Ukususela kwi-1980, ukuxinana kokuhlanganiswa kweesekethe ze-elektroniki kuye kwanda kwinqanaba lonyaka le-1.5 × okanye ngokukhawuleza. Ukuhlanganiswa okuphezulu kukhokelela ekuxininiseni okukhulu ngoku kunye nokuveliswa kobushushu ngexesha lokusebenza.Ukuba ayichithwanga ngokufanelekileyo, obu bushushu bunokubangela ukungaphumeleli kwe-thermal kunye nokunciphisa ixesha lokuphila lamacandelo e-elektroniki.

Ukuhlangabezana neemfuno ezikhulayo zolawulo lwe-thermal, izinto zokupakisha ze-elektroniki ezikumgangatho ophezulu kunye ne-thermal conductivity ziphandwa ngokubanzi kwaye ziphuculwe.

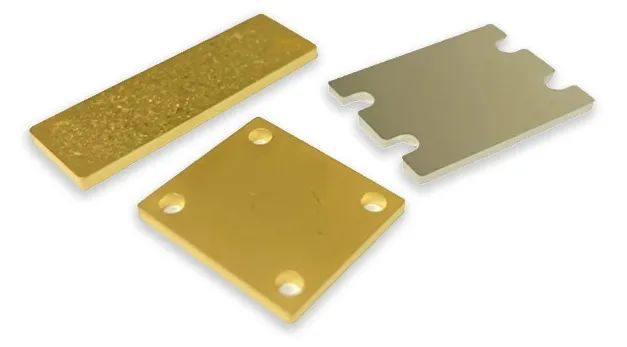

Idayimani/impahla edibeneyo yobhedu

01 Idayimani kunye neCopper

Izinto zokupakisha zemveli ziquka iiseramics, iiplastiki, isinyithi, kunye neealloys zazo. I-Ceramics efana ne-BeO kunye ne-AlN ibonisa i-CTEs ehambelana ne-semiconductors, ukuzinza okulungileyo kweekhemikhali, kunye ne-moderate conductivity ye-thermal. Nangona kunjalo, ukusetyenzwa kwabo okuntsokothileyo, ixabiso eliphezulu (ingakumbi i-BeO enetyhefu), kunye ne-brittleness limit applications. Ukupakishwa kwePlastiki kunika ixabiso eliphantsi, ubunzima obulula, kunye nokugquma kodwa unengxaki yokungahambi kakuhle kwe-thermal kunye nokungazinzi kobushushu obuphezulu. Iintsimbi ezicocekileyo (i-Cu, i-Ag, i-Al) ine-conductivity ephezulu ye-thermal kodwa i-CTE egqithisileyo, ngelixa i-alloys (Cu-W, Cu-Mo) iphazamisa ukusebenza kwe-thermal. Ke ngoko, imathiriyeli yokupakisha inoveli elinganisa ukuhanjiswa okuphezulu kwe-thermal kunye ne-CTE efanelekileyo ifuneka ngokukhawuleza.

| Ukomelezwa | I-Thermal Conductivity (W/(m·K)) | I-CTE (×10⁻⁶/℃) | Ubuninzi (g/cm³) |

| Idayimani | 700-2000 | 0.9–1.7 | 3.52 |

| BeO amasuntswana | 300 | 4.1 | 3.01 |

| Amasuntswana e-AlN | 150–250 | 2.69 | 3.26 |

| Amasuntswana eSiC | 80–200 | 4.0 | 3.21 |

| B₄ C amasuntswana | 29–67 | 4.4 | 2.52 |

| I-Boron fiber | 40 | ~5.0 | 2.6 |

| Amasuntswana e-TiC | 40 | 7.4 | 4.92 |

| Amasuntswana e-Al₂O₃ | 20–40 | 4.4 | 3.98 |

| Amabhovu eSiC | 32 | 3.4 | - |

| Si₃N₄ amasuntswana | 28 | 1.44 | 3.18 |

| TiB₂ amasuntswana | 25 | 4.6 | 4.5 |

| Amasuntswana eSiO₂ | 1.4 | <1.0 | 2.65 |

Idayimani, eyona nto inzima eyaziwayo yendalo (i-Mohs 10), nayo inezinto ezikhethekileyoukuhanjiswa kwe-thermal (200–2200 W/(m·K)).

Diamond micro-umgubo

Ubhedu, nge umgangatho ophezulu we-thermal/wombane (401 W/(m·K)), i-ductility, kunye nokusebenza kakuhle kweendleko, kusetyenziswa ngokubanzi kwii-ICs.

Ukudibanisa ezi propati,idayimani / ubhedu (Dia / Cu) imidibaniso-kunye neCu njenge-matrix kunye nedayimane njengokuqiniswa-zivela njengezinto zolawulo lwe-thermal kwisizukulwana esilandelayo.

02 Iindlela eziPhambili zokuFakwa

Iindlela eziqhelekileyo zokulungiselela idayimane / ubhedu zibandakanya: i-metallurgy powder, indlela yokushisa ephezulu kunye noxinzelelo oluphezulu, indlela yokuntywila, ukukhupha i-plasma sintering, indlela yokutshiza ebandayo, njl.

Ukuthelekiswa kweendlela ezahlukeneyo zokulungiselela, iinkqubo kunye neepropathi zedayimane yobukhulu be-single-particle / composites zethusi

| Ipharamitha | Umgubo weMetallurgy | Vacuum Hot-Ukucinezela | I-Spark Plasma Sintering (SPS) | Uxinzelelo oluphezulu lobushushu (HPHT) | Ukubekelwa isitshizi esibandayo | Nyibilika ukungena |

| Uhlobo lweDayimane | MBD8 | HFD-D | MBD8 | MBD4 | PDA | MBD8/HHD |

| Imatrix | 99.8% Cu powder | I-99.9% ye-electrolytic Cu powder | 99.9% Cu powder | Ingxubevange/umgubo weCu ococekileyo | Umgubo weCu ococekileyo | Pure Cu isambuku / intonga |

| Ukuguqulwa kwesiNxulumanisi | - | - | - | B, Ti, Si, Cr, Zr, W, Mo | - | - |

| Ubungakanani besuntswana (μm) | 100 | 106–125 | 100–400 | 20–200 | 35–200 | 50–400 |

| Iqhezu loMqulu (%) | 20–60 | 40–60 | 35–60 | 60–90 | 20–40 | 60–65 |

| Ubushushu (°C) | 900 | 800–1050 | 880–950 | 1100-1300 | 350 | 1100-1300 |

| Uxinzelelo (MPa) | 110 | 70 | 40–50 | 8000 | 3 | 1–4 |

| Ixesha (min) | 60 | 60–180 | 20 | 6–10 | - | 5–30 |

| Uxinano ngokuzalana (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4–99.7 |

| Ukusebenza | ||||||

| Elona Sebe liPhezulu lokuSebenza kweThermal (W/(m·K)) | 305 | 536 | 687 | 907 | - | 943 |

Ubuchule obuqhelekileyo beDia/Cu buquka:

(1)Umgubo weMetallurgy

Idayimane exutyiweyo/umgubo weCu uyadityaniswa kwaye utshiswe. Ngelixa indleko esebenzayo kwaye ilula, le ndlela ivelisa ukuxinana okulinganiselweyo, i-microstructures engabonakaliyo, kunye nemilinganiselo yesampulu ethintelweyo.

Siyunithi ephakathi

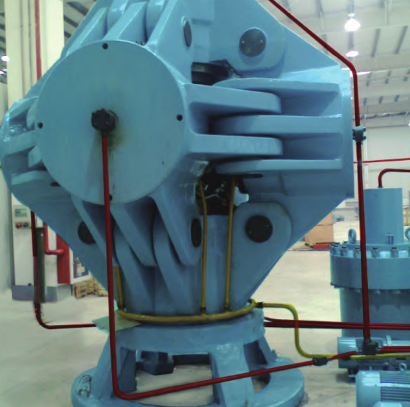

(1)Uxinzelelo oluphezulu lobushushu (HPHT)

Ukusebenzisa ii-multi-anvil presses, i-Cu etyhidiweyo ingena kwiileti zedayimane phantsi kweemeko ezigqithisileyo, ivelise i-composites exineneyo. Nangona kunjalo, i-HPHT idinga imingundo ebiza kakhulu kwaye ayifanelekanga kwimveliso enkulu.

Cubic press

(1)Nyibilika ukungena

I-Molten Cu ingena kwiifomati zedayimani ngokuncediswa ngoxinzelelo okanye ukungena okuqhutywa yi-capillary. Iziphumo zemidibaniso ziphumeza >446 W/(m·K) i-thermal conductivity.

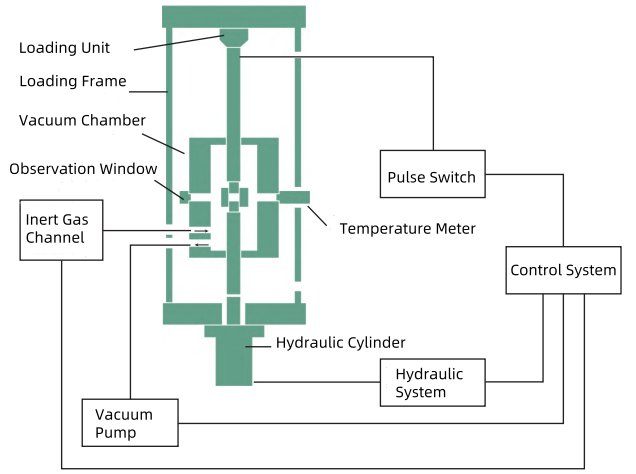

(2)I-Spark Plasma Sintering (SPS)

I-Pulsed yangoku ngokukhawuleza i-sinters ixube i-powders phantsi koxinzelelo. Nangona isebenza kakuhle, ukusebenza kwe-SPS kuyathotywa kumaqhezu edayimani> 65 vol%.

Umzobo weSchematic we-discharge plasma sintering system

(5) I-Cold Spray Deposition

Iipowuda ziyakhawuleza kwaye zifakwe kwi-substrates. Le ndlela yokunyuka ijongene nemingeni kulawulo lokugqiba umphezulu kunye nokuqinisekiswa kokusebenza kwe-thermal.

03 Ukuguqulwa koNxibelelwano

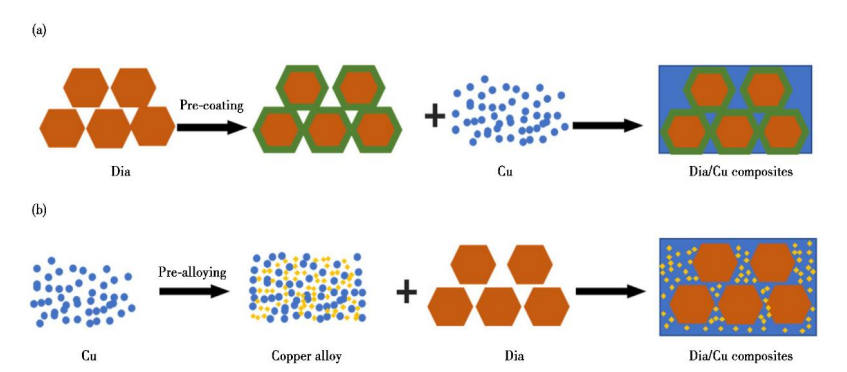

Ukulungiselela izinto ezidibeneyo, ukumanzisa okuhlangeneyo phakathi kwamacandelo kuyimfuneko eyimfuneko yenkqubo edibeneyo kunye neyona nto ibalulekileyo echaphazela ubume be-interface kunye ne-interface bonding state. Imeko engeyiyo yokumanzisa kwi-interface phakathi kwedayimani kunye ne-Cu ikhokelela kwi-interface ephezulu kakhulu yokumelana ne-thermal. Ke ngoko, kubaluleke kakhulu ukwenza uphando lohlengahlengiso kujongano phakathi kwezi zimbini ngeendlela ezahlukeneyo zobugcisa. Okwangoku, kukho iindlela ezimbini zokuphucula ingxaki ye-interface phakathi kwedayimane kunye ne-Cu matrix: (1) unyango lokuguqulwa komphezulu wedayimane; (2) Ukunyangwa kwe-alloying ye-matrix yobhedu.

Uhlengahlengiso lomzobo weskim: (a) Ukwaleka ngokuthe ngqo kumphezulu wedayimani; (b) Umxube weMatrix

(1) Ukuguqulwa komphezulu wedayimani

Ukufakwa kwezinto ezisebenzayo ezifana ne-Mo, i-Ti, i-W kunye ne-Cr kumphezulu womgangatho wesigaba sokuqinisa kunokuphucula iimpawu ezidibeneyo zedayimane, ngaloo ndlela kuphuculwe ukuqhutyelwa kwayo kwe-thermal. I-Sintering ingenza ukuba ezi zinto zingasentla zisabele ngekhabhoni kumphezulu womgubo wedayimane ukwenza umaleko we-carbide transition. Oku kwandisa imeko yokumanzisa phakathi kwedayimane kunye nesiseko sesinyithi, kwaye ukugquma kunokuthintela isakhiwo sedayimani ekutshintsheni kumaqondo aphezulu.

(2) Ukufakwa kwe-matrix yobhedu

Ngaphambi kokulungiswa kwezinto ezidibeneyo, unyango lwangaphambili lwe-alloying lwenziwa kwi-metallic copper, enokuvelisa izinto ezidibeneyo kunye ne-conductivity ephezulu ye-thermal. I-Doping izinto ezisebenzayo kwi-matrix yobhedu ayinakunciphisa kuphela ngokufanelekileyo i-Angle yokumanzisa phakathi kwedayimane kunye nobhedu, kodwa ivelise umaleko we-carbide oqinileyo onyibilikayo kwimatrix yobhedu kwi-diamond / Cu interface emva kokusabela. Ngale ndlela, uninzi lwezikhewu ezikhoyo kwi-interface yezinto eziphathekayo ziguqulwa kwaye zizaliswe, ngaloo ndlela ziphucula i-thermal conductivity.

04 Isiphelo

Izixhobo zokupakisha eziqhelekileyo ziyawa mfutshane ekulawulweni kobushushu obuvela kwiichips eziphambili. I-Dia/Cu composites, ene-CTE enokutyibilika kunye ne-ultrahigh conductivity ye-thermal, imele isisombululo sokuguqula i-electronics yesizukulwana esilandelayo.

Njengeshishini lobugcisa obuphezulu bokudibanisa ishishini kunye norhwebo, i-XKH igxile kuphando kunye nophuhliso kunye nokuveliswa kwezixhobo zedayimane / ubhedu kunye nezixhobo zematrix zetsimbi ezisebenza ngokuphezulu ezifana neSiC/Al kunye neGr/Cu, ebonelela ngezisombululo zolawulo lobushushu obutsha kunye ne-thermal conductivity engaphezulu kwe-900W / (m · K) kumacandelo, imodyuli ye-elektroniki yokupakisha kunye ne-electronic pack.

XKH's Idayimani yobhedu ehonjiswe ngelaminate imathiriyeli ehlanganisiweyo:

Ixesha lokuposa: May-12-2025