Yintoni i-TGV?

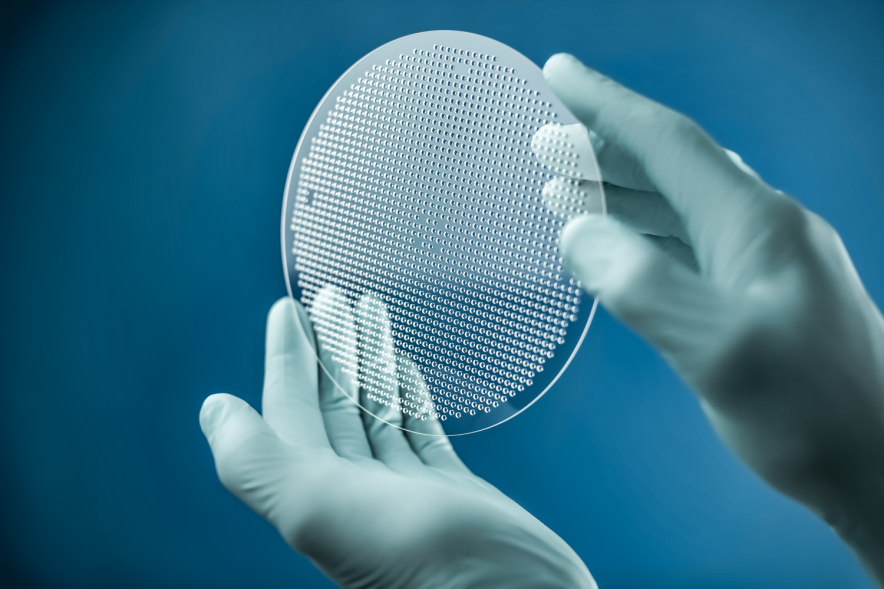

TGV, (NgeGlasi nge), iteknoloji yokudala imingxuma kwi-substrate yeglasi, Ngamagama alula, i-TGV yisakhiwo esiphakamileyo esiphezulu esibetha, sizalise kwaye sidibanise phezulu kunye neglasi ukuze kwakhiwe iisekethe ezidibeneyo kumgangatho weglasi. Le teknoloji ithathwa njengeteknoloji ebalulekileyo kwisizukulwana esilandelayo sokupakishwa kwe-3D.

Ziziphi iimpawu ze-TGV?

1. Ulwakhiwo: i-TGV yindlela yokuqhuba igqobhoze ngokuthe nkqo ngomngxuma owenziwe kwi-substrate yeglasi. Ngokubeka i-conductive metal layer kwi-pore wall, iileya eziphezulu kunye nezantsi zeempawu zombane zidibene.

2. Inkqubo yokuvelisa: I-TGV yokuvelisa ibandakanya ukulungiswa kwangaphambili kwe-substrate, ukwenza umngxuma, ukubekwa kwe-metal layer, ukugcwaliswa komngxuma kunye namanyathelo okucaba. Iindlela zokuvelisa eziqhelekileyo ziyi-chemical etching, i-laser drilling, i-electroplating njalo njalo.

3. Uncedo lwesicelo: Xa kuthelekiswa nentsimbi yemveli ngomngxunya, i-TGV ineenzuzo zobukhulu obuncinci, ukuxinana kweengcingo eziphezulu, ukusebenza ngcono kokutshabalalisa ubushushu njalo njalo. Isetyenziswe ngokubanzi kwi-microelectronics, i-optoelectronics, i-MEMS kunye nezinye iindawo zoqhagamshelwano oluphezulu.

4. Indlela yophuhliso: Ngophuhliso lweemveliso ze-elektroniki ezibhekiselele kwi-miniaturization kunye nokuhlanganiswa okuphezulu, iteknoloji ye-TGV ifumana ingqalelo engakumbi kunye nokusetyenziswa. Kwixesha elizayo, inkqubo yokwenziwa kwayo iya kuqhubeka iphuculwa, kwaye ubukhulu bayo kunye nokusebenza kwayo kuya kuqhubeka nokuphucula.

Yintoni inkqubo ye-TGV:

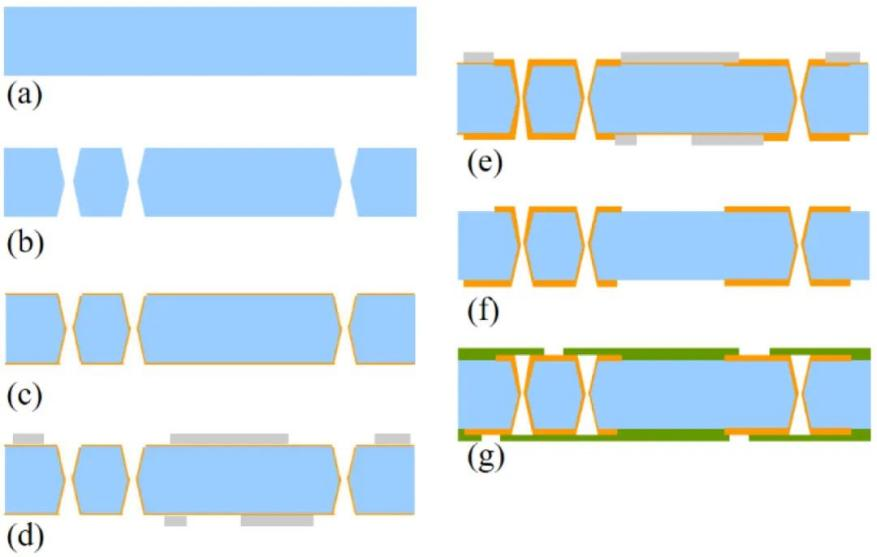

1. Ukulungiswa kwe-substrate yeglasi (a) : Lungiselela i-substrate yeglasi ekuqaleni ukuze uqinisekise ukuba ubuso bayo buhamba kakuhle kwaye bucocekile.

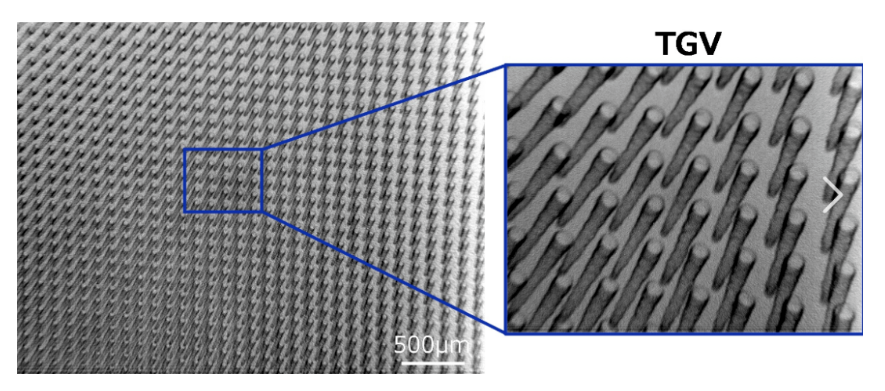

2. I-glass drilling (b) : I-laser isetyenziselwa ukwenza umngxuma wokungena kwi-substrate yeglasi. Ubume bomngxuma ngokuqhelekileyo bu-conical, kwaye emva konyango lwe-laser kwelinye icala, luguqulwa kwaye luqhutywe kwelinye icala.

3. I-Metallization yodonga lomngxuma (c) : I-Metallization iqhutyelwa eludongeni lomngxuma, ngokuqhelekileyo nge-PVD, i-CVD kunye nezinye iinkqubo zokwenza i-conductive seed layer eludongeni lomngxuma, njenge-Ti / Cu, i-Cr / Cu, njl.

4. I-Lithography (d) : Umphezulu we-substrate yeglasi ifakwe nge-photoresist kunye ne-photopatterned. Veza iindawo ezingadingi plating, ukuze kuvele amalungu afuna iplating kuphela.

5. Ukuzaliswa komngxuma (e) : Ubhedu lwe-Electroplating ukuzalisa iglasi ngemingxuma ukwenza indlela epheleleyo yokuqhuba. Ngokuqhelekileyo kufuneka ukuba umngxuma uzaliswe ngokupheleleyo ngaphandle kwemingxuma. Qaphela ukuba i-Cu kumzobo ayigcwaliswanga ngokupheleleyo.

6. I-Flat surface ye-substrate (f) : Ezinye iinkqubo ze-TGV ziya kuthoba umphezulu we-substrate yeglasi egcweleyo ukuqinisekisa ukuba umphezulu we-substrate ugudile, ohambelana namanyathelo enkqubo elandelayo.

7.Uluhlu olukhuselayo kunye noxhumo lwe-terminal (g) : Uluhlu olukhuselayo (njenge-polyimide) lwenziwa phezu kwe-substrate yeglasi.

Ngamafutshane, inyathelo ngalinye lenkqubo ye-TGV libalulekile kwaye lifuna ulawulo oluchanekileyo kunye nokwenza ngcono. Okwangoku sibonelela ngeglasi ye-TGV ngetekhnoloji yomngxuma ukuba iyafuneka. Nceda uzive ukhululekile ukuqhagamshelana nathi!

(Olu lwazi lungentla lusuka kwi-Intanethi, ukujongwa)

Ixesha lokuposa: Jun-25-2024