Ukucoca okumanzi (Ukucoceka okumanzi) yenye yamanyathelo abalulekileyo kwiinkqubo zokuvelisa i-semiconductor, ejolise ekususeni ukungcola okuhlukahlukeneyo ukusuka kumphezulu we-wafer ukuqinisekisa ukuba amanyathelo alandelayo angenziwa kwindawo ecocekileyo.

Njengoko ubukhulu bezixhobo ze-semiconductor buqhubeka nokuncipha kunye neemfuno ezichanekileyo zonyuka, iimfuno zobugcisa zeenkqubo zokucoca i-wafer ziye zaqina ngakumbi. Kwanawona masuntswana amancinane, izinto eziphilayo, ii-ion zetsimbi, okanye iintsalela ze-oxide kumphezulu we-wafer zinokuchaphazela kakhulu ukusebenza kwesixhobo, ngaloo ndlela zichaphazela isivuno kunye nokuthembeka kwezixhobo ze-semiconductor.

Imigaqo engundoqo yokuCoca iWafer

Undoqo wokucoca i-wafer ilele ekususeni ngokufanelekileyo ukungcola okwahlukeneyo kumphezulu we-wafer ngokusebenzisa umzimba, iikhemikhali, kunye nezinye iindlela zokuqinisekisa ukuba i-wafer inomphezulu ococekileyo olungele ukusetyenzwa okulandelayo.

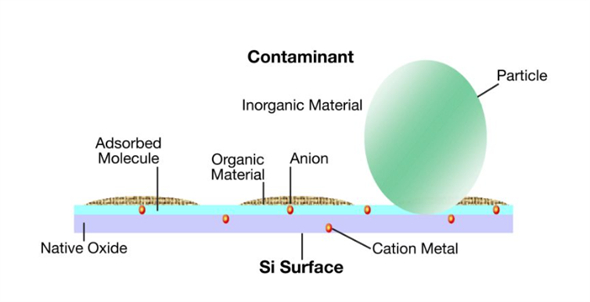

Uhlobo loNgcoliseko

Iimpembelelo eziphambili kwiiMpawu zeSixhobo

| inqaku Ungcoliseko | Iziphene zepateni

Iziphene zokufakelwa kwe-ion

Ukugquma iziphene zokuqhekeka kwefilimu

| |

| Ungcoliseko lwentsimbi | Iintsimbi zealkali | Ukungazinzi kwe-MOS transistor

Ukwaphulwa kwefilimu ye-oxide yesango / ukuthotywa

|

| Iintsimbi ezinzima | Ukonyuka kwe-PN junction reverse kuvuza ngoku

Isango le-oxide yefilimu yokuphazamiseka kweziphene

Ubuncinci bomthwali wokuthotywa ubomi babo bonke

I-oxide excitation layer defect generation

| |

| Usulelo lweMichiza | Izinto Eziphilayo | Isango le-oxide yefilimu yokuphazamiseka kweziphene

Iinguqu zefilimu yeCVD (amaxesha okufakwa kwe-incubation)

Ubungakanani befilimu ye-Thermal oxide (i-oxidation ekhawulezayo)

Ukwenzeka kwenkungu (i-wafer, ilens, mirror, mask, reticle)

|

| I-Inorganic Dopants (B, P) | MOS transistor Vth utshintsho

I-Si substrate kunye nokumelana okuphezulu kwe-poly-silicon sheet resistance resistance

| |

| Iziseko ze-Inorganic (i-amines, i-ammonia) kunye ne-Acids (SOx) | Ukuthotywa kwesisombululo sezinto ezichasayo ezenziwe ngamachiza

Ukwenzeka kokungcoliseka kwamasuntswana kunye nenkungu ngenxa yokuveliswa kwetyuwa

| |

| Iifilimu zoMthonyama kunye neMichiza ye-Oxide ngenxa yokufuma, umoya | Ukonyuka kokumelana noqhagamshelwano

Ukwaphulwa kwefilimu ye-oxide yesango / ukuthotywa

| |

Ngokukodwa, iinjongo zenkqubo yokucoca i-wafer ziquka:

Ukususwa kweNcam: Ukusebenzisa iindlela zomzimba okanye zekhemikhali ukususa amasuntswana amancinci ancanyathiselwe kumphezulu we-wafer. Amasuntswana amancinci anzima kakhulu ukususa ngenxa yamandla anamandla e-electrostatic phakathi kwawo kunye ne-wafer surface, efuna unyango olukhethekileyo.

Ukususwa kwezinto ze-Organic: Izinto ezingcolisayo ze-Organic ezifana negrisi kunye neentsalela ze-photoresist zinokubambelela kumphezulu we-wafer. Ezi zingcolisi ziqhele ukususwa kusetyenziswa ii-oxidizing agents ezinamandla okanye izinyibilikisi.

Ukususwa kwe-Ion ye-Metal: Iintsalela ze-ion zetsimbi kumphezulu we-wafer zinokuthoba ukusebenza kombane kwaye zichaphazele amanyathelo alandelayo okuqhuba. Ngoko ke, izisombululo ezithile zeekhemikhali zisetyenziselwa ukususa ezi ion.

Ukususwa kwe-oksidi: Ezinye iinkqubo zifuna ukuba umphezulu we-wafer ukhululeke kumaleko we-oxide, njengesilicon oxide. Kwiimeko ezinjalo, iileyile ze-oxide zendalo kufuneka zisuswe ngexesha lamanyathelo athile okucoca.

Umceli mngeni wetekhnoloji yokucoca i-wafer ilele ekususeni ngokufanelekileyo ungcoliseko ngaphandle kokuchaphazela kakubi umphezulu we-wafer, njengokuthintela ukurhabaxa komphezulu, ukubola, okanye omnye umonakalo womzimba.

2. Inkqubo yokucoca iWafer

Inkqubo yokucoca i-wafer ibandakanya amanyathelo amaninzi okuqinisekisa ukususwa ngokupheleleyo kwezinto ezingcolileyo kunye nokufezekisa indawo ecocekileyo ngokupheleleyo.

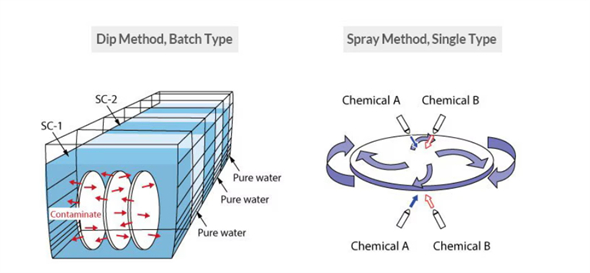

Umzobo: Ukuthelekisa phakathi kweBatch-Type kunye ne-Single-Wafer Cleaning

Inkqubo yokucoca iwafer eqhelekileyo ibandakanya la manyathelo alandelayo:

1. Ukucoca kwangaphambili (UkuCoca kwangaphambili)

Injongo yokucocwa kwangaphambili kukususa ukungcola okungahambiyo kunye neengqungquthela ezinkulu ukusuka kwi-wafer surface, edlalwa ngokuqhelekileyo ngamanzi adibeneyo (i-DI Water) yokuhlanjululwa kunye nokucoca i-ultrasonic. Amanzi ahlanjululweyo anokuqala ukususa amaqhekeza kunye nokungcola okunyibilikayo kwi-wafer surface, ngelixa ukucocwa kwe-ultrasonic kusebenzisa imiphumo ye-cavitation ukuphula ibhondi phakathi kweengqungquthela kunye ne-wafer surface, okwenza kube lula ukukhupha.

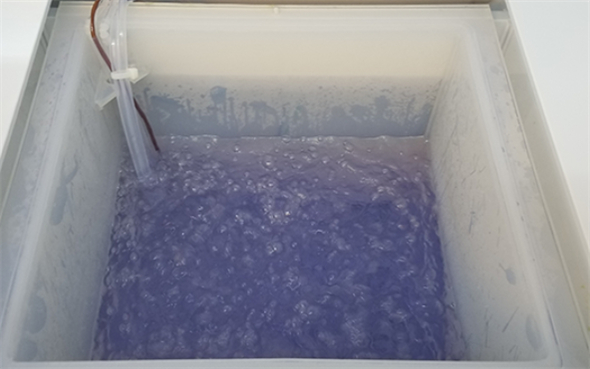

2. Ukucoca imichiza

Ukucoca imichiza yenye yamanyathelo angundoqo kwinkqubo yokucoca i-wafer, usebenzisa izisombululo zeekhemikhali ukususa izinto eziphilayo, ii-ion zetsimbi, kunye nee-oxides ukusuka kumphezulu we-wafer.

Ukususwa kwezinto eziphilayo: Ngokuqhelekileyo, i-acetone okanye i-ammonia / peroxide umxube (SC-1) isetyenziselwa ukunyibilika kunye ne-oxidize izinto ezingcolileyo eziphilayo. Umlinganiselo oqhelekileyo wesisombululo se-SC-1 ngu-NH₄OH

₂O₂

₂O = 1:1:5, kunye nobushushu obusebenzayo obumalunga ne-20°C.

Ukususwa kwe-Ion ye-Metal: I-asidi ye-nitric okanye i-hydrochloric acid / imixube ye-peroxide (SC-2) isetyenziselwa ukususa i-ion zetsimbi ukusuka kwi-wafer surface. Umlinganiselo oqhelekileyo wesisombululo se-SC-2 yi-HCl

₂O₂

₂O = 1:1:6, iqondo lobushushu ligcinwe malunga nama-80°C.

Ukususwa kwe-Oxide: Kwezinye iinkqubo, ukususwa komgangatho we-oxide wendalo ukusuka kwi-wafer surface kuyadingeka, apho isisombululo se-hydrofluoric acid (HF) sisetyenzisiweyo. Umlinganiselo oqhelekileyo wesisombululo seHF yiHF

₂O = 1:50, kwaye inokusetyenziswa kwiqondo lobushushu begumbi.

3. Ukucoceka kokugqibela

Emva kokucocwa kweekhemikhali, ii-wafers zihlala zithatha inyathelo lokugqibela lokucoca ukuqinisekisa ukuba akukho zintsalela zeekhemikhali ezihlala phezu komhlaba. Ukucocwa kokugqibela kusebenzisa amanzi adiyiniweyo ukuze kuhlanjwe ngokucokisekileyo. Ukongezelela, ukucocwa kwamanzi e-ozone (O₃/H₂O) kusetyenziselwa ukususa ngakumbi nayiphi na inkunkuma eseleyo kwi-wafer surface.

4. Ukomisa

Ii-wafers ezicociweyo kufuneka zomiswe ngokukhawuleza ukunqanda ii-watermark okanye ukuncamathiselwa kwakhona kwezinto ezingcolileyo. Iindlela zokomisa eziqhelekileyo ziquka ukomisa nge-spin kunye nokuhlanjululwa kwenitrogen. Eyangaphambili isusa ukufuma kumphezulu we-wafer ngokujikeleza ngesantya esiphezulu, ngelixa le yokugqibela iqinisekisa ukomisa ngokupheleleyo ngokuvuthela irhasi eyomileyo yenitrogen kumhlaba osicaba.

Ungcoliseko

Igama leNkqubo yokuCoca

Inkcazo yomxube weMichiza

Imichiza

| Amacandelo | I-Piranha (SPM) | I-asidi ye-sulfuric / i-hydrogen peroxide / amanzi e-DI | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI amanzi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Iintsimbi (hayi ubhedu) | SC-2 (HPM) | Hydrochloric acid/hydrogen peroxide/DI amanzi | HCl/H2O2/H2O1:1:6; 85°C |

| I-Piranha (SPM) | I-asidi ye-sulfuric / i-hydrogen peroxide / amanzi e-DI | H2SO4/H2O2/H2O3-4:1; 90°C | |

| I-DHF | Dilute hydrofluoric acid/DI amanzi (akayi kususa ubhedu) | HF/H2O1:50 | |

| Izinto eziphilayo | I-Piranha (SPM) | I-asidi ye-sulfuric / i-hydrogen peroxide / amanzi e-DI | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI amanzi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| I-DIO3 | I-ozone emanzini e-de-ionized | I-O3/H2O Imixube elungiselelweyo | |

| I-oxide yeNative | I-DHF | Nciphisa i-hydrofluoric acid / amanzi e-DI | HF/H2O 1:100 |

| BHF | I-asidi ye-hydrofluoric efihliweyo | NH4F/HF/H2O |

3. Iindlela zokuCoca iWafer eqhelekileyo

1. Indlela yokucoca iRCA

Indlela yokucoca i-RCA yenye yezona ndlela zibalaseleyo zokucoca i-wafer kwishishini le-semiconductor, ephuhliswe yi-RCA Corporation ngaphezulu kweminyaka engama-40 eyadlulayo. Le ndlela isetyenziselwa ngokuyinhloko ukususa ukungcola kwezinto eziphilayo kunye nokungcola kwe-ion yensimbi kwaye ingagqitywa ngamanyathelo amabini: SC-1 (i-Standard Clean 1) kunye ne-SC-2 (i-Standard Clean 2).

I-SC-1 Ukucoca: Eli nyathelo lisetyenziswa ikakhulu ukususa izinto ezingcolisekileyo kunye namasuntswana. Isisombululo ngumxube weammonia, ihydrogen peroxide, kunye namanzi, okwenza umaleko obhityileyo wesilicon oxide kumphezulu wewafer.

I-SC-2 Ukucoca: Eli nyathelo lisetyenziswa ikakhulu ukususa izinto ezingcolisa i-ion yesinyithi, kusetyenziswa umxube we-hydrochloric acid, i-hydrogen peroxide, kunye namanzi. Ishiya umaleko obhityileyo wokudlula kwi-wafer surface ukuthintela ukusuleleka kwakhona.

2. Indlela yokuCoca iPiranha (i-Piranha Etch Clean)

Indlela yokucoca i-Piranha yindlela esebenzayo kakhulu yokususa izinto eziphilayo, usebenzisa umxube we-sulfuric acid kunye ne-hydrogen peroxide, ngokuqhelekileyo kumlinganiselo we-3: 1 okanye 4: 1. Ngenxa yezinto ezinamandla kakhulu ze-oxidative yesi sisombululo, inokususa inani elikhulu lezinto eziphilayo kunye nezingcoliso ezinenkani. Le ndlela idinga ukulawulwa okungqongqo kweemeko, ngokukodwa ngokubhekiselele kwiqondo lokushisa kunye nokugxila, ukuphepha ukulimaza i-wafer.

Ukucoca kwe-Ultrasonic isebenzisa i-cavitation effect eyenziwa ngamaza omsindo we-high-frequency kwi-liquid ukususa ukungcola kwi-wafer surface. Xa kuthelekiswa nokucocwa kwe-ultrasonic yendabuko, ukucocwa kwe-megasonic kusebenza kwi-frequency ephezulu, eyenza ukususwa ngokufanelekileyo kwee-sub-micron-size particles ngaphandle kokwenza umonakalo kwi-wafer surface.

4. Ukucoca i-Ozone

Itekhnoloji yokucoca i-ozone isebenzisa iipropathi ezomeleleyo ze-oxidizing ye-ozone ukubola kunye nokususa izinto ezingcolisayo ze-organic ukusuka kumphezulu we-wafer, ekugqibeleni ziguqule zibe yi-carbon dioxide engenabungozi kunye namanzi. Le ndlela ayifuni ukusetyenziswa kwee-reagents zeekhemikhali ezibizayo kwaye ibangela ukungcoliseka okuncinci kokusingqongileyo, okwenza kube yiteknoloji evelayo kwintsimi yokucoca i-wafer.

4. IsiXhobo sokuCoca iWafer

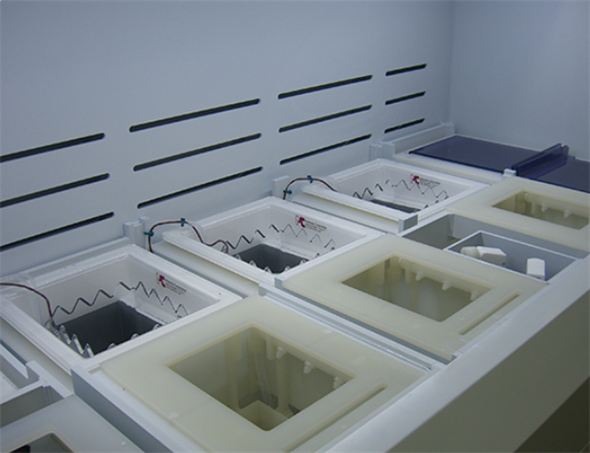

Ukuqinisekisa ukusebenza kakuhle kunye nokukhuseleka kweenkqubo zokucoca i-wafer, iindidi zezixhobo zokucoca eziphambili zisetyenziselwa ukuveliswa kwe-semiconductor. Iindidi eziphambili ziquka:

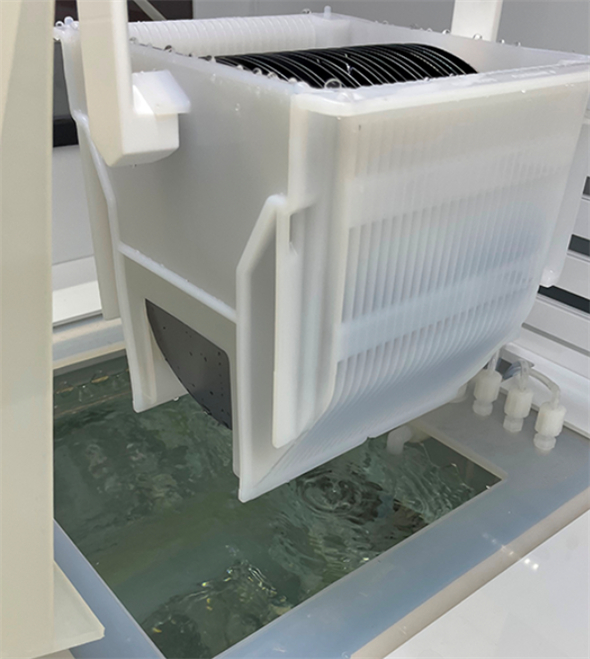

1. Izixhobo zokucoca ezimanzi

Izixhobo zokucoca ezimanzi zibandakanya iitanki zokuntywilisela ezahlukeneyo, iitanki zokucoca i-ultrasonic, kunye ne-spin dryers. Ezi zixhobo zidibanisa amandla omatshini kunye nee-reagents zeekhemikhali ukususa ukungcola kwi-wafer surface. Iitanki zokuntywiliselwa ngokuqhelekileyo zixhotyiswe ngeenkqubo zokulawula ubushushu ukuqinisekisa ukuzinza kunye nokusebenza kwezisombululo zamachiza.

2. Izixhobo zokucoca ezomileyo

Izixhobo zokucoca ezomileyo ikakhulu zibandakanya izicoci zeplasma, ezisebenzisa amasuntswana anamandla aphezulu kwiplasma ukusabela kunye nokususa iintsalela kumphezulu we-wafer. Ukucocwa kweplasma kubaluleke kakhulu kwiinkqubo ezifuna ukugcina ingqibelelo yomhlaba ngaphandle kokuzisa intsalela yeekhemikhali.

3. Iinkqubo zokuCoca ngokuzenzekela

Ngokunyuka okuqhubekayo kwemveliso ye-semiconductor, iinkqubo zokucoca ngokuzenzekelayo ziye zaba yinto ekhethiweyo yokucoca i-wafer enkulu. Ezi nkqubo zihlala zibandakanya iindlela zokuhambisa ezizenzekelayo, iinkqubo zokucoca iitanki ezininzi, kunye neenkqubo zokulawula ngokuchanekileyo ukuqinisekisa iziphumo zokucoca ezihambelanayo kwi-wafer nganye.

5. IiNdlela zekamva

Njengoko izixhobo ze-semiconductor ziqhubeka nokuncipha, itekhnoloji yokucoca i-wafer iguqukela kwizisombululo ezisebenzayo nezinobuhlobo nokusingqongileyo. Itekhnoloji yokucoca yexesha elizayo iya kugxila koku:

I-Sub-nanometer Ukususwa kweNqaku: Ubuchwephesha obukhoyo bokucoca bunokusingatha i-nanometer-scale particles, kodwa ngokunciphisa ngakumbi ubungakanani besixhobo, ukususa i-sub-nanometer particles kuya kuba ngumngeni omtsha.

Ukucoca okuluhlaza kunye ne-Eco-friendly: Ukunciphisa ukusetyenziswa kweekhemikhali ezinobungozi bokusingqongileyo kunye nokuphuhlisa iindlela zokucoca i-eco-friendly, ezifana nokucoca i-ozone kunye nokucoca i-megasonic, kuya kuba kubaluleke kakhulu.

Amanqanaba aPhakamileyo okuSebenza kunye noBukrelekrele: Iinkqubo ezihlakaniphile ziya kwenza ukubeka iliso ngexesha langempela kunye nokulungelelaniswa kweeparitha ezahlukeneyo ngexesha lokucoca, ngakumbi ukuphucula ukucoca kunye nokusebenza kakuhle kwemveliso.

Itekhnoloji yokucoca i-wafer, njengenyathelo elibalulekileyo kwimveliso ye-semiconductor, idlala indima ebalulekileyo ekuqinisekiseni imiphezulu ecocekileyo ye-wafer kwiinkqubo ezilandelayo. Ukudibaniswa kweendlela ezahlukeneyo zokucoca ngokufanelekileyo kususa ukungcola, ukubonelela indawo ecocekileyo ye-substrate kumanyathelo alandelayo. Njengoko iteknoloji iqhubela phambili, iinkqubo zokucoca ziya kuqhubeka ziphuculwa ukuhlangabezana neemfuno zokuchaneka okuphezulu kunye namazinga asezantsi esiphako kwimveliso ye-semiconductor.

Ixesha lokuposa: Oct-08-2024