I-Silicon carbide (i-SiC) ayisiyo itekhnoloji ebaluleke kakhulu yokhuselo lwelizwe kuphela kodwa ikwayinto ebalulekileyo kumashishini eemoto kunye namandla ehlabathi. Njengenyathelo lokuqala elibalulekileyo kwi-SiC enye-crystal processing, ukunqunyulwa kwe-wafer kubeka ngokuthe ngqo umgangatho wokucuthwa okulandelayo kunye nokupholisha. Iindlela zesiNtu zokusika zikholisa ukuzisa iintanda ezingaphezulu kunye nezingaphantsi komhlaba, zonyusa amazinga okuqhawuka kwamawafa kunye neendleko zokwenziwa. Ke ngoko, ukulawula ukonakala komhlaba kubalulekile ekuqhubeleni phambili ukwenziwa kwesixhobo se-SiC.

Okwangoku, i-SiC ingot slicing ijongene nemingeni emibini emikhulu:

- Ilahleko ephezulu yemathiriyeli kwisarha yesiqhelo yeentambo ezininzi:Ukuqina okugqithisileyo kwe-SiC kunye nokuqaqadeka kuyenza ithande ukujija kunye nokuqhekeka ngexesha lokusika, ukucola kunye nokupolisha. Ngokutsho kwedatha ye-Infineon, i-diamond-resin-bonded ye-diamond-resin-bond multi-wire sawing ifezekisa kuphela i-50% yokusetyenziswa kwemathiriyeli ekusikeni, kunye nelahleko ye-wafer eyodwa epheleleyo ifikelela kwi- ~ 250 μm emva kokupolishwa, ishiya imathiriyeli encinci esebenzisekayo.

- Ukusebenza okuphantsi kunye nemijikelo emide yemveliso:Izibalo zemveliso yamazwe ngamazwe zibonisa ukuba ukuvelisa ii-wafers eziyi-10,000 zisebenzisa iiyure ezingama-24 eziqhubekayo zokusarha ngeengcingo ezininzi kuthatha ~intsuku ezingama-273. Le ndlela ifuna izixhobo ezibanzi kunye nezinto ezisetyenziswayo ngelixa ivelisa uburhabaxa obuphezulu kunye nongcoliseko (uthuli, amanzi amdaka).

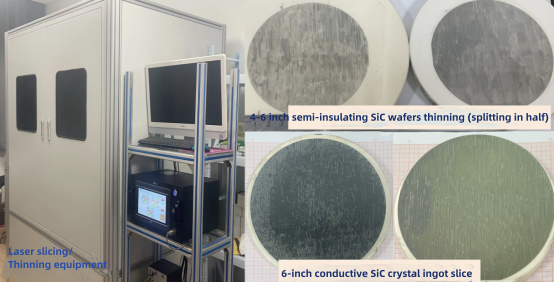

Ukujongana nale miba, iqela likaNjingalwazi u-Xiu Xiangqian kwiYunivesithi yaseNanjing liphuhlise izixhobo zokusika ezichanekileyo zelaser ze-SiC, zisebenzise itekhnoloji yelaser ekhawulezayo yokunciphisa iziphene kunye nokunyusa imveliso. Kwi-ingot ye-SiC eyi-20-mm, obu buchwepheshe buphinda kabini isivuno se-wafer xa kuthelekiswa nokusarha ucingo lwemveli. Ukongeza, ii-laser-sliced wafers zibonisa ukufana okuphezulu kwejiyometri, okubangela ukuncitshiswa kobunzima ukuya kuma-200 μm ngewafa nganye kunye nokwandisa imveliso.

Izinto eziphambili eziluncedo:

- Igqitywe i-R&D kwizixhobo zeprototype ezinkulu, eziqinisekisiweyo zokunqunqa ii-4-6-inch semi-insulating wafers ze-SiC kunye ne-6-inch conductive SiC ingots.

- I-8-intshi ye-ingot slicing iphantsi kokuqinisekiswa.

- Ixesha elifutshane kakhulu lokusika, imveliso yonyaka ephezulu, kunye ne-50% yokuphucula isivuno.

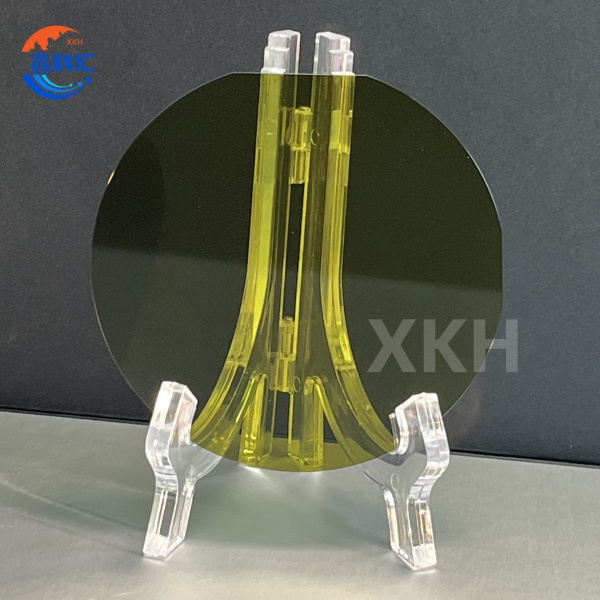

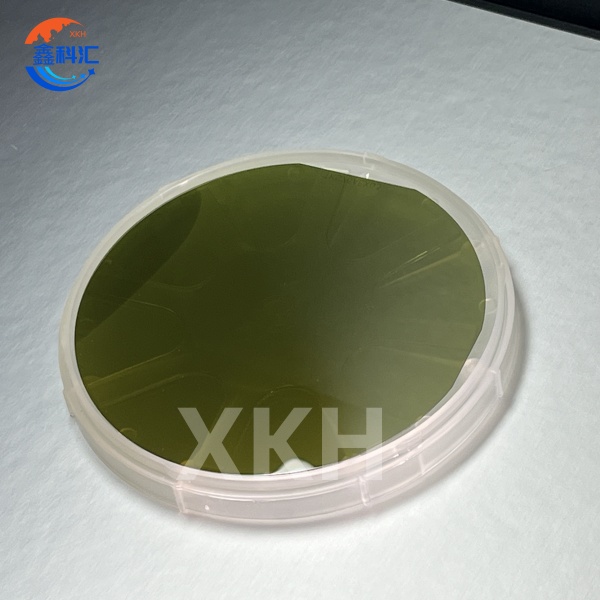

I-substrate ye-SiC ye-XKH yohlobo lwe-4H-N

Amandla eMarike:

Esi sixhobo sikulungele ukuba sisisombululo esingundoqo se-8-intshi ye-SiC ingot slicing, okwangoku ilawulwa yi-Japan evela kumazwe angaphandle ngeendleko eziphezulu kunye nezithintelo zokuthumela ngaphandle. Imfuno yasekhaya ye-laser slicing/thinning equipment ingaphezulu kweeyunithi ezili-1,000, ukanti akukho ndlela yimbi eyenziwe ngamaTshayina ekhoyo. Itekhnoloji yeYunivesithi yaseNanjing inexabiso elikhulu lentengiso kunye nokubanakho kwezoqoqosho.

Ukuhambelana kwezinto ezininzi:

Ngaphandle kwe-SiC, izixhobo zisekela i-laser processing ye-gallium nitride (GaN), i-aluminium oxide (i-Al₂O₃), kunye nedayimane, ukwandisa izicelo zayo zoshishino.

Ngokuguqula ukusetyenzwa kwe-wafer ye-SiC, olu tshintsho lulungisa imiqobo ebalulekileyo kwimveliso ye-semiconductor ngelixa ilungelelaniswa neendlela zehlabathi zokusebenza ezisebenza kakhulu, izixhobo ezisebenza ngamandla.

Isiphelo

Njengomkhokeli weshishini kwi-silicon carbide (SiC) yokuvelisa i-substrate, i-XKH ikhethekileyo ekuboneleleni i-2-12-intshi epheleleyo ye-SiC substrates (kuquka i-4H-N / SEMI-uhlobo, i-4H / 6H / 3C-uhlobo) elungiselelwe kumacandelo akhula kakhulu njengezithuthi zamandla amatsha (i-NEVs, i-voltage ye-5), unxibelelwano lwe-5G, kunye nokugcinwa kwe-5. Sisebenzisa itekhnoloji yokusika itekhnoloji enelahleko ephantsi, kunye netekhnoloji yokucoca echanekileyo, sifezekise imveliso eninzi yee-intshi ezisi-8 kunye nenkqubela phambili kwitekhnoloji yokukhula kwekristale ye-SiC eyi-intshi eyi-12, ukunciphisa kakhulu iindleko zeyunithi nganye. Ukuqhubela phambili, siya kuqhubeka nokwenza ngcono i-ingot-level laser slicing, kunye neenkqubo zokulawula uxinzelelo olukrelekrele, ukunyusa isivuno se-12-intshi ye-substrate ukuya kumanqanaba okhuphiswano lwehlabathi, sixhobisa ishishini lasekhaya le-SiC ukuba laphule iimonopoli zamazwe aphesheya kunye nokukhawulezisa usetyenziso olunomngcipheko kwimimandla ephezulu efana neechips ze-auto-grade kunye ne-AI ye-auto-grade.

I-substrate ye-SiC ye-XKH yohlobo lwe-4H-N

Ixesha lokuposa: Aug-15-2025