1. Intshayelelo

Ngaphandle kwamashumi eminyaka yophando, i-heteroepitaxial 3C-SiC ekhule kwi-silicon substrates ayikafikeleli umgangatho owaneleyo wekristale kwizicelo ze-elektroniki zeshishini. Ukukhula ngokuqhelekileyo kwenziwa kwi-Si(100) okanye i-Si (111) substrates, nganye ibonisa imingeni eyahlukileyo: imimandla echasene nesigaba (100) kunye nokuqhekeka kwe-(111). Ngelixa [i-111] iifilimu ezijoliswe kuzo zibonisa iimpawu ezithembisayo ezifana nokunciphisa ingxinano yesiphene, i-morphology ephuculweyo yomhlaba, kunye noxinzelelo oluphantsi, ezinye iindlela zokuqhelaniswa ne-(110) kunye (211) zihlala zingafundiweyo. Idatha ekhoyo icebisa ukuba iimeko zokukhula ezizezona zingcono zinokuthi ziqhelaniswe ngokuthe ngqo, zibe nzima uphando olucwangcisiweyo. Ngokucacileyo, ukusetyenziswa kwe-high-Miller-index Si substrates (umzekelo, (311), (510)) ye-3C-SiC heteroepitaxy ayizange ixelwe, ishiya indawo ebalulekileyo yophando lokuhlola kwiindlela zokukhula ezixhomekeke kwi-orientation.

2. Uvavanyo

Iingqimba ze-3C-SiC zafakwa nge-atmospheric-pressure chemical vapor deposition (CVD) kusetyenziswa i-SiH4/C3H8/H2 i-precursor gases. Iisubstrates beziyi-1 cm² iiwafer zeSi ezineendlela ezahlukeneyo zokuqhelaniswa: (100), (111), (110), (211), (311), (331), (510), (553), kunye (995). Zonke ii-substrates bezikwi-axis ngaphandle kwe-(100), apho i-2 ° off-cut wafers zaye zavavanywa ngakumbi. Ukucocwa kwangaphambi kokukhula kubandakanya ukuthotywa kwe-ultrasonic kwi-methanol. Iprotocol yokukhula iqulethwe ukususwa kwe-oxide yendalo ngokusebenzisa i-H2 annealing kwi-1000 ° C, ilandelwa yinkqubo eqhelekileyo yamanyathelo amabini: i-carburization yemizuzu eyi-10 kwi-1165 ° C kunye ne-12 sccm C3H8, emva koko i-epitaxy yemizuzu ye-60 kwi-1350 ° C (C / Si ratio = 4) usebenzisa i-2 Siccm 8 kunye ne-4 sccmH 4) usebenzisa i-2 Siccm 8 C3H8 . Ubaleko lokukhula ngalunye lubandakanya uqhelaniso lwe-Si ezine ukuya kwezintlanu, ubuncinane esinye (i-100) sesalathiso esisicaba.

3. Iziphumo kunye neNgxoxo

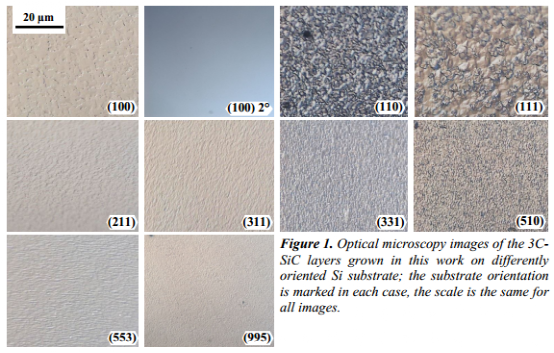

I-morphology ye-3C-SiC layers ekhulile kwii-substrates ezahlukeneyo ze-Si (umzobo 1) ubonise iimpawu ezicacileyo zomhlaba kunye noburhabaxa. Ngokubonakalayo, iisampulu ezikhule kwiSi(100), (211), (311), (553), kunye (995) zivele zifana nesipili, ngelixa ezinye zisuka kubisi (331), (510)) ukuya kuthi ga buthuntu ((110), (111)). Eyona ndawo igudileyo (ebonisa eyona microstructure) ifunyenwe kwi-(100)2 ° off kunye (995) substrates. Okumangalisayo kukuba, zonke iileya zahlala zingaqhekeki emva kokupholisa, kubandakanywa noxinzelelo oluqhelekileyo lwe-3C-SiC (111). Ubungakanani besampulu elinganiselweyo bunokuthi buthintele ukuqhekeka, nangona ezinye iisampulu zibonisiwe ukugoba (30-60 μm ukuphambuka ukusuka embindini ukuya emphethweni) kubonwa phantsi kwe-microscopy ye-optical kwi-1000 × ukukhulisa ngenxa yoxinzelelo lobushushu oluqokelelweyo. Iileya ezigobe kakhulu ezikhule kwi-Si(111), (211), kunye (553) iisubstrates zibonise iimilo eziconcave ezibonisa ukuxinezeleka kokuqina, kufuna umsebenzi wovavanyo olongezelelekileyo kunye nethiyori ukuze inxibelelane necrystallographic orientation.

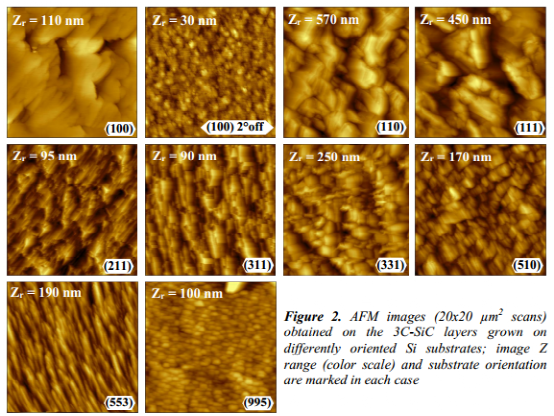

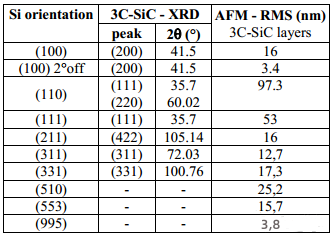

Umzobo 1 ushwankathela i-XRD kunye ne-AFM (ukuskena kwi-20 × 20 μ m2) iziphumo ze-3C-SC zomaleko ezikhule kwii-substrates ze-Si ezineendlela ezahlukeneyo zokuqhelaniswa.

Imifanekiso yeAtomic force microscopy (AFM) (Fig. 2) ingqinelaniswe nokuqwalaselwa kwamehlo. Amaxabiso e-Root-mean-square (RMS) aqinisekise iindawo ezigudileyo kwi-(100)2 ° off kunye ne-(995) substrates, ebonisa izakhiwo ezifana neenkozo ezine-400-800 nm lateral dimensions. Umaleko (110)-okhulileyo wawungowona urhabaxa, ngelixa izinto ezinde kunye/okanye ezinxuseneyo ezinemida ebukhali ngamaxesha athile zavela kwezinye izikhokelo ((331), (510)). I-X-ray diffraction (XRD) θ-2θ i-scans (ishwankathelwe kwiThebhile 1) ibonise i-heteroepitaxy eyimpumelelo kwi-substrates ye-low-Miller-index, ngaphandle kwe-Si (110) ebonisa umxube we-3C-SiC (111) kunye (110) iincopho ezibonisa i-polycrystallinity. Oku kuxutywa kwe-orientation kuye kwaxelwa ngaphambili kwi-Si (110), nangona ezinye izifundo zibone i-3C-SiC kuphela (i-111) ejoliswe kwi-3C-SiC, ebonisa ukuba ukulungiswa kwemeko yokukhula kubalulekile. Kwi-indices ye-Miller ≥5 ((510), (553), (995)), akukho zincopho ze-XRD zichongiwe kumgangatho oqhelekileyo we-θ-2θ uqwalaselo kuba ezi nqwelomoya ziphezulu azifani kule geometry. Ukungabikho kweencopho ezisezantsi ze-3C-SiC (umzekelo, (111), (200)) zibonisa ukukhula kwe-crystalline enye, kufuna ukuthambeka kwesampulu ukuze kubonwe ukungafani kwiinqwelo-moya ezisezantsi.

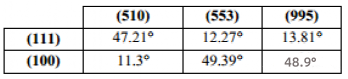

Umzobo we-2 ubonisa ukubalwa kwe-angle yendiza ngaphakathi kwesakhiwo sekristale yeCFC.

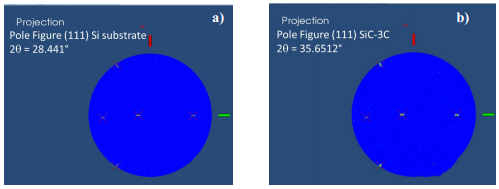

Ii-angles ze-crystallographic ezibaliweyo phakathi kwe-index ephezulu kunye ne-low-index planes (Itheyibhile 2) ibonise i-misorientations enkulu (> 10 °), ichaza ukungabikho kwabo kwi-scan θ-2θ esemgangathweni. Uhlalutyo lwe-Pole figure ke ngoko lwenziwa kwi-(995)-oriented sample ngenxa ye-morphology yayo yegranular engaqhelekanga (enokwenzeka ukusuka kwikholomu yokukhula okanye i-twinning) kunye noburhabaxa obuphantsi. Izibalo ze-111 (umzobo we-3) ukusuka kwi-substrate ye-Si kunye ne-3C-SiC layer yayiphantse yafana, iqinisekisa ukukhula kwe-epitaxial ngaphandle kwe-twinning. Indawo esembindini ibonakala kwi-χ≈15 °, ihambelana ne-angle yethiyori (111)-(995). Iindawo ezintathu ezilinganayo ezilinganayo zivele kwiindawo ezilindelekileyo (χ=56.2 °/φ=269.4 °, χ=79 °/φ=146.7 ° kunye ne-33.6 °), nangona indawo ebuthathaka engalindelekanga kwi-χ=62 °/φ=93.3 ° ifuna uphando olongezelelweyo. Umgangatho wekristale, ovavanywa ngobubanzi bendawo kwi-φ-scans, ubonakala uthembisa, nangona imilinganiselo yegophe eshukumayo iyafuneka kubungakanani. Amanani epoleni (510) kunye (553) iisampulu zisala zigqitywe ukuze ziqinisekise ubume bazo obucingelwayo be-epitaxial.

Umzobo we-3 ubonisa umzobo we-XRD ophezulu obhalwe kwi-(995) isampuli ejoliswe kuyo, ebonisa (i-111) iiplani ze-Si substrate (a) kunye ne-3C-SiC layer (b).

4. Isiphelo

Ukukhula kwe-Heteroepitaxial 3C-SiC kuphumelele kwiindlela ezininzi ze-Si ngaphandle kwe-(110), eyavelisa i-polycrystalline material. I-Si (100) 2 ° off kunye (995) substrates ivelise iileya ezigudileyo (RMS <1 nm), ngelixa (111), (211), kunye (553) zibonise ukugoba okubalulekileyo (30-60 μm). Iisubstrates zesalathisi esiphezulu zifuna udidi oluphezulu lwe-XRD (umzekelo, amanani epali) ukuqinisekisa i-epitaxy ngenxa yokungabikho kwe-θ-2θ iincopho. Umsebenzi oqhubekayo uquka imilinganiselo yokugungqa, uhlalutyo loxinzelelo lweRaman, kunye nokwandiswa kolunye ulungelelwaniso oluphezulu lwesalathisi ukugqiba olu phononongo lokuhlola.

Njengomvelisi odibeneyo odibeneyo, i-XKH inikezela ngeenkonzo zokucwangcisa ngokwezifiso kunye neepotfoliyo ezibanzi ze-silicon carbide substrates, ezinikezela ngeentlobo eziqhelekileyo kunye nezikhethekileyo ezibandakanya i-4H / 6H-N, 4H-Semi, 4H / 6H-P, kunye ne-3C-SiC, ekhoyo kwiidamitha ukusuka kwi-2-intshi ukuya kwi-intshi eyi-12. Ubuchwephesha bethu bokugqibela bokukhula kwekristale, ukuchaneka komatshini, kunye nokuqinisekiswa komgangatho kuqinisekisa izisombululo ezilungiselelwe umbane wamandla, iRF, kunye nezicelo ezivelayo.

Ixesha lokuposa: Aug-08-2025