I-SPC (uLawulo lweNkqubo yoBalo) sisixhobo esibalulekileyo kwinkqubo yokwenziwa kwe-wafer, esetyenziselwa ukubeka esweni, ukulawula, kunye nokuphucula uzinzo lwezigaba ezahlukeneyo kwimveliso.

1. Isishwankathelo seNkqubo ye-SPC

I-SPC yindlela esebenzisa ubuchule bamanani ukujonga nokulawula iinkqubo zokuvelisa. Umsebenzi wayo ophambili kukufumanisa ukungahambi kakuhle kwinkqubo yokuvelisa ngokuqokelela kunye nokuhlalutya idatha yexesha langempela, ukunceda iinjineli ukuba zenze uhlengahlengiso kwangexesha kunye nezigqibo. Injongo ye-SPC kukunciphisa ukuhluka kwinkqubo yokuvelisa, ukuqinisekisa ukuba umgangatho wemveliso uhlala uzinzile kwaye udibana neenkcukacha.

I-SPC isetyenziswa kwinkqubo yokufaka:

Beka iliso kwiiparamitha zesixhobo esibalulekileyo (umzekelo, ireyithi ye-etch, amandla eRF, uxinzelelo lwegumbi, ubushushu, njl.njl.)

Hlalutya izalathi ezingundoqo zomgangatho wemveliso (umzekelo, ububanzi bomgca, ubunzulu be-etch, uburhabaxa bomphetho, njl.njl.)

Ngokubeka esweni ezi parameters, iinjineli zinokubona iindlela ezibonisa ukuthotywa kokusebenza kwezixhobo okanye ukutenxa kwinkqubo yokuvelisa, ngaloo ndlela kuncitshiswe amaxabiso okulahlwa.

2. Amacandelo asisiseko eNkqubo ye-SPC

Inkqubo ye-SPC yenziwe ziimodyuli ezininzi eziphambili:

Imodyuli yokuqokelelwa kwedatha: Ukuqokelela idatha yexesha langempela kwisixhobo kunye nokuhamba kwenkqubo (umzekelo, nge-FDC, iinkqubo ze-EES) kwaye irekhoda iiparamitha ezibalulekileyo kunye neziphumo zemveliso.

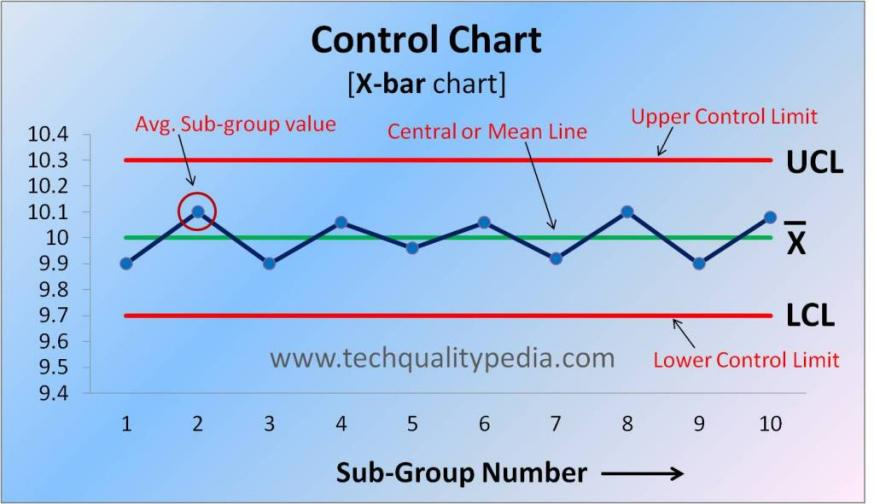

Imodyuli yeTshati yokulawula: Isebenzisa iitshathi zolawulo lwamanani (umzekelo, itshathi ye-X-Bar, itshathi ye-R, itshathi ye-Cp/Cpk) ukubona ngeso lengqondo uzinzo lwenkqubo kunye nokunceda ukufumanisa ukuba inkqubo ilawulwa.

I-Alarm System: Ivuselela ii-alam xa iiparameters ezibalulekileyo zidlula imida yolawulo okanye zibonisa utshintsho lwentsingiselo, ikhuthaza iinjineli ukuba zithathe inyathelo.

Uhlalutyo kunye neModyuli yokuNika iNgxelo: Uhlalutya unobangela wengcambu ye-anomalies esekelwe kwiitshathi ze-SPC kwaye rhoqo ivelisa iingxelo zokusebenza zenkqubo kunye nezixhobo.

3. Inkcazo ebanzi yeetshathi zoLawulo kwi-SPC

Iitshathi zokulawula sesinye sezona zixhobo zisetyenziswa ngokuqhelekileyo kwi-SPC, zinceda ukwahlula phakathi "kokwahluka okuqhelekileyo" (okubangelwa yiyantlukwano yenkqubo yendalo) kunye "noguquko olungaqhelekanga" (olubangelwa kukungaphumeleli kwezixhobo okanye ukuphambuka kwenkqubo). Iitshathi zolawulo eziqhelekileyo ziquka:

I-X-Bar kunye ne-R Charts: Isetyenziselwa ukubeka iliso kwintsingiselo kunye noluhlu ngaphakathi kweebhetshi zemveliso ukujonga ukuba inkqubo izinzile.

Izalathisi ze-Cp kunye ne-Cpk: Isetyenziselwa ukulinganisa amandla enkqubo, oko kukuthi, ingaba imveliso yenkqubo inokuhlangabezana ngokuqhubekayo neemfuno zokucaciswa. I-Cp ilinganisa ubunakho obunokwenzeka, ngelixa i-Cpk iqwalasela ukutenxa kwiziko lenkqubo ukusuka kwimida ecacileyo.

Umzekelo, kwinkqubo ye-etching, unokujonga iiparamitha ezinje ngereyithi ye-etch kunye noburhabaxa bomphezulu. Ukuba ireyithi ye-etch yesixhobo esithile idlula umda wokulawula, ungasebenzisa iitshathi zokulawula ukugqiba ukuba ngaba oku kukwahluka kwendalo okanye ukubonakaliswa kokungasebenzi kakuhle kwezixhobo.

4. Ukusetyenziswa kwe-SPC kwi-Etching Equipment

Kwinkqubo yokubhala, ukulawula iiparamitha zesixhobo kubalulekile, kwaye i-SPC inceda ukuphucula uzinzo lwenkqubo ngezi ndlela zilandelayo:

I-Equipment Condition Monitoring: Iinkqubo ezifana ne-FDC ziqokelela idatha yexesha lokwenyani kwiiparamitha eziphambili zesixhobo sokuthungatha (umzekelo, amandla e-RF, ukuhamba kwegesi) kwaye zidibanise le datha kunye neetshathi zolawulo ze-SPC ukukhangela imiba enokubakho yezixhobo. Umzekelo, ukuba ubona amandla eRF kwitshati yolawulo eshenxa ngokuthe ngcembe kwixabiso elibekiweyo, unokuthatha inyathelo kwangethuba lohlengahlengiso okanye ulungiso ukunqanda ukuchaphazela umgangatho wemveliso.

Ukujongwa koMgangatho weMveliso: Unako kwakhona ukufaka iiparamitha ezingundoqo zomgangatho wemveliso (umzekelo, ubunzulu be-etch, ububanzi bomgca) kwinkqubo ye-SPC ukujonga ukuzinza kwabo. Ukuba ezinye izikhombisi zemveliso ezibalulekileyo ziyaphambuka ngokuthe ngcembe kumaxabiso ekujoliswe kuwo, inkqubo ye-SPC iya kukhupha i-alamu, ebonisa ukuba uhlengahlengiso lwenkqubo luyafuneka.

I-Preventive Maintenance (PM): I-SPC inokunceda ukwandisa umjikelo wokukhusela wokukhusela izixhobo. Ngokuhlalutya idatha yexesha elide ekusebenzeni kwezixhobo kunye neziphumo zenkqubo, unokumisela ixesha elifanelekileyo lokugcinwa kwezixhobo. Umzekelo, ngokubeka iliso kumandla e-RF kunye nobude bobomi be-ESC, unokumisela xa kufuneka ukucoca okanye ukutshintshwa kwecandelo, ukunciphisa amaxabiso okusilela kwesixhobo kunye nexesha lokuncipha kwemveliso.

5. Iingcebiso zokuSetyenziswa kwemihla ngemihla kwiNkqubo ye-SPC

Xa usebenzisa inkqubo ye-SPC kwimisebenzi yemihla ngemihla, la manyathelo alandelayo angalandelwa:

Chaza iiParameters eziPhambili zoLawulo (KPI): Chonga iiparamitha ezibaluleke kakhulu kwinkqubo yokuvelisa kwaye uzibandakanye kwi-SPC esweni. Ezi parameters kufuneka zihambelane ngokusondeleyo nomgangatho wemveliso kunye nokusebenza kwezixhobo.

Cwangcisa iMida yoLawulo kunye neMida yeAlarm: Ngokusekelwe kwidatha yembali kunye neemfuno zenkqubo, seta imida yolawulo efanelekileyo kunye nemida ye-alamu kwiparameter nganye. Imida yokulawula idla ngokusetwa kwi-±3σ (ukunxaxha okuqhelekileyo), ngelixa imida ye-alamu isekelwe kwiimeko ezithile zenkqubo kunye nezixhobo.

Ukubeka iliso ngokuqhubekayo kunye nokuhlalutya: Hlaziya rhoqo iitshathi zokulawula i-SPC ukuhlalutya iindlela zedatha kunye nokuhluka. Ukuba ezinye iiparamitha zigqithise kwimida yolawulo, inyathelo elikhawulezileyo liyafuneka, njengokulungelelanisa iiparamitha zesixhobo okanye ukugcinwa kwezixhobo zokusebenza.

Ukuphatha okungaqhelekanga kunye noHlalutyo lweMbangela yeeNqaku: Xa kukho ukungaqhelekanga, inkqubo ye-SPC irekhoda ulwazi oluneenkcukacha malunga nesiganeko. Kufuneka uxazulule iingxaki kwaye uhlalutye unobangela wokungaqheleki ngokusekwe kolu lwazi. Ngokuqhelekileyo kunokwenzeka ukudibanisa idatha evela kwiinkqubo ze-FDC, iinkqubo ze-EES, njl., ukuhlalutya ukuba umba ungenxa yokusilela kwezixhobo, ukutenxa kwenkqubo, okanye iimeko zangaphandle zokusingqongileyo.

Ukuphuculwa okuqhubekayo: Ukusebenzisa idatha yembali erekhodwe yinkqubo ye-SPC, chonga iindawo ezibuthathaka kwinkqubo kwaye ucebise izicwangciso zokuphucula. Ngokomzekelo, kwinkqubo yokubhala, hlalutya impembelelo ye-ESC yokuphila kunye neendlela zokucoca kwimijikelezo yokugcina izixhobo kunye nokuphucula ngokuqhubekayo iiparamitha zokusebenza kwezixhobo.

6. Ityala lesicelo esisebenzayo

Njengomzekelo osebenzayo, cinga ukuba unoxanduva lwezixhobo zokurhweba i-E-MAX, kwaye i-cathode yegumbi ihlangabezana nokunxiba kwangaphambili, okukhokelela ekunyukeni kwamaxabiso e-D0 (BARC defect). Ngokubeka iliso kumandla e-RF kunye nezinga le-etch ngokusebenzisa inkqubo ye-SPC, uqaphela intsingiselo apho ezi parameters ngokuthe ngcembe zishenxa kumaxabiso azo amiselweyo. Emva kokuba i-alamu ye-SPC iqhutywe, udibanisa idatha esuka kwinkqubo ye-FDC kwaye unqume ukuba umcimbi ubangelwa ukulawulwa kokushisa okungazinzanga ngaphakathi kwegumbi. Emva koko uphumeza iindlela ezintsha zokucoca kunye nezicwangciso zokulondoloza, ekugqibeleni unciphisa ixabiso le-D0 ukusuka kwi-4.3 ukuya kwi-2.4, ngaloo ndlela uphucula umgangatho wemveliso.

7.In XINKEHUI ungafumana.

E-XINKEHUI, unokufezekisa i-wafer egqibeleleyo, nokuba sisilutyana sesilicon okanye i-wafer ye-SiC. Sisebenza ngokukhethekileyo ekuhambiseni ii-wafers ezikumgangatho ophezulu kumashishini ahlukeneyo, sigxile ekuchanekeni kunye nokusebenza.

(iqhekeza lesilicon)

Iziqwenga zethu ze-silicon zenziwe ngobunyulu obuphezulu kunye nokufana, ziqinisekisa iimpawu zombane ezibalaseleyo kwiimfuno zakho ze-semiconductor.

Ukufumana izicelo eziyimfuneko ngakumbi, iiwafa zethu ze-SiC zibonelela ngokwenziwa kobushushu obukhethekileyo kunye nokusebenza kakuhle kwamandla aphezulu, alungele umbane wamandla kunye neendawo ezinobushushu obuphezulu.

(Isica seSiC)

Nge-XINKEHUI, ufumana iteknoloji yokusika kunye nenkxaso ethembekileyo, iiwafers eziqinisekisayo ezihlangabezana nemigangatho ephezulu yoshishino. Sikhethele ukugqibelela kwakho kwe-wafer!

Ixesha lokuposa: Oct-16-2024