisekisa ukuthotyelwa kwe-JEDEC kunye ne-SEMI.

Iibhowule ukuya kuthi ga kwi-150 mm ubukhulu zikhuliswa nge-PVT kunye ne-CVD kunye nokuxinana kwe-dislocation ngaphantsi kwe-1×10³ cm⁻² kunye nezibalo ze-micropipe eziphantsi. Iikristale zembewu zisikwa ngaphakathi kwe-0.1 ° ye-axis ye-c ukuqinisekisa ukukhula okuphindayo kunye nezivuno eziphezulu zokusika.

Ngokudibanisa iipolytypes ezininzi, ukwahluka kwe-doping, amabakala asemgangathweni, ubungakanani be-SiC wafer, kunye ne-boule yangaphakathi kunye nemveliso yekristale yembewu, iqonga lethu le-SiC substrate lilungelelanisa amatyathanga okubonelela kwaye likhawulezise uphuhliso lwesixhobo kwizithuthi zombane, iigridi ezihlakaniphile, kunye nezicelo ezirhabaxa zokusingqongileyo.

I-6inch 4H-N uhlobo lwe-SiC wafer's data sheet

| 6inch SiC wafers data sheet | ||||

| Ipharamitha | I-Sub-Parameter | IBanga le-Z | IBanga le-P | D iBanga |

| Ububanzi | 149.5-150.0 mm | 149.5-150.0 mm | 149.5-150.0 mm | |

| Ukutyeba | 4H‑N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Ukutyeba | 4H‑SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| I-Wafer Orientation | I-off axis: 4.0 ° ukuya <11-20> ± 0.5 ° (4H-N); Kwi-axis: <0001> ±0.5° (4H-SI) | I-off axis: 4.0 ° ukuya <11-20> ± 0.5 ° (4H-N); Kwi-axis: <0001> ±0.5° (4H-SI) | I-off axis: 4.0 ° ukuya <11-20> ± 0.5 ° (4H-N); Kwi-axis: <0001> ±0.5° (4H-SI) | |

| Ukuxinana kweMibhobho | 4H‑N | ≤ 0.2 cm⁻² | ≤ 2 cm⁻² | ≤ 15 cm⁻² |

| Ukuxinana kweMibhobho | 4H‑SI | ≤ 1 cm⁻² | ≤ 5 cm⁻² | ≤ 15 cm⁻² |

| Ukuxhathisa | 4H‑N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Ukuxhathisa | 4H‑SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Ukuqhelaniswa neFlethi okuPhambili | [10-10] ± 5.0 ° | [10-10] ± 5.0 ° | [10-10] ± 5.0 ° | |

| Ubude beFlethi obuPhambili | 4H‑N | 47.5 mm ± 2.0 mm | ||

| Ubude beFlethi obuPhambili | 4H‑SI | Inotshi | ||

| Ukungabandakanywa kuMda | 3 mm | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Uburhabaxa | Polish | Ra ≤ 1 nm | ||

| Uburhabaxa | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Edge Cracks | Akukho nanye | Ubude obuqokelelweyo ≤ 20 mm, eyodwa ≤ 2 mm | ||

| Iipleyiti zeHex | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 0.1% | Indawo eyongezelekayo ≤ 1% | |

| Iindawo zePolytype | Akukho nanye | Indawo eyongezelekayo ≤ 3% | Indawo eyongezelekayo ≤ 3% | |

| Ukubandakanywa kweKhabhoni | Indawo eyongezelekayo ≤ 0.05% | Indawo eyongezelekayo ≤ 3% | ||

| Imikrwelo yoMphezulu | Akukho nanye | Ubude obongezelekayo ≤ 1 × idiameter yewafer | ||

| IiChips zoMda | Akukho kuvunyelweyo ≥ 0.2 mm ububanzi & ubunzulu | Ukuya kuthi ga kwi-7 chips, ≤ 1 mm nganye | ||

| I-TSD (I-Treading Screw Dislocation) | ≤ 500 cm⁻² | N / A | ||

| I-BPD (iSiseko sokuchithwa kweNqwelomoya) | ≤ 1000 cm⁻² | N / A | ||

| Ungcoliseko loMphezulu | Akukho nanye | |||

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye isikhongozeli esinye esisicaba | Iikhasethi ezininzi zewafer okanye isikhongozeli esinye esisicaba | Iikhasethi ezininzi zewafer okanye isikhongozeli esinye esisicaba | |

I-4inch 4H-N uhlobo lwe-SiC wafer's data sheet

| Iphepha ledatha ye-SiC ye-4inch | |||

| Ipharamitha | Zero MPD Production | IBanga leMveliso esemgangathweni (iBanga le-P) | IBanga leDummy (iBanga D) |

| Ububanzi | 99.5 mm–100.0 mm | ||

| Ukutyeba (4H-N) | 350µm±15µm | 350µm±25µm | |

| Ukutyeba (4H-Si) | 500 µm±15µm | 500µm±25µm | |

| I-Wafer Orientation | I-off axis: 4.0 ° malunga ne- <1120> ± 0.5 ° ye-4H-N; Kwi-axis: <0001> ± 0.5 ° ye-4H-Si | ||

| Uxinaniso lweMibhobho (4H-N) | ≤0.2 cm⁻² | ≤2 cm⁻² | ≤15 cm⁻² |

| Uxinaniso lweMibhobho (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Ukuxhathisa (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Ukuxhathisa (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Ukuqhelaniswa neFlethi okuPhambili | [10-10] ± 5.0 ° | ||

| Ubude beFlethi obuPhambili | 32.5 mm ±2.0 mm | ||

| Ubude beFlethi yesibini | 18.0 mm ±2.0 mm | ||

| Ukuqhelaniswa neFlethi yesibini | I-silicon ijonge phezulu: 90 ° CW ukusuka kwiflethi yokuqala ± 5.0 ° | ||

| Ukungabandakanywa kuMda | 3 mm | ||

| LTV/TTV/Bow Warp | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Uburhabaxa | iRa ≤1 nm; I-CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| I-Edge Cracks ngokuKhanya okuPhakamileyo | Akukho nanye | Akukho nanye | Ubude obongezelekayo ≤10 mm; ubude obunye ≤2 mm |

| Iipleyiti zeHex ngokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤0.1% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Akukho nanye | Indawo eyongezelekayo ≤3% | |

| Ukubandakanywa kweCarbon ebonakalayo | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤3% | |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Akukho nanye | Ubude obongezelekayo ≤1 idayamitha yewafer | |

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥0.2 mm ububanzi nobunzulu | I-5 ivunyelwe, ≤1 mm nganye | |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | Akukho nanye | ||

| Ukushenxiswa kwesikrufu somsonto | ≤500 cm⁻² | N / A | |

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye isikhongozeli esinye esisicaba | Iikhasethi ezininzi zewafer okanye isikhongozeli esinye esisicaba | Iikhasethi ezininzi zewafer okanye isikhongozeli esinye esisicaba |

4inch HPSI uhlobo SiC wafer data sheet

| 4inch HPSI uhlobo SiC wafer data sheet | |||

| Ipharamitha | Zero MPD iBanga leMveliso (iBanga leZ) | IBanga leMveliso esemgangathweni (iBanga le-P) | IBanga leDummy (iBanga D) |

| Ububanzi | 99.5-100.0 mm | ||

| Ukutyeba (4H-Si) | 500 µm ±20 µm | 500 µm ±25 µm | |

| I-Wafer Orientation | I-off axis: 4.0 ° malunga ne- <11-20> ± 0.5 ° ye-4H-N; Kwi-axis: <0001> ± 0.5 ° ye-4H-Si | ||

| Uxinaniso lweMibhobho (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Ukuxhathisa (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Ukuqhelaniswa neFlethi okuPhambili | (10-10) ± 5.0 ° | ||

| Ubude beFlethi obuPhambili | 32.5 mm ±2.0 mm | ||

| Ubude beFlethi yesibini | 18.0 mm ±2.0 mm | ||

| Ukuqhelaniswa neFlethi yesibini | I-silicon ijonge phezulu: 90 ° CW ukusuka kwiflethi yokuqala ± 5.0 ° | ||

| Ukungabandakanywa kuMda | 3 mm | ||

| LTV/TTV/Bow Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Uburhabaxa (C ubuso) | Polish | Ra ≤1 nm | |

| Uburhabaxa (Si face) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| I-Edge Cracks ngokuKhanya okuPhakamileyo | Akukho nanye | Ubude obongezelekayo ≤10 mm; ubude obunye ≤2 mm | |

| Iipleyiti zeHex ngokuKhanya okuPhakamileyo | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤0.1% |

| Iindawo zePolytype NgokuKhanya okuPhakamileyo | Akukho nanye | Indawo eyongezelekayo ≤3% | |

| Ukubandakanywa kweCarbon ebonakalayo | Indawo eyongezelekayo ≤0.05% | Indawo eyongezelekayo ≤3% | |

| I-Silicon Surface Scratches ngokuKhanya okuPhakamileyo | Akukho nanye | Ubude obongezelekayo ≤1 idayamitha yewafer | |

| I-Edge Chips NgokuKhanya okuPhakamileyo | Akukho kuvunyelweyo ≥0.2 mm ububanzi nobunzulu | I-5 ivunyelwe, ≤1 mm nganye | |

| Ukungcoliswa komphezulu weSilicon ngokuKhanya okuPhakamileyo | Akukho nanye | Akukho nanye | |

| Ukushenxiswa kweScrew somsonto | ≤500 cm⁻² | N / A | |

| Ukupakishwa | Iikhasethi ezininzi zewafer okanye isikhongozeli esinye esisicaba | ||

Isicelo seSiC wafer

-

Iimodyuli zeSiC Wafer Power ze-EV Inverters

Ii-MOSFET ezisekelwe kwi-SiC wafer kunye ne-diode ezakhelwe kumgangatho ophezulu we-SiC wafer substrates zizisa ilahleko esezantsi kakhulu yokutshintsha. Ngokusebenzisa itekhnoloji ye-SiC wafer, ezi modyuli zamandla zisebenza kumandla ombane aphezulu kunye namaqondo obushushu, nto leyo eyenza ukuba ii-inverters ze-traction zisebenze ngakumbi. Ukudibanisa i-wafer ye-SiC ifa kwizigaba zamandla kunciphisa iimfuno zokupholisa kunye neenyawo, kubonisa amandla apheleleyo e-SiC wafer innovation. -

I-High-Frequency RF & 5G Devices on SiC Wafer

Izandisi ze-RF kunye nokutshintsha okwenziwe kwiiplatifti ze-SiC ze-wafer ze-semi-insulating zibonisa ukuhanjiswa kwe-thermal ephezulu kunye nokutshatyalaliswa kwamandla. I-SiC wafer substrate inciphisa ilahleko ye-dielectric kwi-GHz frequencies, ngelixa amandla e-SiC wafer avumela ukusebenza okuzinzileyo phantsi kwamandla aphezulu, iimeko zokushisa eziphezulu-ukwenza i-SiC wafer i-substrate yokuzikhethela kwizikhululo zesiseko ze-5G ezizayo kunye neenkqubo ze-radar. -

I-Optoelectronic kunye ne-LED Substrates esuka kwi-SiC Wafer

Ii-LED eziluhlaza kunye ne-UV ezikhule kwi-SiC wafer substrates zixhamla kuthelekiso olugqwesileyo lwe-lattice kunye nokulahla ubushushu. Ukusebenzisa i-wafer ye-SiC epolishiweyo yobuso iqinisekisa iileya ze-epitaxial ezifanayo, ngelixa ubulukhuni bendalo be-SiC wafer buvumela ukuba i-wafer ibe yincinci kunye nokupakishwa kwesixhobo esithembekileyo. Oku kwenza i-SiC wafer ibe yindawo yokuya kwiqonga lamandla aphezulu, ubomi obude bezicelo ze-LED.

I-SiC wafer's Q&A

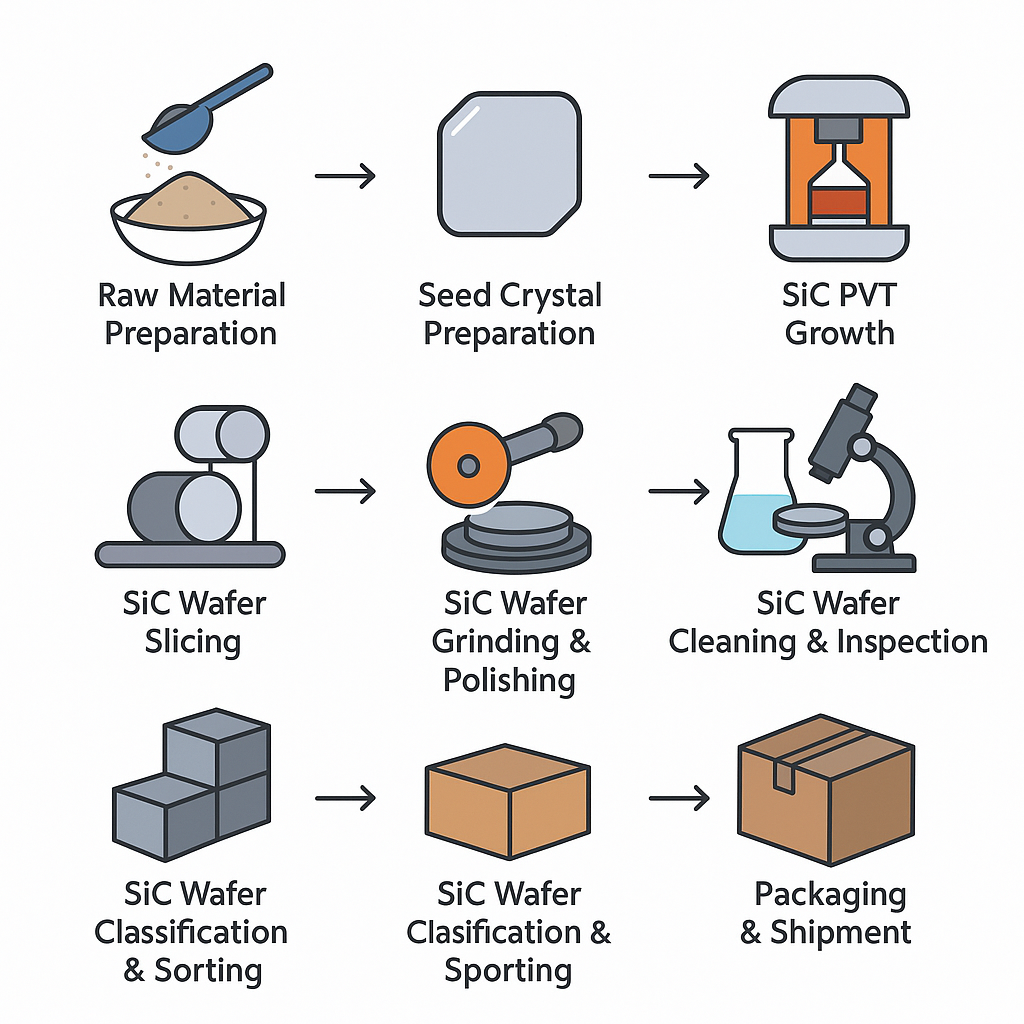

1. Q: Zenziwa njani ii-wafers ze-SiC?

A:

Ii-wafers ze-SiC zenziweAmanyathelo aneenkcukacha

-

Iifafa zeSiCUkulungiswa kwezinto ezikrwada

- Sebenzisa i-≥5N-grade SiC powder (ukungcola ≤1 ppm).

- Sieve kwaye ubhake kwangaphambili ukususa intsalela yekhabhoni okanye iikhompawundi zenitrogen.

-

SiCUkulungiswa kweCrystal yeMbewu

-

Thatha iqhekeza le-4H-SiC yekristale enye, sila ecaleni kwendlela 〈0001〉 yokuqhelaniswa ukuya ~ 10 × 10 mm².

-

Ipolishi echanekileyo ukuya kwi-Ra ≤0.1 nm kwaye iphawule i-crystal orientation.

-

-

SiCUHlumo lwe-PVT (uThutho loMphunga obonakalayo)

-

Layisha i-graphite crucible: ezantsi kunye ne-SiC powder, phezulu kunye nekristale yembewu.

-

Phuma uye kwi-10⁻³–10⁻⁵ Torr okanye gcwalisa ngasemva nge-helium ecocekileyo nge-1 atm.

-

Indawo yomthombo wobushushu ukuya kuma-2100–2300 ℃, gcina indawo yembewu ipholile 100–150 ℃.

-

Lawula izinga lokukhula kwi-1-5 mm / h ukulinganisa umgangatho kunye nokuphumelela.

-

-

SiCIngot Annealing

-

I-Aneal i-SiC ingot ekhulileyo kwi-1600-1800 ℃ iiyure ezi-4-8.

-

Injongo: ukukhulula uxinzelelo lwe-thermal kunye nokunciphisa ukuxinana kwe-dislocation.

-

-

SiCI-Wafer Slicing

-

Sebenzisa isarha yedayimani yocingo ukuze unqumle ingot ibe yi-0.5-1 mm yamawafa angqingqwa.

-

Nciphisa ukungcangcazela kunye namandla asecaleni ukuphepha iintanda ezincinci.

-

-

SiCWaferUkusila & ukupolisha

-

Ukusila ngokurhabaxaukususa umonakalo wokusarha (uburhabaxa ~10–30 µm).

-

Ukusila kakuhleukufikelela flatness ≤5 µm.

-

Ukukhazimliswa kweMichiza-Mechanical (CMP)ukufikelela kwisiphelo esifana nesipili (Ra ≤0.2 nm).

-

-

SiCWaferUkucoca & Ukuhlola

-

Ukucoca nge-ultrasonickwisisombululo sePiranha (H₂SO₄:H₂O₂), amanzi e-DI, emva koko IPA.

-

XRD/Raman spectroscopyukuqinisekisa i-polytype (4H, 6H, 3C).

-

I-Interferometryukulinganisa ukucaba (<5 µm) kunye nokujika (<20 µm).

-

Iingongoma ezine probeukuvavanya ukuxhathisa (umzekelo HPSI ≥10⁹ Ω·cm).

-

Ukuhlolwa kwesiphenephantsi kwepolarized light microscope kunye ne-scratch tester.

-

-

SiCWaferUHlelo & noHlelo

-

Hlela amaqhekeza nge-polytype kunye nodidi lombane:

-

4H-SiC N-uhlobo (4H-N): umxhasi wogxininiso 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-uhlobo (6H-N)

-

Abanye: 3C-SiC, P-uhlobo, njl.

-

-

-

SiCWaferUkupakishwa kunye noThutho

2. Q: Zeziphi iingenelo eziphambili zee-SiC wafers ngaphezu kwee-silicone wafers?

A: Xa kuthelekiswa ne-silicon wafers, ii-SiC wafers zinika amandla:

-

Ukusebenza kwamandla ombane aphezulu(>1,200 V) kunye nokumelana okuphantsi.

-

Uzinzo oluphezulu lobushushu(>300 °C) kunye nophuculo lolawulo lobushushu.

-

Izantya zokutshintsha ngokukhawulezangelahleko esezantsi yokutshintsha, ukunciphisa ukupholisa kwenqanaba lenkqubo kunye nobukhulu kwiziguquli zamandla.

4. Q: Ziziphi iziphene eziqhelekileyo ezichaphazela isivuno se-SiC wafer kunye nokusebenza?

A: Iziphene eziphambili kwii-SiC wafers ziquka i-micropipes, i-basal plane dislocations (BPDs), kunye nemikrwelo yomhlaba. Imibhobho inokubangela ukusilela kwesixhobo esiyingozi; Ii-BPDs zonyuka kwi-resistance ekuhambeni kwexesha; kunye nemikrwelo yomphezulu ikhokelela ekwaphukeni kwewafer okanye ukukhula kakubi kwe-epitaxial. Ukuhlolwa okungqongqo kunye nokunciphisa isiphene kubalulekile ke ngoko ukwandisa isivuno se-wafer ye-SiC.

Ixesha lokuposa: Jun-30-2025