I-high-purity silicon carbide (i-SiC) i-ceramics iye yavela njengezixhobo ezifanelekileyo kumacandelo abalulekileyo kwi-semiconductor, i-aerospace, kunye namashishini ekhemikhali ngenxa ye-thermal conductivity ekhethekileyo, ukuzinza kweekhemikhali, kunye namandla omatshini. Ngokunyuka kweemfuno zomgangatho ophezulu wokusebenza, izixhobo ze-ceramic ezinongcoliseko oluphantsi, uphuhliso lwetekhnoloji yolungiselelo olusebenzayo nolunokaliselwa kwiiseramikhi ze-SiC ezisulungekileyo ziye zaba lugxininiso lophando lwehlabathi. Eli phepha liphonononga ngokucokisekileyo iindlela eziphambili zangoku zokulungiselela ii-ceramics ze-SiC ezicocekileyo, ezibandakanya i-recrystallization sintering, i-pressure sintering (PS), i-hot pressing (HP), i-spark plasma sintering (SPS), kunye nokuvelisa okongeziweyo (AM), kugxininise ekuxoxeni ngeendlela zokucoca, iiparitha eziphambili, izinto eziphathekayo, kunye nemingeni ekhoyo yenkqubo nganye.

Ukusetyenziswa kweeseramics ze-SiC kumkhosi kunye neendawo zobunjineli

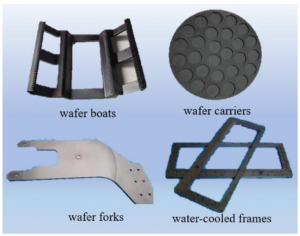

Okwangoku, izinto ze-ceramic ezicocekileyo ze-SiC zisetyenziswa ngokubanzi kwisixhobo sokwenza i-silicon wafer, ukuthatha inxaxheba kwiinkqubo ezingundoqo ezifana ne-oxidation, i-lithography, i-etching, kunye nokufakelwa kwe-ion. Ngokuhambela phambili kwetekhnoloji ye-wafer, ukwanda kobungakanani be-wafer kuye kwaba yinto ebalulekileyo. Isayizi yangoku ye-wafer yesiqhelo yi-300 mm, ukuzuza ukulingana okuhle phakathi kweendleko kunye nomthamo wemveliso. Nangona kunjalo, iqhutywa nguMthetho kaMoore, ukuveliswa kobunzima bee-450 mm zafers sele kukwi-ajenda. Ii-wafers ezinkulu zihlala zifuna amandla aphezulu olwakhiwo ukuxhathisa ukulwa kunye nokuguqulwa, ukuqhubela phambili imfuno ekhulayo yobukhulu obukhulu, amandla aphezulu, ukucoceka okuphezulu kwezinto ze-SiC zeceramic. Kwiminyaka yakutshanje, ukuveliswa okongeziweyo (ushicilelo lwe-3D), njengobuchwephesha bokuchwetheza obukhawulezayo obungadingi kubumba, bubonakalise amandla amakhulu ekwenziweni kweendawo ezintsonkothileyo ze-SiC ze-ceramic ngenxa yolwakhiwo lwe-layer-by-layer kunye nobuchule bokuyila obubhetyebhetye, ukutsala ingqalelo ebanzi.

Eli phepha liza kuhlalutya ngokucwangcisiweyo iindlela ezihlanu zokulungiselela ii-ceramics ze-SiC ezicocekileyo-i-recrystallization sintering, i-pressure sintering, i-hot pressing, i-spark plasma sintering, kunye ne-additive production-igxininise kwiindlela zabo ze-sintering, izicwangciso zokuphucula inkqubo, iimpawu zokusebenza kwezinto eziphathekayo, kunye nethemba lokusetyenziswa kwezoshishino.

Iimfuno zemathiriyeli ekrwada ye-silicon carbide ecocekileyo ephezulu

I. Recrystallization Sintering

I-recrystallized silicon carbide (i-RSiC) yi-high-purity SiC material elungiselelwe ngaphandle kwe-sintering aids kumaqondo aphezulu e-2100-2500 ° C. Ukusukela oko uFredriksson waqala wafumanisa into yokuhlaziya i-recrystallization ngasekupheleni kwenkulungwane ye-19, i-RSiC ifumene ingqwalasela ebalulekileyo ngenxa yemida yayo ecocekileyo yengqolowa kunye nokungabikho kwezigaba zeglasi kunye nokungcola. Kwiqondo lokushisa eliphezulu, i-SiC ibonisa uxinzelelo oluphezulu lomphunga, kwaye indlela yayo yokufaka i-sintering ngokuyinhloko ibandakanya inkqubo ye-evaporation-condensation: iinkozo ezintle ziyaba ngumphunga kwaye ziphinde zigcinwe kwindawo yeenkozo ezinkulu, ukukhuthaza ukukhula kwentamo kunye nokudibanisa ngokuthe ngqo phakathi kweenkozo, ngaloo ndlela kuphuculwe amandla ezinto eziphathekayo.

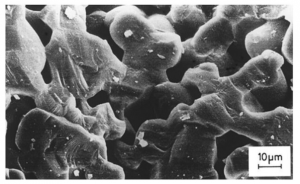

Kwi-1990, i-Kriegesmann ilungiselele i-RSiC kunye noxinzelelo olunxulumene ne-79.1% usebenzisa i-slip casting kwi-2200 ° C, kunye ne-cross-section ebonisa i-microstructure eyenziwe ngeenkozo kunye neepores. Emva koko, uYi et al. isetyenzisile ukugalela ijeli ukulungisa imizimba eluhlaza kwaye yafakwa kwi-2450°C, ukufumana iiseramikhi ze-RSiC ezinobuninzi obuyi-2.53 g/cm³ kunye namandla athambileyo angama-55.4 MPa.

Umphezulu we-SEM oqhekekileyo we-RSiC

Xa kuthelekiswa ne-SiC exineneyo, i-RSiC inoxinano olusezantsi (malunga ne-2.5 g/cm³) kwaye malunga ne-20% ye-porosity evulekileyo, inciphisa ukusebenza kwayo kwizicelo zamandla aphezulu. Ke ngoko, ukuphucula ukuxinana kunye neepropathi zoomatshini ze-RSiC ziye zaba yeyona nto iphambili kuphando. Sung et al. kucetywayo ukungena kwi-silicon etyhidiweyo kwi-carbon / β-SiC edibeneyo edibeneyo kunye ne-recrystallizing kwi-2200 ° C, ukwakhiwa ngempumelelo kwesakhiwo sothungelwano esiqulunqwe ngeenkozo ze-α-SiC. Isiphumo se-RSiC sifumene uxinano lwe-2.7 g/cm³ kunye namandla athambileyo angama-134 MPa, igcina uzinzo olubalaseleyo kumatshini kumaqondo obushushu aphezulu.

Ukwandisa ngakumbi ukuxinana, uGuo et al. i-polymer infiltration kunye ne-pyrolysis (PIP) iteknoloji esebenzayo yonyango oluninzi lwe-RSiC. Ukusebenzisa izisombululo ze-PCS/xylene kunye ne-SiC/PCS/i-xylene slurries njengabangenayo, emva kwemijikelo ye-3-6 ye-PIP, ubuninzi be-RSiC buphuculwe kakhulu (ukuya kwi-2.90 g/cm³), kunye namandla ayo aguquguqukayo. Ukongezelela, bacebise isicwangciso se-cyclic sokudibanisa i-PIP kunye ne-recrystallization: i-pyrolysis kwi-1400 ° C elandelwa yi-recrystallization kwi-2400 ° C, ngokufanelekileyo ukucima i-particle blockages kunye nokunciphisa i-porosity. Imathiriyeli yokugqibela ye-RSiC izuze ukuxinana kwe-2.99 g/cm³ kunye namandla athambileyo e-162.3 MPa, ebonisa ukusebenza okugqwesileyo okugqwesileyo.

Imifanekiso ye-SEM ye-microstructure evolution ye-RSiC epholisiweyo emva kwe-polymer impregnation kunye ne-pyrolysis (PIP)-recrystallization cycles: I-RSiC yokuqala (A), emva komjikelezo wokuqala we-PIP-recrystallization (B), kwaye emva komjikelezo wesithathu (C)

II. Sintering ngoxinzelelo

Iiseramikhi ze-silicon carbide (i-SiC) ezingenaxinzelelo-sintered zilungiswa ngokuqhelekileyo zisebenzisa i-high-purity, i-ultrafine ye-SiC powder njengento ekrwada, kunye nexabiso elincinci lezinto ezincedisayo zokudibanisa, kunye ne-sintered emoyeni ongasebenziyo okanye i-vacuum kwi-1800-2150 ° C. Le ndlela ifanelekile ukuvelisa amacandelo amakhulu kunye ne-complex-structured ceramic components. Nangona kunjalo, kuba i-SiC ibotshelelwe ngokuyintloko, i-coefficient yayo yokuzabalaza iphantsi kakhulu, isenza uxinaniso lube nzima ngaphandle koncedo lokucoca.

Ngokusekwe kumatshini we-sintering, i-sintering engenaxinzelelo ingahlulwa ibe ngamacandelo amabini: i-presureless liquid-phase sintering (PLS-SiC) kunye ne-slide-state sintering (PSS-SiC) engenaxinzelelo.

1.1 PLS-SiC (Liquid-Phase Sintering)

I-PLS-SiC ngokuqhelekileyo i-sintered ngaphantsi kwe-2000 ° C ngokongeza malunga ne-10 wt.% ye-eutectic sintering aids (efana ne-Al₂O₃, CaO, MgO, TiO₂, kunye ne-rare-earth oxides RE₂O₃) ukwenza isigaba se-liquid, ukukhuthaza ukufezekiswa kobunzima kunye nokudluliselwa kwe-particle rear. Le nkqubo ifanelekile kwi-industrial-grade SiC ceramics, kodwa akukho ngxelo ye-SiC ephezulu yococeko ephunyezwe nge-liquid-phase sintering.

1.2 PSS-SiC (Solid-State Sintering)

I-PSS-SiC ibandakanya ukuxinana kwemeko eqinileyo kumaqondo obushushu angaphezu kwama-2000°C malunga ne-1 wt.% yezongezo. Le nkqubo ixhomekeke ikakhulu kukusasazwa kweatom kunye nohlengahlengiso lwengqolowa oluqhutywa ngamaqondo obushushu aphezulu ukunciphisa amandla angaphezulu kunye nokuzuza ukuxinana. Inkqubo ye-BC (i-boron-carbon) yindibaniselwano yokudibanisa eqhelekileyo, enokunciphisa amandla omda wengqolowa kwaye isuse i-SiO₂ kwi-SiC surface. Nangona kunjalo, izongezo ze-BC zemveli zihlala zizisa ukungcola okushiyekileyo, ukunciphisa ubunyulu beSiC.

Ngokulawula umxholo owongezelelweyo (B 0.4 wt.%, C 1.8 wt.%) kunye ne-sintering kwi-2150 ° C kwiiyure ze-0.5, ii-ceramics ze-SiC ezicocekileyo ezicocekileyo kunye nokuhlambuluka kwe-99.6 wt.% kunye nokuxinana kwe-98.4%. I-microstructure ibonise iinkozo eziziinkozo (ezinye zidlula i-450 µm ubude), kunye neepore ezincinci kwimida yeenkozo kunye namasuntswana egraphite ngaphakathi kweenkozo. I-ceramics ibonise amandla okuguquguquka kwe-443 ± 27 MPa, i-elastic modulus ye-420 ± 1 GPa, kunye ne-coefficient yokwandisa i-thermal ye-3.84 × 10⁻⁶ K⁻¹ kuluhlu lobushushu begumbi ukuya kwi-600 ° C, ebonisa ukusebenza kakuhle ngokubanzi.

I-Microstructure ye-PSS-SiC: (A) umfanekiso we-SEM emva kokupholisa kunye ne-NaOH etching; (BD) Imifanekiso ye-BSD emva kokupolisha kunye nokukrolwa

III. I-Hot Pressing Sintering

I-Hot pressing (HP) sintering yindlela yoxinaniso esebenza ngaxeshanye ukushisa kunye noxinzelelo lwe-uniaxial kwizinto zomgubo phantsi kobushushu obuphezulu kunye neemeko zoxinzelelo oluphezulu. Uxinzelelo oluphezulu luthintela kakhulu ukubunjwa kwe-pore kunye nokunciphisa ukukhula kweenkozo, ngelixa ukushisa okuphezulu kukhuthaza ukudibanisa okuziinkozo kunye nokwakhiwa kwezakhiwo ezixineneyo, ekugqibeleni zivelise i-ceramics ye-SiC ephezulu, ecocekileyo. Ngenxa yobume bendlela yokucinezela, le nkqubo idla ngokubangela i-grain anisotropy, echaphazela i-mechanical and wear properties.

I-ceramics ye-SiC ecocekileyo kunzima ukuyixina ngaphandle kwezongezo, ezifuna i-ultrahigh-pressure sintering. Nadeau et al. ulungiselele ngempumelelo i-SiC exineneyo ngokupheleleyo ngaphandle kwezongezo kwi-2500 ° C kunye ne-5000 MPa; Sun et al. ifunyenwe izinto ezininzi ze-β-SiC ezinobunzima beVickers ukuya kuthi ga kwi-41.5 GPa kwi-25 GPa kunye ne-1400 ° C. Ukusebenzisa uxinzelelo lwe-GPa ye-4, ii-ceramics ze-SiC ezinoxinano olumalunga ne-98% kunye ne-99%, ubunzima be-35 GPa, kunye ne-elastic modulus ye-450 GPa zilungiswe kwi-1500 ° C kunye ne-1900 ° C, ngokulandelanayo. I-Sintering micron-size SiC powder kwi-5 GPa kunye ne-1500 ° C ivelise i-ceramics enobunzima be-31.3 GPa kunye nobuninzi be-98.4%.

Nangona ezi ziphumo zibonisa ukuba uxinzelelo lwe-ultrahigh lunokufikelela kwi-additive-free densification, ubunzima kunye neendleko eziphezulu zezixhobo ezifunekayo zinciphisa usetyenziso lwemizi-mveliso. Ke ngoko, kulungiselelo olusebenzayo, ukulandelela izongezo okanye umgubo wegranulation zihlala zisetyenziselwa ukomeleza amandla okuqhuba.

Ngokudibanisa i-4 wt.% ye-phenolic resin njenge-additive kunye ne-sintering kwi-2350 ° C kunye ne-50 MPa, ii-ceramics ze-SiC ezinomlinganiselo we-92% kunye nococeko lwe-99.998%. Ukusebenzisa amanani aphantsi ongeziweyo (i-boric acid kunye ne-D-fructose) kunye ne-sintering kwi-2050 ° C kunye ne-40 MPa, i-SiC ephezulu-yococeko kunye noxinzelelo oluhambelanayo> 99.5% kunye nomxholo we-B oseleyo we-556 ppm kuphela walungiswa. Imifanekiso ye-SEM ibonise ukuba, xa kuthelekiswa neesampuli ezingenaxinzelelo-sintered, iisampulu ezixinzelelweyo ezishushu zineenkozo ezincinci, iipores ezimbalwa, kunye noxinzelelo oluphezulu. Amandla e-flexural ayengama-453.7 ± 44.9 MPa, kwaye i-modulus elastic ifike kwi-444.3 ± 1.1 GPa.

Ngokwandisa ixesha lokubamba kwi-1900 ° C, ubukhulu bengqolowa bunyuke ukusuka kwi-1.5 μm ukuya kwi-1.8 μm, kunye ne-thermal conductivity iphuculwe ukusuka kwi-155 ukuya kwi-167 W · m⁻¹·K⁻¹, ngelixa iphinda ikhulise ukumelana nokubola kwe-plasma.

Ngaphantsi kweemeko ze-1850 ° C kunye ne-30 MPa, ucinezelo olushushu kunye noxinzelelo olushushu olukhawulezayo lwe-granulated kunye ne-annealed SiC powder luvelise i-ceramics exineneyo ye-β-SiC ngaphandle kwezongezo, kunye nobuninzi be-3.2 g / cm³ kunye ne-sintering ye-150-200 ° C ngaphantsi kweenkqubo zendabuko. I-ceramics ibonise ubulukhuni be-2729 GPa, ukuqina kwe-fracture ye-5.25-5.30 MPa·m^1/2, kunye nokuxhathisa okugqwesileyo kwe-creep (amazinga e-creep 9.9 × 10⁻¹⁰ s⁻¹ kunye ne-3.8 × 10⁻⁻⁹0 ° C1⁻⁻¹0 ° C kunye ne-10⁻⁻¹0 ° C / 10 ° C1 / 10 ° C1 100 MPa).

(A) umfanekiso we-SEM womgangatho okhazimlisiweyo; (B) Umfanekiso we-SEM womgangatho wokuqhekeka; (C, D) umfanekiso we-BSD womgangatho okhazimlisiweyo

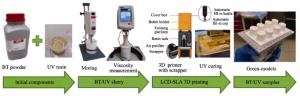

Kuphando loshicilelo lwe-3D lweeseramikhi zepiezoelectric, uludaka lweceramic, njengeyona nto iphambili ephembelela ukwenziwa kunye nokusebenza, ibe yeyona nto kugxilwe kuyo ngaphakathi nangaphandle. Uphononongo lwangoku lubonisa ngokubanzi ukuba iiparameters ezifana nobungakanani bepowder particle size, i-slurry viscosity, kunye nomxholo oqinileyo kuchaphazela kakhulu umgangatho wokwenza kunye neempawu ze-piezoelectric zemveliso yokugqibela.

Uphando lufumene ukuba i-ceramic slurries elungiselelwe usebenzisa i-micron-, i-submicron-, kunye ne-nano-sized barium titanate powders ibonisa umahluko omkhulu kwi-stereolithography (umz., i-LCD-SLA) iinkqubo. Njengoko ubungakanani be-particle buncipha, i-slurry viscosity iyanda ngokuphawulekayo, kunye ne-nano-size powders evelisa i-slurries kunye ne-viscosities efikelela kwiibhiliyoni ze-mPa·s. I-Slurries kunye ne-micron-size powders ithanda ukuchithwa kunye nokuxobulwa ngexesha lokushicilela, ngelixa i-submicron kunye ne-nano-size powders ibonisa ukuziphatha okuzinzile ngakumbi. Emva kobushushu obuphezulu be-sintering, iisampulu ze-ceramic eziye zaphunyelelwa zafumana ingxinano ye-5.44 g/cm³, i-piezoelectric coefficient (d₃₃) emalunga ne-200 pC/N, kunye nelahleko ephantsi, ebonisa iimpawu ezibalaseleyo zokuphendula ngombane.

Ukongezelela, kwiinkqubo ze-micro-stereolithography, ukulungelelanisa umxholo oqinileyo we-PZT-uhlobo lwe-slurries (umz., i-75 wt.%) imizimba ene-sintered enobunzima be-7.35 g / cm³, ukuphumeza i-piezoelectric constant ukuya kwi-600 pC / N phantsi kweendawo zombane ze-poling. Uphando ngembuyekezo ye-micro-scale deformation iphucule ngokubonakalayo ukuchaneka kokwakheka, ukuphucula ukuchaneka kwejometri ukuya kuthi ga kwi-80%.

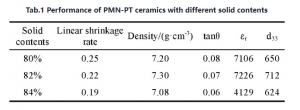

Olunye uphononongo kwi-PMN-PT piezoelectric ceramics lubonakalise ukuba umxholo oqinileyo unefuthe elibukhali kwisakhiwo se-ceramic kunye neempawu zombane. Kwi-80 wt.% isiqulatho esiqinileyo, ii-byproducts zivele lula kwiiseramics; njengoko umxholo oqinileyo uye wanda ukuya kwi-82 wt.% nangaphezulu, izinto eziphumayo ziye zanyamalala ngokuthe ngcembe, kwaye ulwakhiwo lwe-ceramic lwaba nyulu, kunye nokusebenza okuphuculweyo kakhulu. Kwi-82 wt.%, ii-ceramics zibonise iimpawu zombane ezifanelekileyo: i-piezoelectric constant ye-730 pC/N, imvume ehambelana ne-7226, kunye nelahleko ye-dielectric ye-0.07 kuphela.

Isishwankathelo, ubungakanani bamasuntswana, umxholo oqinileyo, kunye neempawu ze-rheological ze-slurries ze-ceramic azichaphazeli nje kuphela ukuzinza kunye nokuchaneka kwenkqubo yokushicilela kodwa kwakhona ukugqiba ngokuthe ngqo ukuxinana kunye nempendulo ye-piezoelectric yemizimba e-sintered, ezenza iiparameters eziphambili zokuphumeza i-3D-printed piezoelectric ceramics.

Inkqubo ephambili ye-LCD-SLA 3D yoshicilelo lweesampuli zeBT / UV

Iimpawu ze-PMN-PT zeseramikhi ezinemixholo eyomeleleyo eyahlukeneyo

IV. Intlantsi yePlasma Sintering

I-Spark plasma sintering (SPS) yitekhnoloji ye-sintering ephucukileyo esebenzisa ipulsed yangoku kunye noxinzelelo lomatshini ngaxeshanye olufakwa kwipowder ukufezekisa ukuxinana ngokukhawuleza. Kule nkqubo, okwangoku itshisa ngokuthe ngqo i-mold kunye ne-powder, ivelisa ukushisa kwe-Joule kunye ne-plasma, eyenza i-sintering esebenzayo ngexesha elifutshane (ngokuqhelekileyo kwimizuzu eyi-10). Ukufudumeza okukhawulezayo kukhuthaza ukusasazeka komphezulu, ngelixa ukukhutshwa kwe-spark kunceda ukususa iigesi ze-adsorbed kunye ne-oxide layers ukusuka kwi-powder surface, ukuphucula ukusebenza kwe-sintering. Impembelelo ye-electromigration ebangelwa ziindawo ze-electromagnetic nayo yongeza ukusasazwa kweathom.

Xa kuthelekiswa nokucinezela okushushu okuqhelekileyo, i-SPS isebenzisa ukufudumeza ngokuthe ngqo ngakumbi, ivumela ukuxinana kumaqondo obushushu aphantsi ngelixa ithintela ngokufanelekileyo ukukhula okuziinkozo ukufumana i-microstructures efanelekileyo kunye efanayo. Umzekelo:

- Ngaphandle kwezongezo, usebenzisa i-SiC powder yomhlaba njengento eluhlaza, i-sintering kwi-2100 ° C kunye ne-70 MPa imizuzu engama-30 ivelise iisampulu kunye ne-98% yoxinaniso.

- I-Sintering kwi-1700 ° C kunye ne-40 MPa yemizuzu eyi-10 ivelise i-cubic SiC kunye ne-98% yoxinaniso kunye nobukhulu beenkozo ze-30-50 nm kuphela.

- Ukusebenzisa i-80 µm granular SiC powder kunye ne-sintering kwi-1860 ° C kunye ne-50 MPa kwimizuzu emi-5 kubangele ukusebenza okuphezulu kweeseramikhi ze-SiC ezinobunzima obungama-98.5%, ubunzima obuncinci be-Vickers be-28.5 GPa, amandla athambileyo angama-395 MPa, kunye nokwaphuka ^ 4.1/m2m.

Uhlalutyo lwe-Microstructural lubonise ukuba njengoko ukushisa kwe-sintering kwanda ukusuka kwi-1600 ° C ukuya kwi-1860 ° C, i-porosity yezinto eziphathekayo yehla kakhulu, isondela kubuninzi obupheleleyo kumaqondo aphezulu.

I-microstructure ye-SiC Ceramics ifakwe kubushushu obuhlukeneyo: (A) 1600 °C, (B) 1700 °C, (C) 1790 °C kunye (D) 1860 °C

V. Imveliso eyongezelelweyo

Imveliso eyongeziweyo (AM) isandula ukubonisa amandla amakhulu ekuyileni amacandelo eceramic antsonkothileyo ngenxa yenkqubo yawo yokwakha umaleko ngomnye. Kwi-ceramics ye-SiC, i-teknoloji ye-AM eninzi iye yaphuhliswa, kubandakanywa i-jetting ye-binder (BJ), i-3DP, i-laser sintering ekhethiweyo (SLS), ukubhalwa kwe-inki ngqo (DIW), kunye ne-stereolithography (SL, DLP). Nangona kunjalo, i-3DP kunye ne-DIW inokuchaneka okuphantsi, ngelixa i-SLS idla ngokubangela uxinzelelo lwe-thermal kunye nokuqhekeka. Ngokwahlukileyo, i-BJ kunye ne-SL zibonelela ngeenzuzo ezinkulu ekuveliseni ubunyulu obuphezulu, ii-ceramics ezichanekileyo ezichanekileyo.

- iJetting Binder (BJ)

Itekhnoloji ye-BJ ibandakanya umaleko-ngamaleko wokutshiza kwi-binder ukuya kumgubo webhondi, ilandelwe kukudipha kunye nokuntywila ukuze ufumane imveliso yokugqibela yeceramic. Ukudibanisa i-BJ kunye ne-chemical vapor infiltration (CVI), i-high-purity, ii-ceramics ze-SiC ze-crystalline ngokupheleleyo zilungiswe ngempumelelo. Inkqubo ibandakanya:

① Ukwenza imizimba ye-SiC ceramic eluhlaza usebenzisa i-BJ.

② Ukunciphisa nge-CVI kwi-1000 ° C kunye ne-200 Torr.

③ Iceramic yokugqibela yeSiC yayinoxinano lwe-2.95 g/cm³, ukuhanjiswa kwe-thermal ye-37 W/m·K, kunye namandla athambileyo angama-297 MPa.

I-Schematic diagram ye-adhesive jet (BJ) yokushicilela. (A) Uyilo oluncediswa yikhompyutha (i-CAD) imodeli, (B) isazobe somzobo womgaqo-siseko we-BJ, (C) ushicilelo lwe-SiC ngu-BJ, (D) uxinaniso lwe-SiC ngokungena kwekhemikhali yomphunga (CVI)

- I-Stereolithography (SL)

I-SL yitekhnoloji yokwenziwa kwe-ceramic esekwe kwi-UV echaneke kakhulu kunye nobuchule obuntsonkothileyo bokuyila. Le ndlela isebenzisa i-photosensitive ceramic slurries enomxholo ophezulu oqinileyo kunye ne-viscosity ephantsi ukwenza imizimba ye-3D ye-ceramic eluhlaza ngokusebenzisa i-photopolymerization, ilandelwa yi-debinding kunye ne-high-temperature sintering ukufumana imveliso yokugqibela.

Ukusebenzisa i-35 vol.% ye-SiC slurry, imizimba ephezulu ye-3D eluhlaza yalungiswa phantsi kwe-405 nm UV irradiation kwaye igxininiswe ngakumbi ngokutshiswa kwe-polymer kwi-800 ° C kunye nonyango lwe-PIP. Iziphumo zibonise ukuba iisampulu ezilungiswe nge-35 vol.% slurry zizuze ukuxinana okunxulumene ne-84.8%, ziqhuba kakuhle ngama-30% kunye nama-40% amaqela olawulo.

Ngokuzisa i-lipophilic SiO₂ kunye ne-phenolic epoxy resin (PEA) ukuguqula i-slurry, ukusebenza kwe-photopolymerization kwaphuculwa ngokufanelekileyo. Emva kokucoca kwi-1600 ° C kwi-4 h, ukuguqulwa okusondeleyo kwi-SiC kwafezwa, kunye nomxholo we-oksijini wokugqibela we-0.12% kuphela, okwenza ukuba inyathelo elinye lenziwe kwi-ceramics ye-SiC ecocekileyo, eyinkimbinkimbi ngaphandle kwe-oxidation yangaphambili okanye amanyathelo okungena ngaphambili.

Umzobo wesakhiwo soshicilelo kunye nenkqubo yayo ye-sintering. Ukubonakala kwesampulu emva kokumisa kwi-(A) 25 ° C, i-pyrolysis ku- (B) 1000 ° C, kunye ne-sintering ku- (C) 1600 ° C.

Ngokuyila i-Si₃N₄ i-slurries ye-ceramic e-photosensitive ye-stereolithography yoshicilelo lwe-3D kunye nokusebenzisa iinkqubo zokuguga kunye nobushushu obuphezulu, iiseramics ze-Si₃N₄ ezine-93.3% yoxinano lwethiyori, amandla okuqina angama-279.8 MPa, kunye ne-3a308 elungiselelwe amandla e-MPa, kunye ne-303. Uphononongo lufumene ukuba phantsi kweemeko ze-45 vol.% umxholo oqinileyo kunye ne-10 s exposure time, imizimba enye eluhlaza kunye ne-IT77-level curing precision inokufumaneka. Inkqubo ephantsi yobushushu obuphantsi kunye nezinga lokufudumeza kwe-0.1 °C/min yanceda ukuvelisa imizimba eluhlaza engenazintanda.

I-Sintering linyathelo eliphambili elichaphazela ukusebenza kokugqibela kwi-stereolithography. Uphando lubonisa ukuba ukongeza i-sintering aids inokuphucula ngokufanelekileyo ingxinano ye-ceramic kunye neempawu zoomatshini. Ukusebenzisa i-CeO₂ njenge-sintering aid kunye ne-electric field-assisted sintering technology ukulungiselela i-ceramics ye-Si₃N₄ ephezulu, i-CeO₂ yafunyanwa ukuba yahlula kwimida yengqolowa, ukukhuthaza ukutyibilika komda weenkozo kunye noxinaniso. Iziphumo zeseramikhi zibonise ubulukhuni beVickers be-HV10/10 (1347.9 ± 2.4) kunye nokuqina kokwaphuka kwe (6.57 ± 0.07) MPa·m¹/². Nge-MgO-Y₂O₃ njengezongezo, i-ceramic microstructure homogeneity yaphuculwa, iphucula kakhulu ukusebenza. Kwinqanaba elipheleleyo le-doping ye-8 wt.%, amandla e-flexural kunye ne-thermal conductivity ifikelele kwi-915.54 MPa kunye ne-59.58 W·m⁻¹·K⁻¹, ngokulandelanayo.

VI. Ukuqukumbela

Isishwankathelo, iiseramikhi ze-silicon carbide (SiC) ezicocekileyo, njengesixhobo sobunjineli obubalaseleyo, zibonise amathuba okusebenza okubanzi kwii-semiconductors, i-aerospace, kunye nezixhobo ezikwimeko egqithisileyo. Eli phepha lihlalutye ngokucwangcisiweyo iindlela ezintlanu zokulungiselela ii-ceramics ze-SiC ezicocekileyo-i-recrystallization sintering, i-sintering pressureless, i-hot pressing, i-spark plasma sintering, kunye nokuveliswa kwe-additive-kunye neengxoxo ezicacileyo kwiindlela zabo zoxinaniso, ukulungelelaniswa kweparameter engundoqo, ukusebenza kwezinto eziphathekayo, kunye neenzuzo ezifanelekileyo kunye nokunciphisa.

Kucacile ukuba iinkqubo ezahlukeneyo nganye ineempawu ezizodwa malunga nokuphumeza ubunyulu obuphezulu, ukuxinana okuphezulu, izakhiwo ezintsonkothileyo, kunye nokuba nokwenzeka koshishino. Itekhnoloji yokuvelisa ezongezelelweyo, ngokukodwa, ibonise amandla anamandla ekuyileni izinto ezinokwakheka okuntsokothileyo kunye nezilungelelanisiweyo, kunye nokuphumelela kwimihlaba engaphantsi efana ne-stereolithography kunye nejetting ye-binder, iyenza ibe lukhokelo lophuhliso olubalulekileyo lokulungiswa kwe-ceramic ye-SiC.

Uphando lwexesha elizayo malunga nokulungiswa kwe-ceramic ecocekileyo ye-SiC kufuneka ihlolisise nzulu, ikhuthaze ukuguquka ukusuka kwi-laboratory-scale ukuya kubukhulu obukhulu, izicelo zobunjineli ezinokwethenjelwa kakhulu, ngaloo ndlela zibonelela ngenkxaso yezinto ezibalulekileyo zokwenziwa kwezixhobo eziphezulu kunye nobuchwepheshe bolwazi lwesizukulwana esilandelayo.

I-XKH lishishini lobugcisa obuphezulu obukhethekileyo kuphando kunye nokuveliswa kwezinto eziphezulu ze-ceramic. Inikezelwe ekunikeni izisombululo ezilungiselelwe abathengi ngendlela yococeko oluphezulu lwesilicon carbide (SiC) iiseramikhi. Inkampani iphethe itekhnoloji yokulungiselela izinto eziphambili kunye nobuchule obuchanekileyo bokuqhuba. Ishishini layo libandakanya uphando, ukuveliswa, ukusetyenzwa ngokuchanekileyo, kunye nonyango oluphezulu lwe-ceramics ye-SiC ecocekileyo, ukuhlangabezana neemfuno ezingqongqo ze-semiconductor, amandla amatsha, i-aerospace kunye nezinye iinkalo ze-ceramics ephezulu yokusebenza. Ukusetyenziswa kweenkqubo ze-sintering ezivuthiweyo kunye nobuchwepheshe bokwenza okongeziweyo, sinokunika abathengi inkonzo yokumisa enye ukusuka kusetyenziso lwefomyula yezinto, ulwakhiwo oluntsonkothileyo ukuya ekusetyenzweni okuchanekileyo, siqinisekisa ukuba iimveliso zineempawu ezibalaseleyo zoomatshini, ukuzinza kwe-thermal kunye nokuxhathisa umhlwa.

Ixesha lokuposa: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)